WRS 200 2.200-000.0

59684990 (01/23)

59684990 (01/23)

Material damage through incorrect installation

Allow only qualified staff to perform the installation.

Also adhere to the operating instructions of the vehicle on which the attached equipment is installed.

Keep these installation instructions for future reference or for future owners.

The packing materials can be recycled. Please dispose of packaging in accordance with the environmental regulations.

Electrical and electronic devices contain valuable, recyclable materials and often components such as batteries, rechargeable batteries or oil, which - if handled or disposed of incorrectly - can pose a potential danger to human health and the environment. However, these components are required for the correct operation of the device. Devices marked by this symbol are not allowed to be disposed of together with the household rubbish.

Notes on the content materials (REACH)Current information on content materials can be found at: www.kaercher.de/REACH

Please report any defects or shipping damage discovered immediately to your dealer or department store.

Designation | Order number | |

|---|---|---|

| WRS 200 | 2.200-000.0* |

| Adapter set PL-C, PL-D | 2.852-577.0** |

| Adapter set PL-E (MC 250) | 2.852-959.0** |

| Hydraulics set MIC 35/42 | 2.200-003.0*** |

Hydraulics set MIC 50/70 | 2.200-004.0*** | |

Hydraulics set MC 130 | 2.200-005.0*** | |

Hydraulics set MC 250 | 2.200-012.0*** | |

| Water connection attachment kit (MC 130) | 2.200-008.0 *** |

Water connection attachment kit (MC 250) | 2.200-013.0 *** | |

| Wiring harness (MC 250) | 4.839-790.0 *** |

* included in scope of delivery

** is additionally required

*** required depending on the vehicle

Only use original accessories and original spare parts. They ensure that the appliance will run fault-free and safely.

Information on accessories and spare parts can be found at www.kaercher.com.

Designation | Order number | |

|---|---|---|

| WR 100 Adv | 2.200-009.0 (MIC 35/42)** 2.200-010.0 (MIC 50/70)** 2.200-011.0 (MC 130)** 2.200-011.0 (MC 250)*** |

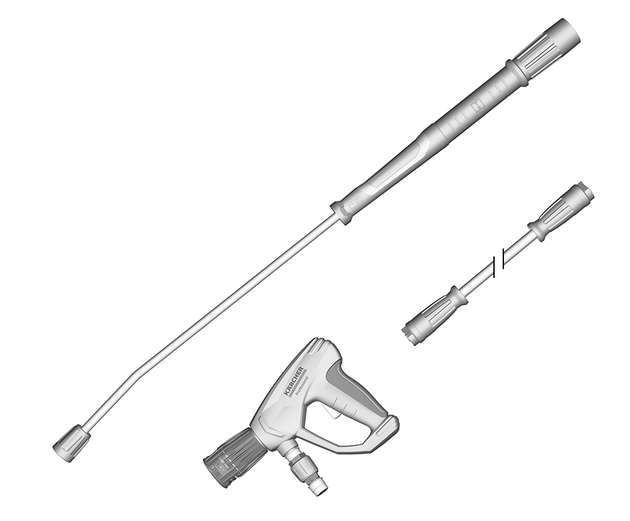

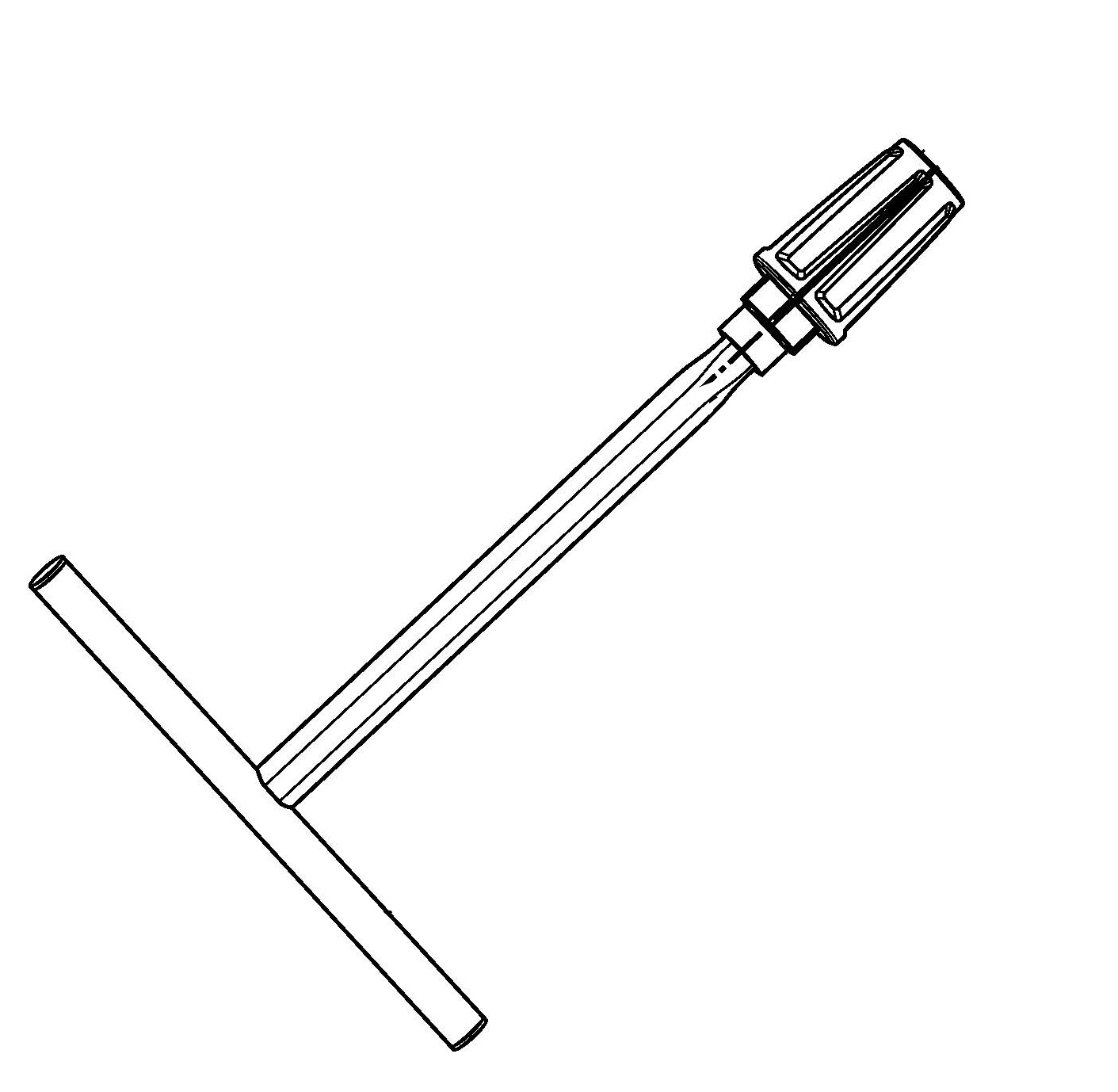

| Spray lance set High-pressure gun | 2.200-002.0 |

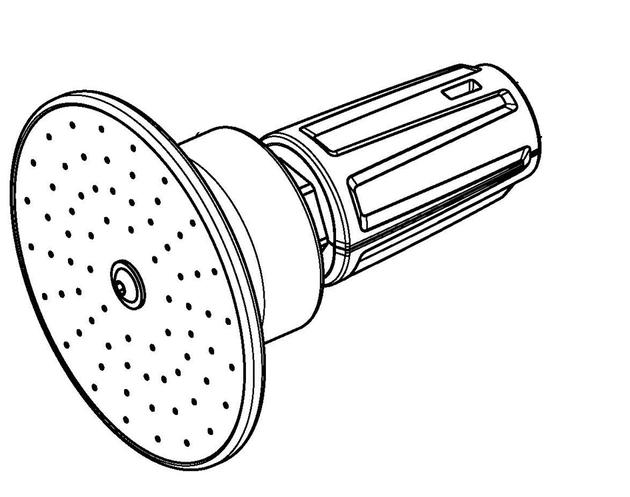

| WR 10 | 2.114-016.0* NoteOnly use only together with nozzle 2.114-004.0 (not included in scope of delivery) |

| WR 20 | 2.114-014.0* |

| WR 50 | 2.114-013.0* |

| WR 100 | 2.114-015.0* |

* can only be used in conjunction with the high-pressure gun spray lance set 2.200-002.0

* can only be used in conjunction with the attachment kit for water connection 2.200-008.0

*** can only be used in conjunction with attachment kit for water connection 2.200-013.0 and wiring harness 4.839-790.0

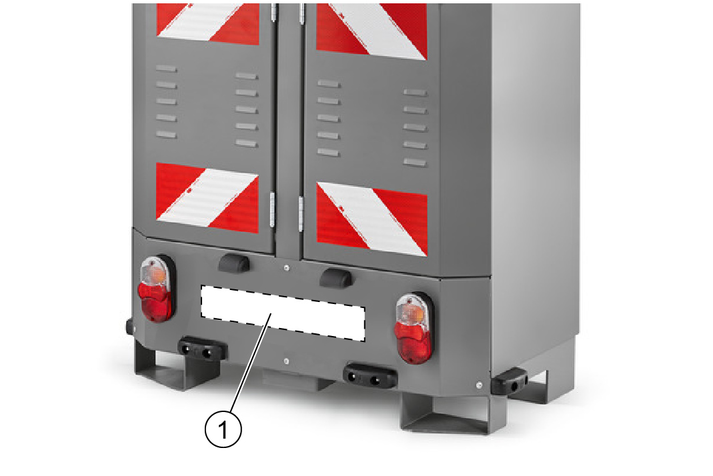

A licence plate (repeater licence plate) must be attached before use on public roads.

A damaged blade guard must not be used

The warranty conditions issued by our sales company responsible apply in all countries. We shall remedy possible malfunctions on your device within the warranty period free of cost, provided that a material or manufacturing defect is the cause. In a warranty case, please contact your dealer (with the purchase receipt) or the next authorised customer service site.

You can find more detailed information at: www.kaercher.com/dealersearch

Before the initial startup of the device, be sure to fill the fuel tank with diesel fuel, even in cold water operation, otherwise the fuel pump may get damaged.

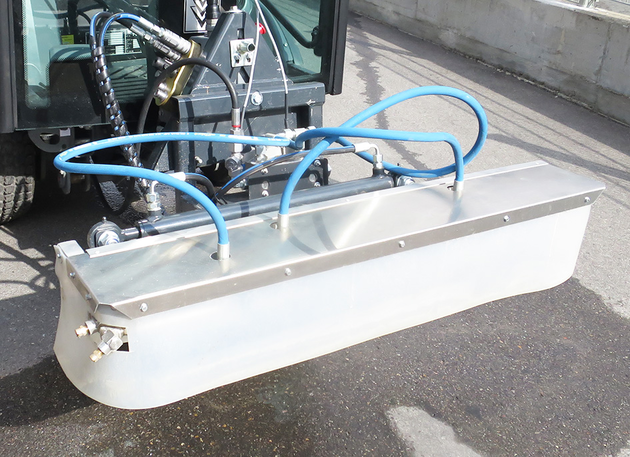

These operating instructions describe the handling of the WRS 200 attachment kit.

The attachment kit can be attached to the following vehicles using the corresponding adapter.

MIC 35/42

MIC 50/70

MC 130

MC 250

The WRS 200 attachment kit is intended for the outdoor elimination of weeds using a hot water high-pressure cleaner and associated weeding tools.

The high-pressure cleaner can also be used for cleaning locations that are difficult to access.

The device may only be connected to the public water supply via a suitable backflow preventer.

The WRS 200 attachment kit may only be used for the intended use, as illustrated and described in these operating instructions.

Intended use also includes adherence to the prescribed servicing activities and intervals.

The vehicle and attachments may only be used, maintained and repaired by persons familiar with the vehicle and attachments and the associated hazards.

The legally applicable general safety and accident prevention regulations must be adhered to. All other safety regulations, occupational health care regulations and road traffic regulations must be adhered to.

The operating personnel must:

Be physically and mentally suitable

Have been instructed in the handling of the vehicle and attachments

Have read and understood these operating instructions and the operating instructions for the vehicle to which this attachment kit is attached

Have provided the operating company with verification of capability to operate the vehicle

Be explicitly nominated to operate the vehicle by the operating company

The following safety instructions apply to the device:

Observe the respectively applicable national regulations for liquid jet cleaners.

Observe the respectively applicable national accident prevention regulations. Liquid jet cleaners must be tested regularly and the results of the test recorded in writing.

Note that the heating system in the device is classified as a furnace. Furnaces must be inspected regularly according to the applicable national regulations.

According to the application national regulations, this device must be initially commissioned by a qualified person when used commercially. KÄRCHER has already performed and documented this initial commissioning for you. You can request the documentation for this from your KÄRCHER partner. Please provide the part number and works number of the device when requesting documentation.

We explicitly state that the application national regulations require that this device must be inspected regularly by a qualified person. Please contact your KÄRCHER partner for this.

No modifications may be made to the device or accessories.

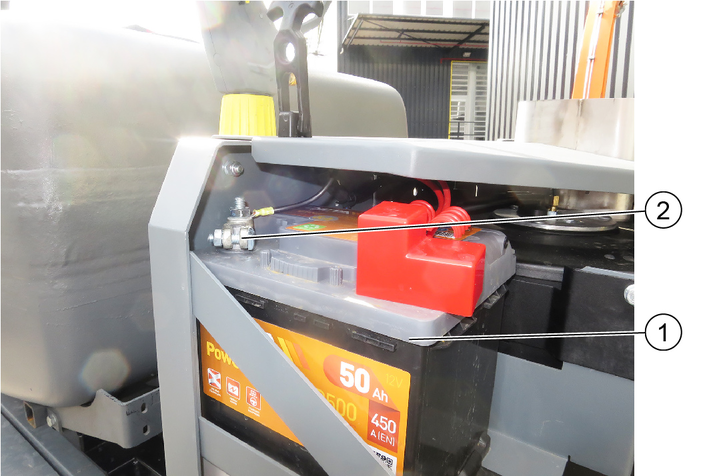

Fasten the battery clamps before the initial startup.

Information on safety, charging, care and disposal of the battery is provided in the vehicle operating instructions.

Always cover the plus terminal of the battery with the protective cap.

The following safety instructions apply to the high-pressure hose:

Use only original high-pressure hoses.

The high-pressure hose and the spray unit must be suitable for use at the maximum operating pressure specified in the technical data.

Avoid contact with aggressive chemicals.

Inspect the high-pressure hose daily.

Do not continue using kinked hoses. Do not continue using the high-pressure hose if the outer wire mesh layer is visible.

Do not continue using a high-pressure hose with a damaged thread.

Lay the high-pressure hose so that it cannot be driven over or presents a tripping hazard to persons.

A hose that has been driven over, kinked or subjected to impacts may no longer be used, even if no damage is visible.

Store the high-pressure hose in a manner avoiding mechanical stresses on the hose.

Replace the symbols immediately if they become illegible or get lost.

| DANGERRisk of burns from hot surfaces Allow the vehicle to cool down before working on it. |

| WARNINGRisk of injury from high-pressure jet Do not direct the high-pressure jet at persons, animals, live electrical equipment or at the device itself. Protect the device high-pressure cleaner frost. |

| Warning of rotating tools |

| Dangerous electrical voltage! Do not place any foreign objects or tools on the battery. |

| ATTENTIONDanger of hearing damage Use suitable hearing protection when working with the device. |

| Wear suitable protective goggles when working with the device. |

| Wear protective gloves |

Safety devices protect the user and may not taken out of operation or functionally circumvented.

Adhere to the safety instructions in the chapters!

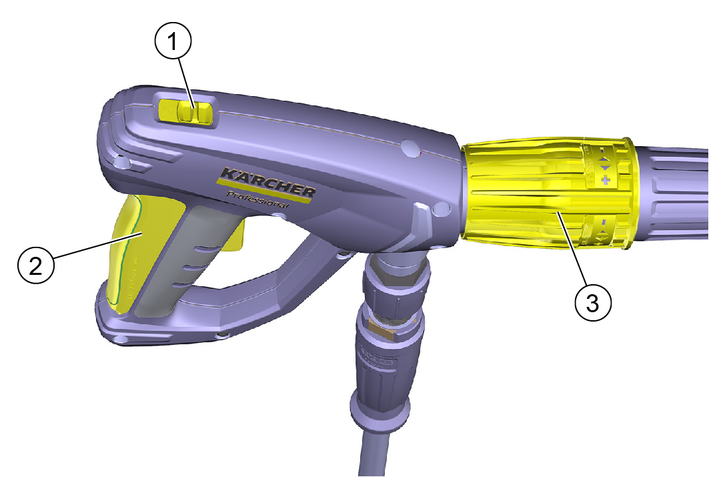

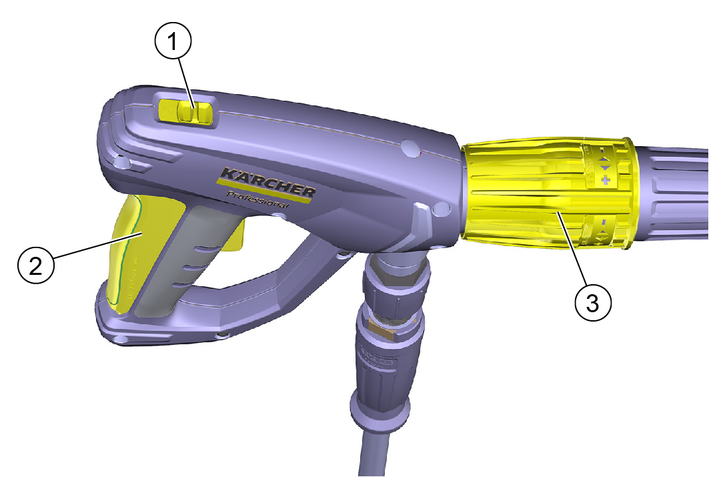

When the trigger on the high-pressure gun is released, the pressure switch switches off the high-pressure pump and the high-pressure jet stops.

The pump switches on again when the trigger is pulled.

The safety latch on the high-pressure gun locks the trigger of the high-pressure gun.

Lock the trigger with the safety latch when not using the device.

The water shortage safeguard (flow switch) prevents the burner from overheating in the case of a shortage of water.

Indication of an imminent threat of danger that will lead to severe injuries or even death.

Indication of a potentially dangerous situation that may lead to severe injuries or even death.

Indication of a potentially dangerous situation that may lead to minor injuries.

Indication of a potentially dangerous situation that may lead to damage to property.

Wear suitable gloves when working with the device.

Wear hearing protection whenever a sound pressure level over 80 dB(A) is specified in the operating instructions. See chapter Technical data in the operating instructions.

Wear suitable protective clothing and safety goggles to protect yourself from water or dirt backsplash.

Aerosols can be formed when using high-pressure cleaners. Inhaling aerosols can be harmful for your health. Employers are obliged to perform a hazard assessment in order to define, depending on the surface to be cleaned and the environment, protective measures necessary to prevent inhalation of aerosols. Respiratory protection masks of class FFP 2 or above are suitable for protection against aqueous aerosols.

Risk of asphyxiation. Keep packaging film out of the reach of children.

Only use the device for its proper use. Take into account the local conditions and beware of third parties, in particular children, when working with the device.

The device is not intended for use by persons with restricted physical, sensory or mental abilities or those lacking in experience and / or lacking in knowledge.

Only people who have been instructed on how to use the device, or have proven their ability to operate it, and have been explicitly instructed to use it, must use the device.

Children must be supervised to prevent them from playing with the appliance.

Children and minors must not use the device.

Safety devices are provided for your own protection. Never modify or bypass safety devices.

The device must not be operated if the high-pressure hose is damaged. Replace a damaged high-pressure hose at once. Only those hoses and connections recommended by the manufacturer may be used.

The screw connections of all connection hoses must be leak-tight.

Observe the regulations at your water distribution company. The device may only be connected to the public water supply via a suitable backflow preventer.

When using the device in hazard zones (e.g. service stations), adhere to the respective safety regulations.

Operation in explosive atmospheres is prohibited.

Damaged wheels / tyre valves are extremely dangerous. Damaged wheels / tyre valves can be damaged by the high-pressure jet and explode. The first sign of this is discolouration of the tyres. Keep a spray distance of at least 30 cm when cleaning the wheels / tyre valves.

Do not use the device if people without the proper protective clothing are in its reach.

With short spray lances, your hand may come into contact with the high-pressure jet. Never use a spotlight nozzle or rotary nozzle with steel tubes that are shorter than 75 cm.

A recoil force will arise due to the water stream ejecting from the spray lance. An angular spray lance produces a force that acts in upward direction. Make sure you grip the gun and spray lance firmly.

When using angular spray units, recoil forces and twisting forces may alter.

Do not aim the high-pressure jet at yourself, e.g. to clean clothes or shoes.

Do not direct the high-pressure jet at persons, animals, live electrical equipment or at the device itself.

Close the doors before driving.

Do not spray any objects which contain harmful substances (e.g. asbestos).

Check the device and the accessories, such as the high-pressure hose, high-pressure gun and safety devices, to make sure they are in proper safe and reliable condition before each operation. Do not use the device if it is damaged. Replace damaged components immediately.

Only use high-pressure hoses, control panels and couplings specified by the manufacturer.

Never leave the device unsupervised while it is in operation.

Never open the cover while the motor is running.

Never clamp the lever of the high-pressure gun during operation.

Allow the hoses to cool down after hot water operation or operate the device briefly using cold water operation.

The device must be placed on an even, firm subsurface.

Before cleaning, carry out a risk assessment of the surface to be cleaned to determine any health and safety protection requirements. The necessary protective measures must be taken accordingly.

Do not operate the device at temperatures below 0 °C.

Only clean the motor at washing stations with an oil separator.

Keep the detergent out of the reach of children.

When using detergents, observe the safety data sheet of the detergent manufacturer, in particular instructions on protective gear.

Only use the detergents supplied or specified by the manufacturer. The use of other detergents or chemicals can impair the safety of the device.

Should detergents come into contact with eyes, rinse these out immediately and thoroughly using water and seek medical attention immediately. The same applies if detergents are swallowed.

The device may not be used for spreading pesticides.

Explosion hazard due to unsuitable fuel. Only fill the fuel specified in the operating instructions.

Exhaust gases are toxic. Never breathe in the exhaust gases. Ensure rooms where the device is operated are sufficiently ventilated and that exhaust gases can be conducted away.

During tanking, make sure that no fuel gets on hot surfaces.

Risk of burns. Never bend down over the exhaust gas opening and never reach inside it. Do not touch the heating boiler while the burner is in operation.

Never close off exhaust gas openings.

Make sure that no exhaust gases are emitted close to air vents.

Observe the safety instructions for petrol-driven devices in the operating instructions.

Always switch the device off prior to cleaning, maintenance and replacement of parts.

Depressurise the high-pressure system prior to all work on the device or its accessories.

Repairs may only be carried out by approved customer service sites or staff qualified in this area who are familiar with all relevant safety instructions.

Pay attention to the safety inspection for mobile devices for industrial use in accordance with the locally applicable regulations

Short-circuits or other damage. Do not clean the device with a hose or high-pressure water jet.

Do not use acetone, undiluted acids or solvents, as they corrode the materials used on the device.

Only use accessories and spare parts which are approved by the manufacturer. Only original accessories and original spare parts ensure that the appliance will run fault-free and safely.

Only have repairs and installation of spare parts performed by the approved Customer Service in order to prevent any hazards.

Please note: All types of fuel are simply referred to as "fuel" in these operating instructions.

Please consult Kärcher-Service in the case of any uncertainties or questions.

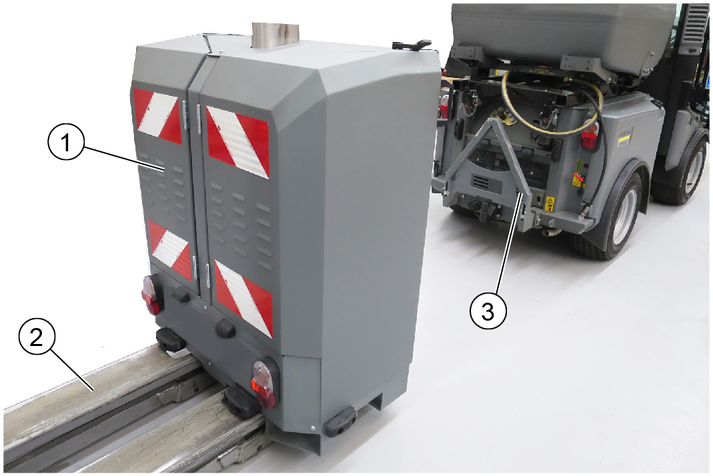

A suitably large water tank should be available in order to use the WRS 200.

The water tank must be safely fastened to the rear of the vehicle.

Attention must be paid to the maximum permissible weight and permissible axle loads of the vehicle when selecting the water tank.

According to the attachment guideline, the outer edges must not protrude more than 400 mm beyond the contour of the vehicle. This is not conformant when no additional attachments are mounted (not permitted).

Platform C and D

When the WRS 200 is mounted on the rear of the vehicle, a counterweight must be mounted on the front bar of the WR 100 Adv (weed elimination accessory) or another suitable counterweight must be mounted.

Platform E (MC 250)

Operation with the WRS 200 is only permitted in combination with the interchangeable frame (4.059-478.0).

Due to the maximum axle load of the vehicle, the waste water tank of the vehicle cannot be used and is automatically opened and forcibly emptied via software settings when WRS mode is selected. The waste water tank always remains open when the WRS 200 is in operation.

Furthermore, when using the WR100 Adv, additional weights may not be used in the front area due to the axle loads.

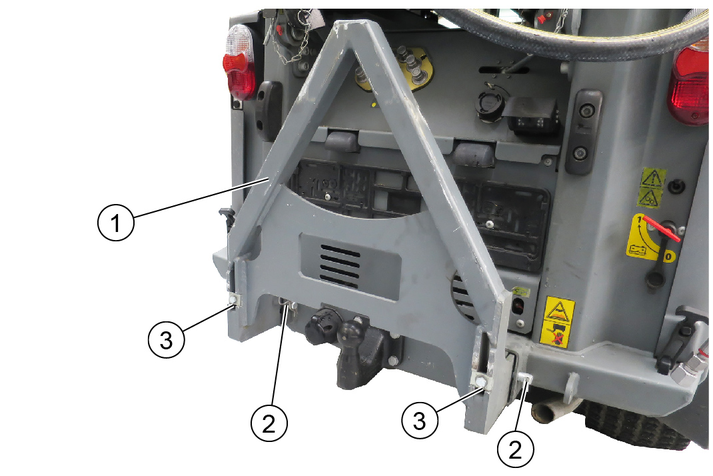

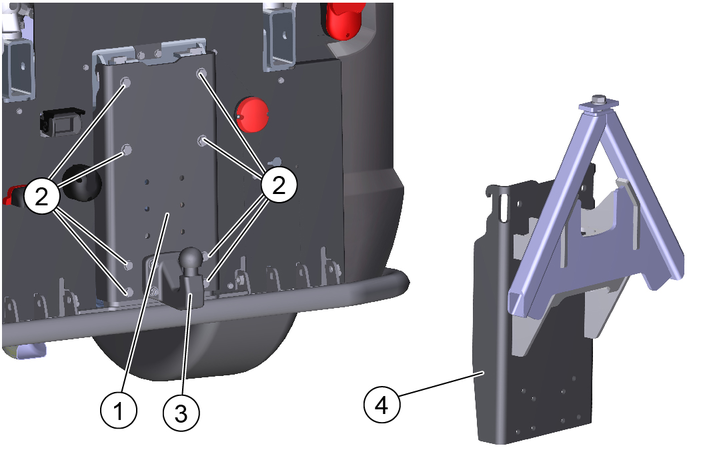

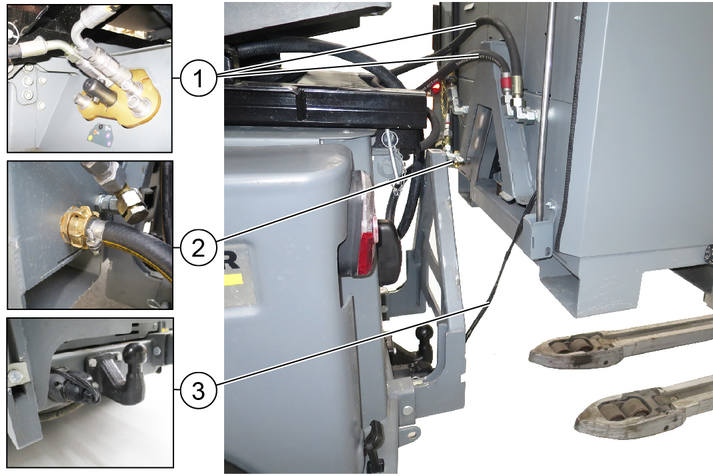

Depending on the vehicle certification, a trailer coupling must or must not be attached. Existing fastening elements are to be used.

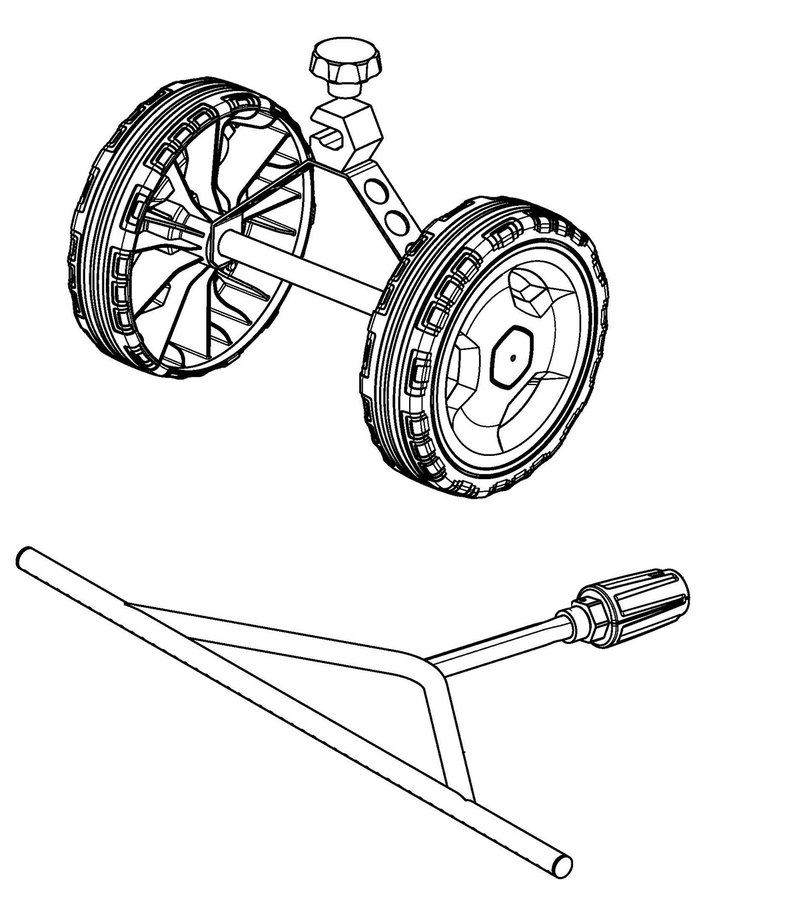

The adapter with coupling triangle is attached to the rear of the vehicle for mounting the WRS 200.

Push the adapter into the mounting frame of the vehicle, observing the position of the various vehicles.

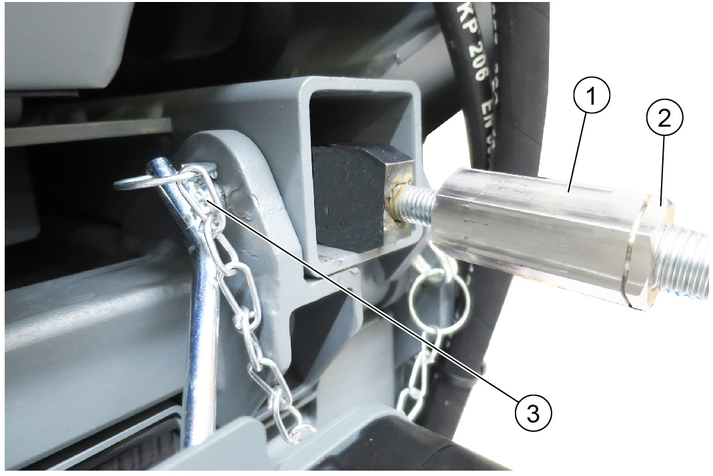

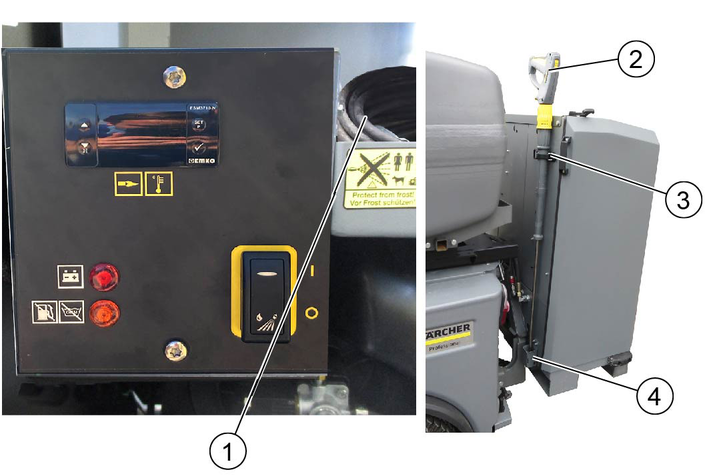

Figure: Installation on an MC 130 secured with a bolt and spring pin

Required for installation on an MC 130

MIC 35/42: Slide the adapter into the position (first or second hole) and secure it on the left and right with bolts and spring pins.

MC 130: Fasten the metal strip at the bottom of the adapter. Slide in the adapter as shown in the illustration (third hole) and secure it on the left and right with bolts and spring pins.

Tighten the screws to fasten the adapter firmly in place.

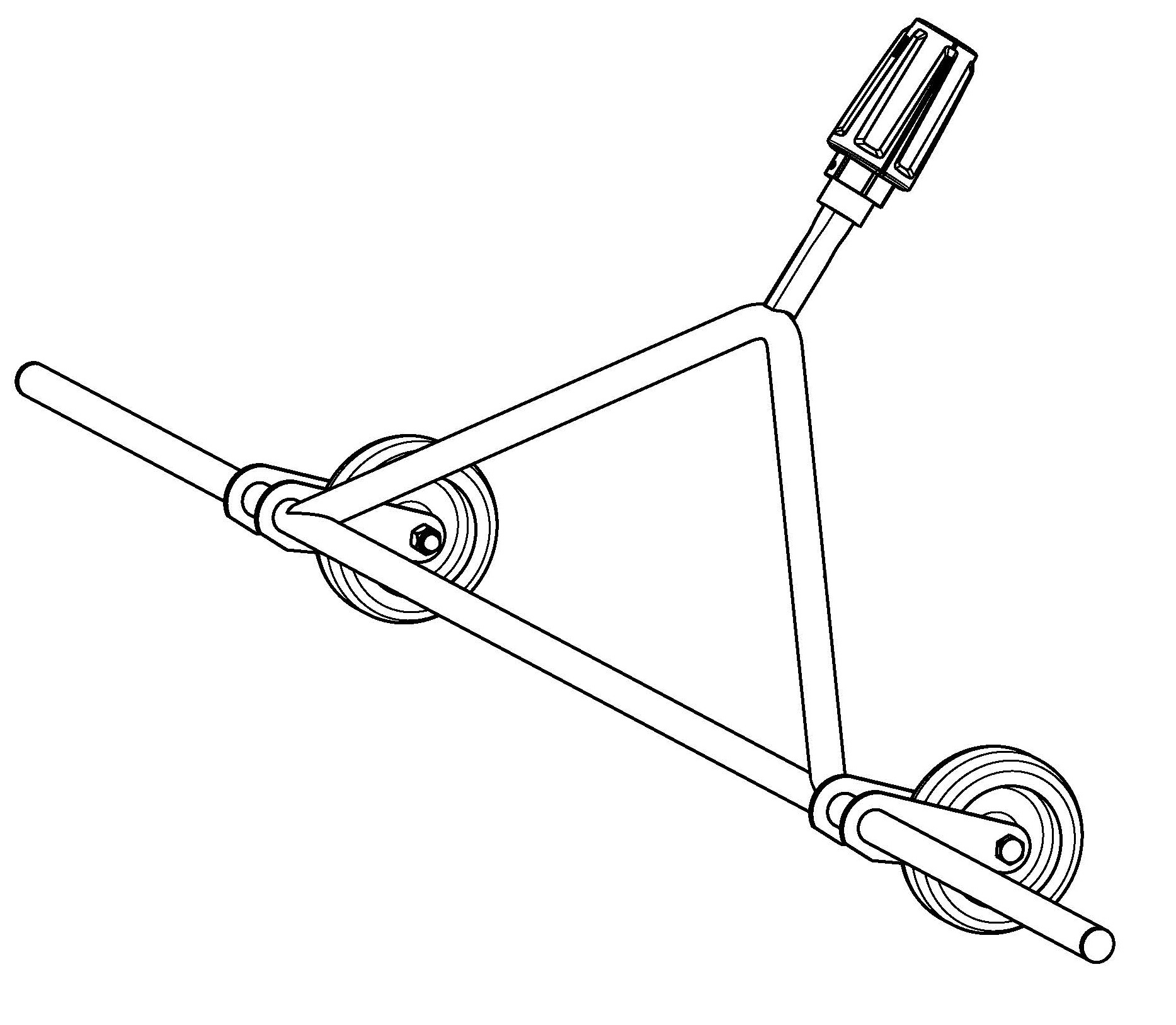

The adapter with coupling triangle is attached to the rear of the vehicle for mounting the WRS 200.

Dismantle the adapter plate with the trailer coupling on the vehicle (8 screws and washers).

If necessary, fasten the existing trailer coupling to the adapter plate with M10x45 screws, washers and nuts (4x).

Hang up the adapter plate with the coupling triangle in the same way as above and fasten with 8 screws and washers.

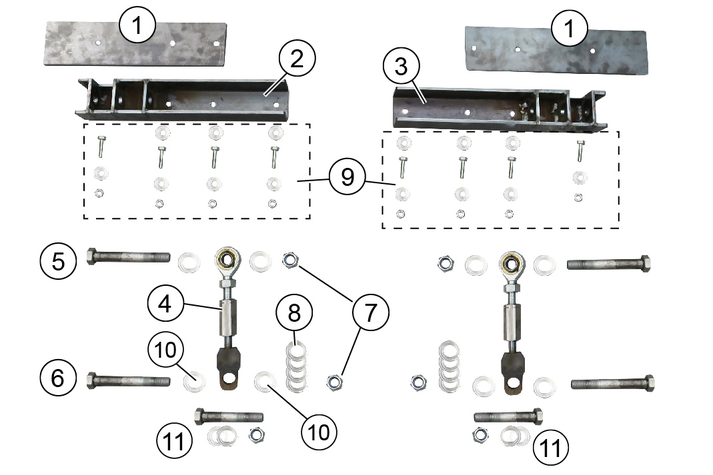

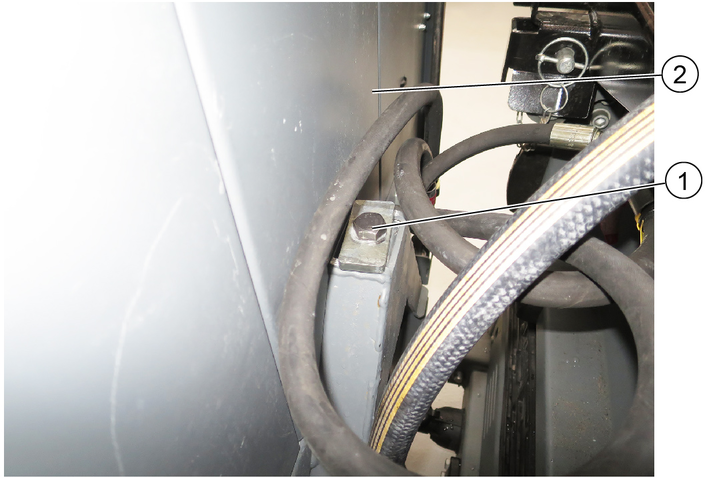

The top mount stabilises the WRS 200 during operation and transport. It must be attached to the WRS 200 once only.

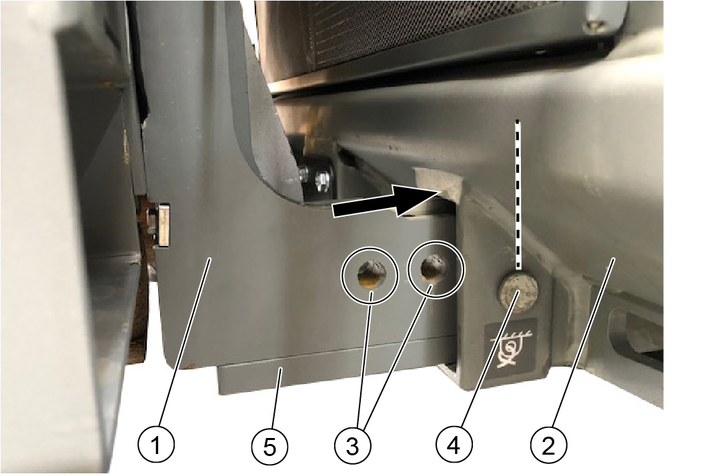

For the MIC 35/42 (platform C) and the MC 250 (platform E), mounting is performed below the air holes.

For the MC 130 or MIC 50/70 (platform D), mounting is performed above the air holes. The following description shows the mounting for platform D.

The holes for attaching the mount are already present.

Unless specified otherwise, all nuts and screws are to be tightened to the standard torque.

Mounting to the carrier vehicle is made via 2 upper links. Mounting is described in a later chapter.

Top mount attachments

For mounting to the carrier vehicle

M8x30 screws (8x)

M8 nuts (8x)

8x200 washers (14x)

For mounting the upper link on platform D

Check the scope of delivery.

Install this screw without a washer

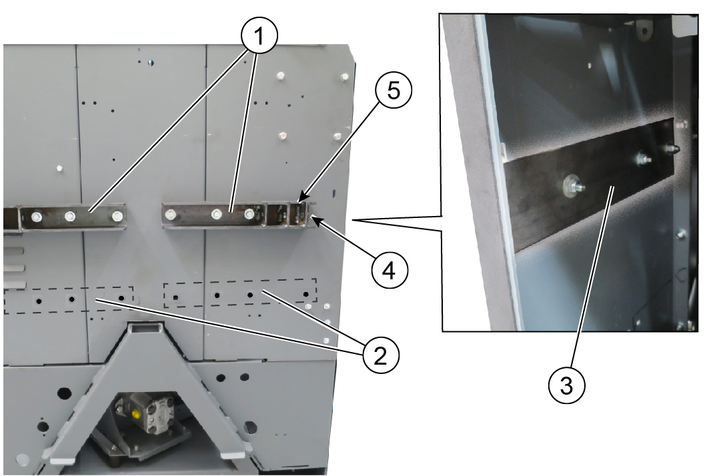

Attach the reinforcement plate with mount on the WRS 200 (observe the correct mounting procedure according to the platform).

Use screws with washers and nuts.

At the mount side: Fit the outer screw without a washer.

Attach the right-hand mount in the same manner.

The upper link must be attached differently for platform C, platform D or platform E.

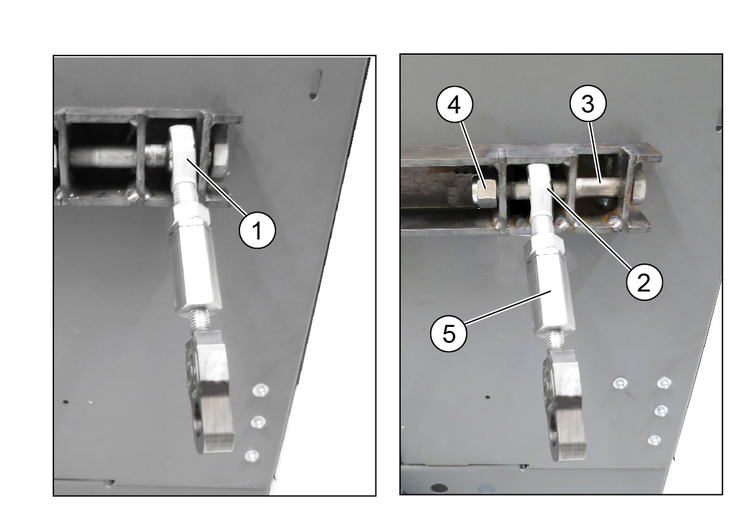

Attach the upper link in the corresponding position using a screw and stop nut.

The WRS 200 is attached to the adapter with coupling triangle and secured by a screw.

It is additionally fastened to the vehicle by the upper links.

Have a second person help with the installation.

Use the lift truck to position the WRS 200 approximately 30 cm in front of the adapter and then lift it until it is positioned above the adapter.

Connect the hydraulic hoses to the WRS 200 and insert them into the PTO hydraulic connection of the vehicle (observe the correct flow direction and, if applicable, the colour encoding).

Connect up the water hose.

Insert the cable with plug into the trailer socket.

Slowly move the WRS 200 forwards as far as it will go and then lower it into the adapter coupling triangle.

Secure the WRS 200 with the screw. Torque 80 Nm.

Figure: Upper link fastener for platform C

Attach the left-hand and right-hand upper links to the vehicle.

Platform C: Attach using the existing retaining pins on the vehicle and secure with the clips (see illustration).

Platform D and E: Attach to the vehicle using screw, washers and nuts (included in scope of delivery) (see illustration).

Figure: Upper link fastener for platform D and E

Adjust the position of the WRS 200 using the adjusting nuts and secure with the counter-nuts.

Risk of injury

Check that the battery, accessories, supply lines, water filter and connections are in a correct condition before using the device.

Only use the device when it is in a correct condition.

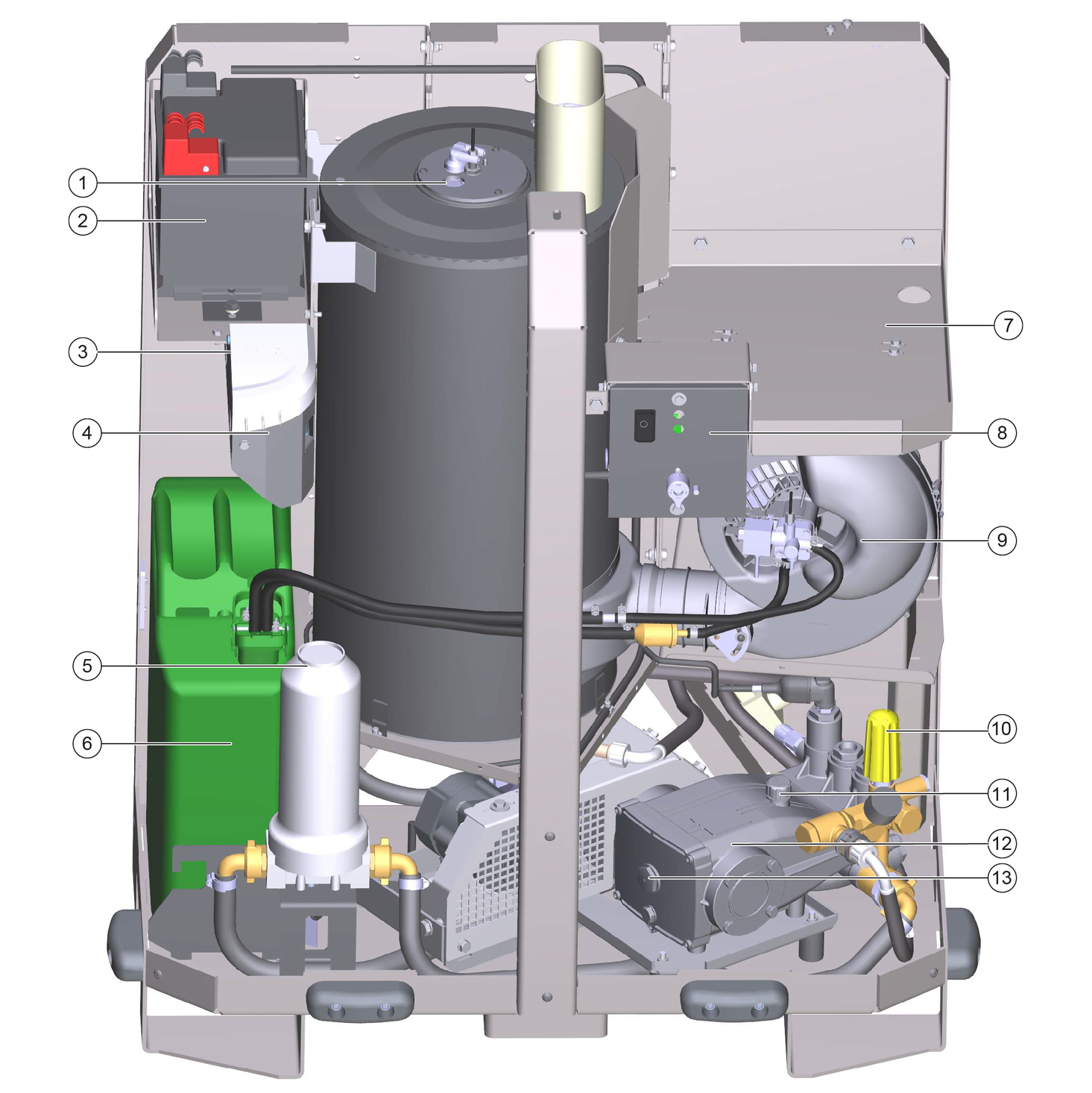

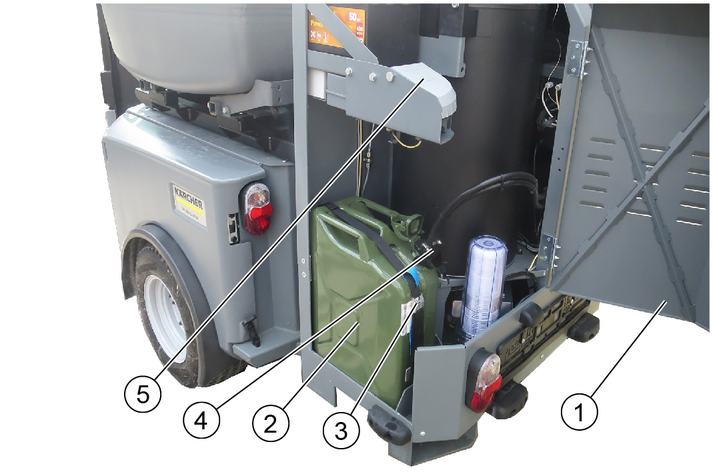

Check the filling level in the fuel canister and fill if necessary.

Check the filling level in the system care container and fill with RM 110 if necessary.

Check the filling level in the water tank and fill if necessary.

A licence plate (repeater licence plate) must be attached before use on public roads. The license plate must be attached centrally with a 40 mm clearance, parallel to the tail lights.

Explosion hazard due to overflowing fuel

Take care ensure that no fuel spills onto hot surfaces when refuelling.

Explosion hazard due to smoking and naked flames

Ensure strict prohibition of smoking and open flames during the refuelling procedure.

Health risk from inhaled vapours

Do not refuel in confined spaces.

Risk of damage due to incorrect fuel

Refuel with Diesel only.

Risk of damage due to the fuel pump running dry

Check the filling level of the fuel canister regularly, refuel in time as necessary.

Refill with fuel only when the canister is detached. Use only original canisters.

Release the rubber latch on the left-hand door and open the door.

Release the retaining strap from the canister.

Open the tank cap and allow any fuel to drip off before removing the cap.

Fasten the tank cap with fuel lines open at the top.

Remove the canister.

Refill with Diesel.

Insert the canister and secure with the retaining strap.

Fit the tank cap with fuel lines.

Close the tank cap.

Wipe off any spilt fuel.

Close the left-hand door and secure with the rubber latch.

The RM 110 system care liquid (descaler) is a highly effective agent for preventing calcification of the heating coil when operating with hard water. This is drip-fed dosed into the water supply.

The dosage is set at the factory for water hardnesses of up to approx. 30 °dH. The dosing valve can be adjusted if necessary. See chapter "Adjusting dosage".

Health risk

Observe the safety and handling instructions for handling RM 110.

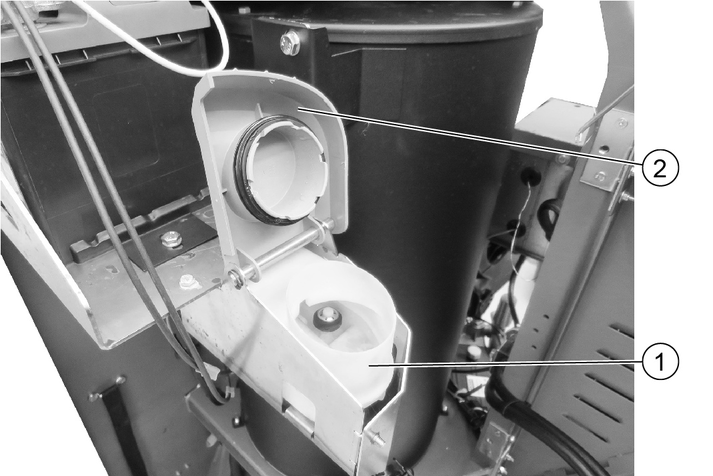

Open the lid of the system care container.

Add RM 110 system care liquid to the container, do not overfill.

Maximum filling level is 2 cm below the filling edge.

Close the cover.

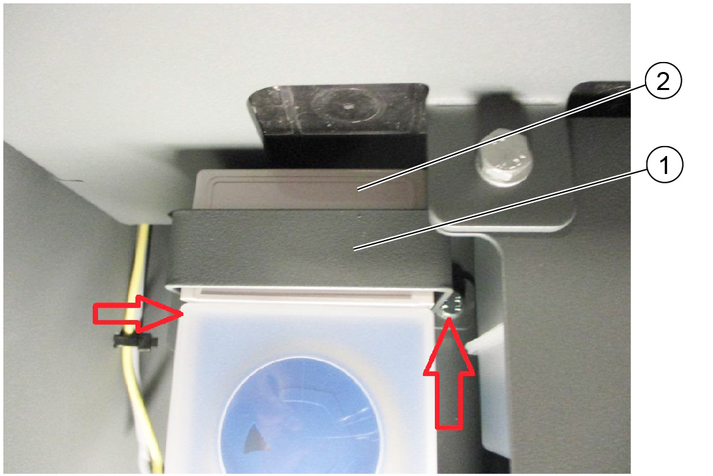

The dosage is set at the factory for water hardnesses of up to approx. 30 °dH (position between 1 and 2). Change the position if necessary.

Remove the bar by removing the 2 screws (marked with arrows) using a socket wrench.

Remove the cover.

Up to 10 °dH

Up to 55 °dH

Adjust position 1 to 2 for the desired degree of water hardness.

Higher positions are irrelevant because these degrees of hardness do not occur.

Attach the cover.

Attach the bar.

Risk of injury from high-pressure jet or electric shock.

Check that the device, accessories, supply lines and connections are in a correct condition before using the device.

Only use the device when it is in a correct condition.

The high-pressure hose is stored in a storage compartment behind the right-hand door.

The high-pressure gun with spray lance is located in holders attached to the left front side of the WRS 200.

Release the rubber latch on the right-hand door (at the top side) and open the door.

Remove the high-pressure hose.

Release the rubber latch from the upper holder.

Remove the high-pressure gun with spray lance.

Connect the high-pressure hose to the high-pressure gun.

Connect the high-pressure hose to the high-pressure connection.

Establish the water supply to the WRS 200 (GEKA coupling). Ensure that the mains is disconnected!.

Connect the water hose to the WRS 200.

Pump running dry

Damage to the device

If pressure does not build up in the device after 2 minutes then switch the device off and proceed according to the instructions in the chapter "Help in case of malfunctions".

Risk of damage

Always keep the doors closed when working and driving.

The high-pressure cleaner is operated by the hydraulic PTO connection on the vehicle.

The burner can be switched-in for generating hot water.

The high-pressure cleaner is intended for use as a hot water high-pressure cleaner for the elimination of weeds and as a cold water high-pressure cleaner for cleaning regions that are difficult to access.

The water jet is applied using a high-pressure gun with spray lance and a corresponding nozzle attachment.

Weed elimination can also be performed over larger areas using an optional front bar. Contact Kärcher for more information.

The work temperature can be preselected at the thermostat.

The burner does not switch on until the blower switch is switched on.

When the warning light comes on, the burner switches off

Set the thermostat to 105 °C and switch on the blower (burner) for weed control.

Switch off the blower switch immediately on completion of work to prevent the battery from being drained.

For cold water high-pressure cleaning, set the thermostat to 25 °C and switch off the blower (burner).

The WRS 200 is equipped with an integrated battery that is charged by an alternator.

The battery is required for starting the burner.

Please consult the operating instructions of the carrier vehicle for information on care, maintenance and safe handling of batteries.

When storing the device for longer than 1 month, disconnect the minus terminal of the battery and recharge the battery every 2 months.

Vehicle settings:

The procedure varies from vehicle to vehicle. Please refer to the operating instructions of the vehicle used for the exact procedure.

PTO 40 litres/min

Engine speed at least:

MIC 35/42: 2250 rpm

MIC 50/70: 2100 rpm

MC 130: 2400 rpm

MC 250: 1200 rpm

Deactivate the seat contact switch (when working with the standard high-pressure gun and spray lance accessories).

WRS 200 settings (hot water operation):

Switch on the blower (burner).

Adjust the temperature on the thermostat using SET and the ˄˅ buttons. Confirm with √ (setting range +25 °C to +105 °C, temperature deviation +/- 5 °C).

The burner will now heat up automatically to the set temperature (see heating symbol in the display). When the temperature is reached, the burner switches off (heating symbol in the display goes out). If the deviation falls below 5 °C, the burner switches on again and regulates up to max. 105 °C. The set temperature is stored and retrieved in the operation (in case work is interrupted during the working day).

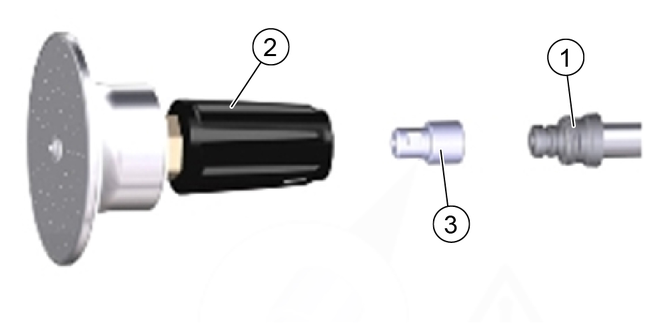

Fit the desired accessory (optional) to the spray lance.

Adjust the pressure control at the spray lance or at the high-pressure pump as required.

Vehicle settings:

PTO 40 litres/min

Engine speed at least:

MIC 35/42: 2250 rpm

MIC 50/70: 2100 rpm

MC 130: 2400 rpm

MC 250: 1200 rpm

Deactivate the seat contact switch (when working with the standard high-pressure gun and spray lance accessories).

The procedure differs according to the vehicle and the vehicle operating instructions must be consulted.

WRS 200 settings:

Set the temperature on the thermostat to 25 °C using SET and the ˄˅ buttons and confirm with √.

If necessary, drain hot water through the front bar or the high-pressure gun until the ACTUAL temperature reaches 25 °C.

Switch off the blower (burner).

Fit the high-pressure nozzle to the lance.

Adjust the pressure control at the spray lance or at the high-pressure cleaner as required.

Risk of injury due to recoil force

A recoil force will arise due to the water stream ejecting from the spray lance. Make sure you grip the high-pressure gun and spray lance firmly when working.

Unlock the safety latch on the high-pressure gun, rear position.

Pull the trigger and commence working.

Fight weeds with the hot water jet, working slowly

As necessary: Adjust the pressure control at the spray lance or at the high-pressure cleaner as required.

Risk of damage to the spray head

Set the pressure regulation on the high-pressure pump to minimum pressure.

Additionally, use the 2.114-004.0 nozzle (not included in scope of delivery).

Fasten the nozzle between the lance and the WR 10 spray head.

Turn down the pressure regulation on the high-pressure pump to a minimum.

Store the trigger gun with spray lance and high-pressure hose in the storage locations provided when driving on public roads or after finishing work.

Park the vehicle and allow the engine to continue running.

Set the temperature on the thermostat to 25 °C using SET and the ˄˅ buttons and confirm with √. Switch off the blower (burner).

Operate the high-pressure cleaner in cold water mode until the high-pressure cleaner, high-pressure hose and high-pressure gun with spray lance have cooled down (danger of burns).

Switch off the PTO work hydraulics.

Switch off the engine.

Close off the water inlet at the water tank.

Press the trigger of the high-pressure gun and release the pressure remaining in the system.

Secure the trigger with the safety latch.

Unscrew the high-pressure hose from the high-pressure connection of the WRS 200. Fit a protective cap to prevent soiling.

Fit the high-pressure gun with spray lance into the mount and holder and secure with the rubber retainer.

Open the right-hand door and place the high-pressure hose in the storage compartment.

Risk of injury and damage

Be aware of the weight of the device during storage.

In order to preserve warranty claims, all servicing and maintenance work during the warranty period has to be performed by an authorised Kärcher Customer Service, in accordance with the inspection check list.

Time & date | Activity | By whom |

|---|---|---|

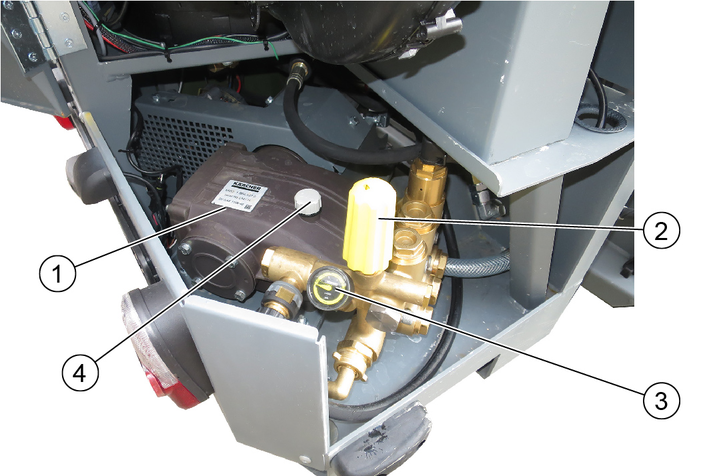

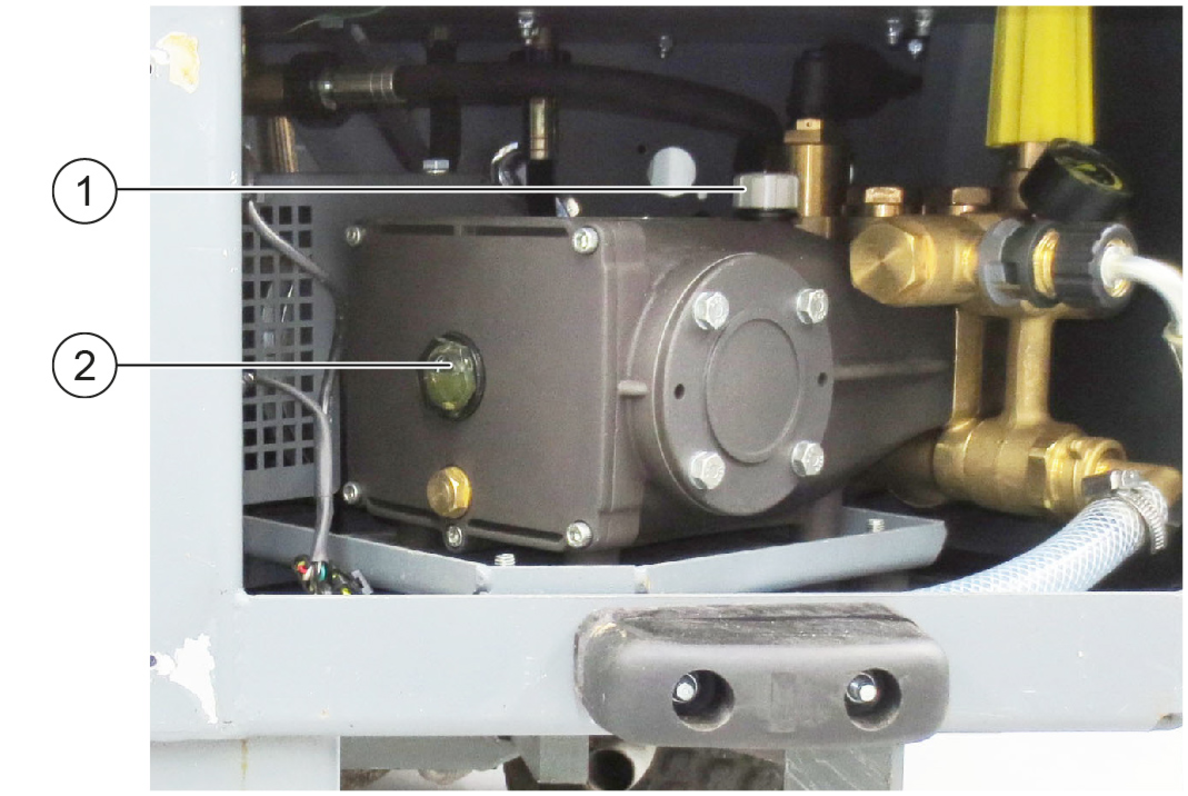

Daily | Check the oil level in the high-pressure pump, refill with oil if necessary | Operator |

Daily | General visual inspection of the WRS 200 | Operator |

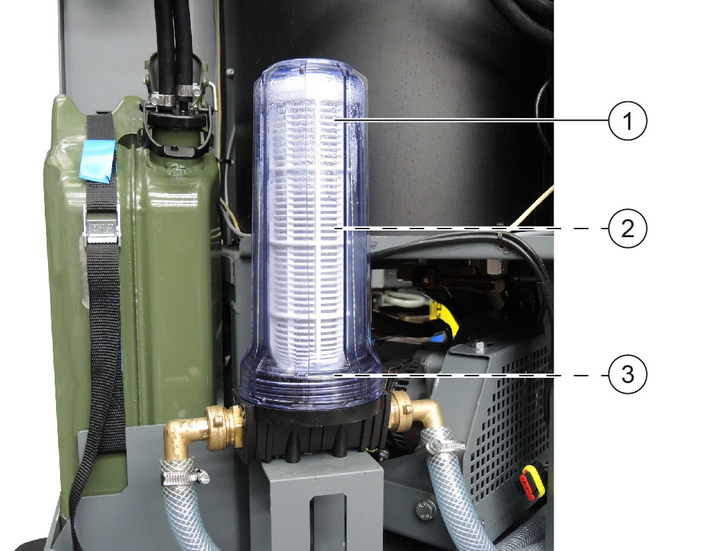

Daily | Check the water filter, clean if necessary | Operator |

Daily | Check the filling level in the system care container and fill with RM 110 if necessary | Operator |

Weekly | Check the fastening screws for tight seating | Operator |

After the first 50 operating hours | Replace the oil in the high-pressure pump | Customer Service |

Every 50 operating hours or weekly | Check the battery, see the information on the battery | Operator |

Every 600 operating hours or annually | Replace the oil in the high-pressure pump | Customer Service |

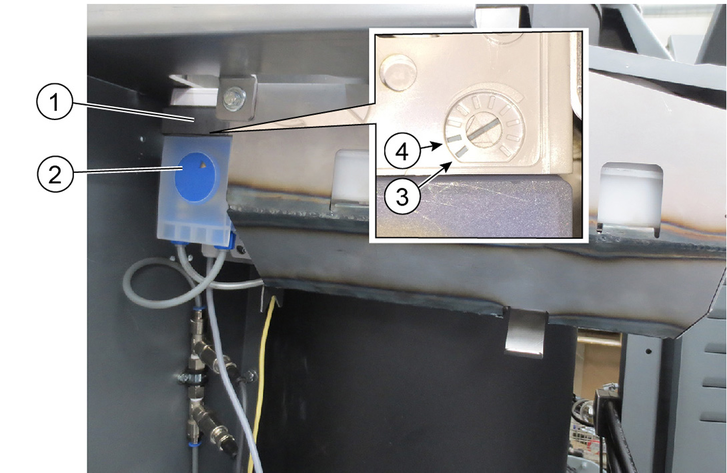

Open the left-hand door.

Visually check the water filter externally for soiling.

For removing the water filter:

Close off the water inlet.

Allow the pump to run briefly until the housing is empty.

Unscrew and remove the casing.

Check the seal and replace if necessary.

Clean the water filter and replace if necessary.

Lubricate the housing seal and sealing surface of the water filter with silicone grease.

Install in the reverse order.

Open the water inlet.

Risk of burns!

Allow the high-pressure pump to cool down before refilling with oil.

Check the oil level when the high-pressure pump has cooled down.

The correct oil level is in the middle of the sight glass.

Check the oil level at the sight glass and refill with oil if necessary (to the middle of the sight glass).

Oil type 15W-40.

Unscrew the cap from the oil filler opening.

Refill with oil.

Screw the cap onto the oil filler opening.

Wipe off any overflowed oil.

You can remedy minor faults using the following overview.

If in any doubt, please contact your authorised Customer Service.

Risk of injury

Switch off the carrier vehicle before carrying out any care and maintenance work.

Risk of electric shock

Disconnect the plus terminal of the battery before carrying out any care and maintenance work.

Repair work and work on electrical components must only be performed by your authorised Customer Service.

Cause:

Battery is not charging

Remedy:

Contact Customer Service

Cause:

Container empty

The burner switches off

Remedy:

Refill with RM 110 system care liquid

Cause:

Fuel canister empty

Remedy:

Refill Diesel

Cause:

Blower switch switched off

Remedy:

Switch on the blower switch

Cause:

Burner incorrectly adjusted or dirty

Remedy:

Contact Customer Service

Cause:

Fuel solenoid valve defective

Diesel fuel continues dripping

Remedy:

Contact Customer Service

Cause:

No ignition spark present (visible through the sight glass in the burner cover)

Remedy:

Contact Customer Service

Cause:

Condensation in the nozzle carrier

Remedy:

Contact Customer Service

Cause:

Fuel pressure too low

Remedy:

Contact Customer Service

Cause:

Leaks in the high-pressure pump suction area

Remedy:

Check the piping system

Cause:

Water filter dirty

Remedy:

Clean/replace the water filter

Cause:

Nozzle clogged/washed out

Remedy:

Clean/replace the nozzle

Cause:

Supply line to high-pressure pump leaking or clogged

Remedy:

Have this checked by Customer Service

Cause:

Safety valve leaking

Remedy:

Have the setting and seals checked by Customer Service

Cause:

Supply lines to high-pressure pump leaking

Remedy:

Check and contact Customer Service if necessary

Cause:

High-pressure pump leaking

Remedy:

Check, 3 drops of water per minute are normal

In case of more serious leaks, have the device checked by Customer Service

Cause:

Nozzle clogged

Remedy:

Clean the nozzle

Cause:

Overflow valve incorrectly adjusted/defective

Remedy:

Have the overflow valve adjusted/replaced by Customer Service

Cause:

Device is scaled

Remedy:

Contact Customer Service

Water connection | |

Feed pressure (max.) | 1 MPa |

Input temperature (max.) | 30 °C |

Input amount (min.) | 30 l/min |

Minimum water supply hose diameter | 3/4 in |

Device performance data | |

Nozzle size of standard nozzle | 25070 |

Operating pressure | 1-20 MPa |

Operating pressure (max.) | 22 MPa |

Water flow rate | 28 l/min |

Dimensions and weights | |

Weight | 300 kg |

Typical operating weight | 315 kg |

Length | 550 mm |

Width | 955 mm |

Height | 1290 mm |

Operating materials | |

Fuel | Diesel |

Oil type | 15W-40 |

Determined values in acc. with EN 60335-2-79 | |

Hand-arm vibration value | 1,5 m/s2 |

Uncertainty K | 0,6 m/s2 |

Sound pressure level LpA | 79 dB(A) |

Uncertainty KpA | 3 dB(A) |

Sound power level LWA + uncertainty KWA | 99 dB(A) |

We hereby declare that the machine described below complies with the relevant basic safety and health requirements in the EU Directives, both in its basic design and construction as well as in the version placed in circulation by us. This declaration is invalidated by any changes made to the machine that are not approved by us.

Product: High-pressure cleaner

Type: 2.200-xxx

Currently applicable EU Directives2006/42/EC (+2009/127/EC)

2014/30/EU

2000/14/EC

ECE R 10

Harmonised standards usedEN 60335-1

EN 60335-2-79

EN 1829-1

EN 1829-2

EN ISO 12100: 2010

EN 13309: 2010

Conformity evaluation process used2000/14/EC: Annex V

Sound power levelMeasured: 96

Guaranteed: 99

The signatories act on behalf of and with the authority of the company management.

Documentation supervisor:

S. Reiser

Alfred Kärcher SE & Co. KG

Alfred-Kärcher-Str. 28 - 40

71364 Winnenden (Germany)

Ph.: +49 7195 14-0

Fax: +49 7195 14-2212

Winnenden, 2018/09/01