MC 130 ClassicMC 130MC 130 Plus

5969XXX0 (10/21)

5969XXX0 (10/21)

Read the original instructions and the safety instructions before using your vehicle for the first time. Act in accordance with them.

Read the original instructions and the safety instructions before using your vehicle for the first time. Act in accordance with them.

Keep these operating instructions for future reference or for future owners.

Please report any defects or shipping damage identified on the vehicle when it is handed over directly to your dealer or department store.

Yanmar engine 42 hp

Version with diesel particle filter

Rear wheel drive (2WD)

Yanmar engine 42 hp

Version with diesel particle filter

All-wheel drive (4WD)

Kubota engine 70 hp

Version with diesel particle filter

All-wheel drive (4WD)

The warranty conditions issued by our relevant sales company apply in all countries. We shall remedy possible malfunctions on your appliance within the warranty period free of cost, provided that a material or manufacturing defect is the cause. In a warranty case, please contact your dealer (with the purchase receipt) or the next authorised customer service site.

(See overleaf for the address)

The following versions of the vehicle are described in these operating instructions.

MC 130 Classic MC 130 MC 130 Plus

The vehicle may only be used for the intended use, as illustrated and described in these operating instructions.

Intended use also includes adherence to the prescribed maintenance activities and intervals.

The vehicle and attachments may only be used, maintained and repaired by persons familiar with the vehicle and attachments and the associated hazards.

The legally applicable general safety and accident prevention regulations must be adhered to. All other safety regulations, occupational health care regulations and road traffic regulations must be adhered to.

The operating personnel must:

Be physically and mentally suitable.

Have been instructed in the handling of the vehicle and attachments.

Have read and understood these operating instructions and the operating instructions for any attachments or towed machinery prior to starting work.

Have provided the operating company with verification of capability to operate the vehicle.

Be explicitly nominated to operate the vehicle by the operating company.

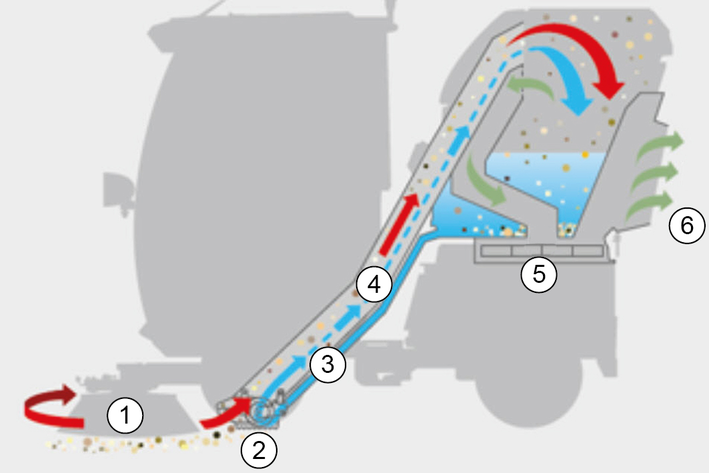

This vehicle is a vacuum sweeper.

The vacuum sweeper is intended for cleaning dirty outdoor surfaces.

The vehicle must conform to the applicable national regulations if used on public roads.

The vehicle is only suitable for use on the surfaces listed in the operating instructions.

The dust created is bound by sprayed water.

The side brushes rotate inwards and convey the waste in front of the suction mouth.

The suction fan generates a vacuum and sucks the waste into the waste container.

The filtered exhaust gas escapes from the rear side of the waste container.

The dust is more effectively bound through the recycled water operation (water circulation).

Asphalt

Industrial floor

Screed

Concrete

Paving stones

Any type of improper use is prohibited.

The operating personnel are liable for hazards resulting from incorrect use. Using the vehicle for other purposes than those described in this documentation is prohibited.

No modifications must be made to the vehicle.

Never sweep/vacuum explosive liquids, inflammable gases or undiluted acids and solvents. These include petrol, paint thinners or heating oil, which can form explosive vapours or mixtures through suction air turbulence, also acetone, undiluted acids and solvents because these attack the materials used in the machine.

Never sweep or vacuum reactive metal dusts (e.g. aluminium, magnesium, zinc) because they form explosive gases in conjunction with highly alkaline or acidic cleaning agents.

Never sweep or vacuum burning or smouldering objects.

Do not remain in the hazard zone.

Never operate the vehicle in potentially explosive environments.

Never transport persons on the vehicle, the loading area or attachments.

Do not use the vehicle as a front loader.

Do not use the vehicle in the forestry industry.

Do not use the vehicle for dispersing insecticide, pesticide or fertiliser.

The packing materials can be recycled. Please dispose of packaging in accordance with the environmental regulations.

The packing materials can be recycled. Please dispose of packaging in accordance with the environmental regulations.

Electrical and electronic appliances contain valuable, recyclable materials and often components such as batteries, rechargeable batteries or oil, which - if handled or disposed of incorrectly - can pose a potential threat to human health and the environment. However, these components are required for the correct operation of the appliance. Appliances marked by this symbol are not allowed to be disposed of together with the household rubbish.

Electrical and electronic appliances contain valuable, recyclable materials and often components such as batteries, rechargeable batteries or oil, which - if handled or disposed of incorrectly - can pose a potential threat to human health and the environment. However, these components are required for the correct operation of the appliance. Appliances marked by this symbol are not allowed to be disposed of together with the household rubbish.

Current information on content materials can be found at: www.kaercher.com/REACH

Observe the national regulations at the location.

Observe company-specific specifications.

Dispose of any operating and auxiliary materials according to the valid safety data sheets.

Vehicles that are no longer fit for service contain valuable recyclable materials. We recommend you cooperate with a waste management company with regard to the disposal of your vehicle.

Indication of an imminent threat of danger that will lead to severe injuries or even death.

Indication of a potentially dangerous situation that may lead to severe injuries or even death.

Indication of a potentially dangerous situation that may lead to minor injuries.

Indication of a potentially dangerous situation that may lead to damage to property.

Risk of asphyxiation. Keep packaging film out of the reach of children.

Only use the vehicle for its proper use. Take into account the local conditions and beware of third parties, in particular children, when working.

Persons with reduced physical, sensory or mental capabilities, or those with a lack of experience and knowledge, are only allowed to use the vehicle if they are supervised or have been instructed with respect to using the appliance safely, and understand the resultant dangers involved.

Only people who have been instructed on how to use the vehicle, or have proven their ability to operate it, and have been explicitly instructed to use it, must use the vehicle.

Children must not operate the vehicle.

Children must be supervised to prevent them from playing with the vehicle.

Safety devices are provided for your own protection. Never modify or bypass safety devices.

Danger of tilting if hill or slope is too steep! Observe the maximum permissible values in the technical data when driving up hills and slopes.

Danger of tilting in case of excessive tilting at side! Observe the maximum permissible values in the technical data when driving lateral to the travel direction.

Danger of tipping on unstable surfaces! Only use the vehicle on stable surfaces.

Risk of accident due to not adapting speed. Approach corners slowly.

The list on the risk of overturning is not necessarily comprehensive.

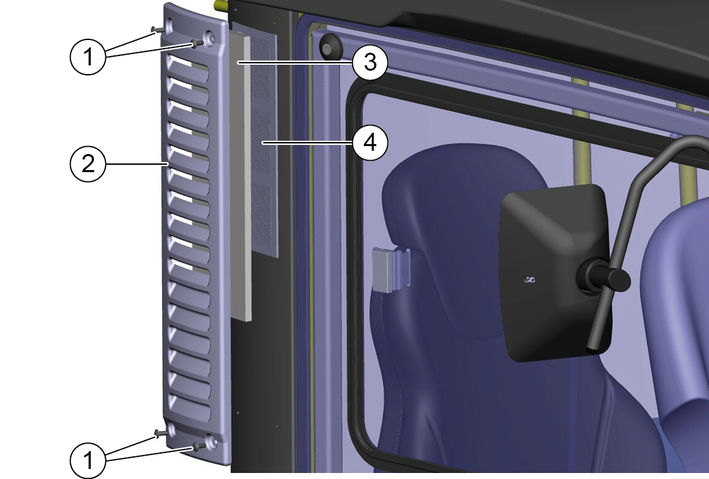

Driver cabins are equipped with air exit slats. Always keep these free from obstructions to ensure sufficient ventilation.

Ensure free visibility on public roads before use (e.g. fog-proof windscreens, mirrors, etc.).

Diesel engine: Never operate vehicles with diesel engines in confined spaces.

Danger of poisoning: Do not inhale the exhaust gases.

Never close off the exhaust gas openings.

Never bend down over the exhaust gas opening. Never reach inside the exhaust gas opening.

Always keep away from the drive area. Be aware of the engine after-running time after switching off (3-4 seconds).

Pay attention to the weight of the vehicle to avoid accidents and injuries, see Chapter Technical data.

Pay attention to the vehicle height during transport on a trailer or lorry and secure the vehicle, see Chapter Technical data.

Switch off the engine and remove the ignition key before performing cleaning or maintenance work on the vehicle, replacing parts or changing the functionality of the vehicle.

Repairs may only be carried out by approved customer service sites or staff qualified in this area who are familiar with all relevant safety instructions.

Adhere to the safety checks according to the applicable local regulations for mobile commercial vehicles.

The articulated joint, tyres, radiator fins, hydraulic hoses and valves, seals, electrical and electronic components must not be cleaned using a high-pressure cleaner.

The information in this chapter is also provided on a supplementary sheet that must always be carried on the vehicle.

The vehicle has a hydrostatic drive and articulated steering. It therefore exhibits driving characteristics that are different to those of a motorcar.

Danger of tipping over

Please note that the driving characteristics of a vehicle with articulated steering differ considerably from those of a motorcar.

Drive around curves at an even and appropriate speed. This applies, in particular, for driving uphill/downhill and driving across the face of a slope.

Be aware of the changes in the centre of gravity of the vehicle depending on attachments.

Adjust the travel speed to the ambient conditions when driving in a straight line and when driving around bends, e.g. road conditions and the load status.

Note decoupling of the front and rear part of the vehicle via a central pendulum joint.

Release the accelerator pedal provides a form of active braking. This differs from a motorcar where only the engine brake reduces vehicle speed.

The braking force applied when you release the accelerator pedal is weaker in higher gears and stronger in lower gears.

The braking force applied when you release the accelerator pedal in transport mode is significantly weaker than in working mode.

Vehicles with articulated steering exhibit a more direct response to steering movements than motorcars, particularly when taking bends at high speed, on snow, ice and wet/loose ground as well as during turning manoeuvres on slopes. Avoid rapid successive steering movements.

Centre of gravity / pendulum characteristicsRear attachments and load statuses influence the vehicle's centre of gravity and the driving characteristics. You must be ready to adjust to changed driving characteristics, particularly after changing attachments and in the case of changeable load statuses. Limit ranges may be reached earlier.

The vehicle has a central pendulum joint to provide a high degree of all-terrain mobility. This enables both vehicle halves to move transversely to the travel direction independently from one another.

This special property means that the driver does not receive immediate feedback on the behaviour of the rear half of the vehicle. You should therefore take care to use the mirrors to keep an eye on the rear of the vehicle.

Risk of injury on sweepers with high dumping

Secure the lifted waste container before working. Fit the retainer only from outside the hazard zone.

Replace the symbols immediately if they become illegible or get lost.

| DANGERRisk of burns from hot surfaces Allow the vehicle to cool down before working on it. |

| DANGERRisk of burns due to hot exhaust pipe Do not touch the exhaust pipe. Before working, allow the exhaust pipe to cool down. |

| DANGERDanger of tilting Only drive on terrain with a maximum lateral incline of 10°. |

| DANGERRisk of injury on account of splashing objects Keep an adequate distance from persons, animals and objects. |

| WARNINGRisk of injury Risk of being squeezed or hurt at the belts, side-brushes, waste container, cover. |

| DANGERDanger of crushing Make sure that no persons are present in the vicinity of the articulated joint or vehicle during operation. When using the vehicle for towing, make sure that no persons are located during operation between vehicle and trailer. |

| DANGERRisk of injury from rotating parts Open the bonnet only when the motor has come to a halt. |

| ATTENTIONDamage from incorrect transport During the transport, place always the transport lock on the articulated joint. |

| WARNINGHealth risk due to poisonous exhaust gases Do not inhale exhaust gases. |

| DANGERRisk of injury due to unauthorised usage Remove the ignition key to protect against unauthorised use and prior to cleaning and maintenance work. |

| ATTENTIONSafety for cleaning and maintenance Prior to cleaning and maintenance work, park the vehicle on a level and firm subsurface. |

| DANGERDanger of injury due to use of unspecified locations for seating Sit exclusively on the driver’s seat. |

| DANGERRisk of injury due to rolling over No persons may be present in the vicinity of the vehicle during use. |

| DANGERRisk of impact, risk of crushing When transporting or working under suspended loads, use suitable means for supporting. |

| DANGERDanger of tilting Only empty the waste container when the vehicle is placed on a level and firm subsurface. |

| DANGERRisk of fire Do not sweep up burning or glowing objects such as cigarettes, matches or similar objects. |

| DANGERRisk of crushing Keep your hands away from this area. |

| Main switch (battery isolation switch) |

| Lubrication point |

| Lubricating strip |

| Lashing point |

| Quality of the brake fluid and position where brake fluid can be filled Position of container for brake fluid |

| Locating point for a jack or a support |

| Position of main fuse |

| Position of fuse F2 |

| Emergency exit |

| Read operating instructions |

| Wear protective gloves |

| WARNINGRisk of injury from high-pressure jet Do not direct the high-pressure jet at persons, animals, live electrical equipment or at the device itself. Protect the device high-pressure cleaner frost. |

| DANGERRisk of injury from rotating brushes Ensure that no persons are in the vicinity of the danger zone. |

| ATTENTIONRisk of injury from the machine rolling away Always apply the parking brake when parking the machine. |

| DANGERClimbing prohibited Tip the waste container only when nobody is in the hazard zone. |

| DANGERTipping prohibited Attach the sweeper attachment only when in the operating position. |

| ATTENTION

The machine drives only when the waste container is retracted. |

| ATTENTIONClimbing prohibited Do not climb on the machine. |

| WARNINGRisk of injury Tip the waste container only on a level surface. |

Immediately replace illegible or absent symbols.

Safety devices protect the user and may not taken out of operation or functionally circumvented.

Adhere to the safety instructions in the chapters!

The main switch interrupts the electrical supply line to the starter motor.

Always disconnect the battery after parking the vehicle (Battery disconnected position).

Prerequisites for starting the motor:

Main switch activated (position battery connected)

Driver is sitting on the driver’s seat

When the driver's seat is vacant:

The vehicle cannot be driven.

The front PTO cannot be switched on or off.

The parking brake requires hydraulic pressure to release.

The parking brake is therefore applied when the engine is switched off.

The parking brake is also applied when the engine is running and the travel direction lever is in the NEUTRAL position.

The "Parking brake applied" warning light in the multifunction display lights up when the parking brake is applied.

The operator is protected from lightning strikes when sitting in the driver cabin.

The driver cabin has a roll-over protection structure (ROPS), which prevents rolling over after tipping over.

The driver cabin does not have a structure providing protection from falling objects (FOPS).

The driver cabin does not have a structure providing protection from falling objects (OPS).

Always use the safety belt.

Only use the batteries and chargers recommended by the manufacturer

Only replace batteries with batteries of the same type.

Before disposing of the vehicle, remove the battery and dispose of it in accordance with national or local regulations.

Observe the following warnings when handling the batteries:

| Observe notes in the instructions for the battery, on the battery and in these operating instructions. |

| Wear eye protection. |

| Keep acids and batteries away from children. |

| Risk of explosion |

| Fire, sparks, open flames and smoking are prohibited. |

| Risk of acid burns |

| First aid. |

| Warning |

| Disposal |

| Do not throw batteries in the bin. |

Risk of fire and explosion

Do not place tools or other objects on the battery.

Naked flames and smoking must be strictly avoided.

Ensure the room is well ventilated when charging batteries.

Only use batteries and chargers approved by Kärcher (original spare parts).

Environmental risk due to improper disposal of batteries

Ensure that defect or used batteries are disposed of safely (contact a waste management company or Kärcher Service).

When used normally, and when observing the instructions, lead-acid batteries do not pose any risk.

However, keep in mind that lead-acid batteries contain sulphuric acid which can cause serious chemical burns and corrosion.

If there is spillage or, if the battery is leaking, acid is escaping, lay down a binding agent such as sand. Do not let it reach the sewer system, soil or a body of water.

Neutralise the acid with lime/baking soda and dispose of it according to local regulations.

Contact a waste management company to dispose of faulty batteries.

Rinse out your eyes or rinse off your skin with copious amounts of fresh water if acid splashes into your eyes or onto your skin.

Then consult a doctor immediately.

Wash any contaminated clothing with water.

Change clothes.

Definition of the term, hydraulic PTO

Power Take Off = hydraulic force output

Definition of the term, AUX

Auxiliary valve

Right-hand side connections

Left-hand side connections

Right-hand side connections

AUX hydraulic connection, raise/lower

Hydraulic PTO (40 l/min)

Left-hand side connections

AUX hydraulic connection, raise/lower

Return line (40 l/min)

Terminology electric PTO

Power Take Off = electric power output

Right-hand side connections

Left-hand side connections

The main switch interrupts the electrical supply line to the starter motor.

If the main switch is pressed when the engine is running (battery disconnected), the engine will stop.

Always disconnect the battery when the vehicle is parked.

The emergency operation hydraulic valve is located under a cover behind the driver cabin.

A description of this is provided in chapter Troubleshooting guide.

This hydraulic valve is required when:

The waste container/attachment frame cannot be raised because the device hydraulics have failed. For example when the engine fails.

The front power lift/suction mouth cannot be raised because the device hydraulics have failed. For example when the engine fails.

The parking brake spring actuator cannot be released, e.g. for towing the vehicle.

There are two different versions of the switch lever depending on the version of the vehicle.

The hydraulic system can be switched between the waste container and attachment frame via the switchover valve.

The waste container and attachment frame are electronically monitored. Both functions cannot be activated simultaneously.

The driver's door is located at the left side in the travel direction, the emergency exit is located at the right side.

The door opener and door handles can be used as a aid for entering and exiting the cab.

Lock both doors with the ignition key after parking the vehicle.

A lockable storage compartment is located under the passenger seat. This can be used for storing documents, operating instructions, small parts or the towing eye.

The emergency exit is located at the left side in the travel direction. Open the emergency exit by pulling the door handle.

The emergency hammer is located at the upper left, behind the passenger seat. In case of emergency, destroy the windscreen with the emergency hammer.

The control panel is located on the left arm rest of the driver's seat. The arm rest can be individually adjusted to suit the driver, see chapter

For left-hand drive vehicles (optional), e.g. for the UK, the control panel is located on the right arm rest of the driver's seat.

The indicators in the switches light when the switches are switched on.

Raise front power lift and front PTO off (back)

Lower front power lift and front PTO on (forwards)

Operate AUX 1 (right/left)

Switch on front power lift floating position (forwards)

Switch off front power lift floating position (back)

Operate AUX 2 (forwards/back)

Operate AUX 3 (left)

(A) | Front PTO 40 l/min, 80 l/min |

(B) | Rear PTO 40 l/min |

(C) | Button for setting the engine speed |

(D) | Not used |

(E) | Not used |

(F) | Press the button to save set values or programs and open submenus. |

(G) | Rotary knob for changing values and selecting programs. |

The indicators in the switches light when the switches are switched on.

The suction fan has an afterrun time of approx. 15 seconds after being switched off

(A) | Left and right side brush speed button For individual extraction (option), left side brush speed button |

(B) | For individual extraction (option), right side brush speed button |

(C) | Engine speed Press to adjust the values NoteThe suction performance depends on the set engine speed.

|

(D) | For individual extraction (option), right side brush contact pressure button |

(E) | Left-hand and right-hand side brush contact pressure button For individual extraction (option), left side brush contact pressure button |

(F) | Save button Press to save adjusted values or programs |

(G) | Rotary knob Press to change the adjusted values |

The fresh air is sucked through a dust filter or fine dust filter at the side of the driver cabin.

The circulation air function ensures that a fogged windscreen clears more quickly when the air-conditioner or air blower is switched on. The cab air can also be warmed more quickly. Also useful in the case of unpleasant outdoor odours.

Pull the air recirculation lever forwards.

Only use this function for a limited period, since air is not exchanged from the outside with this setting.

The switch for emptying the waste container is located next to the driver's seat.

Switch on the water pump (control panel).

Turn the corresponding dosage knob.

Turning to the left increases the spray water volume. Turning to the right increases the spray water volume.

The indicator in the switch lights up when it is switched on.

The ignition lock is located below the travel direction lever.

The following indicators are shown on the display after switching on the ignition.

The display changes when the corresponding function button is pressed. Pressing again or pressing the "Home" button returns you to the previous display.

The settings button is used for changing the settings.

Function buttons | |

|---|---|

F1 | Information such as the vehicle operating instructions can be stored here In working mode: Switch in the high-pressure cleaner (Option) |

F2 | Display date and time |

F3 | Settings |

F4 | Bridging the seat contact switch, see chapter Operation with a bridged seat contact switch |

F5 | Reversing warning buzzer on/off |

F6 | Reversing camera on/off |

F7 | Suction mouth camera on/off |

F8 | Set Tempomat |

F9 | Resume Tempomat |

F10 | Service menu |

Setting buttons | ||

|---|---|---|

| + button | Jumps one field up when making settings |

| - button | Jumps one field down when making settings |

| "Home" button | Navigates to the "Home" screen for the respective operating mode (Transport / Work) |

| Esc button | Jumps one step back when making settings |

| "Return" button | Completes a setting procedure |

The following indicators are shown on the display in start/transport mode.

The following symbols and warning indicators can be shown on the display.

| Parking light |

| Driving light |

| High beam |

| Fog lamps |

| Hydraulic oil filter malfunction |

| Preheating active |

| Battery charge status warning |

| Malfunction |

| Hydraulic oil level warning |

| Fuel level warning |

| Floating position 1 |

| Floating position 2 |

| Floating position 1 and 2 |

| Driving direction indicator |

| Perform the regeneration process |

| Engine air filter malfunction |

| Critical malfunction, switch off the engine |

| Lower suction mouth |

| Seat contact switch malfunction |

| Engine coolant temperature warning |

| Parking brake active |

| Rear light indicator lamp flasher |

| Engine oil pressure warning |

| Hydraulic oil temperature too high warning |

| Regeneration not possible |

| High exhaust temperature |

| Switch off the engine |

| Engine malfunction |

| Service required |

The following indicators are shown on the display when switching to Working mode (PTO).

The function and settings buttons have already been described previously.

The following indicators are shown on the display when switching to Working mode (PTO).

The hydraulic system must be depressurised before disconnecting the hydraulic hoses from the hydraulic connections.

Unplug the signal plug for attachment device detection (front).

Switch on the ignition (do not start the engine).

Switch on the PTO work hydraulics (at the arm rest control panel).

Press the function key F 10 on the display.

Press function key F 6.

The rear hydraulic system is depressurised

Press function key F1.

The front hydraulic system is depressurised

Disconnect the hydraulic hoses.

Remove the attachment device.

Attachment is performed in reverse sequence.

Horns: Press the button on the end

Flash to the right: Lever forwards

Flash to the left: Lever backwards

High beam: Press the lever down with the driving light switched on

Flasher: Pull lever and release

Turn the ring: Turn on the windscreen wiper

Turn forward - interval

Turn backwards - 1. Continuous wipe level, keep turning for 2nd level

Press the ring: Wiping with washer water

Select the travel direction using the travel direction selector switch.

The following functions can be selected using the travel direction selector switch, the selected programs are shown on the display.

Neutral position

The travel direction selector switch is in the middle

Forwards direction of travel

Press the travel direction selector switch upwards and forwards

Travel direction backwards

Press the travel direction selector switch upwards and pull backwards

Switchover between the fast (Hare) and slow (Tortoise) operating programs

Press the travel direction selector switch to the end position (travel direction switch must first be in the neutral position).

Other than in a normal motorcar, releasing the accelerator pedal abruptly reduces the speed.

The braking force applied when you release the accelerator pedal is weaker in higher gears and stronger in lower gears.

The braking force applied when you release the accelerator pedal in transport mode is significantly weaker than in working mode.

Pressing the accelerator pedal increases the engine speed.

The accelerator pedal is sprung. Releasing the accelerator pedal reduces the engine speed.

The hydrostatic drive brakes or stops the vehicle when the accelerator pedal is released.

The brake pedal activates the braking system for the front wheels.

Parking brake for securing the parked vehicle.

If the "Parking brake active" warning light in the display lights up then the parking brake is engaged.

The structure of the vacuum sweeper consists of a waste container, sweeping mechanism and suction mouth.

Only accessories, spare parts and upgrade kits that are approved by the manufacturer may be used. To avoid risks, all repairs and installation of spare parts may only be carried out by the authorised customer service personnel. For information about accessories and spare parts, please visit www.kaercher.com.

The following accessories and options can be purchased additionally and attached to the device:

In recycling mode, the suction hose is continuously cleaned by water from the waste container.

The water is filtered by a pipe filter in the waste container and then channelled through the recycling water hose to the suction mouth via a valve.

This recycling water is immediate sucked in again at the suction mouth and then channelled back to the waste container through the suction hose.

The suction hose is continuously cleaned.

When retrofitted, the brackets must be installed and also the side panel cutouts for holding the brush and shovel handles.

The suction mouth camera is fastened at the sweeper system suction mouth.

The reversing camera is located at the rear of the vehicle.

The reversing camera is no substitute for an awareness of the surroundings

Always pay attention to the surroundings when reversing.

Ensure no persons, animals or objects are located in the manoeuvring range.

The optionally available radio is locate in the ceiling console.

See the manufacturer's operating instructions for operating the radio.

The seat contact switch can be bridged to allow using the work hydraulic system (PTO) when the driver's seat is not occupied.

This allows e.g. the suction hose or high-pressure cleaner to be used when nobody is sitting on the driver's seat.

This function is only possible in working mode, see chapter Bridging the seat contact switch.

Apply the parking brake.

Press function key F4.

The "Seat contact switch overridden" warning symbol appears on the display.

Press function key F4 again to switch off the function.

The seat contact switch is now bridged and the PTO remains active.

Read the operating instructions for attachments!

When using attachments or pulled devices and trailers prior to initial startup, read the corresponding operating instructions and follow them.

Pay attention to permissible loads, see chapter Technical data.

Pull out the locking pin.

Pull out both bolts.

Slide the transport lock into the storage.

Insert the pins.

Secure the pins with locking pins.

Put the main switch into the "battery connected" position.

Risk of accident and injury due to faulty vehicle

Do not start up the vehicle if one point from the safety check is not fulfilled but rather repair the vehicle.

Perform the recommended safety checks each time before using the vehicle.

Check the following points before each startup:

Release the transport lock, see chapter Release the transport lock at the articulated joint

Check the cleanliness of the hydraulic connections

Check the hydraulic lines for leaks

Check the hydraulic oil level, see chapter Checking the hydraulic oil level and topping up the hydraulic oil

Check the engine oil level, see chapter

Check the coolant level, see chapter

Check the coolant for sufficient antifreeze if a danger of frost exists

Check the electrical cables for damage

Check that all nuts and bolts are securely seated

Check the vehicle, engine and radiator grille for damage

Check the cleanliness of the engine air filter

Check the cleanliness of the cab dust filter

Check the fluid level in the windscreen washer reservoir, see chapter

Type pressures and tyre wear

In the vehicle

Ease of movement of the accelerator pedal

Are the working hydraulics (PTO) switched off?

With the ignition switched on: Do the charge indicator and oil pressure warning lights light up?

Start the engine and check the following:

Do the charge indicator and oil pressure warning lights go out?

Are the temperature indicator and fuel level indicator functioning?

Are the lighting system, travel direction indicator and flasher system functioning correctly?

Perform this safety check in addition to the device carrier safety check.

Check the operational and traffic safety of the vehicle before driving.

Fastening of the waste container.

Check the hydraulic and electric connections to the device carrier.

Check the spray water connections to the sweeping system and suction mouth.

Check the recycling water connection to the suction mouth (option).

Check the spray water filling level at the fresh water tank.

Recycling water filling level in waste container (option).

Check the sweeping system and brushes for entangled cords and tape.

Check the connections at the sweeping system and suction mouth.

Check the fastening of the sweeping system and suction mouth.

Danger of accident

Only adjust the driver’s seat when the device is standing.

Adjust the inclination, height and position of the left arm rest for operating the control panel.

Height adjustment with “air-suspended seat” option:

Pump the seat all the way up with the compressor and then lower it 2 - 3 cm.

The driver's seat is automatically damped.

The passenger seat is horizontally adjustable, pull the lever upwards to adjust.

Danger of accident

Only adjust the position of the steering wheel when the device is standing.

Pull and hold the inclination adjustment lever and set the steering wheel to the desired inclination.

Push in the lever.

Release the height adjustment locking lever and set the steering wheel to the desired height.

Lock the locking lever.

Risk of explosion

Do not refuel in confined spaces.

Do not smoke and avoid open flames.

Ensure that no fuel gets on hot surfaces.

Switch off the ignition.

Open the tank cap.

Fill with fuel.

Only the fuel specified in the operating instructions may be used.

Wipe of any spilt fuel and close the tank cap.

Estimate the required amount of fuel in advance to avoid overflows.

Open the cap on the filling nozzle.

Switch lever in the "Fill" position.

Fit a water supply hose onto the filling nozzle.

Fill the water reservoir.

To prevent back suction, the water hose must not be inserted into the water reservoir when filling.

Close off the water inlet.

Remove the water supply hose.

Close the cap on the filling nozzle.

Switch the switchover lever to the "Closed" position.

With a water circulation system (Recycling mode), water is directly filled into the waste container.

Unlock the right-hand panel and pivot it outwards.

Remove the lock from the water filling connection and water outlet.

Connect the water hose to the water filling connection

Fill the waste container with water (max. 100 litres) until water escapes from the open water drain.

Reattach both locks.

Close the panels.

Switch on recycling mode at the control panel.

Danger of crushing

Make sure that no persons are present in the vicinity of the articulated joint or vehicle during operation.

When using the vehicle for towing, make sure that no persons are located during operation between vehicle and trailer.

Risk of burns

Only use the vehicle if all panels are attached.

Risk of damage due to overheated hydraulic oil or overheated motor!

In case of excessive hydraulic oil temperature or an excessive coolant temperature, set the motor speed to idle mode (do not switch off the motor).

Perform the measures in the “Malfunctions” section

Risk of damage due to missing lubrication

If the warning light for the oil pressure lights up during operation, immediately move the vehicle out of the danger zone, switch off the motor immediately and rectify the fault.

Reduced stability due to attachments

Adjust the driving style.

Drive the first 100 hours of operation gently and avoid overloading.

Replace the engine oil, engine oil filter and hydraulic oil filter after 50 operating hours (authorised Customer Service department only).

The parking brake requires hydraulic pressure to release. The brakes are automatically actuated when the engine is switched off.

The parking brake is also applied when the engine is running and the travel direction lever is in the NEUTRAL position.

The "Parking brake applied" warning light in the multifunction display lights up when the parking brake is applied.

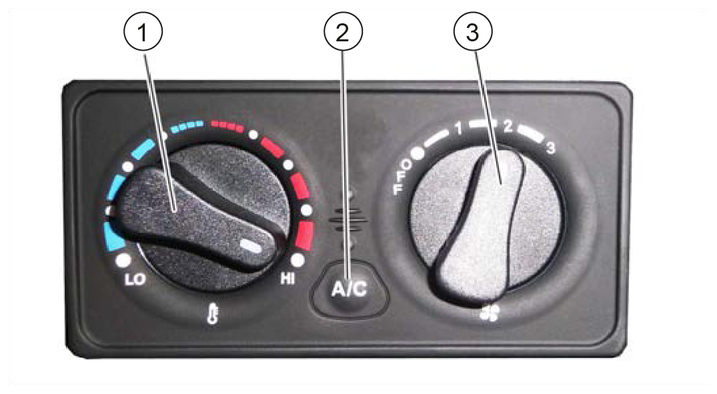

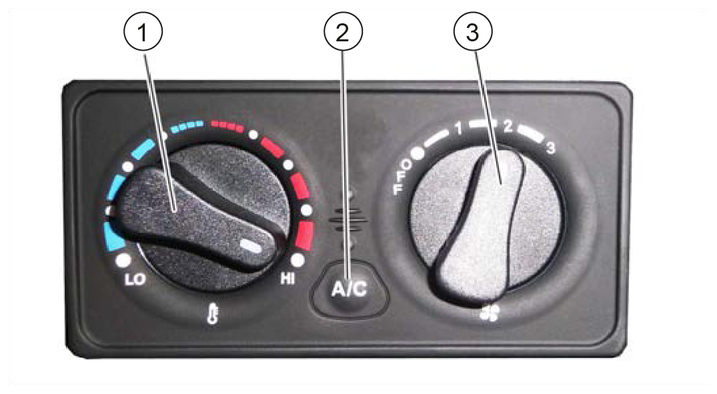

Adjust the ventilation, heating and air-conditioner (option) using the 3 controllers.

Adjust the volume and direction of the airflow at the ventilation nozzles.

The main switch must be switched on.

Sit down on the driver seat and fasten the seat belt.

Insert the ignition key into the ignition lock.

Set the travel direction lever into central position (neutral position).

Turn on the ignition.

Warning lights for charge control and motor oil pressure must be on.

Start the motor.

Warning lights for charge control and motor oil pressure must go out; if not, switch off the motor and rectify the error.

At ambient temperatures below 0 °C: Warm up the vehicle at a low motor speed until the “Hydraulic oil temperature too low” warning light goes out.

Press the travel direction selector switch towards the steering wheel and in the desired travel direction.

The travel direction is shown in the display.

Bring the travel direction selector switch into the middle position (neutral position).

The engine idles.

Press the travel direction selector switch to the end position.

Select the transport speed (between tortoise 20 km/h and hare 40 km/h).

The symbols are shown in the display.

Regulate the travel speed using the accelerator pedal.

Operating error

The vehicle must be at a standstill and the travel direction selector switch in the neutral position before changing the travel speed.

If the travel direction selector switch is in the forwards or reverse position when changing speed, the tortoise/hare symbol on the display will change but the travel speed will not switch over.

Risk of accident

Do not drive while the waste container is raised.

Risk of accident

Do not let go of the accelerator pedal abruptly during driving. The vehicle will be braked when the accelerator pedal is released. The vehicle will be decelerated to a lesser extent when the accelerator pedal is released in transport mode rather than in operating mode.

Risk of damage

Make sure that the vehicle does not become stuck when driving over obstacles.

Drive over obstacles up to 150 mm slowly and carefully at an angle of 45°.

Obstacles above 150 mm may only be driven over using a suitable ramp.

Risk of accident

When driving on public roads for transport purposes (and not when cleaning of public roads), switch off the PTO and close the lowering choke for the front power lift.

Switch off PTO.

Carefully depress the accelerator pedal.

Control the travel direction using the steering wheel.

Release the accelerator pedal.

The vehicle brakes automatically and comes to a standstill.

For a stronger braking effect or in case of an emergency, actuate the brake pedal.

The Tempomat is only active in Working mode.

Activating Tempomat

Select the desired working speed using the accelerator.

Press function key F 8.

Tempomat is activated.

Deactivating Tempomat

Press the brake pedal or function key F 8.

Function key F 9 (Resume Tempomat) activates the previously set speed.

Stop the vehicle.

Bring the travel direction lever into the neutral position (middle position).

In this position, the parking brake is automatically actuated; the vehicle does not move.

Lowe the front power lift.

If a sweeper is used:

Raise the side brushes.

Switching off the "eco" function

or

Switch off the water pump.

Wait 20 seconds.

Switch off the suction fan.

Raise the suction mouth.

Switch off the PTO.

All sweeping functions are deactivated.

Allow the engine to run in idle mode for 1 to 2 minutes.

Switch off the ignition and remove the ignition key.

Wait for 30 seconds to allow the engine control unit storage process to complete.

Turn the main switch to position 0.

Press the pedal briefly: Full brush contact pressure and increased brush speed for heavy soiling.

Hold the pedal pressed: Suction mouth remains lowered when reversing, vacuumed substances are also taken up when reversing.

(A) | Button for setting the side brush speed For individual extraction (option), left side brush speed button |

(B) | Button for setting the side brush speed For individual extraction (option), right side brush speed button |

(C) | Button for setting the engine speed NoteThe suction power depends on the set engine speed.

|

(D) | Left and ride brush contact pressure button For individual extraction (option), right side brush contact pressure button |

(E) | Left and ride brush contact pressure button For individual extraction (option), left side brush contact pressure button |

(F) | Press the Save button to save set values or programs |

(G) | Rotary knob for changing values and selecting programs |

Switch on the PTO.

Press the Side brush speed button.

The settings appear on the display.

Use the rotary knob to select the desired side brush speed.

Press the Save button.

The side brush speed has now been saved.

Press the Engine speed button.

The settings appear on the display.

Use the rotary knob to select the desired engine speed.

Press the Save button.

The engine speed has now been saved.

Press the Side brush contact pressure button.

The settings appear on the display.

Use the rotary knob to select the desired contact pressure.

Press the Save button.

The contact pressure is saved.

Operation with the right-hand joystick

The suction fan has an afterrun time of approx. 15 seconds after being switched off

The indicators in the switches light when the switches are switched on.

Start the engine, see chapter Start motor.

Switch on the hydraulic system.

Set the desired engine speed.

Switch on lower suction mouth.

Set the side brush speed.

Switch on the suction fan.

Move the left-hand joystick forwards.

The right and left brush arms are lowered and the brushes are switched on

Adjust the sweeping width.

Move the right-hand joystick forwards.

The right side brush lowers and is switched on.

Adjust the sweeping width (optional).

When brushing dry, dusty waste:

Switch on the water pump.

Optional: Switch on the water circulation function if necessary.

Risk of tilting

Only empty the waste container on a firm even subsurface.

Maintain the safety distance while emptying on dumps or ramps.

Danger due to rolling away

Set the travel direction lever to neutral for emptying.

Apply parking brake.

Danger of injury

Switch off the suction fan before emptying the waste container.

Risk of injury

During the emptying process, persons and animals must not abide within the swivelling range of the waste container.

Crush hazard

Never reach into the rod assembly for the emptying mechanism.

Stop the vehicle.

Apply the parking brake.

Bring the travel direction lever into the neutral position (middle position).

Set the switch lever to the "Waste container" position.

Switch on the PTO.

Lift the right side brush and switch it off by moving the left joystick to the right and then pushing it back.

Lift the right side brush by moving the right joystick to the left and then pushing it back.

Switch off the water pump.

Wait 20 seconds.

Switch off the suction fan.

Actuate the toggle switch.

Empty the waste container.

Note

Always raise the waste container fully to the end position.

The DPF collects soot particles that are burned off by increasing the emission temperature when the filter is clogged (regeneration).

The regeneration process runs either automatically during working mode or driving mode but can also be started manually if required.

The higher the speed when driving, or the greater the load, the less frequent the need for manual regeneration.

Risk of burns

During the regeneration process, exhaust gases up to a temperature of 600°C may be omitted.

Do not start the regeneration process in combustible areas.

Only interrupt the regeneration process in the case of an emergency.

If the regeneration indicator on the display lights up during operation then a regeneration process must be started.

Regeneration can be performed automatically or manually.

Work can continue during Automatic regeneration.

For manual cleaning ("Parked regeneration"), stop at suitable location within 15 minutes.

Regeneration duration is approx. 30 minutes.

Set the travel direction to the NEUTRAL position and do not press the accelerator pedal.

The driver's seat can be vacated during this period.

To start the regeneration process, first press function key F 10 (lower right key), then press F 1 for Automatic or F 2 for Manual cleaning.

The engine speed increases noticeably during both types of cleaning. When cleaning has finished the indicator lamp goes out and the engine speed decreases again.

The regeneration instructions above should suffice in most cases and more detailed descriptions are provided in the section "Faults with display".

Risk of burns

During the regeneration process, exhaust gases up to a temperature of 600°C may be omitted.

Do not start the regeneration process in combustible areas.

Work can continue during Automatic regeneration.

The automatic regeneration can be postponed in certain situations.

Risk of burns

During the regeneration process, exhaust gases up to a temperature of 600°C may be omitted.

Do not start the regeneration process in combustible areas.

Risk of burns from hot exhaust gases

Keep people, animals and flammable objects away from the regeneration area.

Only interrupt the regeneration process in the case of an emergency.

Manual regeneration is not possible at less than 50 hours.

The average duration of the burning procedure during manual regeneration is approximately 20 minutes.

Manual regeneration can only be started when all 4 characteristics are green:

The parking brake is activated

The engine temperature has exceeded a particular limit value

The machine is in driving mode N (neutral)

OK then lights up green and the manual burning procedure can be started

Ensure there is enough antifreeze in the coolant.

During winter use, the sweeping system and suction mouth must be disassembled and placed into storage.

Use the high-pressure cleaner only for the following activities:

Cleaning with the high-pressure jet without detergent (e.g. façades, park seats, garden paths).

Only operate the high-pressure cleaner with the flat jet nozzle provided.

This high-pressure cleaner is intended and tested for the exclusive use with the sweeper vacuum MC 130.

When the water quantity is reduced via the pressure/quantity control on the trigger gun, the overflow valve opens and part of the water flows back to the suction side of the pump.

The safety valve opens when the permissible operating pressure is exceeded and the water flows back to the suction side of the pump.

Return flow of dirty water into the drinking water network

Health risk

Observe the regulations of your water supply company.

According to applicable regulations, the device must never be used with the drinking water network without a system separator. Use a system separator from KÄRCHER or a system separator as per EN 12729 Type BA. Water that has flowed through a system separator is classified as undrinkable. Always connect the system separator to the water supply and never directly to the water connection on the device.

Risk of injury from high-pressure jet

Do not direct the high-pressure jet at persons, animals, live electrical equipment or at the device itself.

Protect the device high-pressure cleaner frost.

Environmental pollution through oil

Clean engines only at locations having an appropriate oil separator.

Only nozzles of the sizes listed in the technical data may be used.

If you have not already done so:

Connect the high-pressure hose and spray lance.

Connect the water supply hose and open the stop cock of the water inlet.

The high-pressure cleaner may be operated only at an engine speed of 1600 rpm and only in work mode.

Check the water filling level and fill the water reservoir of the MC 130 if necessary.

Open the stop cock of the water inlet.

Put travel direction lever in the NEUTRAL position - centre position and start the motor.

Remove the trigger gun and high-pressure hose from storage.

Switch on the PTO work hydraulics.

Press F1 function key on the display and switch on the high-pressure cleaner.

Engine speed automatically increases to 1600 rpm.

A "high pressure" symbol appears in the display.

Switch on the high-pressure cleaner via the button on the display.

Unlock the trigger gun.

Pull the trigger on the trigger gun and commence cleaning.

For first use or when the water reservoir is empty, the high-pressure cleaner must be vented:

Operate the high-pressure cleaner without the nozzle until there is no more air in the system.

Close the trigger gun.

Switch off the high-pressure cleaner with the switch on the right of the driver's seat.

Switch off the work hydraulics.

Actuate the trigger gun until the device is depressurised.

Actuate the safety lever of the trigger gun to prevent the gun trigger from being unintentionally triggered.

Fasten and secure the trigger gun with spray lance and high-pressure hose in storage.

If the high-pressure cleaner is not needed, for example during winter operation (spreading salt and other work):

Blow out the system with compressed air - see chapter Frost protection.

Remove the high-pressure gun with spray lance and high-pressure hose from the device.

Take off the device cover (3 quick fasteners) and close the high-pressure output with the protective part intended for it.

Disconnect the water inlet at the GEKA connection.

Close the water inlet for the high-pressure pump.

Fix (store) the water supply hose of the water reservoir under the waste container.

Check all hydraulic hoses and connections for leaks.

Check the high-pressure hose for damage (danger of bursting).

Immediately replace a damaged high-pressure hose.

Check the device (pump) for leaks.

3 drops of water per minute are permissible and can leak out of the bottom of the appliance. Contact Customer Service in the case of more serious leaks.

To read the oil level or clean the water screen, remove the device cover (3 quick fasteners).

Read the oil level when the device is on a flat surface. The oil level must be in the middle of the sight glass.

Contact Customer Service immediately if the oil is milky (water in oil).

Clean the sieve in the water connection.

Depressurise the device.

Unscrew the cover with filter.

Clean the filter with clean water or compressed air.

Assemble in the reverse order.

Changing oil.

For oil quantity and type, see Technical data.

Have the oil changed by Customer Service.

Danger of frost

Incompletely emptied devices can be destroyed by frost.

Completely empty the device and accessories.

Protect the device from frost.

Store the device in a frost-protected place.

If frost-free storage is not possible:

Close off the water inlet.

Allow the device for run for a maximum of 1 minute until the pump and lines are empty.

Blow the high-pressure pump, supply hose, water filter and high-pressure hose out with compressed air.

Risk of injury due to inadvertently starting up device and also due to electric shock.

Switch off the device and remove the ignition key before performing any work.

Have electrical components checked and repaired by the authorised Customer Service.

In case of any malfunctions not mentioned in this chapter, contact the authorised Customer Service when in doubt or when you have been explicitly advised to do so.

Pump leaking

Up to 3 drops of water per minute are permissible.

Remedy:

In case of more serious leaks, have the device checked by Customer Service.

Pump knocking

Remedy:

Check the water supply line for leaks.

Vent the device, see section "Venting the device".

Contact Customer Service if necessary.

Switch on the work hydraulics and high-pressure switch.

Fill the water reservoir.

Clean the water inlet sieve, check the water supply.

Check/replace the high-pressure nozzle.

Hydraulic connection | ||

|---|---|---|

Supply from the hydraulic system of the MC 130 | ||

Connection output | kW | 4.5 |

Water connection | ||

Water supply from the water reservoir of the MC 130 | ||

Input temperature (max.) | °C | 60 |

Performance data | ||

Working pressure | MPa | 7-15 |

Nozzle size | 036 | |

Max. operating pressure | MPa | 19 |

Flow rate | l/min | 10 |

Recoil force of the trigger gun. (max.) | N | 30 |

Determined values in acc. with EN 60335-2-79 | ||

Sound pressure level LpA | dB(A) | 75 |

K uncertaintypA | dB(A) | 3 |

Sound power level LWA + K uncertaintyWA | dB(A) | 97 |

Hand-arm vibration value | m/s2 | 1.6 |

K uncertainty | m/s2 | 0.7 |

Operating materials | ||

Oil volume | l | 0.4 |

Oil type | SAE 15W-40 | |

Dimensions and weights | ||

Weight | kg | |

We hereby declare die technical documents according to EC Directive 2006/42/EC (+2009/127/EC) Annex VII Part B have been created for the incomplete machine described below and that this conforms to the following points of the directive:

Annex I Points 1.1, 1.2, 1.3, 1.4, 1.5, 1.6 and 1.7. I Point 1.1,

This declaration is invalidated by any changes made to the incomplete machine that are not approved by us.

Product: | Attachment kit |

High-pressure cleaner | |

Type: | 2.851-952.7 |

Harmonised standards used, based on: | |

EN 60335–2–79 | |

Authorities can request the relevant documentation for the incomplete machine from the documentation supervisor. Documents are provided via email.

Before commissioning or installation of the incomplete machine, it must be ensured that the complete machine into which the incomplete machine is installed conforms to the EC Machinery Directive 2006/42/EC (+2009/127/EC).

Please refer to the EC Declaration of Conformity for the machine for more information on this.

The signatories act on behalf of and with the authority of the company management.

Documentation supervisor:

S. Reiser

Alfred Kärcher SE & Co. KG

Alfred-Kärcher-Str. 28 - 40

71364 Winnenden (Germany)

Ph.: +49 7195 14-0

Fax: +49 7195 14-2212

Winnenden, 2017/07/18

Remove the manual suction hose from the stowage compartment.

As necessary:

Connected the water hose provided and open the stop cock lever on the handle.

Close the dosing knobs in the cabin to prevent the emission of spray water for the suction mouth and sweeper jets, otherwise there will not be enough spray water for the manual suction hose.

Pull out the switch lever into the "Vacuum with suction hose" position.

Start the motor.

Switch on the PTO (at the arm rest control panel).

Switch on the blower.

As necessary: Switch on the water pump at the control panel.

Select the engine speed.

The suction performance depends on the engine speed selected.

1600 rpm - for light waste

2200 rpm - for normal waste

2500 rpm - for strong, heavy waste

Hold the suction pipe by the handle (adjustable) and begin vacuuming.

Set the engine speed to 2200 rpm for installing the manual suction hose.

When using the water hose: Switch off the water pump, disconnect the water hose and stop appropriately.

Insert the suction pipe with handle, press against the cover and fasten in position.

The vacuum pulls the suction pipe against the cover and the suction hose contracts. This is necessary to allow it to be stowed in the bracket.

Press the rest of the suction hose into the bracket and press the flap closed until the latch engages.

Switch off the blower.

Press in the switch lever into the "Work in sweeping mode" position.

Please read the attachment operating instructions before fitting an attachment.

Attachments are optional and can be fitted to the front power lift (see chapter Front power lift (option)) or to the front or rear mounting frames.

Danger due to change to vehicle's centre of gravity and to driving characteristics. When transporting fluids, sloshing motion may occur, which will then rock the vehicle.

In the case of modifications, particularly when converting from winter to summer use and in the case of changes to load conditions, the driver must be prepared for the change in driving characteristics.

Risk of crushing when attaching attachments

Do not reach between the front power lift and the attachment.

Risk of burns from hot hydraulic couplings

Wear protective gloves when disconnecting the hydraulic couplings.

Wear suitable protective clothing, safety gloves and gloves when installing and removing attachments. This also applies during usage and application.

Please contact your responsible dealer before fitting attachments that are not specifically intended for this vehicle. Your dealer will check if installation and use of these attachments is permitted on your vehicle. This is important for the safety of the driver and the vehicle and also for any warranty claims.

Attachments that endanger the safety or stability of the vehicle may not be used.

Risk of damage

Keep hydraulic connections clean.

Clean the plug and coupling with a lint-free cloth before use.

Pull the ring of the coupling sleeve downwards and hold.

Press the coupling connector of the attachment hydraulic hose into the coupling sleeve.

Release the coupling ring. Check that it is securely engaged.

To decouple, pull the ring downwards, hold it and pull out the hydraulic hose.

For permissible support load and trailer load, see chapter Technical data.

The locking mechanism secures the attachment devices (e.g. sweeper system, front power lift).

Danger of accident

Check the locking mechanism for correct adjustment with each attachment.

Press the locking lever downwards.

The lock is engaged beyond the dead point.

Adjust the lock via the clamping nut.

The front axle of the vehicle must always be loaded with at least 30% of the net weight of the vehicle, and the rear axle must always be loaded with at least 30% of the net weight of the vehicle.

Before purchasing the attachment, check that these requirements are met by weighing the vehicle-attachment combination.

The following data is required for determining the total weight, the axle loads, the tyre loading capacity and the required minimum ballast:

All weights in kg (weigh the vehicle if necessary)

All dimensions in meters (m)

TL | (kg) | = | Net weight of the vehicle | * |

TV | (kg) | = | Front axle load of the empty vehicle | * |

TH | (kg) | = | Rear axle load of the empty vehicle | * |

GH | (kg) | = | Total weight rear attachment / rear ballast | ** |

GV | (kg) | = | Total weight of front attachment / front ballast | ** |

a | (m) | = | Distance between front attachment (front ballast) centre of gravity and middle of front axle, max. = 0.86 m | ** *** |

b | (m) | = | Wheelbase of the vehicle | * *** |

c | (m) | = | 0.56 | |

d | (m) | = | Distance between the centre of the equipment-side attachment point and the centre of gravity of the rear attachment / rear ballast | ** *** |

* See chapter "Technical data"

** See operating instructions of the attachment

*** Measure

Enter the result into the table.

See the manufacturer's specifications for the value "x" or use a value of x = 0.45 if no specifications are available.

Enter the result into the table.

If the necessary minimum front ballast weight (GV min) is not reached with the front attachment (GV) then the weight of the front attachment must be increased to the minimum front ballast weight.

Enter the actual calculated permissible front axle load and the permissible front axle load specified in the work machine operating instructions into the table.

If the necessary minimum rear ballast weight (GH min) is not reached with the rear attachment (GH), then the weight of the rear attachment must be increased to the minimum rear ballast weight.

Enter the result into the table.

Risk of crushing when lowering/raising the waste container

Maintain sufficient clearance to the waste container and the rollers on the parking supports.

Maintain sufficient clearance to hazard zone and stop raising/lowering immediately when a person enters the hazard zone.

Risk of injury and damage

The dirt receptacle and fresh water tank are empty.

Remove the waste container only on a level and smooth surface.

The waste container must be secured on the parking supports for installation.

Set the switchover valve to the attachment frame position.

Drive the rear of the vehicle carefully under the waste container.

Raise the attachment frame slowly until under the waste container.

Hook the waste container onto the attachment frame using the retaining hooks.

Continue raising the attachment frame until the load on the front parking supports is relieved.

Lift the attachment frame only until the rollers of the front parking supports are approx. 20 mm in the air.

Pull out the front parking supports. For this, pull the retainer to unlock and then press the lever.

Completely lower the attachment frame together with the waste container.

Pull out the rear parking supports. For this, pull the retainer to unlock and then press the lever.

Push the retaining pin the of waste container in and secure with the locking pin.

Connect electrical and hydraulic connections.

Turn the steering wheel all the way to the right to provide better access to the connections on the articulated joint.

Connect the water recycling hose.

Connect the fresh water hose.

Connect the high-pressure cleaner hose (optional).

Install the suction hose between the waste container and suction mouth.

Risk of crushing when lowering/raising the waste container

Maintain sufficient clearance to the waste container and the rollers on the parking supports.

Maintain sufficient clearance to hazard zone and stop raising/lowering immediately when a person enters the hazard zone.

Risk of injury and damage

Empty the waste container and water reservoir before removing

Set the waste container down only on a level and smooth surface.

Turn the steering wheel all the way to the right to provide better access to the articulated joint.

Disconnect and remove the suction hose from the waste container.

Disconnect the hoses for water recycling, fresh water and the high-pressure cleaner (optional).

Steer the vehicle straight ahead.

Open the locking pin for the waste container from the retaining pin and remove it.

Pull out the retaining pin.

Adjust the rear parking supports to an appropriate height and secure in this position.

The corresponding height depends on the tyre type and the tyre pressure.

Push in the rear parking supports all the way to the end stops and secure in this position. To do this, press the safety lever down and push in the supports as far as they will go. Then secure the safety lever with the retaining clip.

Depressurise the hydraulic system, see chapter

Disconnect the electrical and hydraulic connections from the waste container.

Set the switchover valve to the tilting attachment frame position. See chapter

Raise the attachment frame with waste container.

Push in the front parking supports as far as they will go and secure them. To do this, press the safety lever down and push in the supports as far as they will go. Then secure the safety lever with the retaining clip.

Lower the attachment frame.

Actuate the roller brakes on the front parking supports.

The waste container now stands free on the parking supports.

Drive the rear of the vehicle carefully out from under the waste container.

A changing carriage is required for attaching/removing the sweeper system.

Optional accessory, order no. 2.852-065.0.

Stop the vehicle on level, solid ground and secure it against rolling away.

Raise the side brushes and extend both side brushes outwards.

Rod

Locking lever

Unlock the sweeping system by inserting the rod and pulling the locking lever upwards.

The rod needed for this is clamped in a holder between the driver's seat and passenger seat.

Use the lift truck to move the changing carriage centrally inwards as far as it will go.

Move the last distance (centring process) faster.

Risk of damage! Watch out for cables and hoses.

Raise the lift truck until the changing carriage makes contact with the sweeper system.

Retract both side brush arms.

Check the side brush arms for correct seating.

Depressurise the hydraulic system. See chapter Depressurise the hydraulic system (pressure relief).

Set the ignition to position 1 in working mode (do not start the engine).

The brushes lower and the hydraulic system depressurises.

Disconnect all connections and joints.

Remove the suction hose between the waste container and suction mouth.

Disconnect the (thick) water hose.

Move the sweeper system out using the lift truck.

Place the cables and hoses in the storage boxes.

Park the sweeper system in a safe place.

Extend the lift truck.

Stop the vehicle on level, solid ground and secure it against rolling away.

Attach the sweeper system to the vehicle in the reverse sequence.

Lock the sweeper system (lever down).

Check the locking, see chapter Checking adjusting the attachment locking mechanism.

Depressurise the hydraulic system. See chapter Depressurise the hydraulic system (pressure relief).

Connect the hydraulic hoses to the couplings.

Various different attachment devices can be attached to the front power lifter using a 3-point mounting.

A changing carriage is required for attaching/removing the front power lift.

Optional accessory, order no. 2.852-067.0.

Stop the vehicle on level, solid ground and secure it against rolling away.

Move the locking lever upwards.

Use the lift truck to position the front power lift centrally in front of the vehicle.

Insert the front power lift into the mounting frame on the vehicle, all the way to the end stop.

Move the locking lever downwards.

Check the locking, see chapter Checking adjusting the attachment locking mechanism.

Lower and retract the lift truck.

Depressurise the hydraulic system. See chapter Depressurise the hydraulic system (pressure relief).

Connect the hydraulic hoses to the couplings.

Raise the front power lift.

Use a lift truck to move the changing carriage under the front power lift.

Raise the lift truck.

Make sure that the frame of the front power lift is securely seated in the mounting of the removable frame.

Depressurise the front hydraulic system (pressure relief).

Release the hydraulic hoses.

Fasten the hydraulic hoses to the front power lift with cable ties.

Open the lock on both sides of the vehicle, see chapter “Opening/closing the lock”.

Use a lift truck to move the front power lift out of the vehicle mounting frame.

Set down the front power lift in a safe place.

The pallet on which the sweeper system is delivered is also used as a mounting aid for attachment/removal.

Move the lift truck under the pallet with the positioned sweeper system.

Pull the locking lever upwards.

Move the sweeper system into the holder on the vehicle and position it approximately 10 cm in front of the vehicle.

Connect the hydraulic hoses, paying attention to the colour coding.

The connection assignments are described in a later chapter

Connect the water hoses.

Insert the device detection connector at the vehicle.

Insert the sweeper system into the vehicle mounting bracket, all the way to the end stop.

Lock the sweeper system by pressing the locking lever down (using the curved rod).

The locking mechanism must be adjusted correctly via the adjusting nuts when the system is attached for the first time or transferred to another vehicle. When correctly adjusted, the locking mechanism must engage when pressed down beyond the dead point.

Attach the side brushes.

Operation of the 2-brush sweeper system is described in a later chapter.

Plug in the hydraulic hoses according to the colour coding.

Plug in the water hoses at the left and right sides.

The indicators in the switches light when the switches are switched on.

Joystick forwards: Lower the brush arms simultaneously and switch on the side brushes

Joystick backwards: Raise the brush arms simultaneously and switch off the side brushes

Joystick to the left/right: Pivot the brush arms simultaneously

(A) | Sweeping brush speed selection, common for the left-hand and right-hand sides |

(B) | Button is not used |

(C) | Engine speed Press to adjust the values NoteThe suction power depends on the set engine speed.

|

(D) | Not used |

(E) | Left-hand and right-hand side brush contact pressure button |

(F) | Save button Press to save adjusted values or programs |

(G) | Rotary knob Press to change the adjusted values |

Switching over to the 2-brush sweeping system (pulled):

Switch on the ignition.

Press F10 on the vehicle display.

Use F5 to select a pulled sweeper system.

A green bar in the display indicates a reduction in the brush contact pressure.

A red bar indicates an increase in the brush contact pressure.

The existing lubrication points (grease nipples) are labelled.

Lubricate daily with multi-purpose grease.

Check the sweeping brushes for tangled cords and straps and remove as necessary.

Keep the hydraulic connections clean and check for leaks once a week.

Check the sweeping brushes for wear and damage and replace if necessary.

Adjust the sweeping area as shown in the illustration.

Right: 9 am- 2 pm

Right-hand side: 10 am- 3 pm

Adjusting the side inclination

Unscrew the screws.

Adjust the side inclination via the rotation point of screw 1.

Tighten the screws.

Adjusting the head inclination forwards

Unscrew the counternut.

Adjusting the head inclination via the hexagon.

Tighten the counternut.

Adjusting the brush contact pressure

The brush system has a hydraulic brush contact pressure relief system.

Risk of injury and damage

Note the weight of the device.

Risk of damage

Store the attachment kit in a protected, level and dry place. Ensure that the sweeping brushes are not loaded.

Store the sweeping system that has been removed from the vehicle on the changing carriage.

Ensure that the sweeping brushes are not loaded during attachment to the vehicle.

Dimensions and weights | 2-brush sweeping system (pulled) |

|---|---|

Length | 950 mm |

Width | 1250 mm |

Height | 750 mm |

Weight (transport weight) | 115 kg |

Remove the sweeper system in the reverse sequence to the attachment procedure. Set the sweeping system down on the pallet. Remove the sweeping brushes first.

Always first depressurise the system before disconnecting the hydraulic hoses, see the corresponding section in the vehicle operating instructions.

The pallet on which the sweeper system is delivered is also used as a mounting aid for attachment/removal.

Move the lift truck under the pallet with the positioned sweeper system.

Pull the locking lever upwards.

Position the sweeper system approximately 10 cm in front of the vehicle.

Connect the hydraulic hoses, paying attention to the colour coding.

The connection assignments are described in a later chapter

Connect the water hoses.

Plugging in the electrical socket plug connection on the vehicle.

Insert the sweeper system into the vehicle mounting bracket, all the way to the end stop.

Lock the sweeper system by pressing the locking lever down (using the curved rod).

The locking mechanism must be adjusted correctly via the adjusting nuts when the system is attached for the first time or transferred to another vehicle. When correctly adjusted, the locking mechanism must engage when pressed down beyond the dead point.

Attach the side brushes and front brush.

Operation of the sweeper system is described in a later chapter.

Plug in the hydraulic hoses according to the colour coding.

Plug in the water hoses at the left and right sides.

The indicators in the switches light when the switches are switched on.

Joystick forwards: Front brush lowers and switches on

Increase the contact pressure in the case of heavy soiling

Joystick backwards: Front brush raises and switches off

Joystick to the left/right: Front brush moves to the left/right

Joystick forwards: Lower the brush arms simultaneously and switch on the side brushes

Joystick backwards: Raise the brush arms simultaneously and switch off the side brushes

Joystick to the left/right: Pivot the brush arms simultaneously

(A) | Front brush rotary speed selection |

(B) | Sweeping brush rotary speed selection |

(C) | Engine speed Press to adjust the values NoteThe suction power depends on the set engine speed.

|

(D) | Sweeping brush load relief |

(E) | Front brush load relief/pressure |

(F) | Save button Press to save adjusted values or programs |

(G) | Rotary knob Press to change the adjusted values |

A green bar in the display indicates a reduction in the brush contact pressure.

A red bar indicates an increase in the brush contact pressure.

The front brush must be secured in the desired position when using the device as a weed brush.

Three positions are possible.

Secure the desired working position with bolts and spring pins. See chapter Transport lock.

Press the Change of rotation direction button when working in the Left position.

The front brush must be secured when driving on public roads (transport journeys).

Move the front brush carriage all the way to the left.

Secure the front brush in the corresponding position using a pin and spring pin.

Further information can be found in the operating instructions for the vehicle.

Maintenance and care of the sweeping unit

Check the front brush and sweeping brush for tangled cords and straps and remove as necessary.

Keep the hydraulic connections clean and check for leaks once a week.

Check the front brush and sweeping brush for wear and tear and replace if necessary.

Maintenance and care of the bearings/linear unit

Malfunction or risk of damage

The bearing units are self-lubricating dry bearings and must never be lubricated with any lubricant.

Brake cleaners, lubricants or other cleaners can corrode and destroy the bearing foil. Check the bearing foil for wear and damage and replace if necessary.

The existing lubrication points (grease nipples) are labelled.

Lubricate daily with multi-purpose grease.