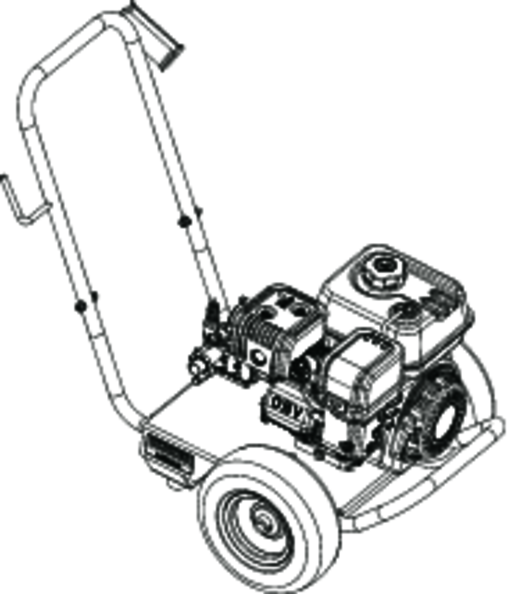

HD 6/15 G Classic HD 7/20 G Classic

97684400 (12/20)

97684400 (12/20)

Read these original operating instructions and the enclosed safety instructions before using the device for the first time. Proceed accordingly.

Read these original operating instructions and the enclosed safety instructions before using the device for the first time. Proceed accordingly.

Keep both books for future reference or for future owners.

Use this high-pressure cleaner only for the following types of work:

The high-pressure jet is intended exclusively for cleaning, e.g. machines, vehicles, structures, tools, facades, terraces and garden equipment.

We recommend using a dirt blaster as a special accessory for stubborn soiling.

The device is suitable for operation in altitudes of up to 500 m. For operation in higher altitudes the engine must be adapted by the KÄRCHER Customer Service.

Operating the device at gas stations or other dangerous areas

Risk of injury!

Follow the respective safety regulations.

Please do not let waste water contaminated with mineral oil reach soil, water or the sewage system. Only clean the engine and the engine bottom in a suitable site with an oil trap.

Dirty water

Premature wear and tear or deposits in the device

Supply the device using only clean water, or recycled water that does not exceed the specified limit values.

The following limit values apply to the water supply:

pH value: 6.5-9.5

Electrical conductivity: Conductivity of fresh water + 1200 µS/cm, maximum conductivity 2000 µS/cm

Settleable particles (sample volume 1 l, settling time 30 minutes): < 0.5 mg/l

Filterable particles: < 50 mg/l, no abrasive substances

Hydrocarbons: < 20 mg/l

Chloride: < 300 mg/l

Sulphate: < 240 mg/l

Calcium: < 200 mg/l

Total hardness: < 28 °dH, < 50° TH, < 500 ppm (mg CaCO3/l)

Iron: < 0.5 mg/l

Manganese: < 0.05 mg/l

Copper: < 2 mg/l

Active chloride: < 0.3 mg/l

Free of unpleasant odours

The packing materials can be recycled. Please dispose of packaging in accordance with the environmental regulations.

The packing materials can be recycled. Please dispose of packaging in accordance with the environmental regulations.

Electrical and electronic devices contain valuable, recyclable materials and often components such as batteries, rechargeable batteries or oil, which - if handled or disposed of incorrectly - can pose a potential danger to human health and the environment. However, these components are required for the correct operation of the device. Devices marked by this symbol are not allowed to be disposed of together with the household rubbish.

Electrical and electronic devices contain valuable, recyclable materials and often components such as batteries, rechargeable batteries or oil, which - if handled or disposed of incorrectly - can pose a potential danger to human health and the environment. However, these components are required for the correct operation of the device. Devices marked by this symbol are not allowed to be disposed of together with the household rubbish.

Current information on content materials can be found at: www.kaercher.de/REACH

Only use original accessories and original spare parts. They ensure that the appliance will run fault-free and safely.

Information on accessories and spare parts can be found at www.kaercher.com.

Check the contents for completeness when unpacking. If any accessories are missing or in the event of any shipping damage, please notify your dealer.

| Risk of burns from hot surfaces. |

| Do not aim the high-pressure jet may at persons, animals, live electrical equipment or the device itself. Protect the device against frost. |

| According to applicable regulations, the device must never be used with the drinking water network without a system separator. Ensure that the connection to your house water system, with which the high-pressure cleaner is operated, is equipped with a system separator according to EN 12729 type BA. Water that has flowed through a system separator is classified as undrinkable. Always connect the system separator to the water inlet and never directly to the device. |

| Health risk from poisonous exhaust gases. Never inhale the exhaust gases. |

| Flammable |

| No smoking is allowed. |

| Fires, sparks, open flames and smoking are prohibited. |

| Observe notes in the instructions for the battery, on the battery and in these operating instructions. |

| Warning |

It is essential that you read the safety instructions 5.951-949.0 before initial start-up.

Observe the national regulations for liquid jet cleaners.

Observe the national accident prevention regulations. Liquid jet cleaners must be tested regularly. The test result must be recorded in writing.

Do not modify the device or accessories.

Do not operate the device if fuel has been spilled. In such a case, move the device to another location and avoid any sparking.

Do not store fuel in the proximity of naked flames or devices such as ovens, heating boilers, water heaters, etc. that have a pilot light or may generate sparks. Do not use or spill fuel in the above environment.

Keep easily flammable objects at least 2 m away from the muffler.

Do not operate the device without a muffler. Check the muffler regularly and clean or replace it if necessary.

Do not operate the device in forests, bushy or grassy areas if the exhaust pipe is not equipped with a spark catcher.

Do not run the motor with the air filter removed or without a cover over the intake opening.

Do not adjust any control springs, governor control linkage or other parts that could increase the speed of the motor.

Do not touch any hot parts such as the muffler, cylinder or cooling fins.

Never bring your hands and feet close to rotating parts.

Never operate the device in confined spaces.

Do not use unsuitable fuels as they can be dangerous.

Missing or modified safety devices

Safety devices are provided for your own protection.

Never modify or bypass safety devices.

The safety lever on the high-pressure gun prevents the device from being switched on inadvertently.

If the high-pressure gun is closed, the overflow valve opens and the entire water volume will flow back to the pump suction side.

The overflow valve is set by the manufacturer and sealed. Setting shall only be carried out by Customer Service.

The safety valve opens if the pressure relief valve is faulty.

The safety valve is set and sealed at the factory. The adjustment is made by Customer Service.

The thermostat valve opens when the maximum permissible water temperature is exceeded and discharges the hot water outdoors.

Control elements for the cleaning process are yellow.

Risk of injury!

Device, tubes, high-pressure hose and connections must be in faultless condition.

Otherwise, the device must not be used.

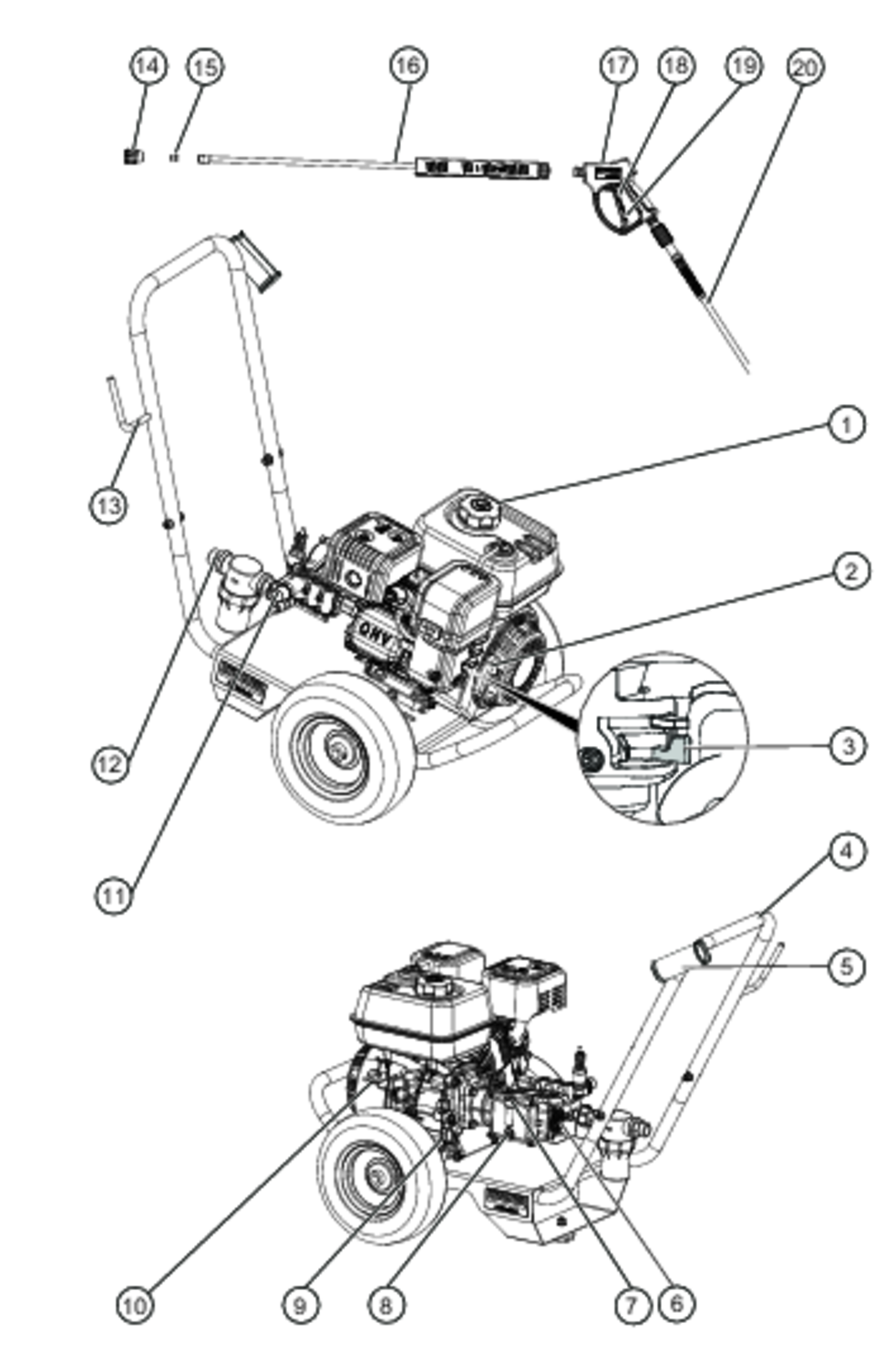

Check the contents of the package when unpacking.

Notify the dealer immediately in the case of shipping damage.

Place the device on a flat and level surface.

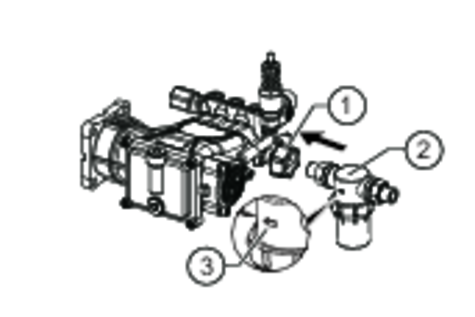

Check the high-pressure pump oil level at the oil level indicator.

The oil level must be in the middle of the oil level indicator.

Top up the oil if necessary. For oil type, see ChapterTechnical data.

Before initial start-up of the engine, read the original instructions for the engine and observe the safety instructions.

Check the oil level in the engine.

Do not start up the device if the oil level is low.

Top up the oil if necessary. For oil type see ChapterTechnical data.

Unsuitable fuel

Risk of explosion

Only fill with petrol. Unleaded petrol (86 RON) can be used.

Open the fuel tank cap.

Fill the fuel tank with fuel.

Close the cap of the fuel tank.

Wipe up any spilled fuel.

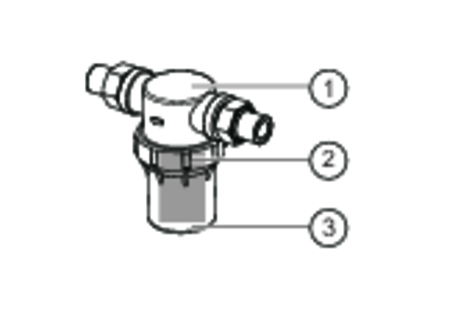

Please follow the direction of the mark on the water filter (except HD 6/15).

Attach the water filter, the arrow must point to the pump.

Fasten the union joint on the pump.

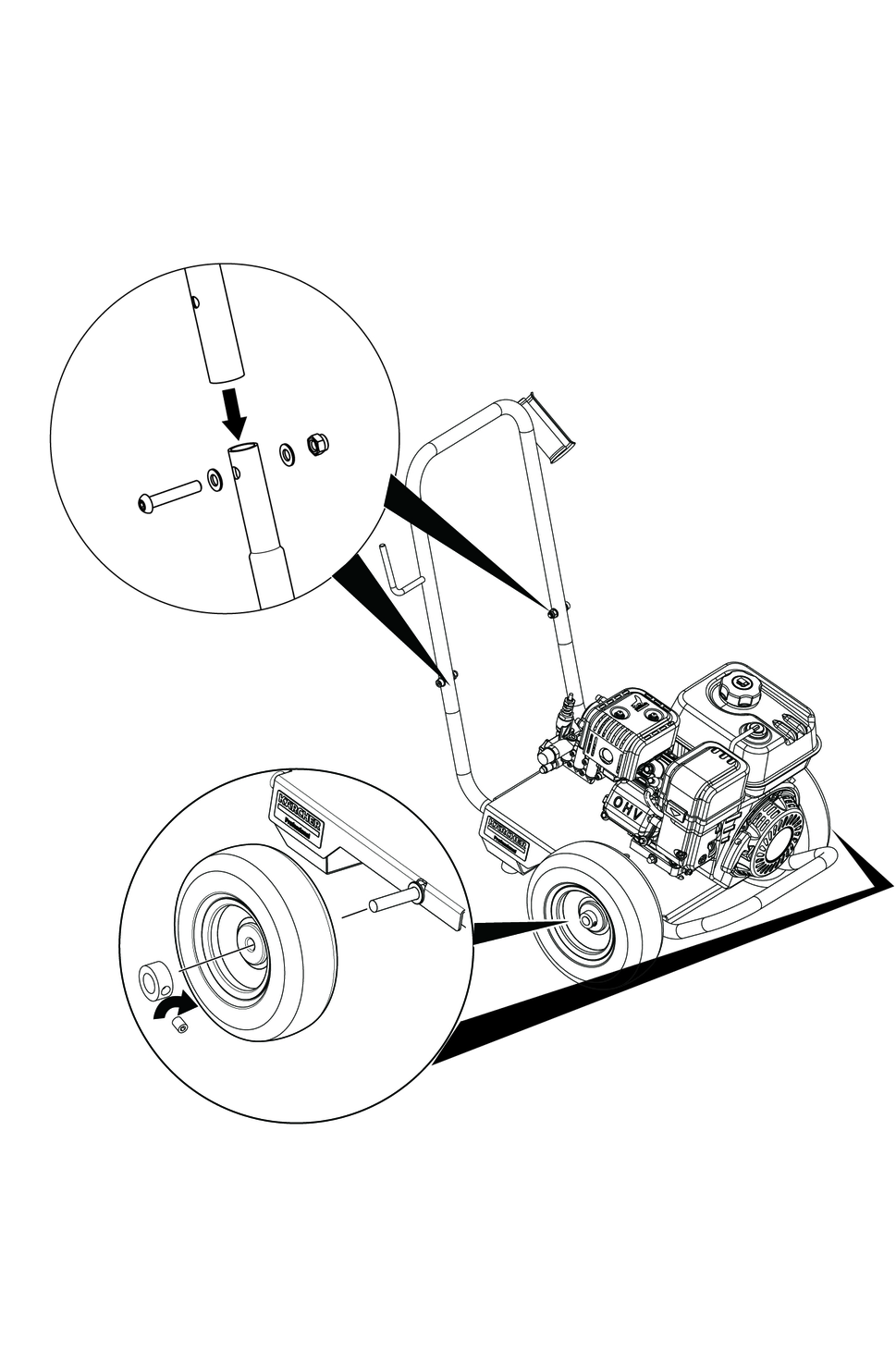

Put the push handle on the base frame.

Secure the push handle with the screws and nuts.

Push the wheels onto the axle.

Push the fastener onto the axle and tighten the screws.

Connect the spray lance to the high-pressure gun.

Install the nozzle with the nozzle screw at the spray lance.

Screw the high-pressure hose to the high-pressure gun.

Fasten the high-pressure hose to the high-pressure connection.

Health risk from return flow of contaminated water into the drinking water network.

Observe the regulations of your water supply company.

Check the feed pressure, input temperature and input amount of the water supply. See Chapter Technical data for the requirements.

Connect the system separator and water connection of the device with a hose (minimum length 7.5 m, minimum diameter 3/4”).

The supply hose is not included in the scope of delivery.

Open the water inlet.

Open the water inlet.

Remove the high-pressure nozzle.

Start the engine according to the original instructions for the engine.

Allow the device to run until the escaping water is free of air bubbles.

Switch off the device.

Fit the high-pressure nozzle.

Risk of explosion!

Flammable liquids or gases can ignite or cause an explosion.

Do not spray flammable liquids. Do not operate this device in hazardous areas (e.g. filling stations).

Environmental damage.

Clean engines at places with a suitable oil separator only.

Open the water supply.

Start the engine with the high-pressure gun actuated according to the operating instructions of the engine manufacturer.

Risk of damage

Do not pull the starter rope when the engine is running.

The high-pressure nozzle can be removed to facilitate the start-up process.

Press the lever on the high-pressure gun as long as necessary until the engine starts.

Risk of injury!

Switch the device off prior to replacing nozzle and do not activate hand spray gun until the device is pressureless.

Secure the high-pressure gun. To do so, push the safety lever towards the front.

Unscrew nozzle screws and remove the nozzle.

Put on a new nozzle.

Screw on the nozzle screws and tighten them by hand.

Close the high-pressure gun to interrupt operation.

Open the high-pressure gun to continue operation again.

In case of extended interruptions (several minutes), switch off the engine.

Activate the high-pressure gun until the device is pressureless.

Secure the hand spray gun using the safety lever so that it doesn’t open accidentally.

When the lever of the high-pressure gun is released, the engine continues to run at zero speed. The water thus circulates within the pump and gets heated.When the cylinder head at the pump has reached the maximum permissible temperature (65 °C), the therm-valve opens. Hot water is drained. Cold water will follow and cool the pump.

After operating the water using saline water (sea water), open the high-pressure gun and rinse the device for at least 2 - 3 minutes using tap water.

Set the engine switch to “OFF” and close the fuel valve.

Shut off the water supply.

Activate the high-pressure gun until the device is pressureless.

Press the safety lever of the high-pressure gun to secure the lever of the pistol against being released accidentally.

Remove the water inlet hose from the device.

Risk of injury, risk of damage

Be aware of the weight of the device during transport.

Place the spray lance with the high-pressure gun on the hooks.

Coil up the high-pressure hose and hang it over the hook.

Push the push handle down, and pull / push the device.

When transporting the device in vehicles, secure the device against shifting and tipping over.

Failure to observe the weight

Risk of injury and damage

Be aware of the weight of the device during storage.

Store the device indoors only.

Frost destroys the device if it is not completely drained of water.

Store the device in a frost-free location.

If frost-free storage is not possible:

Drain excess water.

Pump commonly available anti-freeze through the device.

Allow the device to run for a maximum of 1 minute until the pump and lines are empty.

Use commonly available, Glycol-based vehicle anti-freeze. Observe the handling instructions of the anti-freeze manufacturer.

Danger due to device inadvertently starting up

Risk of injury

Switch off the engine switch and remove the spark plug connector prior to all work on the device.

Hot surfaces

Risk of injury

Allow the device to cool down prior to all work.

Observe the information on care and service in the original instructions for the motor.

You can agree on regular safety inspections or close a maintenance contract with your dealer. Please seek advice on this.

Check the high-pressure hose for damage.

Immediately replace a damaged high-pressure hose.

Check the device for leaks.

3 drops of water per minute are permissible. Contact Customer Service in the case of more serious leaks.

Check the oil level of the engine and pump. Contact Customer Service if the oil is milky (water mixing with the oil).

Clean the water filter, see ChapterCleaning the water filter.

Replace the oil in the high-pressure pump.

Replace the oil in the engine.

Carry out maintenance tasks on the engine according to the specifications provided in the operating instructions of the engine.

Have the device maintained by Customer Service.

Shut off the water inlet.

Unscrew the filter cup.

Pull the filter insert downwards and off.

Clean the filter insert and filter cup.

Re-install the filter insert.

Screw on the filter cup again and tighten.

For the oil type and filling quantity, see ChapterTechnical data.

Provide a catch pan for at least 1 litre of oil.

Unscrew the oil drain plug.

Drain the oil into the catch pan.

Screw in the oil drain plug.

Slowly fill with new oil until the middle of the oil level indicator is reached. Air bubbles must be able to escape.

Risk of injury if the device is left running in an unattended state.

Switch off the engine and remove the spark plug connector before performing any work on the device.

Risk of burns!

Do not touch hot mufflers, cylinders or radiator ribs.

In case of any malfunctions not mentioned in this chapter, contact the authorised Customer Service when in doubt or when you have been explicitly advised to do so.

Device does not start

Remedy:

Follow operating instructions of the motor manufacturer!

Contact Customer Service if necessary.

Device does not reach required pressure

Remedy:

Check operating speed of the motor.

Check the size of the nozzle and compare with the required size specified in the chapterTechnical data.

Vent the device, see ChapterVenting the device.

Clean the water filter.

Check the water supply volume and compare with the required volume specified in the chapterTechnical data.

Clean all inlet pipes to the pump.

Contact Customer Service if necessary.

Pump leaking

Up to 3 drops of water per minute are permissible.

Remedy:

In case of more serious leaks, have the device checked by Customer Service.

Pump knocking

Remedy:

Clean the water filter.

Check the water supply line for leaks.

Vent the device, see ChapterVenting the device

Contact Customer Service if necessary.

The warranty conditions issued by our relevant sales company apply in all countries. We shall remedy possible malfunctions on your appliance within the warranty period free of cost, provided that a material or manufacturing defect is the cause. In a warranty case, please contact your dealer (with the purchase receipt) or the next authorised customer service site.

(See overleaf for the address)

Internal combustion engine | |

Engine type | G210FA |

Maximum power | 4.4 / (5.9) kW (HP) |

Fuel consumption (max.) | 2.24 l/h |

Engine speed | 3500 1/min |

Fuel tank capacity | 3.0 l |

Fuel type | unleaded vehicle petrol (86 ROZ) |

E10 Fuel suitability | Yes |

Oil type | 15W40

10W30 |

Oil volume | 0.6 l |

High-pressure pump | |

Maximum operating pressure | 25 (250) MPa (bar) |

Operating pressure | 20 (200) MPa (bar) |

Flow rate | 700 (11.67) l/h (l/min) |

Nozzle size | 035 |

Pump oil type | 15W40

10W30 |

Oil quantity of a high-pressure pump | 0.25 l |

Opening temperature thermal valve | 60 ± 5 °C |

Water connection | |

Feed pressure (max.) | 1 (10) MPa (bar) |

Feed pressure (min.) | 0.1 (1) MPa (bar) |

Input temperature (max.) | 60 °C |

Input amount (min.) | 900 (15) l/h (l/min) |

Minimum water supply hose length | 7.5 m |

Minimum water supply hose diameter | 3/4 in |

Device performance data | |

Degree of protection | IPX5 |

High-pressure gun recoil force | 39 N |

Dimensions and weights | |

Weight (without accessories) | 40.0 kg |

Length x width x height | 878x538x702 mm |

Determined values in acc. with EN 60335-2-79 | |

High-pressure gun hand-arm vibration value | 18.6 m/s2 |

Uncertainty K | 1.5 m/s2 |

Sound pressure level LpA | 90 dB(A) |

Uncertainty KpA | 2.5 dB(A) |

Sound power level LWA + uncertainty KWA | 106 dB(A) |

CO2Emissions according to the measurement procedure of EU regulation 2016/1628 Euro V | |

Motor | 880.45 g/kWh |

Internal combustion engine | |

Engine type | G300FA |

Maximum power | 6.8 / (9.1) kW (HP) |

Fuel consumption (max.) | 2.04 l/h |

Engine speed | 3500 1/min |

Fuel tank capacity | 5.5 l |

Fuel type | unleaded vehicle petrol (86 ROZ) |

E10 Fuel suitability | Yes |

Oil type | 15W40

10W30 |

Oil volume | 0.95 l |

High-pressure pump | |

Maximum operating pressure | 28 (280) MPa (bar) |

Operating pressure | 23 (230) MPa (bar) |

Flow rate | 800 (13.30) l/h (l/min) |

Nozzle size | 038 |

Pump oil type | 15W40

10W30 |

Oil quantity of a high-pressure pump | 0.39 l |

Opening temperature thermal valve | 60 ± 5 °C |

Water connection | |

Feed pressure (max.) | 1 (10) MPa (bar) |

Feed pressure (min.) | 0.1 (1) MPa (bar) |

Input temperature (max.) | 60 °C |

Input amount (min.) | 1040 (17) l/h (l/min) |

Minimum water supply hose length | 7.5 m |

Minimum water supply hose diameter | 3/4 in |

Device performance data | |

Degree of protection | IPX5 |

High-pressure gun recoil force | 48 N |

Dimensions and weights | |

Weight (without accessories) | 44.2 kg |

Length x width x height | 878x538x702 mm |

Determined values in acc. with EN 60335-2-79 | |

High-pressure gun hand-arm vibration value | 6.2 m/s2 |

Uncertainty K | 1.5 m/s2 |

Sound pressure level LpA | 93 dB(A) |

Uncertainty KpA | 2.5 dB(A) |

Sound power level LWA + uncertainty KWA | 108 dB(A) |

CO2Emissions according to the measurement procedure of EU regulation 2016/1628 Euro V | |

Motor | 817.85 g/kWh |

Internal combustion engine | |

Engine type | G390FA |

Maximum power | 8.5 / (11.4) kW (HP) |

Fuel consumption (max.) | 4.22 l/h |

Engine speed | 3500 1/min |

Fuel tank capacity | 6.5 l |

Fuel type | unleaded vehicle petrol (86 ROZ) |

E10 Fuel suitability | Yes |

Oil type | 15W40

10W30 |

Oil volume | 1.1 l |

High-pressure pump | |

Maximum operating pressure | 30 (300) MPa (bar) |

Operating pressure | 25 (250) MPa (bar) |

Flow rate | 900 (15.00) l/h (l/min) |

Nozzle size | 043 |

Pump oil type | 15W40

10W30 |

Oil quantity of a high-pressure pump | 0.39 l |

Opening temperature thermal valve | 60 ± 5 °C |

Water connection | |

Feed pressure (max.) | 1 (10) MPa (bar) |

Feed pressure (min.) | 0.1 (1) MPa (bar) |

Input temperature (max.) | 60 °C |

Input amount (min.) | 1170 (20) l/h (l/min) |

Minimum water supply hose length | 7.5 m |

Minimum water supply hose diameter | 3/4 in |

Device performance data | |

Degree of protection | IPX5 |

High-pressure gun recoil force | 57 N |

Dimensions and weights | |

Weight (without accessories) | 49.7 kg |

Length x width x height | 878x538x702 mm |

Determined values in acc. with EN 60335-2-79 | |

High-pressure gun hand-arm vibration value | 7.0 m/s2 |

Uncertainty K | 1.5 m/s2 |

Sound pressure level LpA | 94 dB(A) |

Uncertainty KpA | 2.5 dB(A) |

Sound power level LWA + uncertainty KWA | 110 dB(A) |

CO2Emissions according to the measurement procedure of EU regulation 2016/1628 Euro V | |

Motor | 817.85 g/kWh |