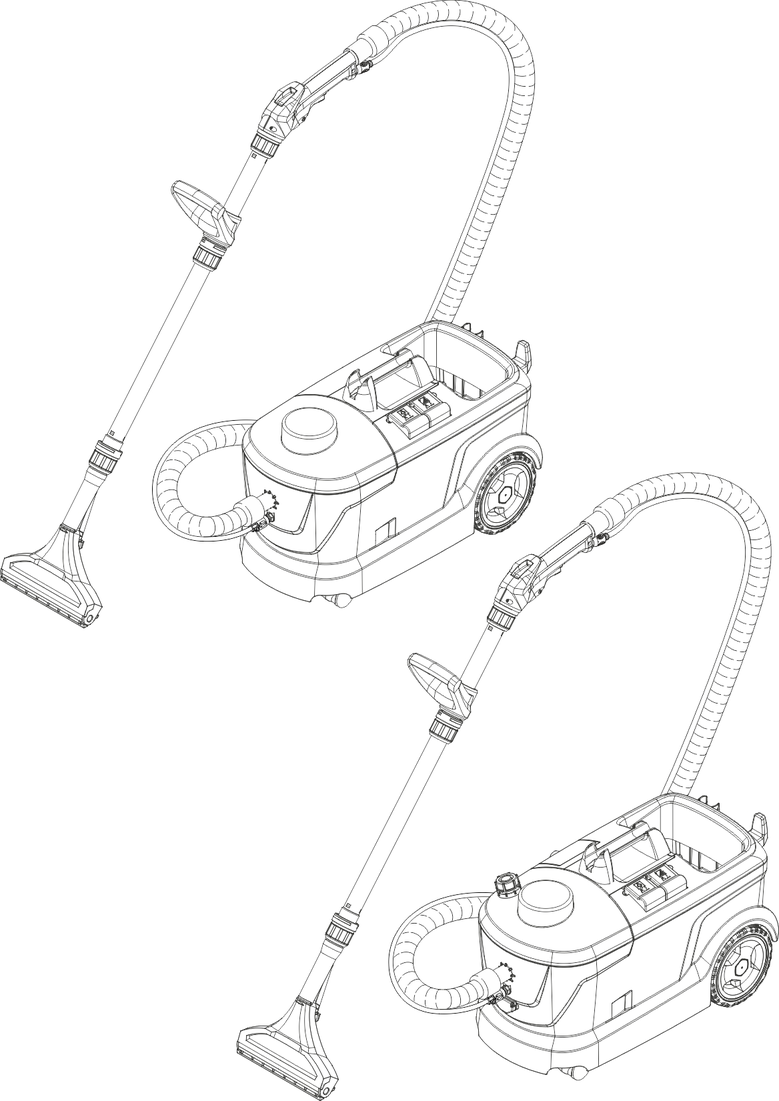

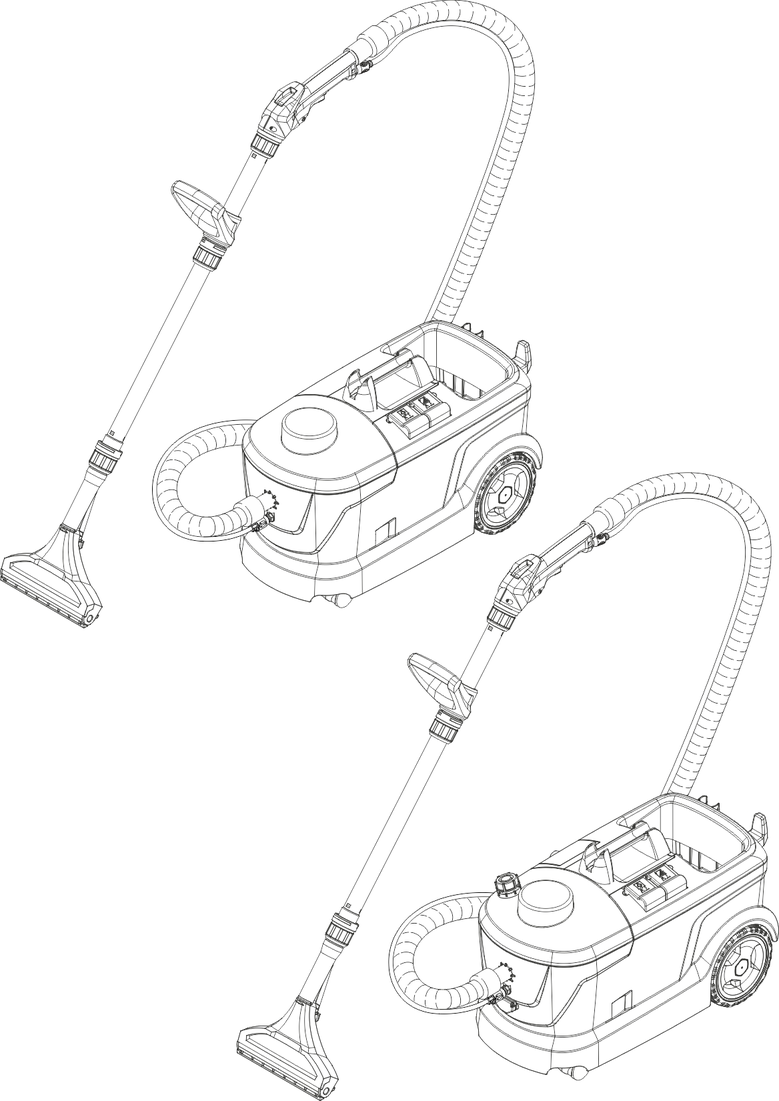

Puzzi 10/1Puzzi 10/2 Adv

59698390 (02/23)

59698390 (02/23)

Read these original instructions and the enclosed safety instructions before using the device for the first time. Act in accordance with them.

Read these original instructions and the enclosed safety instructions before using the device for the first time. Act in accordance with them.

Keep both books for future reference or for future owners.

If the operating instructions and safety instructions are not observed, the device can be damaged and dangers could arise for users and other persons.

Notify the dealer immediately in the case of shipping damage.

Check the package contents when unpacking for missing accessories or for damage.

The packing materials can be recycled. Please dispose of packaging in accordance with the environmental regulations.

The packing materials can be recycled. Please dispose of packaging in accordance with the environmental regulations.

Electrical and electronic devices contain valuable, recyclable materials and often components such as batteries, rechargeable batteries or oil, which - if handled or disposed of incorrectly - can pose a potential danger to human health and the environment. However, these components are required for the correct operation of the device. Devices marked by this symbol are not allowed to be disposed of together with the household rubbish.

Electrical and electronic devices contain valuable, recyclable materials and often components such as batteries, rechargeable batteries or oil, which - if handled or disposed of incorrectly - can pose a potential danger to human health and the environment. However, these components are required for the correct operation of the device. Devices marked by this symbol are not allowed to be disposed of together with the household rubbish.

Current information on content materials can be found at: www.kaercher.de/REACH

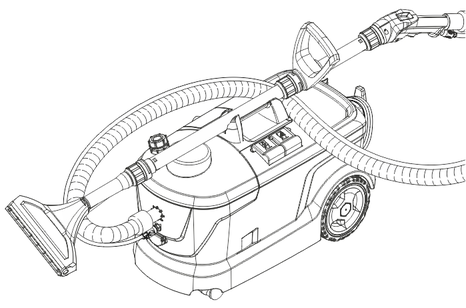

This spray retraction device is intended for wet cleaning of carpets.

This device is suitable for commercial use, e.g. in hotels, schools, hospitals, factories, shops, offices, and rental companies.

Colour | Part number | Flow volume | Application | Approved for device |

|---|---|---|---|---|

Yellow | 6.415-165.0 | 2.0 l/min | Floor nozzle | Puzzi 10/2 |

Green | 6.415-105.0 | 0.7 l/min | Floor nozzle | Puzzi 9/1 Bp |

Brown | 6.415-166.0 | 1.0 l/min | Floor nozzle | Puzzi 8/1, Puzzi 10/1 |

Blue | 6.415-928.0 | 1.0 l/min | Upholstery nozzle | Puzzi 8/1, Puzzi 10/1, Puzzi 10/2, Puzzi 30/4 |

Red | 6.415-097.0 | 0.55 l/min | Upholstery nozzle, short | Puzzi 8/1, Puzzi 9/1 Bp |

Check the power cord, extension cable and hoses for damage before each start-up.

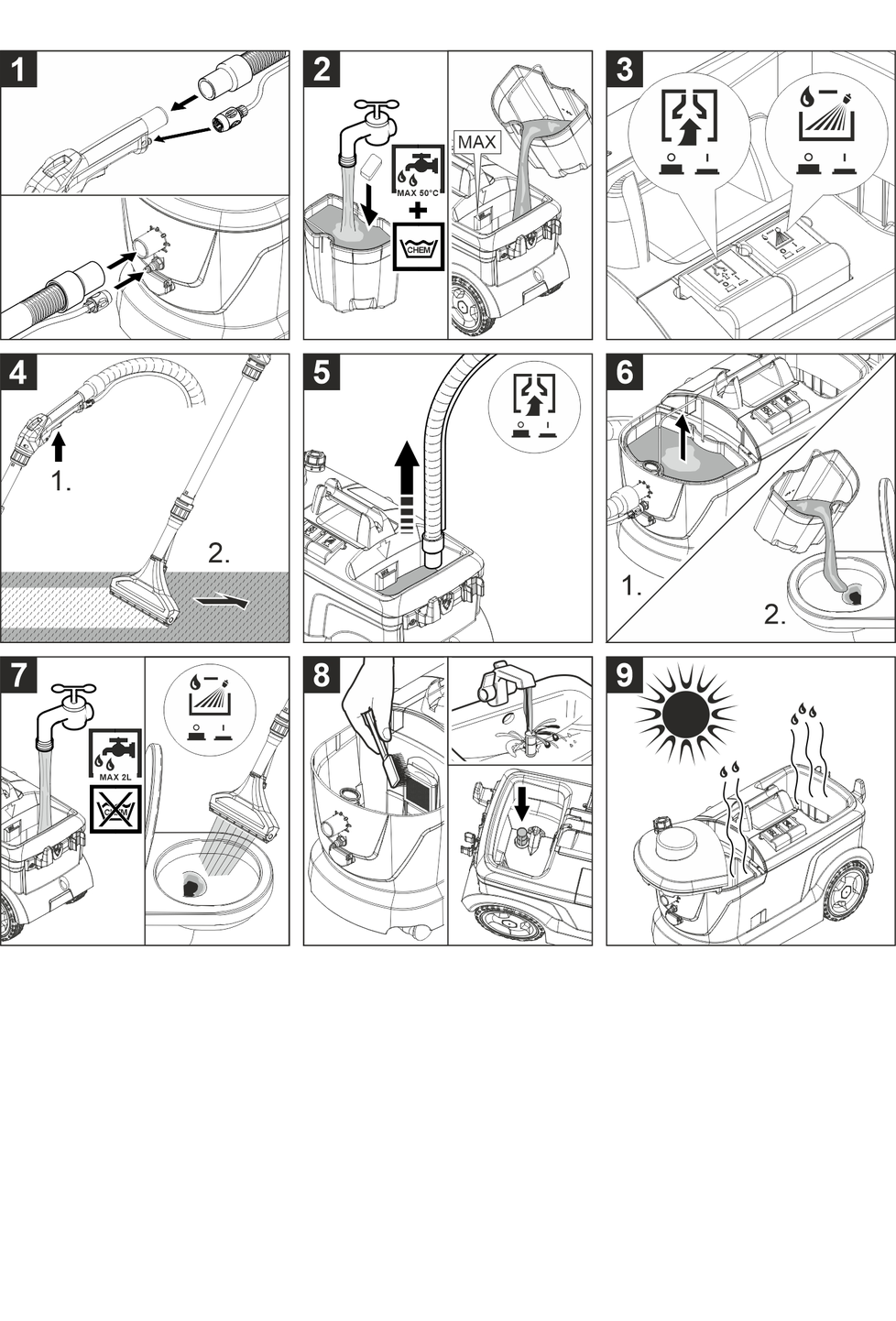

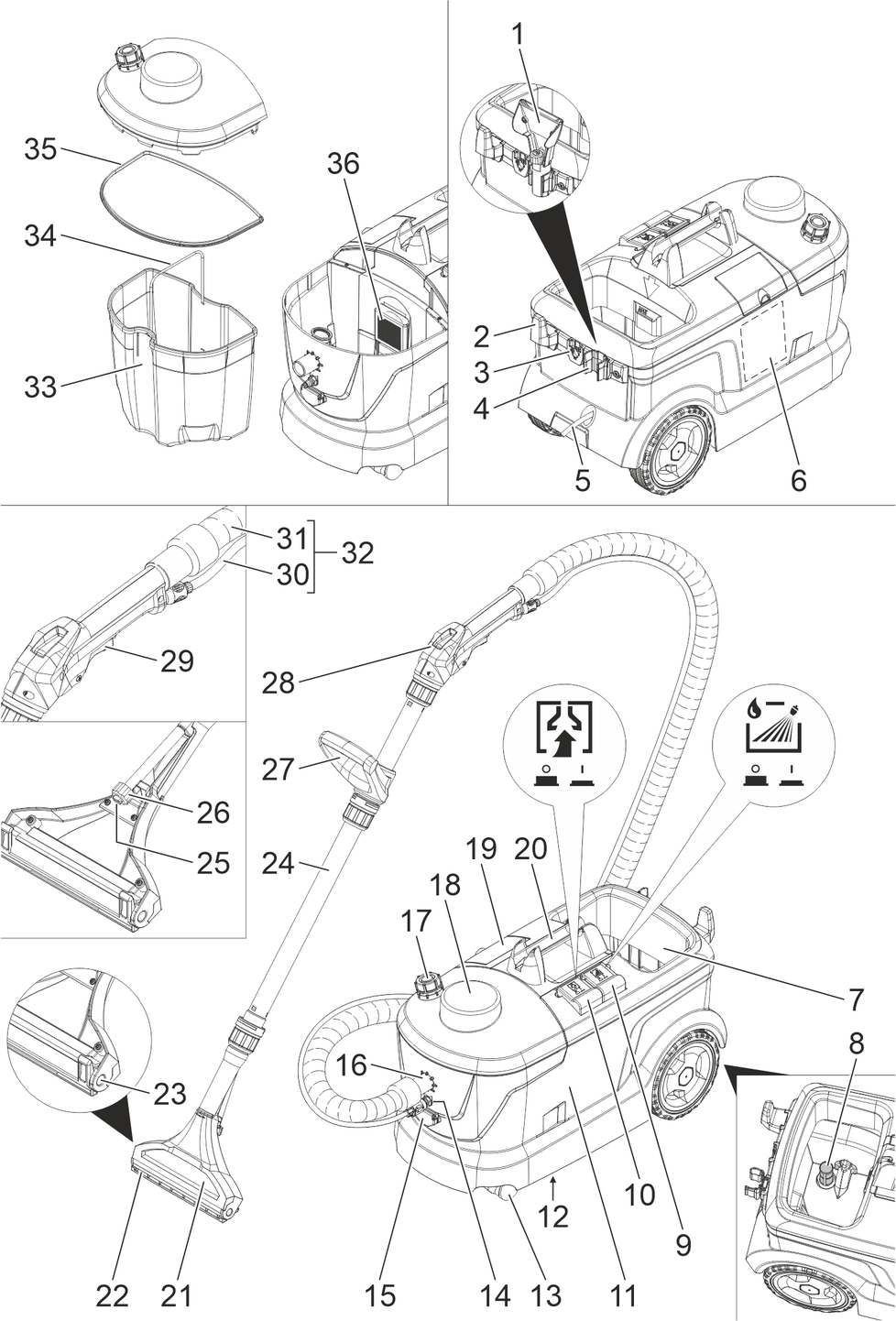

Fit the suction pipe onto the floor nozzle and hand-tighten the union nut on the floor nozzle.

If necessary, slide the D-handle onto the suction pipe and hand-tighten in the desired position. The D-handle is easier to slide on with the help of dishwashing detergent or other lubricant.

Fit the handle onto the suction pipe and hand-tighten the union nut on the handle.

Connect the suction hose to the suction hose connection on the device. Insert the spray hose coupling into the spray hose connection on the device and latch into place.

Connect the suction hose to the handle. Connect the spray hose coupling to the handle and latch into place.

Danger from detergents

Risk of injury and damage

Observe all instructions that are included with the detergents used.

Warm water (maximum 50 °C) increases the cleaning effect. Check the temperature resistance of the surface to be cleaned.

Use detergents sparingly to conserve the environment.

Mix fresh water and detergent in a clean container (concentration as specified for the detergent). Dissolve the detergent in the water.

Pour the cleaning solution into the fresh water tank. The filling level must not exceed the "MAX" mark.

Foam is generated in the wastewater container when cleaning previously shampooed carpets. Foaming can be prevented by adding defoaming agents.

Puzzi 10/1 only: Add defoaming agent (special accessory) to the wastewater container.

Puzzi 10/2 Adv only: Open the defoaming agent container. Fill with defoaming agent (special accessories).

Press the floor nozzle latch on one side.

Swing out and remove the carpet adapter.

Insert a new carpet adapter and engage the latch.

Puzzi 10/2 Adv only:

An additional power socket is provided for connecting additional electrical devices.

Danger of electric shock

Risk of injury and damage.

The socket is only intended for the direct connection of the PW 30/1 additional brush washer head to the Puzzi 10/2 Adv. Any other use of the socket is prohibited.

Connect the mains plug.

Press the suction switch to switch on the suction turbine.

Press the spray switch to switch on the spray pump.

Danger from cleaning solution

Risk of damage

Before using the device, check the object to be cleaned for colour fastness and water resistance in an inconspicuous place.

Press the lever on the handle to spray the cleaning solution.

Run over the surface to be cleaned in overlapping paths. Pull the nozzle backwards (do not push).

When interrupting work, the suction pipe (with floor nozzle) can be placed in the carrying handle of the device.

Switch off the spray switch and the suction switch.

Pull out the mains plug.

Switch off the suction switch and the spray switch when the wastewater container is full.

Remove the cover.

Remove the wastewater container from the device and empty it.

Switch off the device.

Briefly operate the lever on the handle to relieve pressure.

Disconnect the handle from the spray/suction hose.

Hang the suction hose in the fresh water tank.

Press the suction switch to switch on the suction turbine.

Suck the fresh water tank empty and switch off the device.

Remove the cover.

Remove the wastewater container from the device and empty it.

Connect the handle (with suction pipe and floor nozzle) to the suction hose.

Connect the spray hose coupling to the handle and latch into place.

Pour approximately 2 litres of tap water into the fresh water tank. Do not add detergents.

Press the spray switch to switch on the spray pump.

Hold the floor nozzle over a drain.

Operate the lever on the handle and flush the device for 1 to 2 minutes.

Switch off the device.

Flush the device.

Drain the wastewater container and clean it under running water.

Empty the fresh water tank.

Clean the exterior of the device with a damp cloth.

To avoid unpleasant smells, remove all water from the device before long downtimes.

Let the device dry thoroughly: Remove the cover or move it to the side.

Store the device in a dry room and secure it against unauthorised use.

Spray and vacuum up the cleaning solution in one step.

Repeated vacuuming without spraying shortens the drying time.

Apply cleaning solution with the suction turbine switched off and let it work for 10 to 15 minutes.

Clean the area as with normal soiling.

Puzzi 10/1 only: Attach the upholstery nozzle instead of the floor nozzle (with suction pipe).

Use less detergent for sensitive fabrics and spray the surface at a distance of approx. 200 mm. Then only vacuum.

Spray heavily soiled areas in advance and allow the cleaning solution to work for 5 to 10 minutes.

Always work from light to shadow (from window to door).

Always work from the cleaned to the uncleaned area.

The more sensitive the covering (oriental bridges, Berber, upholstery fabric) the lower the concentration of detergent.

Carpets with jute backs can shrink and bleed in colour if the work is too wet.

Brush wet pile carpets in the direction of the pile after cleaning when wet (e.g. with a fibre brush or scrubber).

Impregnating after wet cleaning prevents the textile from being quickly soiled again.

To avoid pressure points or rust stains, do not walk on or furnish the cleaned area until after it has fully dried.

To improve the cleaning result, rinse the object with clean water after using detergents.

Description | Name | Dosing | Order number |

|---|---|---|---|

CarpetPro cleaner (0.8 kg) | RM 760 powder | 1 % | 6.295-849.0 |

CarpetPro cleaner, iCapsol (16 piece) | RM 760 tabs | 2 tabs for 8 litres | 6.295-850.0 |

CarpetPro cleaner, quick-drying (10 litre) | RM 767 liquid | 1.2 % | 6.295-198.0 |

CarpetPro cleaner (10 litres) | RM 764 liquid | 1 % | 6.295-854.0 |

CarpetPro impregnation (5 litres) | RM 762 liquid | 20 % | 6.295-852.0 |

Defoaming (2.5 litres) | RM 761 liquid | 0.5 % | 6.291-389.0 |

For further information, please request the product information sheet and the EU safety data sheet for the relevant cleaning agent.

Failure to observe the weight

Risk of injury and damage

Be aware of the weight of the device during transportation.

Place the suction pipe on the carrying handle for transport and place the spray / suction hose on the device. Wind up the mains cable and hang it in the cable hook.

When transporting the device in vehicles, secure it to prevent it from slipping or overturning in accordance with the respective valid guidelines.

Failure to observe the weight

Risk of injury and damage

Be aware of the weight of the device during storage.

The device may only be operated indoors.

Danger of electric shock

Injuries due to touching live parts

Switch off the device.

Remove the mains plug.

Remove the cover.

Remove the wastewater container from the device.

Clean the fluff filter regularly with a brush.

Unscrew the fresh water filter.

Clean the fresh water filter under running water.

Unscrew the union nut.

Clean the nozzle mouthpiece.

Danger of electric shock

Injuries due to touching live parts

Switch off the device.

Remove the mains plug.

The device is not working

Remedy:

Check the socket and the power supply fuse.

Check the mains cable and the mains plug of the device.

Switch on the device.

No water emitted from the nozzle

Remedy:

Fill up the fresh water tank.

Check the couplings on the spray hose for correct seating.

Clean or replace the nozzle mouthpiece.

Clean the fresh water filter.

Spray pump defective, contact customer service.

Single-sided spray jet

Remedy:

Clean the nozzle mouthpiece.

Poor suction performance

Remedy:

Check that the cover is seated correctly.

Clean the seal on the cover and the contact surface on the device.

Clean the fluff filter.

Check the suction hose for clogging; clean if necessary.

Spray pump is loud

Remedy:

Refill the fresh water tank.

Heavy foaming in the wastewater container

Remedy:

Add defoaming agent in the wastewater container or fill up the defoaming agent container.

If the malfunction cannot be corrected, the device must be checked by the Customer Service department.

The device is not working

Remedy:

Check the socket and the power supply fuse.

Check the mains cable and the mains plug of the device.

Switch on the device.

No water emitted from the nozzle

Remedy:

Fill up the fresh water tank.

Check the couplings on the spray hose for correct seating.

Clean or replace the nozzle mouthpiece.

Clean the fresh water filter.

Spray pump defective, contact customer service.

Single-sided spray jet

Remedy:

Clean the nozzle mouthpiece.

Poor suction performance

Remedy:

Check that the cover is seated correctly.

Clean the seal on the cover and the contact surface on the device.

Clean the fluff filter.

Check the suction hose for clogging; clean if necessary.

Spray pump is loud

Remedy:

Refill the fresh water tank.

Heavy foaming in the wastewater container

Remedy:

Add defoaming agent in the wastewater container or fill up the defoaming agent container.

The warranty conditions issued by our sales company responsible apply in all countries. We shall remedy possible malfunctions on your device within the warranty period free of cost, provided that a material or manufacturing defect is the cause. In a warranty case, please contact your dealer (with the purchase receipt) or the next authorised customer service site.

You can find more detailed information at: www.kaercher.com/dealersearch

Only use original accessories and original spare parts. They ensure that the appliance will run fault-free and safely.

Information on accessories and spare parts can be found at www.kaercher.com.

EU Declaration of Conformity |

We hereby declare that the machine described below complies with the relevant basic safety and health requirements in the EU Directives, both in its basic design and construction as well as in the version placed in circulation by us. This declaration is invalidated by any changes made to the machine that are not approved by us.

Product: Spray retraction device

Type: 1.100-xxx

Type: 1.193-xxx

Currently applicable EU Directives2006/42/EC (+2009/127/EC)

2011/65/EU

2014/30/EU

Harmonised standards usedEN IEC 63000: 2018

EN 55014-1: 2017 + A11: 2020

EN 55014-2: 2015

EN 60335-1

EN 60335-2-68

EN 61000-3-2: 2014

EN 61000-3-3: 2013

EN 62233: 2008

National standards used-

The signatories act on behalf of and with the authority of the company management.

Documentation supervisor:

S. Reiser

Alfred Kärcher SE & Co. KG

Alfred-Kärcher-Str. 28 - 40

71364 Winnenden (Germany)

Ph.: +49 7195 14-0

Fax: +49 7195 14-2212

Winnenden, 2020/10/01

Declaration of Conformity (UK) |

We hereby declare that the product described below complies with the relevant provisions of the following UK Regulations, both in its basic design and construction as well as in the version put into circulation by us. This declaration shall cease to be valid if the product is modified without our prior approval.

Product: Spray retraction device

Type: 1.100-xxx

Type: 1.193-xxx

Currently applicable UK RegulationsS.I. 2008/1597 (as amended)

S.I. 2012/3032 (as amended)

S.I. 2016/1091 (as amended)

Designated standards usedEN IEC 63000: 2018

EN 55014-1: 2017 + A11: 2020

EN 55014-2: 2015

EN 60335-1

EN 60335-2-68

EN 61000-3-2: 2014

EN 61000-3-3: 2013

EN 62233: 2008

National standards used-

The signatories act on behalf of and with the authority of the company management.

Documentation supervisor:

S. Reiser

Alfred Kärcher SE & Co. KG

Alfred-Kärcher-Str. 28 - 40

71364 Winnenden (Germany)

Ph.: +49 7195 14-0

Fax: +49 7195 14-2212

Winnenden, 2020/10/01

Electrical connection | |

Mains voltage | 220-240 V |

Mains voltage (AR) | 220 V |

Phase | 1 ~ |

Power frequency | 50-60 Hz |

Degree of protection | IPX4 |

Protection class | II  |

Blower motor nominal power | 1200 W |

Spray pump power | 40 W |

Device performance data | |

Fresh water filling quantity | 10 l |

Wastewater filling quantity | 9 l |

Air quantity (max.) | 74 l/s |

Vacuum (max.) | 25,4 (254) kPa (mbar) |

Spray pressure | 0,1 MPa |

Spray pressure (max.) | 0,3 MPa |

Spray volume | 1 l/min |

Cleaning solution temperature (max.) | 50 °C |

Dimensions and weights | |

Typical operating weight | 10,5 kg |

Length x width x height | 705 x 320 x 435 mm |

Ambient conditions | |

Ambient temperature (max.) | +40 °C |

Determined values in acc. with EN 60335-2-68 | |

Sound pressure level LpA | 71 dB(A) |

Uncertainty KpA | 1 dB(A) |

Hand-arm vibration value | <2,5 m/s2 |

Uncertainty K | 0,2 m/s2 |

Mains cable | |

Power cord type | H05VV-F 2x1,0 mm2 |

Part number (EU) | 6.650-363.0 |

Part number (GB) | 6.650-380.0 |

Part number (AU) | 6.650-385.0 |

Part number (AR) | 6.650-382.0 |

Cable length | 7,5 m |

Electrical connection | |

Mains voltage | 220-240 V |

Mains voltage (AR) | 220 V |

Phase | 1 ~ |

Power frequency | 50-60 Hz |

Degree of protection | IPX4 |

Protection class | II  |

Blower motor nominal power | 1200 W |

Power (tot.) | 1450 W |

Spray pump power | 80 W |

Power rating of the device socket (max.) | 250 W |

Device performance data | |

Fresh water filling quantity | 10 l |

Wastewater filling quantity | 9 l |

Air quantity (max.) | 74 l/s |

Vacuum (max.) | 25,4 (254) kPa (mbar) |

Spray pressure | 0,2 MPa |

Spray pressure (max.) | 0,3 MPa |

Spray volume | 2 l/min |

Cleaning solution temperature (max.) | 50 °C |

Dimensions and weights | |

Typical operating weight | 11,0 kg |

Length x width x height | 705 x 320 x 435 mm |

Ambient conditions | |

Ambient temperature (max.) | +40 °C |

Determined values in acc. with EN 60335-2-68 | |

Sound pressure level LpA | 71 dB(A) |

Uncertainty KpA | 1 dB(A) |

Hand-arm vibration value | <2,5 m/s2 |

Uncertainty K | 0,2 m/s2 |

Mains cable | |

Power cord type | H05VV-F 2x1,0 mm2 |

Part number (EU) | 6.650-363.0 |

Part number (GB) | 6.650-380.0 |

Part number (AU) | 6.650-385.0 |

Part number (AR) | 6.650-382.0 |

Cable length | 7,5 m |

Zubehör / Accessories / Accessoires

|  |  |  | |

| 4.762-014.0 Hartflächenadapter, hard surface adapter, adaptateur pour surface rigide | 240 | ||

| 4.130-001.0 * | DN 32 | 110 | |

| 4.130-010.0 | DN 32 | 0,25 | |

| 5.070-010.0 Behälter für Reinigungsmittel, container for detergent, réservoir pour détergent | |||

| 6.980-078.0 | DN 20-26 | ||

| 6.980-077.0 | |||

| 6.980-080.0 |

DN = Konus-Verbindung, cone connection, connexion de cône

* = nur Puzzi 10/2 Adv, Puzzi 10/2 Adv only, uniquement Puzzi 10/2 Adv