KM 100/120 R G

59990960 (02/23)

59990960 (02/23)

Read the original instructions before using the device for the first time and act in accordance with it. Keep the original instructions for future reference or for future owners.

Read the original instructions before using the device for the first time and act in accordance with it. Keep the original instructions for future reference or for future owners.

Please report any defects or shipping damage identified on the vehicle when it is handed over directly to your dealer or department store.

The packing materials can be recycled. Please dispose of packaging in accordance with the environmental regulations.

The packing materials can be recycled. Please dispose of packaging in accordance with the environmental regulations.

Electrical and electronic devices contain valuable, recyclable materials and often components such as batteries, rechargeable batteries or oil, which - if handled or disposed of incorrectly - can pose a potential danger to human health and the environment. However, these components are required for the correct operation of the device. Devices marked by this symbol are not allowed to be disposed of together with the household rubbish.

Electrical and electronic devices contain valuable, recyclable materials and often components such as batteries, rechargeable batteries or oil, which - if handled or disposed of incorrectly - can pose a potential danger to human health and the environment. However, these components are required for the correct operation of the device. Devices marked by this symbol are not allowed to be disposed of together with the household rubbish.

Current information on content materials can be found at: www.kaercher.de/REACH

Vehicles that are no longer fit for service contain valuable recyclable materials. We recommend you cooperate with a waste management company with regard to the disposal of your vehicle.

The warranty conditions issued by our sales company responsible apply in all countries. We shall remedy possible malfunctions on your device within the warranty period free of cost, provided that a material or manufacturing defect is the cause. In a warranty case, please contact your dealer (with the purchase receipt) or the next authorised customer service site.

You can find more detailed information at: www.kaercher.com/dealersearch

Only use original accessories and original spare parts. They ensure that the appliance will run fault-free and safely.

Information on accessories and spare parts can be found at www.kaercher.com.

Indication of an imminent threat of danger that will lead to severe injuries or even death.

Indication of a potentially dangerous situation that may lead to severe injuries or even death.

Indication of a potentially dangerous situation that may lead to minor injuries.

Indication of a potentially dangerous situation that may lead to damage to property.

| DANGERRisk of burns from hot surfaces Allow the vehicle to cool down before working on it. |

| DANGERRisk of fire Do not sweep up burning or glowing objects such as cigarettes, matches or similar objects. |

| DANGERRisk of accident from tipping Only use high dumping on level ground. |

| WARNINGRisk of injury Risk of being squeezed or hurt at the belts, side-brushes, waste container, cover. |

| WARNINGRisk of injury Cut and crush injuries from moving vehicle parts inside. Do not reach into openings in the device. |

| DANGERRisk of accident due to improper handling Read these operating instructions and the safety instructions before using the device for the first time. |

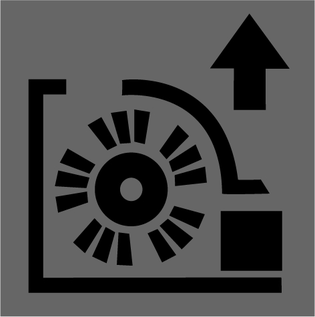

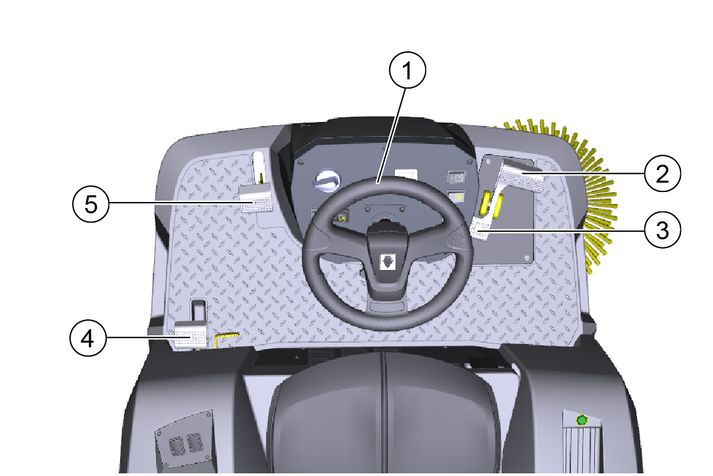

| Parking brake |

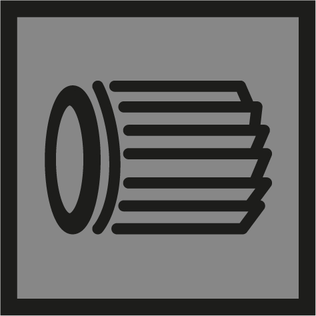

| Tyre pressure |

| Attachment point for jack |

| Lashing point |

| Max. load of the storage area 20 kg |

| Max. load 150 kg |

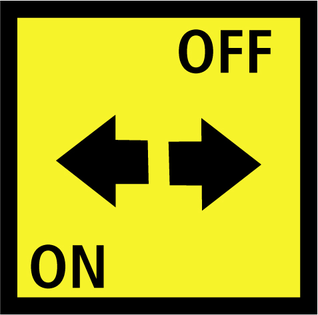

| ON position: device can be driven with its own drive OFF position: device can be pushed |

| Filler opening hydraulic oil tank |

| Coarse dirt flap pedal |

| Wet sweeping flap |

| Releasing/fastening the dust filter |

Use the sweeper to clean commercial floor areas.

Use the sweeper for the following intended areas of application:

Parking spaces

Footpaths

Production systems

Logistics areas

Hotels

Retail trade

Storage areas

Only use the sweeper in accordance with the information in these operating instructions. Any other use is considered as improper use. The manufacturer assumes no liability for any resultant damage. The user is solely responsible for the risk.

The sweeper can only be used with the StVZO attachment kit for operation on public roads.

No modifications must be made to the sweeper.

Only the areas approved by the company or the company's representatives must be driven on and cleaned.

Operation in enclosed spaces is prohibited.

Never sweep or suction up explosive liquids, gases, non-diluted acids or solvents (e.g. petrol, paint thinner, heating oil) because they form explosive vapours or mixtures in conjunction with the suction air.

Never sweep or suction up acetone, non-diluted acids or solvents, as they will corrode and damage the materials used on the device.

Never sweep or suction up reactive metal dusts (e.g. aluminium, magnesium, zinc). They form explosive gases in conjunction with highly alkaline or acidic cleaning agents.

Do not sweep or suction up burning or smouldering objects. There is a risk of fire.

Do not sweep up any harmful substances.

Standing in hazard zones is prohibited. Operation in explosive spaces is prohibited.

Carrying passengers is prohibited.

This device must not be used to push/pull or transport objects.

Asphalt

Industrial floor

Screed

Concrete

Paving stones

The sweeper operates using the direct-throw principle.

The rotating side brushes clean corners and edges of the sweeping surface and convey the waste into the path of the roller brush.

The rotating roller brush conveys the waste directly into the waste container.

The dust which is swirled up in the waste container is separated by a dust filter, and the suction fan suctions the filtered clean air.

The dust filter is cleaned automatically.

Safety devices protect the user and may not taken out of operation or functionally circumvented.

Adhere to the safety instructions in the chapters!

The bonnet and the right panel have a safety device. When the cover or panel are opened, the running combustion motor is switched off.

The motor can only be started when both are closed.

The roller brush is automatically blocked while the waste container is being emptied.

To prevent persons from reaching into the emptying mechanism and the swivel range of the waste container, lifting, lowering and emptying the waste container is only possible with two-handed operation.

It is not permitted to stand under the waste container unless it is fully raised and secured against lowering with the supplied, correctly fitted safety brace.

A seat contact switch ensures that the machine can only be started when the driver is sitting in the driver's seat.

Only use the device for its proper use. Take into account the local conditions and beware of third parties, in particular children, when working with the device.

Check the device with the operating devices to make sure it is in proper condition and operational safe and reliable. If it is not in perfect condition, you must not use it.

Adhere to the respective safety regulations in hazard zones (e.g. service stations). Never operate the device in explosive spaces.

The device is not intended for use by persons with restricted physical, sensory or mental abilities or those lacking in experience and / or lacking in knowledge.

Only people who have been instructed on how to use the device, or have proven their ability to operate it, and have been explicitly instructed to use it, must use the device.

Before starting work, the operator must check whether the safety devices have been attached properly and are fully functional.

The device operator is responsible for accidents with other people and their property.

The operator must wear close-fitting clothing and sturdy footwear. Avoid loose-fitting clothing.

Children must be supervised to prevent them from playing with the appliance.

Children and minors must not use the device.

Check the immediate vicinity before setting off (e.g. children). Make sure you have a sufficient view.

Never leave the device unattended unless the device is secured against unintentional movement. Always apply the parking brake before leaving the device.

Remove the ignition key or KIK (Kärcher Intelligent Key) to prevent unauthorised use of the device.

Do not use the device in areas in which there is a possibility of being struck by falling objects.

Do not look directly into the light source on devices equipped with Blue Spot lighting.

The list on the risk of overturning is not necessarily comprehensive.

Danger of tilting if hill or slope is too steep! Observe the maximum permissible values in the technical data when driving up hills and slopes.

Danger of tilting in case of excessive tilting at side! Observe the maximum permissible values in the technical data when driving lateral to the travel direction.

Danger of tilting on unstable subsurfaces! Only use the device on firm subsurfaces.

Risk of accident due to not adapting speed. Approach corners slowly.

Observe the special safety instructions in the operating instructions of the motor manufacturer.

Operation in enclosed spaces is prohibited.

Danger of poisoning: Do not inhale the exhaust gases.

Never close off the exhaust gas openings.

Never bend down over the exhaust gas opening and take hold of it.

Be aware of the engine after-running time after switching off (3-4 seconds). Keep away from the drive area during this time.

Disconnect the battery before working on the electrical system.

Before cleaning, maintenance, replacing parts and resetting to another function, you must switch off the device and remove the ignition key.

Repairs may only be carried out by approved customer service sites or staff qualified in this area who are familiar with all relevant safety instructions.

Adhere to the safety inspection requirements for mobile devices for industrial use in accordance with the locally applicable regulations (e.g. in Germany: VDE 0701).

Short-circuits or other damage. Do not clean the device with a hose or high-pressure water jet.

Always wear suitable gloves when working on the device.

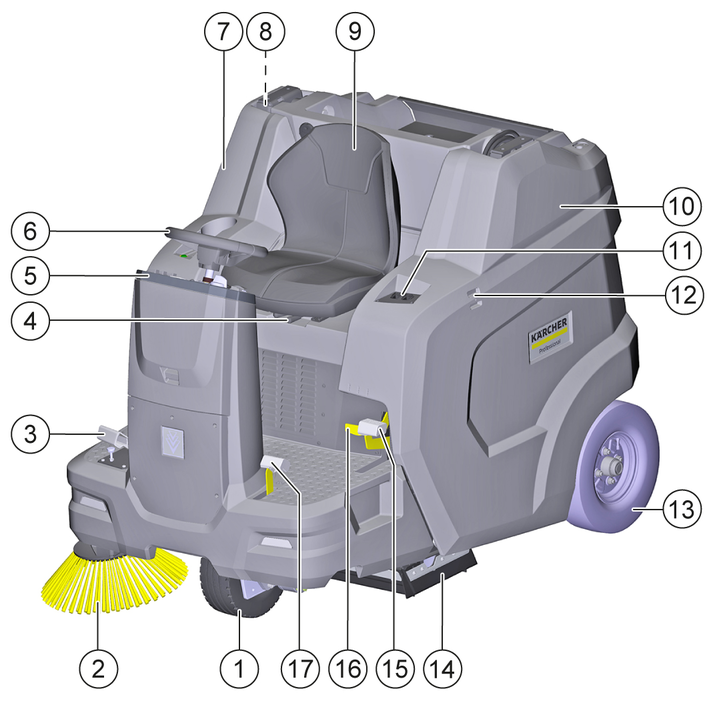

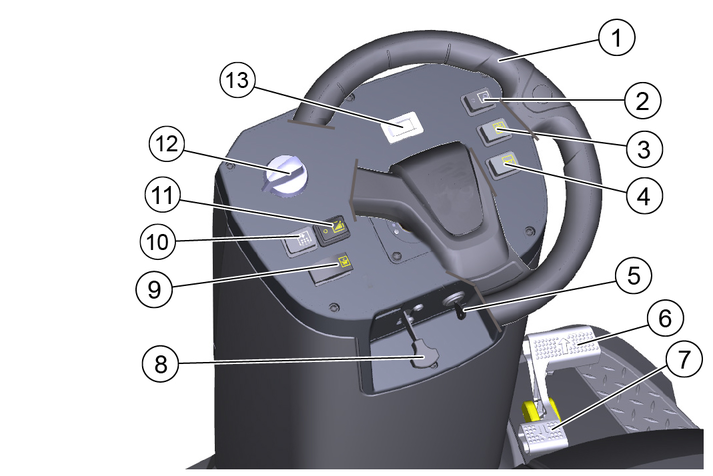

* described in more detail in a later chapter

The following equipment is not shown if it is already installed at the factory when ordered or can be installed by the service department at a later date.

Comfort seat

Flashing beacon

Work light

StVZO kit

Blue spot

Overhead guard

Left side brush

Water spray system

Fleet management module

* described in more detail in a later chapter

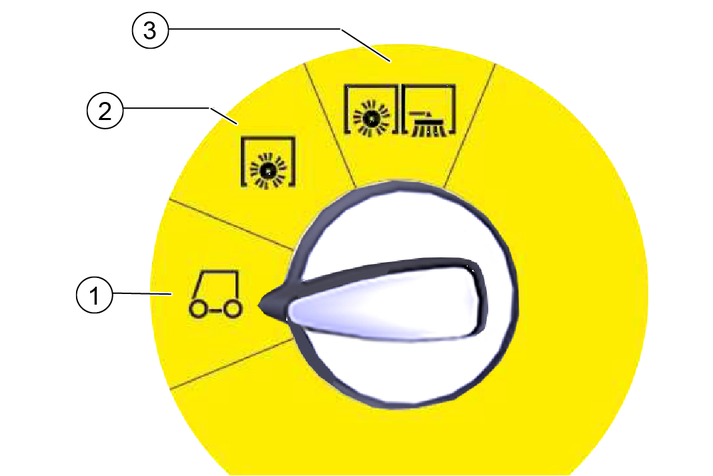

The functions are only activated when the key switch is switched on.

The motor can be started in this position

The sweeper can be driven to the place of use

Roller brush and side brushes are raised and switched off

Roller brush is lowered and switched on

Roller brush, right and left side brushes (optional) are lowered and switched on

Malfunction due to open panels

Only open the panels when the key switch is on <0> and the key has been removed.

Opening during operation is prohibited.

The bonnet must be opened for certain activities:

Refuelling

Checking/topping up the hydraulic oil level

Replace hydraulic oil filter

(only by authorized customer service)

Checking/replacing roller brushes

Disconnecting the battery

To open the bonnet, grasp the recessed grip at the front, unlock it upwards, then swivel it to the side.

The panel on the right must be opened for certain activities:

Opening/closing the freewheel

Opening the fuel cock

Checking/topping up the engine oil level

Motor oil change

Checking/replacing spark plug

Cleaning/replacing air filters

To open the panel, grasp the recessed grip, unlock it upwards, then swing it to the side.

The maximum permissible load on the storage compartments is 20 kg.

Ensure that the load is securely fastened.

Only use the batteries and chargers recommended by the manufacturer

Only replace batteries with batteries of the same type.

Before disposing of the vehicle, remove the battery and dispose of it in accordance with national or local regulations.

Observe the following warnings when handling the batteries:

| Observe notes in the instructions for the battery, on the battery and in these operating instructions. |

| Wear eye protection. |

| Keep acids and batteries away from children. |

| Risk of explosion |

| Fire, sparks, open flames and smoking are prohibited. |

| Risk of acid burns |

| First aid |

| Warning |

| Disposal |

| Do not throw batteries in the bin. |

Danger of fire and explosion!

Do not place tools or similar items on the battery. Risk of short-circuit and explosion.

Smoking and naked flames must be strictly avoided.

Rooms where batteries are charged must have good ventilation as highly explosive gas is emitted during charging.

Risk of acid burns

Use caution with leaking batteries (sulphuric acid may leak).

Risk of injury!

Ensure that wounds never come into contact with lead.

Always clean your hands after working on batteries.

Environmental risk due to improper disposal of batteries

Ensure that defect or used batteries are disposed of safely (contact a waste management company or Kärcher Service).

When used normally, and when observing the instructions, lead-acid batteries do not pose any risk.

However, keep in mind that lead-acid batteries contain sulphuric acid which can cause serious chemical burns and corrosion.

If there is spillage or, if the battery is leaking, acid is escaping, lay down a binding agent such as sand. Do not let it reach the sewer system, soil or a body of water.

Neutralise the acid with lime/baking soda and dispose of it according to local regulations.

Contact a waste management company to dispose of faulty batteries.

Rinse out your eyes or rinse off your skin with copious amounts of fresh water if acid splashes into your eyes or onto your skin.

Then consult a doctor immediately.

Wash any contaminated clothing with water.

Change clothes.

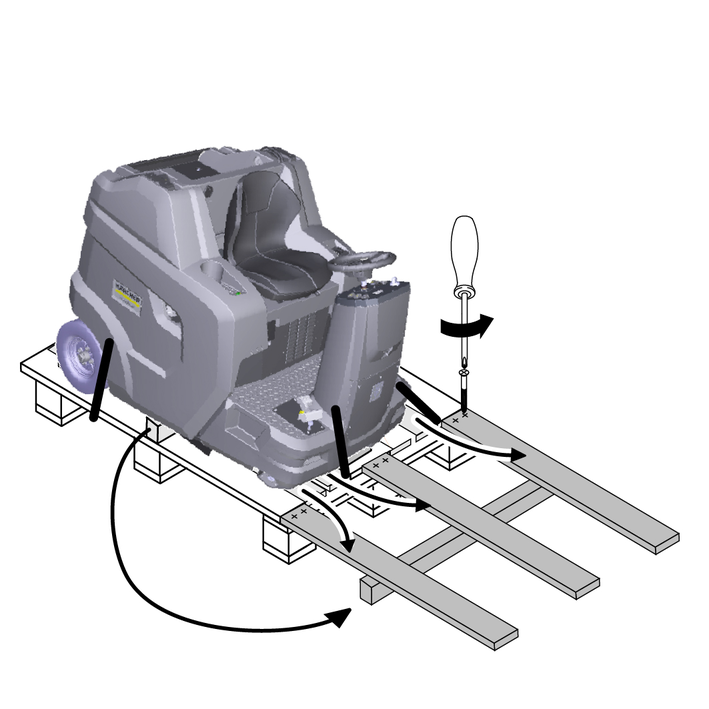

Risk of accidents when unloading the device

Use a suitable ramp when unloading the device.

Do not use a forklift to unload / load the device.

Be aware of the weight of the device when unloading / loading.

See also the chapter “Technical data”.

Figure: Ramp

Connect the battery and charge if necessary.

Use the enclosed boards to build a ramp according to the sketch.

Cut the plastic packing strips and remove the film.

Remove the strap fastening at the attachment points.

Unscrew the three floor boards shown and the squared timber on the pallet.

Position the boards on the edge of the pallet; align the boards so that they lie in front on the wheels on the device. Screw the boards tight.

Place the squared timber under the boards as a support.

Remove the wooden blocks locking the wheels.

Release the parking brake.

Carefully drive the device off the pallet via the ramp (see chapter “Moving the device with its own drive”) or push it off the pallet (see chapter “Moving the device without its own drive”).

Risk of accidents due to absence of braking power

Secure the device to prevent it from rolling away before you actuate the neutral lever.

Risk of damage to the hydrostatic drive

Push the device slowly and only over a short distance.

Do not tow the device under any circumstances.

The device is ready to drive

Device can be pushed

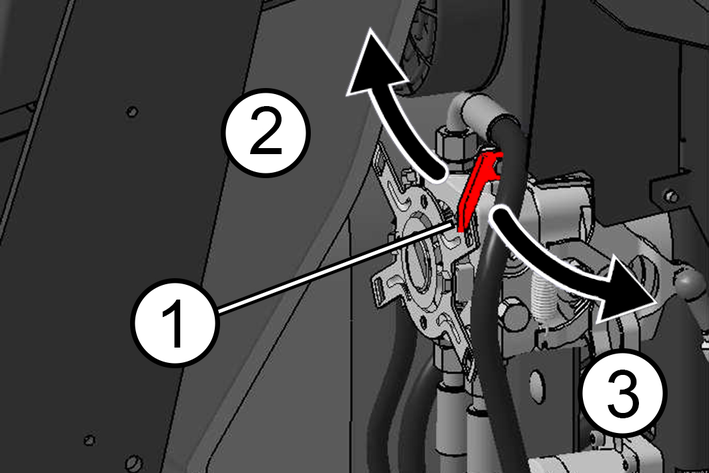

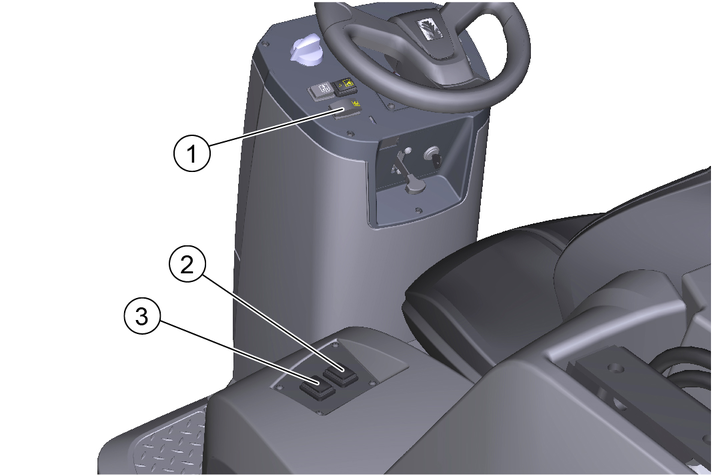

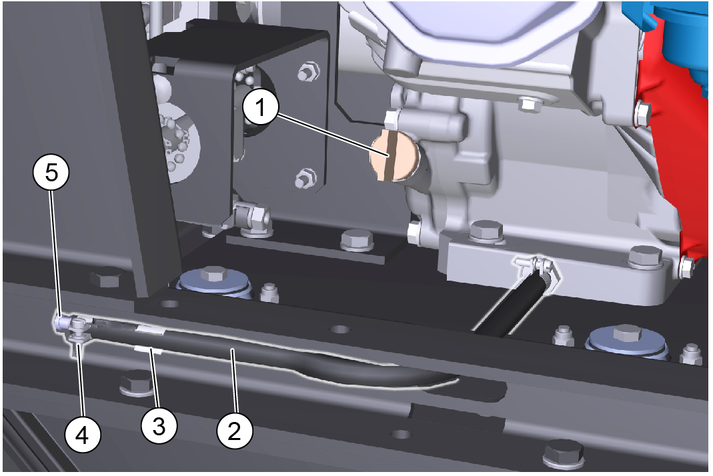

Open the neutral lever to move the device.

Swivel the right panel outwards.

Pull the neutral lever towards your body (open).

Release the parking brake.

Move device.

After moving the device, close the neutral lever.

Apply the parking brake.

Push the neutral lever away from your body (close).

Close the right panel.

The side brush or brushes are attached to the driver's seat with a cable tie when delivered.

Attach the side brushes to the device before initial startup. See chapter "Changing the side brushes".

Risk of burns from hot surfaces

Stay away from hot motor, exhaust pipe, angle piece and hydraulic drive motor.

Allow the device to cool down before the safety check.

Missing information in the chapter “Care and maintenance | Maintenance work”.

Check the safety function of the bonnet/panel on the right.

The combustion motor must not start when the bonnet is open.

The combustion motor must not start when the panel is open.

Check the seat contact switch to make sure it is fully functional.

With the combustion motor running, the device must switch off when the driver gets up from the driver's seat.

Check the tyre pressure.

Check the engine oil level.

Check the filling level of the hydraulic tank.

Check the roller brush and side brushes for foreign objects and any tangled pieces of tape.

Check the accelerator pedal for ease of movement and functional reliability (only when the device is at a standstill).

Empty the waste container.

Check the filling level of the fuel tank.

Explosion hazard due to overflowing fuel

Take care ensure that no fuel spills onto hot surfaces when refuelling.

Explosion hazard due to smoking and naked flames

Ensure strict prohibition of smoking and open flames during the refuelling procedure.

Health risk from inhaled vapours

Do not refuel in confined spaces.

Risk of damage due to incorrect fuel

Only fill up with suitable fuel as specified in the technical data.

Switch off the device (switch off the motor).

Pivot the bonnet outwards.

Open the tank cap.

Fill with fuel.

Wipe of any spilt fuel and close the tank cap.

Danger of accident

Only adjust the driver’s seat when the device is standing.

Pull the seat adjustment lever to the right and move the driver's seat to the desired position.

Release the seat adjustment lever.

Move the driver's seat back and forth to check that it is properly latched in place.

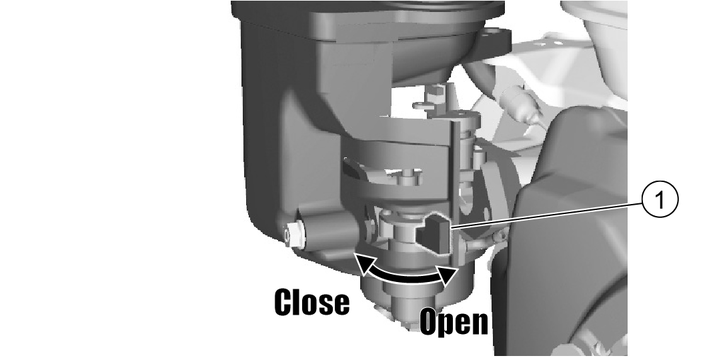

To open or close the fuel cock, turn it in the corresponding direction up to the stop.

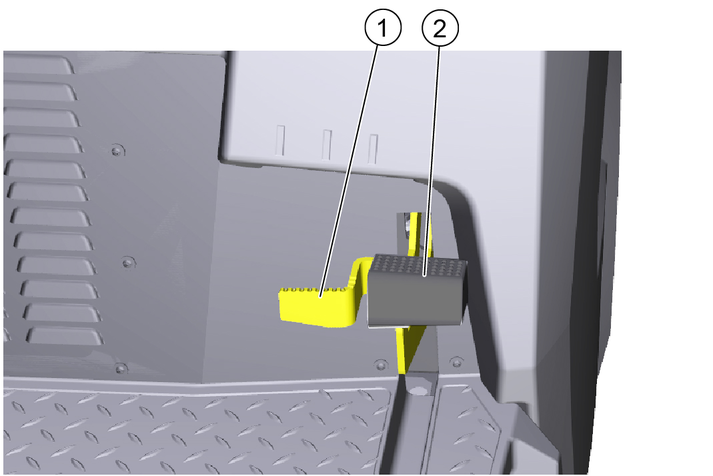

Apply the parking brake:

Press the parking brake (engages).

Release the parking brake:

Press the release button, the parking brake is released.

To start the motor, the bonnet must be closed and the driver must sit in the driver's seat.

Open the fuel cock.

Sit in the driver's seat (seat contact switch).

Set the programme selection switch to “Drive” position.

Insert the key in the key switch and turn to the “I - ON” position, the motor starts.

During cold exterior temperatures: Operate the choke lever.

Risk of injury when reversing

There must be no danger to third parties when reversing.

If necessary, have them instructed.

Risk of accident

Do not drive while the waste container is raised.

Risk of damage to the drive!

Before driving, make sure that the neutral lever is closed.

Always press the accelerator pedal carefully and slowly. Do not switch suddenly from reverse to forward drive or vice versa.

Carefully press the accelerator pedal.

Continuously regulate the travel speed with the accelerator pedal.

Avoid jerking the pedal.

Adapt the travel speed to the respective conditions.

Steer the travel direction using the steering wheel.

Release the accelerator pedal, the device brakes automatically and stops.

In an emergency, also apply the parking brake.

Risk of injury from abrupt stopping

Do not get out of the driver's seat while driving or carrying out cleaning work (the seat contact switch brings the device to an abrupt halt).

Risk of injury from stones or chippings

When the coarse dirt flap is open, beware of people, animals and objects in the vicinity (projectile stones or chippings are dangerous).

Risk of damage due to parcel tape or similar material

Do not sweep parcel tape, pieces of string or similar items (damage to the sweeping mechanics).

Objects or loose obstacles must not be driven over or pushed.

Adjust the travel speed to the circumstances for optimum cleaning results.

Sweeping is only permitted with the waste container retracted.

If the programme selector is set to “Drive”, the container flap is automatically closed.

If you switch the programme selector switch to “Sweeping”, the container flap opens automatically and the waste container is ready to pick up waste.

Empty the waste container at regular intervals.

If mainly chippings were swept up (heavy waste), empty the waste container earlier.

When cleaning surfaces, set the programme selector to “Sweeping with roller brush”.

To clean side edges, also use the side brushes by setting the programme selector switch to “Sweeping with roller brush and side brushes”.

Fixed obstacles up to 6 cm high can be driven over slowly and carefully.

Drive over fixed obstacles of more than 6 cm in height with a suitable ramp.

For cleaning work, select the forwards direction of travel.

For surface cleaning: Lower the roller brush by setting the programme selector to “Sweeping with the roller brush”.

For wet or damp surfaces: Open the wet sweeping flap.

For cleaning close to the edge: also lower the right side brushes by setting the programme selector switch to “Sweeping with roller brush and side brushes”.

To pick up larger objects (50 mm): Briefly press the coarse dirt flap pedal.

Clean the dust filter from time to time.

The dust filter is automatically cleaned at regular intervals.

In dusty environments, also press the filter cleaning switch.

The high dumping system on the unit allows the waste to be directly emptied into a waste container (see chapter “Technical data” for maximum discharge height).

Risk of injury due to falling objects!

When lifting and lowering the waste container, there is a risk of injury from objects falling from the storage surface.

Before lifting the waste container, remove all objects that are not securely fastened from the storage surface.

Risk of injury due to tipping of the machine when emptying the waste container!

Empty the waste container only on firm, level ground.

Maintain a safety distance when emptying on stockpiles and ramps.

Risk of injury when standing in the swivel range of the waste container!

Make sure that no persons or animals are in the swivel range of the waste container during the emptying process.

Risk of injury due to crushing or shearing off of body parts when reaching into the mechanics of the waste container!

Do not reach into the movement area or the components of the emptying mechanism of the waste container.

Risk of injury if the waste container falls!

The raised waste container can fall abruptly and cause serious injuries due to crushing and trapping.

Do not walk underneath the waste container if it is unsecured.

Secure the raised waste container properly with the supplied safety brace before walking underneath the waste container.

Set the programme selector switch to the “Drive” position (the waste container can only be lifted in this position).

Roughly position the device.

After switching off the device, wait at least 1 minute so that the dust can settle before emptying.

Press the high discharge button on the control panel and keep it pressed.

Press the waste container switch and raise the waste container.

To empty it into a waste bin, lift the waste container completely and slowly move towards the collection container.

For free emptying, lift the waste container approximately to the middle until the container flap can be opened (if the emptying height is too low, the operation of the container flap is blocked).

Apply the parking brake.

Press the container flap switch and empty the waste container.

Close the container flap.

Release the parking brake.

Drive away from the emptying station.

Lower the waste container completely.

The dust filter is automatically cleaned when the device is switched off.

Park the device on a level surface.

Turn the programme selection switch to the “Drive” position.

Apply the parking brake.

Remove the key from the key switch.

Close the fuel cock.

Risk of accident when loading

Risk of injury and damage

Always close the neutral lever when loading the device. Only then are the drive and parking brake ready for operation. The device must always be moved with its own drive on inclines or slopes.

Note the net weight (transport weight) of the device when transporting it on trailers or vehicles.

Only load and unload devices on a level surface.

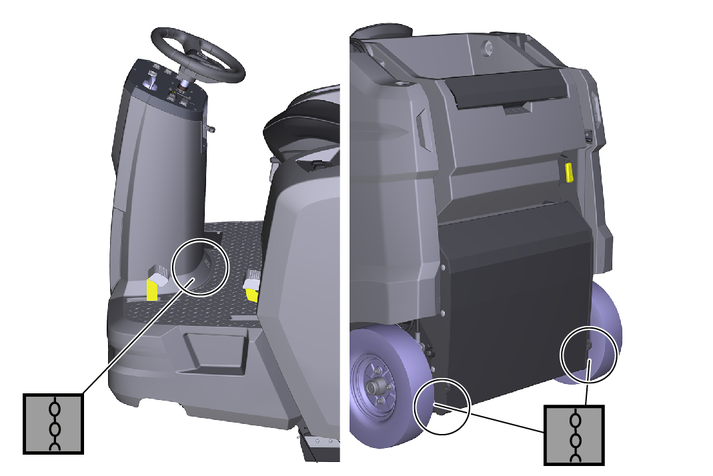

Secure the device in accordance with the respectively applicable guidelines to prevent it from slipping or overturning.

Close the fuel cock.

Secure the sweeper to the wheels with wedges.

Secure the sweeper with lashing straps or ropes.

Note the markings for fastening areas on the basic frame (chain symbols).

The left and right rear fastening points are openings (approx. Ø 30 mm) in the frame between the rear wheel and the waste container.

At the front is the fastening area between the footrest and the front tower.

Disconnect the minus terminal at the battery.

Remove key.

Risk of injury and damage

Be aware of the weight of the device before storing it.

Additionally, observe the notes in the operating instructions of the motor.

Park the sweeper on a level surface in a dry, frost-free environment. Protect against dust with a tarpaulin.

Secure the sweeper against rolling away (parking brake).

Close the fuel cock.

Remove key.

Disconnect the negative pole of the battery if the sweeper is not used for more than 4 weeks.

Charge the battery approx. every 2 months.

If the sweeper is not used for a long time:

Drain the fuel completely from the tank.

Change the motor oil.

Unscrew the spark plug and pour 5 ml of fresh motor oil into the spark plug bore. Crank the motor several times without the spark plug (do not start). Screw in the spark plug.

Adhere to the safety instructions for care and maintenance at the beginning of these operating instructions.

Short-circuits or other damage. Do not clean the device with a hose or high-pressure water jet.

Improper cleaning

Risk of damage.

Do not use any abrasive or aggressive detergents.

Health risk from dust

For interior cleaning with compressed air.

Wear a dust mask and safety goggles.

Open panels.

Blow out the device with compressed air.

Clean the unit using a damp cloth, wetted with a mild washing lye.

Closing the panels.

Clean the unit using a damp cloth, wetted with a mild washing lye.

To preserve eligibility for warranty claims, all servicing and maintenance work during the warranty period has to be performed by an authorised Customer Service (ICL), in accordance with the inspection check list.

The operating hour counter indicates the time of the maintenance intervals.

The intervals for service and maintenance work by the customer/operator are listed in the chapter “Maintenance by the customer”. The work must be carried out by qualified staff. A Kärcher specialist dealer can be consulted at any time if needed.

Further maintenance work must be carried out by the authorized Customer Service according to the inspection checklist. Please inform the Customer Service department in time.

All servicing and maintenance work must be performed by a qualified specialist. If necessary, you can consult a Kärcher specialist dealer at any time.

Work on the hydraulics may only be carried out by the authorized Customer Service department.

See chapter "Maintenance work" for descriptions.

Daily

See chapter “Safety check before starting”.

Weekly

Risk of injury if the waste container falls!

The raised waste container can fall abruptly and cause serious injuries due to crushing and trapping.

Do not walk underneath the waste container if it is unsecured.

Secure the raised waste container properly with the supplied safety brace before walking underneath the waste container.

Check the moving parts to make sure that they move smoothly.

Before all maintenance and repair work with the sweepings container raised, install the safety brace, see chapter Installing/removing the waste container safety brace.

Check the sealing strips in the sweeping area for correct adjustment and for wear.

Checking sealing strips on container flap of waste container (3x)

Check the roller brush and side brush for wear.

Check the dust filter and clean the filter box as necessary.

Check the air filter.

Check the fuel and hydraulic systems for leaks.

Check the tension of belts, check for wear and check that they are functional.

Maintenance every 50 operating hours

Clean the air filter (more frequently when used in a dusty environment).

Maintenance every 100 operating hours

Motor oil change (first change after 20 operating hours).

Check and clean the spark plug.

Clean the air filter.

Clean the sediment basin.

Maintenance every 300 operating hours

Change the air filter.

Clean the fuel filter.

Change the spark plug.

Maintenance after wear

Replace the sealing strips.

Replace the roller brush.

Replace the side brush.

In order to preserve warranty entitlements, all servicing and maintenance work during the warranty period has to be performed by an authorised Kärcher Customer Service, in accordance with the inspection check list.

Initial inspection after 20 operating hours

Maintenance every 100 operating hours

Maintenance every 300 operating hours

Check the oil level when the device is parked and standing horizontally.

Danger of burns

Do not touch any hot surfaces such as the exhaust pipe or motor.

Park the device on a level surface.

Allow the motor to cool.

Check the motor oil level no earlier than 5 minutes after the motor has been switched off.

Close the right-hand panel.

Unscrew the oil dipstick and read the oil level.

If the oil level is below MIN, top up the motor oil.

For the correct oil type see chapter "Technical data".

Do not overfill, just fill up to MAX.

If the oil level is correct, screw in the dipstick.

Close the panel.

Perform the oil change on a warm engine so that the oil drains better.

Shut down the engine.

Place the device on a level surface.

Provide a suitable catch pan for the used oil.

Open the right panel (pivot).

Unscrew the oil dipstick.

Remove the drain hose from the support.

Open the hose clip on the drain hose and pull out the locking piece.

Allow the oil to drain completely into the catch pan.

Insert the locking piece and tighten with a hose clip.

Fill new engine oil (see "Technical data") up to the lower edge of the filler opening.

Screw in and tighten the oil dipstick.

Close the panel.

Dispose of the old oil in accordance with the environmental regulations.

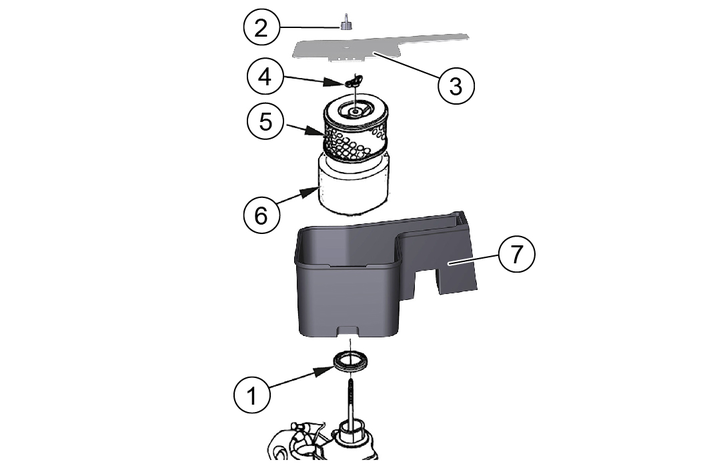

Unscrew the wing nut.

Remove the cover.

Check the air filter for soiling, clean if necessary.

Slide the cover into the fixing, then put it on.

Pay attention to the correct position in the fixing.

Screw on the wing nuts and tighten.

Unscrew the wing nuts on the cover.

Remove the cover.

Unscrew the air filter wing nuts.

Remove the air filter insert.

Remove the foam filter insert from the paper filter insert.

Check both air filter inserts for damage.

Replace any damaged air filter inserts.

Clean any reused air filter inserts.

Knock the paper filter insert a few times on a hard surface to clean it or blow it out from the inside with compressed air (maximum 0.2 MPa).

Foam filter insert:

Clean in warm soapy water.

Rinse with clear water.

Or clean in a non-inflammable solvent.

Allow to dry.

Immerse in clean engine oil.

Press out the excess oil.

Wipe off the inner side of the cover and air filter housing with a damp cloth. Take care to ensure that no dirt enters the engine.

Fit the foam filter insert on the paper filter insert.

Fit the air filter insert into the air filter housing.

Ensure that the seal is correctly fitted between the air filter housing and the engine.

Fit the air filter wing nuts and tighten.

Fit the cover.

Fit the cover wing nuts and tighten.

Turn the fuel cock to the "OFF" position.

Unscrew the settling cup.

Remove the O-ring.

Clean the settling cup in a non-inflammable solvent.

Thoroughly dry the settling cup.

Fit the O-ring into the housing.

Screw in and tighten the settling cup.

Turn the fuel cock to the "ON" position.

Check that the settling cup is tightly seated.

Turn the fuel cock to the "OFF" position.

Pull off the spark plug connector.

Clean the region around the spark plug to prevent dirt from entering the engine when the spark plug is removed.

Unscrew the spark plug with a 13/16" spark plug wrench.

Replace a spark plug that has worn electrodes or a broken insulator.

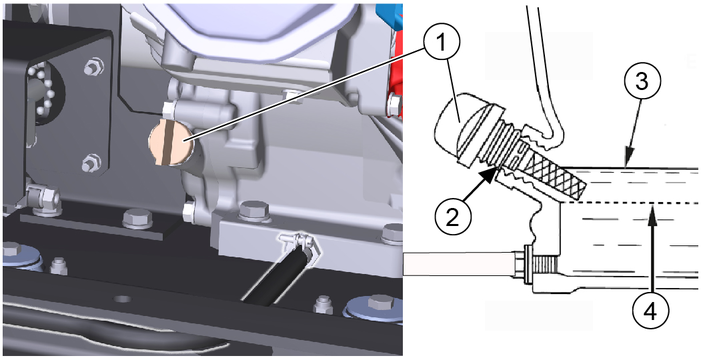

Check the electrode gap of the spark plug. Target value 0.7...0.8 mm.

Check the spark plug seal for damage.

Risk of damage

A loose spark plug can overheat and damage the engine. An overtightened spark plug can damage the thread in the engine.

Observe the following instructions for tightening the spark plug.

Carefully screw the spark plug in by hand. Do not cross the thread.

Screw the spark plug all the way in using the plug spanner and the tighten as follows.

Tighten a used spark plug by an additional 1/8...1/4 turn.

Tighten a new spark plug by an additional 1/2 turn.

Plug on the spark plug connector.

Risk of damage to the hydraulic system

Pay attention to the utmost cleanliness when refilling.

Work on the hydraulic system may only be carried out by the authorized Customer Service department.

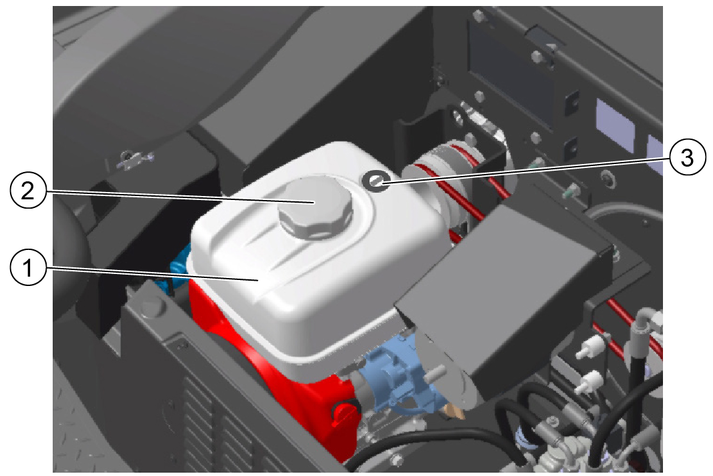

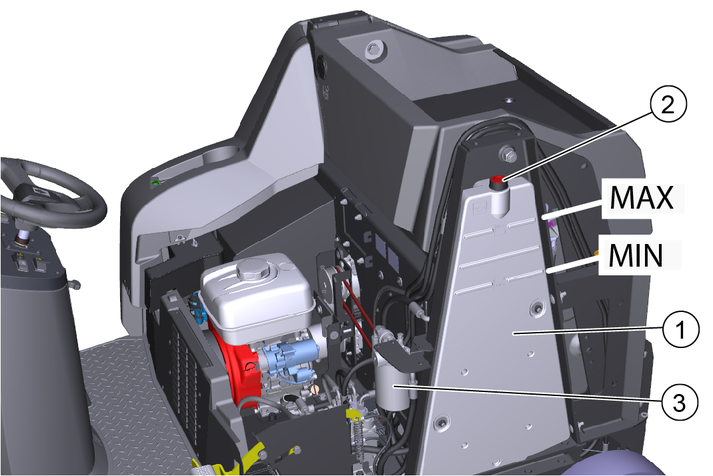

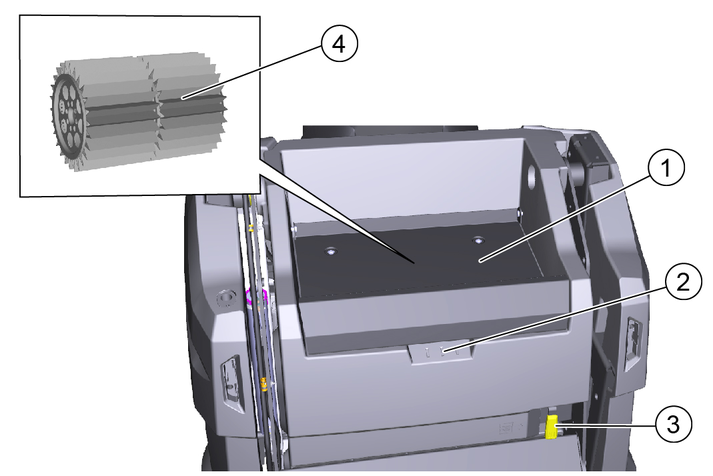

Figure without bonnet

Park the device.

Open the bonnet.

Check the hydraulic oil level when the motor is cold.

The correct hydraulic oil level must be between the upper “MAX” and lower mark “MIN”.

Top up the hydraulic oil if necessary.

Remove the breather cap.

Top up the hydraulic oil.

For the hydraulic oil type: See chapter "Technical data".

Attach the breather cap.

Close the bonnet.

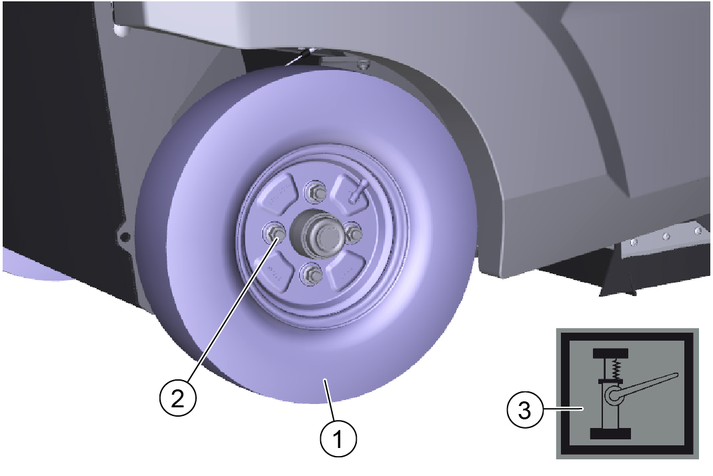

Risk of injury

Only park the vehicle on a stable surface.

Check that the ground is stable. Additionally secure the device against rolling away with a wheel chock.

Use a suitable, commonly available jack.

Park the device on a level surface.

Check that the ground is stable.

Secure the device against rolling away.

Open the side panel or bonnet.

Place the jack at the marked attachment points on the frame.

Use a suitable tool to release the wheel nuts by approx. 1 turn.

Lift the device with a jack.

Unscrew and remove wheel nuts.

Remove the wheel.

Have the defective wheel repaired in a specialist workshop or have it replaced.

Position the wheel, screw in the wheel nuts as far as they will go and tighten slightly.

Lower the device with the jack.

Close the side panel or bonnet

Tighten the wheel nuts to the required torque (56 Nm).

Contact the Customer Service department to remove the front wheel.

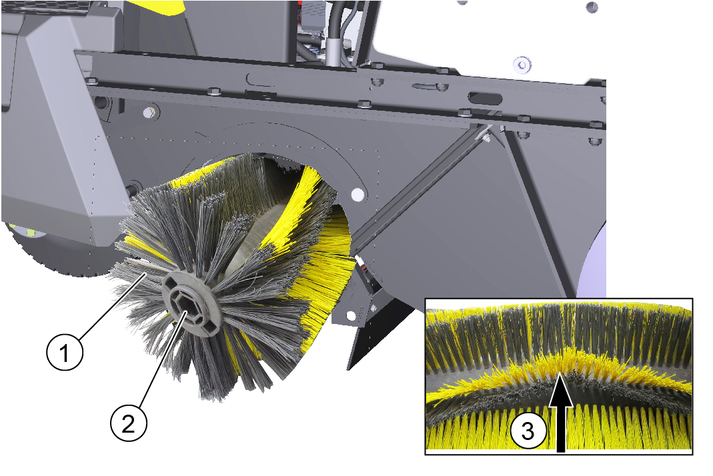

Thanks to the floating bearing of the side brushes, the sweeping area automatically adjusts itself when the bristles are worn. If it is too worn (bristle length approx. 10 cm), replace the side brushes.

Park the device.

Unscrew the 3 screws on the underneath.

Remove the side brush.

If necessary, clean the mount.

Connect the new side brush to the driver and fasten it in place with the screws.

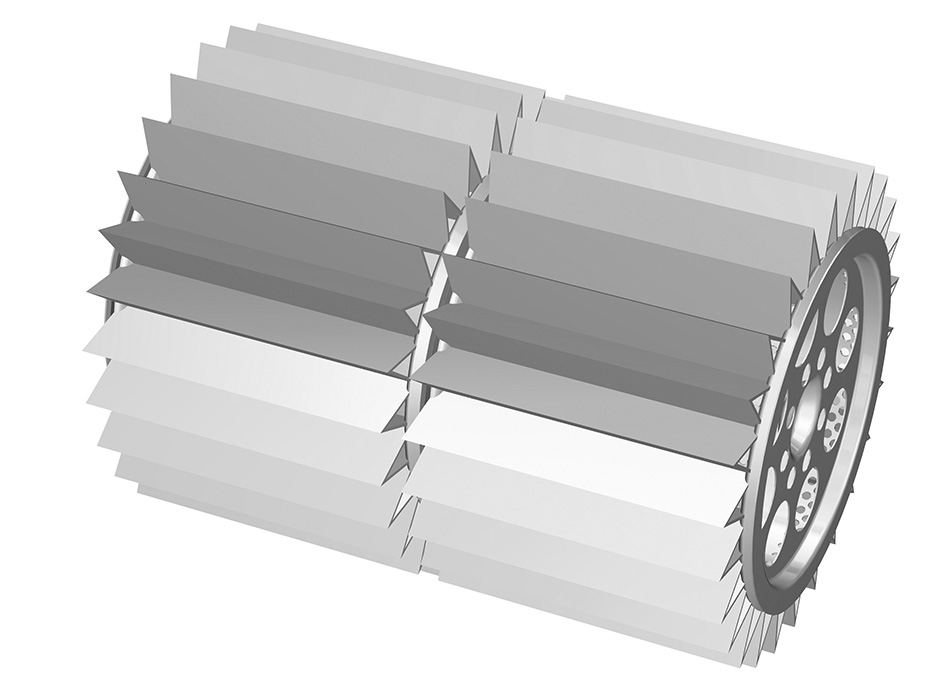

Due to the floating mounting of the roller brush, the sweeping level automatically adjusts itself when the bristles are worn. Replace if it is too worn (cleaning result is not satisfactory).

Park the device.

Open the bonnet.

Unscrew the left-hand knurled screw.

Remove the bearing plate.

Unscrew the right-hand knurled screw.

Remove the cover plate.

Pull out the roller brush.

Check roller brushes for wear and entangled pieces of tape.

As necessary: Install the new roller brush.

When installing, ensure that the bristles are correctly aligned (roller brush mounts are identical).

Install the cover plate and bearing plate in reverse order.

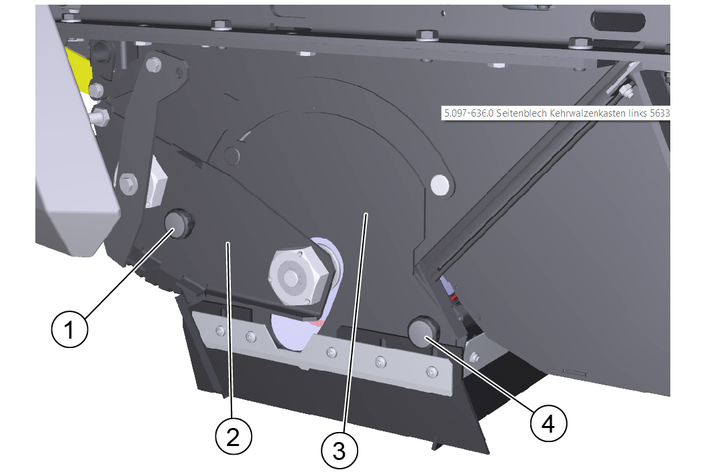

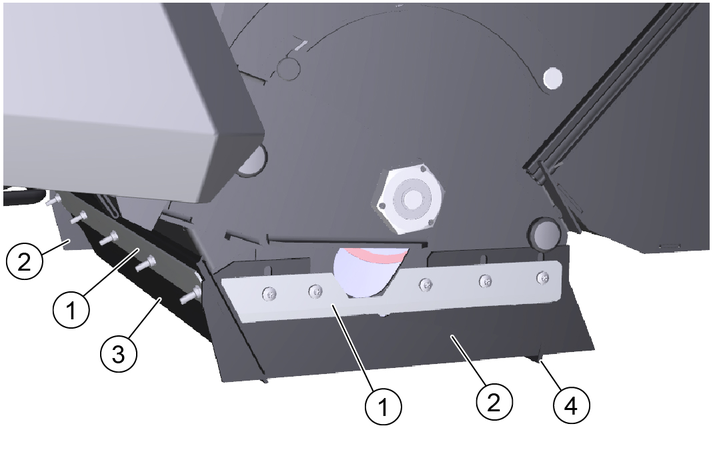

Sealing strips | Setting values |

|---|---|

Side sealing strips | Distance from floor 0 - 1 mm |

Front sealing strip | Trailing distance 10-15 mm |

Rear sealing strip | Trailing distance 5-10 mm |

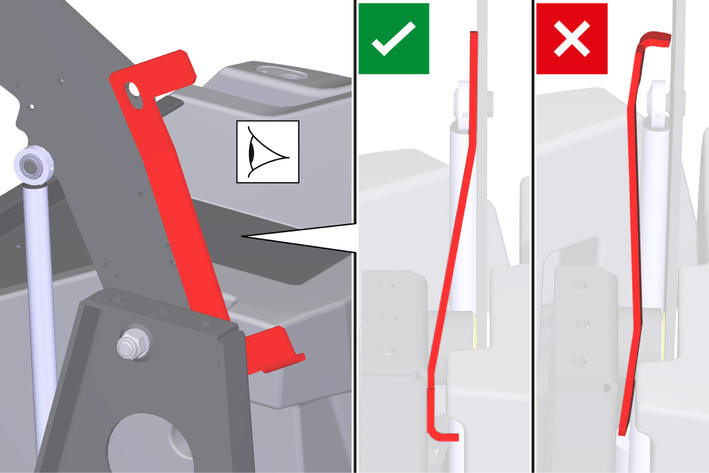

The trailing distance of the front and rear sealing strip defines how much the sealing lip folds backwards when driving the device forwards.

When set correctly, there must be a gap between the side sealing strips and the floor.

Unfasten the fastening of the sealing strips.

Set the sealing strip by shifting it in the elongated holes.

Refer to the table for the values.

Once the settings are correct, fasten the sealing strips.

Health risk from dust

Wear a dust mark and safety goggles when working on the filter system.

Observe the safety instructions on the handling of fine dust.

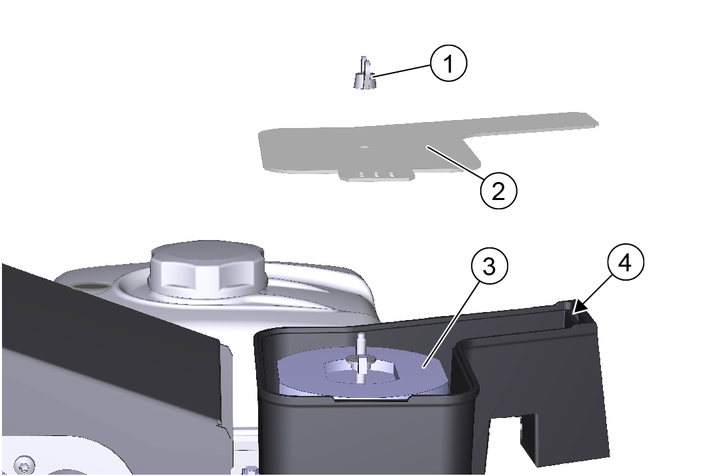

Park the device.

Wait at least 1 minute for the dust to settle.

Pivot the cover upwards on the recessed grip.

Move the dust filter lever to the right.

Remove the dust filter upwards.

As necessary: Clean the dust filter. (vacuum or carefully tap it out) or insert a new dust filter.

Installation:

Park the machine on a firm, horizontal surface.

Lower the waste container completely, see chapter Emptying the waste container.

Switch off the machine, see chapter Switching off the device.

Open the right-hand panel, see chapter Opening/closing the right panel.

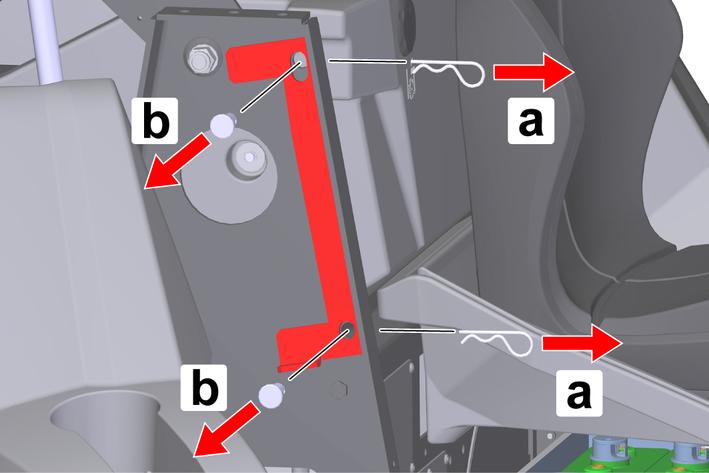

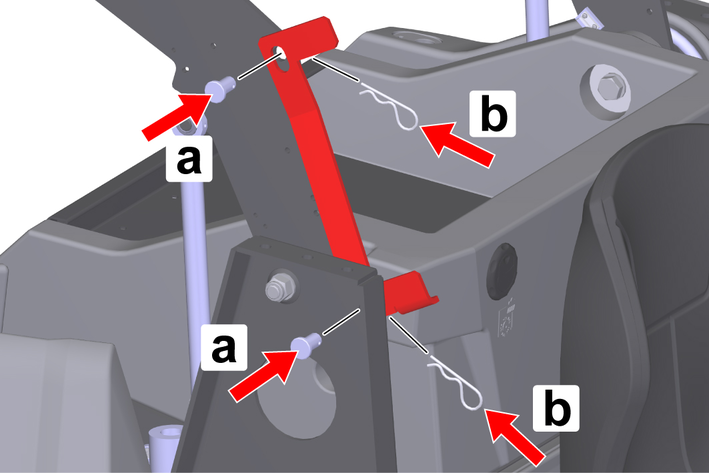

Remove the safety brace.

Pull the cotter pins out of the bolts.

Pull out the bolts and remove the safety brace on the tie bar.

Position the safety brace between the right-hand tie bar and the right-hand lift arm as shown.

Install the bolts.

Insert the bolts into the holes.

Insert the cotter pins into the holes in the bolts until the cotter pins engage.

Risk of damage!

Raising or lowering the waste container with the safety brace installed causes damage to the machine and the safety brace! To prevent the waste container from being raised or lowered hydraulically, it is not possible to close the right-hand panel when the safety brace is fitted. This activates the safety circuit.

Do not close the right-hand panel by force!

Removal:

Removal is performed in the reverse sequence.

You can remedy minor faults using the following overview.

Contact the Customer Service department in the case of any faults not listed!

Risk of accidents and injuries due to unintentional movement of the vehicle

Switch off the vehicle before carrying out any care and maintenance work, and remove the ignition key.

Risk of electric shock

Disconnect the battery when working on electrical components.

Repair work and work on electrical components must only be performed by your authorised Customer Service.

Remedy:

Check/charge the starter battery.

Key switch to position “I - ON”.

Programme selector switch to "Drive" position

During cold exterior temperatures: Operate the choke lever.

Sit in the driver's seat (seat contact switch is activated).

Fully close the bonnet and right panel.

Check motor oil level, top up motor oil if necessary.

Fill with fuel.

Open the fuel cock.

Check spark plug.

Cause:

Remedy:

Check the filling level of the fuel tank.

Check the position of the choke lever.

Check connections and lines of fuel system.

Check/clean/replace spark plug.

Clean/replace the air filter.

Cause:

Remedy:

Release the parking brake.

Check the position of the neutral lever.

Check/top up the filling level of the hydraulic oil tank.

In the event of freezing temperatures and cold hydraulic oil: Allow the device to warm up for at least 3 minutes.

Cause:

Remedy:

Petrol engine:

Open the bonnet (be careful of the rotating V-belt).

Close the fuel cock.

Cause:

Remedy:

Empty the waste container.

Check / clean / replace the dust filter.

Check that the dust filter is firmly in place.

In case of light soiling, clean the dust filter.

In case of damage or heavy soiling, replace the dust filter.

Check the sealing strips in the sweeping area to check for wear. Readjust or replace if necessary.

Check/replace the seals on the filter box.

Check/replace sealing strips on waste container.

Cause:

Remedy:

Check the roller brush and side brush for wear, replace them as necessary.

Check the sealing strips for wear, replace them as necessary.

Check that the coarse dirt flap is fully functional.

Close the wet sweeping flap.

Check the hydraulic oil tank filling level.

Check the hydraulic system for leaks.

Cause:

Remedy:

Turn the programme selection switch to the desired “Sweeping” programme.

Check the filling level of the hydraulic oil tank.

Check the hydraulic system for leaks.

Check the roller brush / side brush for any tangled pieces of tape.

Contact Customer Service.

Cause:

Remedy:

The shear protection screw on the waste container (left and right sides) has sheared off, replace the broken screw.

Contact Customer Service.

Cause:

Remedy:

The waste container is secured with the safety brace. Remove the high-pressure nozzle, see chapter Installing/removing the waste container safety brace.

If a function fails, you can check the device fuses before contacting Customer Service.

Risk of damage through incorrect handling

The controller or device components can be damaged by incorrectly inserted device fuses!

Replace device fuses only with fuses of the same type (blade-type fuse) and value (A)

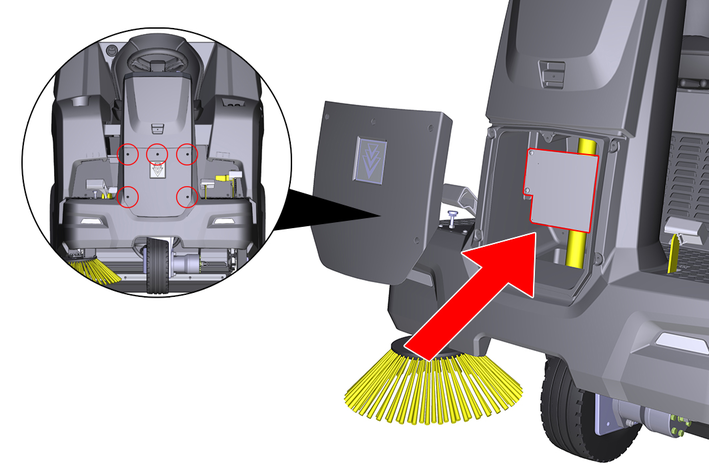

The device fuses are located on the vehicle's electronic controller.

The controller is located under the front cover of the steering column:

Switch off the device and secure it against rolling away.

Disconnect the minus terminal at the battery.

Completely unscrew 5 screws from the front cover.

Remove the cover.

Identify faulty device fuses using the table.

Replace any faulty device fuses.

Reattach the cover.

Reconnect the minus terminal of the battery.

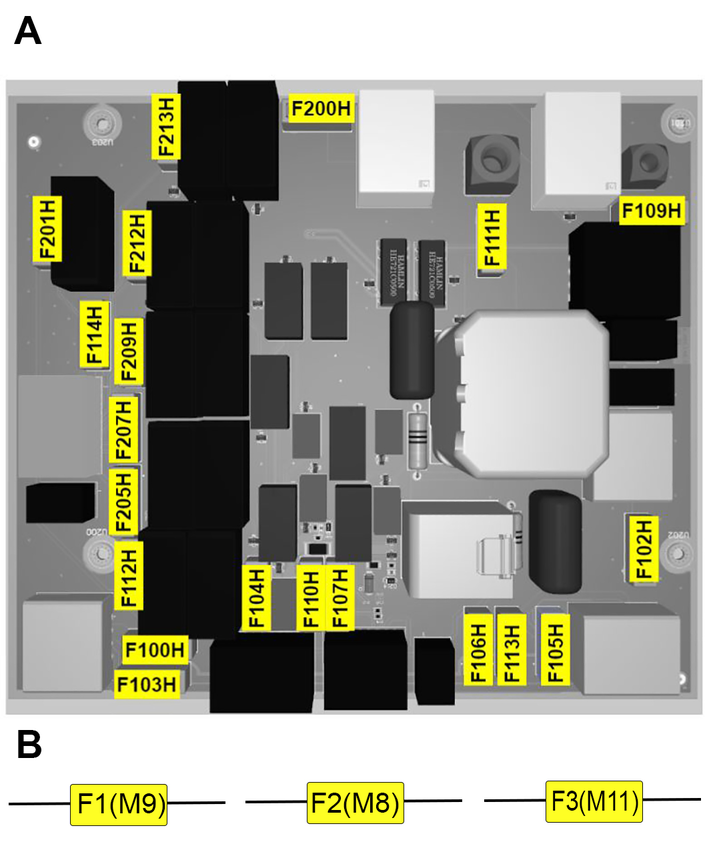

Device fuses (overview)

A: Fuses on the electronic controller

Device fuse | Value (A) | Designation |

|---|---|---|

F100H | 7.5 | Key-operated switch |

F102H | 7.5 | Work light |

F103H | 7.5 | Water pump |

F104H | 3 | LED |

F105H | 7.5 | Work light |

F106H | 3 | Blue spot |

F107H | 1 | Counter TCU |

F109H | 5 | Filter motor |

F110H | 7.5 | Signal horn |

F111H | 10 | Lifting motors |

F112H | 5 | Start the motor |

F113H | 1 | Flashing beacon |

F114H | 1 | Position sensor, emptying |

F200H | 30 | Main fuse |

F201H | 3 | K1 Main valve |

F205H | 3 | K7 |

F207H | 3 | K6 Close flap |

F209H | 3 | K3 Open flap |

F212H | 3 | K5 Lower |

F213H | 3 | K2 Lift |

B: Fuses in the wiring harness (fuse holder)

Device fuse | Value (A) | Designation |

|---|---|---|

F1 (M9) | 7.5 | Lifting motor |

F2 (M8) | 7.5 | Lifting motor |

F3 (M11) | 7.5 | Lifting motor |

The following is an overview (excerpts thereof) of wear parts or optionally available accessories.

Accessories | Description | Order no. |

|---|---|---|

Side brush, standard | For indoor and outdoor surfaces | 6.905-986.0 |

Side brush, soft | For fine dust, on indoor and outdoor surfaces Moisture resistant | 6.906-133.0 |

Side brush, hard | For removal of stubborn dirt, for outdoor use Moisture resistant | 6.906-065.0 |

Weed brush | Side brush for removing weeds | 6.906-065.0 |

Roller brush, standard | For indoor and outdoor surfaces Wear and moisture resistant | 6.905-095.0 |

Roller brush, soft | For fine dust, on indoor and outdoor surfaces Moisture resistant | 6.905-190.0 |

Roller brush, hard | For removal of stubborn dirt, for outdoor use Moisture resistant | 6.905-191.0 |

Dust filter (round filter) |  | 6.414-532.0 |

Sealing strip, side Left and right |  | 5.365-078.0 |

Sealing strip, rear |  | 5.365-053.0 |

Sealing strip, front |  | 5.294-000.0 |

Side brush attachment kit, left | Has to be installed by Customer Service | 2.852-912.7 |

Front wheel | As a replacement | 6.435-120.0 |

Rear wheel | As a replacement | 6.435-291.0 |

Home Base accessories | Description | Order no. |

|---|---|---|

Adapter | For securing to Home Base rail (device) | 5.035-488.0 |

Double hook | Can only be used in conjunction with adapter | 6.980-077.0 |

Detergent container | Can only be used in conjunction with adapter | 4.070-006.0 |

Coarse dirt pliers set | Coarse dirt pliers including attachment to the device | 4.035-524.0 |

Device performance data | |

Travel speed (max.) | 7 km/h |

Working speed (max.) | 7 km/h |

Climbing ability (max.) | 18 % |

Working width without side brushes | 730 mm |

Working width with 1 side brushes | 1000 mm |

Theoretical surface performance | |

Surface performance | 7000 m2/h |

Battery | |

Battery type | Maintenance-free |

Working voltage of the battery | 12 V |

Ambient conditions | |

Ambient temperature | -5...+40 °C |

Humidity, non-condensing | 0...90 % |

Dimensions and weights | |

Length | 1660 mm |

Width | 1110 mm |

Height | 1355 mm |

Net weight (transport weight) | 570 kg |

Approved total weight | 944 kg |

Width of roller brush | 730 mm |

Diameter of roller brush | 285 mm |

Diameter of side brush | 410 mm |

Waste container | |

Waste container volume | 120 l (kg) |

Discharge height (max.) | 1520 mm |

Filter and suction system | |

Filter area | 6 m2 |

Internal combustion engine | |

Engine type | Honda GX 270 |

Type | 1 cylinder 4 stroke |

Engine capacity | 270 cm3 |

CO2 emission according to the measurement procedure of EU regulation 2016/1628 (level V) | 762 g/kWh |

Cooling type | Air-cooled |

Engine performance | 6,3 / 8,4 kW/PS |

Spark plug type | BPR6ES (NGK) |

Fuel tank capacity | 5,3 l |

Engine speed | 3600 1/min |

Working time with a fully filled fuel tank | ca. 3,5 h |

Operating materials | |

Fuel type | Benzin bleifrei (min. 91 Oktan) |

Engine oil type | API SJ |

Engine oil volume | 1,1 l |

Oil type | SAE 10W30 |

Type of hydraulic oil | Shell Tellos S 3 V 68 |

Tyres | |

Tyre size, front | ø 300 mm |

Tyre size, rear | 4.00-8 6PR |

Tyre pressure | 0,6 (6) MPa (bar) |

Determined values in acc. with EN 60335-2-72 | |

Hand-arm vibration value | 1,9 m/s2 |

Seat vibration value | 0,4 m/s2 |

Sound pressure level LpA | 79 dB(A) |

Uncertainty | 2,5 dB(A) |

Sound power level LWA + uncertainty KWA | 95 dB(A) |

We hereby declare that the machine described below complies with the relevant basic safety and health requirements in the EU Directives, both in its basic design and construction as well as in the version placed in circulation by us. This declaration is invalidated by any changes made to the machine that are not approved by us.

Product: Sweeper vacuum ride-on machine

Type: 1.280-xxx.0

Currently applicable EU Directives2006/42/EC (+2009/127/EC)

2014/30/EU

2000/14/EC

2014/53/EU

Harmonised standards usedEN 60335-1

EN 60335-2-72

EN 62233: 2008

EN 55012: 2007 + A1: 2009

EN 61000-6-2: 2005

TCUEN 301 511 V12.5.1

EN 300 440 V2.1.1

EN 300 328 V2.2.2

EN 300 330 V2.1.1

Applied conformity evaluation method2000/14/EG: Annex V

Sound power level dB(A)Measured: 92,5

Guaranteed: 95

The signatories act on behalf of and with the authority of the company management.

Documentation supervisor:

S. Reiser

Alfred Kärcher SE & Co. KG

Alfred-Kärcher-Str. 28 - 40

71364 Winnenden (Germany)

Ph.: +49 7195 14-0

Fax: +49 7195 14-2212

Winnenden, 2021/02/01