BP 3.200 HomeBP 4.900 Home

5.991-000.0 (08/22)

5.991-000.0 (08/22)

Read these original operating instructions and the enclosed safety instructions before using the device for the first time. Proceed accordingly.

Keep both books for future reference or for future owners.

This device has been developed for private use and is not intended for the loads imposed by commercial use.

This device is intended for indoor use only.

The pump is not suitable for boosting the existing line pressure.

Permissible feed fluids:

Processed water

Well water

Spring water

Rain water

Swimming pool water with intended dosage of additives

The temperature of the delivered liquid must not exceed 35 °C.

The manufacturer accepts no liability for possible damage caused by improper use or incorrect operation.

Indication of an imminent threat of danger that will lead to severe injuries or even death.

Indication of a potentially dangerous situation that may lead to severe injuries or even death.

Indication of a potentially dangerous situation that may lead to minor injuries.

Indication of a potentially dangerous situation that may lead to damage to property.

The packing materials can be recycled. Please dispose of packaging in accordance with the environmental regulations.

The packing materials can be recycled. Please dispose of packaging in accordance with the environmental regulations.

Electrical and electronic appliances contain valuable, recyclable materials and often components such as batteries, rechargeable batteries or oil, which - if handled or disposed of incorrectly - can pose a potential threat to human health and the environment. However, these components are required for the correct operation of the appliance. Appliances marked by this symbol are not allowed to be disposed of together with the household rubbish.

Electrical and electronic appliances contain valuable, recyclable materials and often components such as batteries, rechargeable batteries or oil, which - if handled or disposed of incorrectly - can pose a potential threat to human health and the environment. However, these components are required for the correct operation of the appliance. Appliances marked by this symbol are not allowed to be disposed of together with the household rubbish.

Current information on content materials can be found at: www.kaercher.com/REACH

Only use original accessories and original spare parts. They ensure that the appliance will run fault-free and safely.

Information on accessories and spare parts can be found at www.kaercher.com.

The scope of delivery for the appliance is shown on the packaging. Check the contents for completeness when unpacking. If any accessories are missing or in the event of any shipping damage, please notify your dealer.

The warranty conditions issued by our sales company responsible apply in all countries. We shall remedy possible malfunctions on your device within the warranty period free of cost, provided that a material or manufacturing defect is the cause. In a warranty case, please contact your dealer (with the purchase receipt) or the next authorised customer service site.

(See overleaf for the address)

The maximum amount of equipment is described in these operating instructions. Depending on the model used, there are differences in the scope of delivery (see packaging).

We recommend using only original Kärcher suction hoses, filter components and hose connections. Using components from other manufacturers can lead to malfunctions when sucking the feed fluid, especially when using bayonet connection systems.

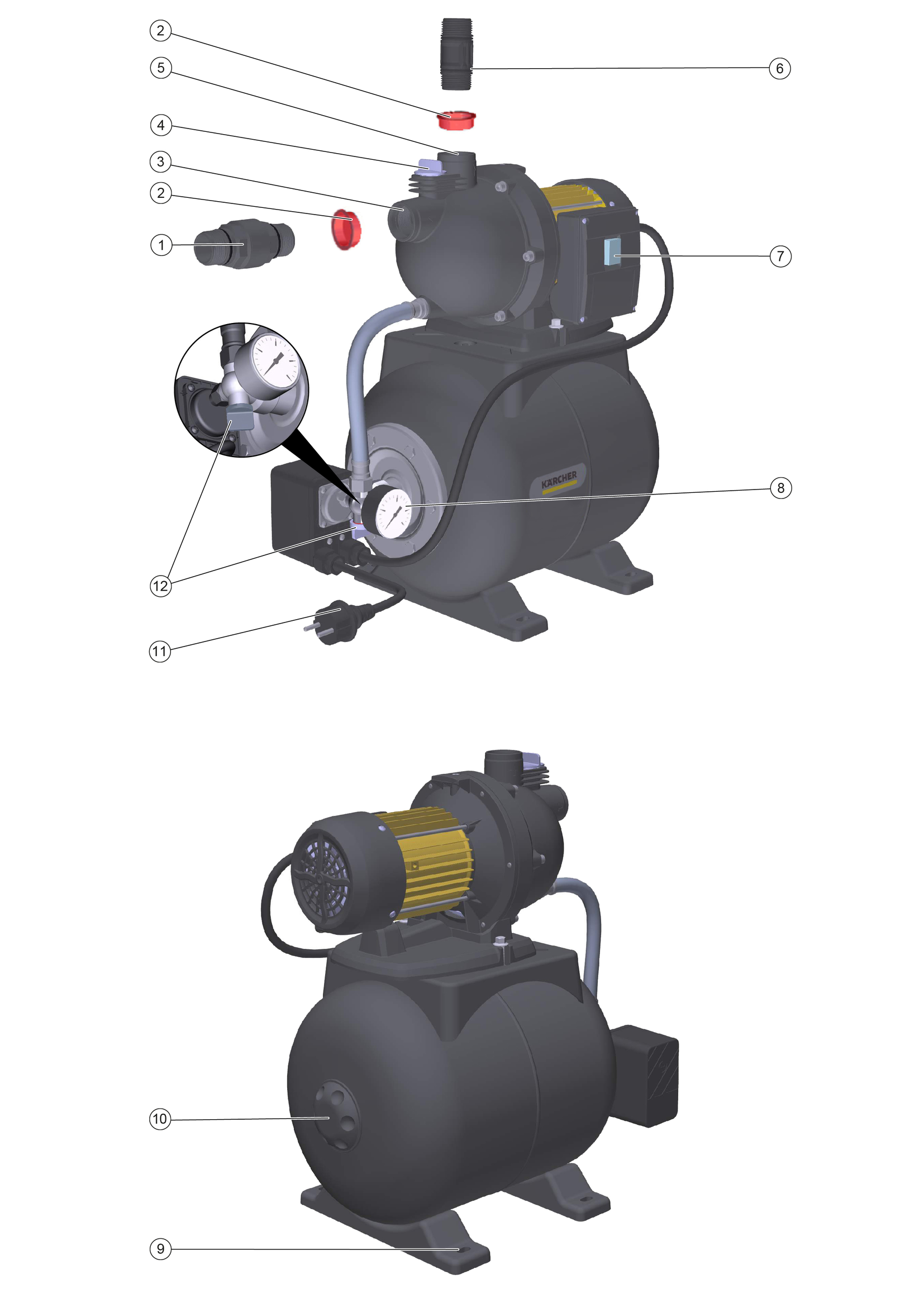

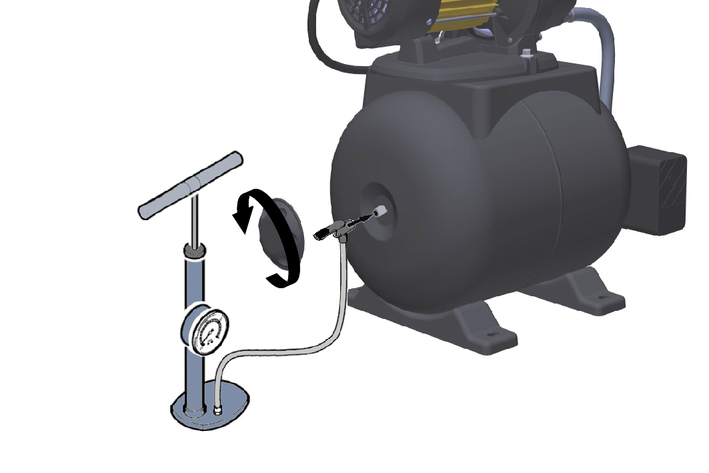

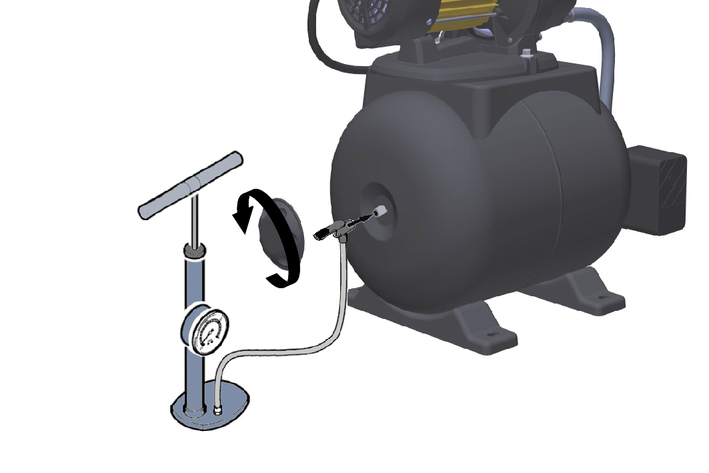

Before initial startup, check the pressure of the air filling in the storage tank. If necessary, top up to 2.0 bar with a commercially available air pump when switched off/depressurised.

Secure the device against slipping, screw it down if necessary.

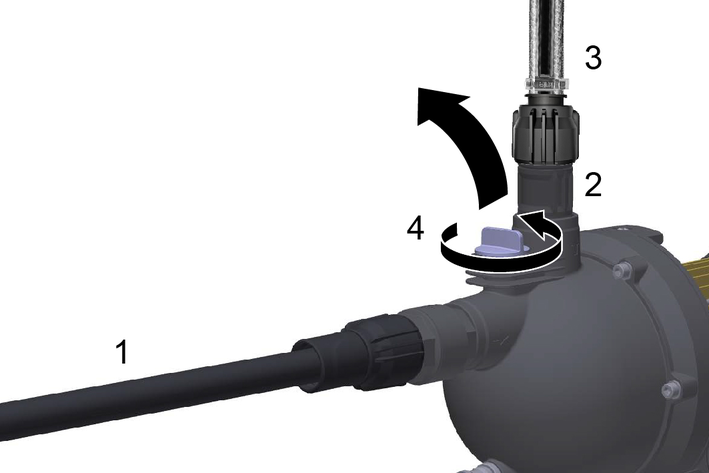

Remove the sealing plug.

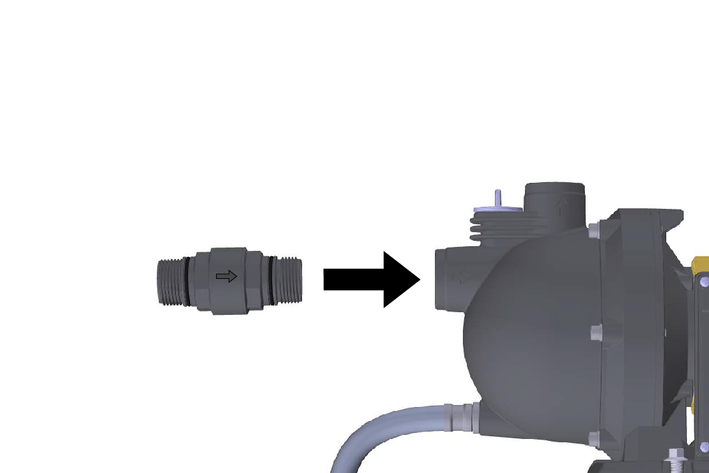

Screw the connection adapter with integrated check valve into the suction connection of the pump (inlet).

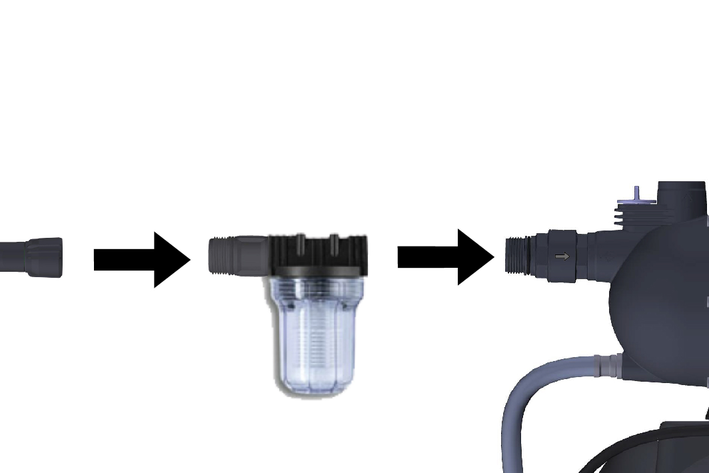

If the water is dirty, we recommend fitting a pre-filter (see Special accessories) between the check valve and the suction hose.

Connect vacuum-proof suction hose with integrated backflow stop to suction side. (Available as an special accessory).

Screw the connection adapter into the pressure connection of the pump (outlet).

Connect the pressure line.

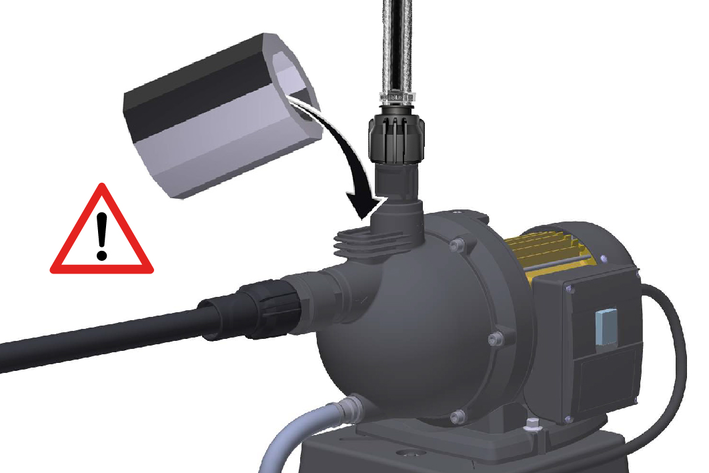

Open the filling nozzle cap.

Fill with water until it overflows.

Screw the cap tightly onto the filling nozzle.

Open existing stop valves in the pressure line.

Even minor leaks lead to malfunctions.

In case of leaks, seal all connections with a suitable sealant (e.g. Teflon tape) to avoid malfunctions due to leakage or air intake.

In a permanent installation, the pump can be screwed to a suitable surface.

Screw the pump tightly to a level surface using suitable screws.

In addition, in the case of a fixed installation, it is recommended to fit a flexible component on the pressure side, such as a flexible pressure equalization hose (see Special accessories), on the pressure side. This has the following advantages:

Greater flexibility in erection and installation.

Sound reduction since no vibration is transmitted in to the pipes of the house water system.

With smaller leaks, the pump switches less often.

In order to simplify the subsequent draining and pressure relief of the system, we recommend the installation of a stop cock between the pump and the pressure line (not included in the scope of delivery).

Closing the stop cock prevents water from flowing out of the pressure line when the pump is drained.

Plug the mains plug into the socket.

Switch the device on with the ON/OFF switch.

Pump starts immediately. Wait until the pump sucks in and delivers evenly, then close the stop valves in the pressure line.

After reaching the switch-off pressure, the pressure switch switches off the motor. The storage tank is now filled, the domestic water supply is ready for operation.

If there is no water supply, the switch-off pressure is not reached and the pressure switch can no longer shut off the device. This heats up the water in the pump head.

To prevent damage to the pump due to overheating, the power supply is interrupted by the thermal switch in the event of overheating. After cooling down, the power supply is restored.

The cooling time until the engine restarts can be up to 150 minutes.

We recommend the use of a dry-running protection device (see special accessories) for regular protection against water shortage.

Risk of injury, the system is pressurised!

When opening a pressurised system, you can be injured by flying parts.

Depressurise the device before opening the connections (for pressure, see chapter Technical data)

Switch off the device at the ON/OFF switch.

Unplug the device at the mains plug.

Danger of electric shock.

Always switch the device off and disconnect the mains plug before working on the device.

The device is maintenance-free.

Open and close connected stop valves for pressure relief.

The system is depressurised.

Rinse the pump with clear water after each use when pumping water with additives.

Check the pressure of the air filling in the storage tank every six months, if necessary top up to 2.0 bar when the device is switched off/depressurised (unplug the device, open the water tap)

The type plate is located below the cover. Unscrew the cover in an anti-clockwise direction.

Risk of injury

Risk of injury from falling device.

When transporting the device, observe the weight of the device (see chapter Specifications) and secure it accordingly when transporting it in vehicles.

Risk of injury and damage!

The device may tip over on sloping surfaces.

Be aware of the weight of the device during storage.

Empty the device completely before storage.

Store the device in a frost-protected place.

You will find the possible special accessories on the last page of these operating instructions.

Malfunctions often have simple causes that you can remedy yourself using the following overview. When in doubt, or in the case of malfunctions not mentioned here, please contact your authorised Customer Service.

Pump is running, but not delivering

Cause:

There is air in the pump.

Remedy:

See chapter Preparation

Cause:

The air cannot escape on the pressure side.

Remedy:

Open the tapping point on the pressure side.

Cause:

No water available.

Remedy:

Check the water reservoir.

The pump does not start up, or stops suddenly during operation

Cause:

The power supply is disconnected.

Remedy:

Check the fuses and the electrical connections.

Cause:

Thermal protection switch in the motor has switched off the pump due to overheating of the motor.

Remedy:

Pull out the mains plug.

Allow the pump to cool down.

Clean the suction area.

Prevent dry running.

The cooling time until the motor starts can be up to 150 minutes.

The pump switches itself off and also on again

Cause:

The thermal protection fuse has switched off the pump to protect it from overheating or switched it on again after it has cooled down.

Remedy:

To prevent recurrence, the system should be checked for leaks and sealed.

The motor restarts immediately after switching off

Cause:

The pressure in the system is lost.

Remedy:

Check the connections including seals and check for water leakage. The slightest leakage affects operation.

Cause:

The air pressure in the storage tank is too low.

Remedy:

Fill the storage tank with 2.0 bar (see chapter Care and maintenance).

Cause:

The return valve does not close properly.

Remedy:

Check the check valve on the suction side.

Cause:

The membrane in the pressure tank is defective.

Remedy:

Have the membrane replaced.

The pump capacity drops or is too low

Cause:

The suction filter or the check valve (special accessory) are contaminated.

Remedy:

Clean the suction filter or the check valve (special accessory).

Cause:

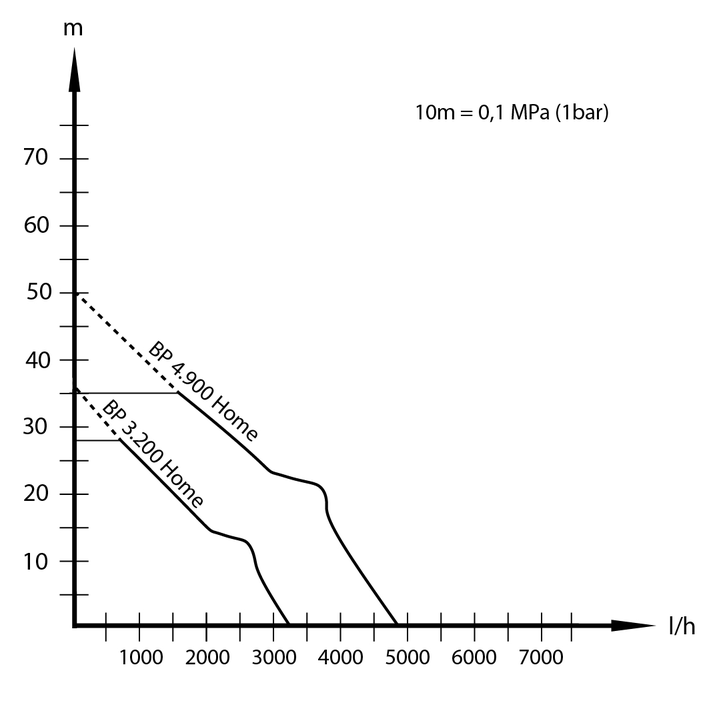

The delivery rate of the pump depends on the delivery head and the connected periphery.

Remedy:

Observe the max. delivery head (see chapter Specifications) Select a different hose diameter or a different hose length if necessary.

Vibrating noise during water removal

Cause:

The membrane in the pressure tank vibrates.

Remedy:

An operating noise that can be eliminated by reducing the pressure of the air filling in the storage tank.

Mains voltage | 230-240 V |

Power frequency | 50 Hz |

Nominal power | 600 W |

Device performance data | |

Maximum flow rate | 3200 l/h |

Suction height (max.) | 8 m |

Pressure (max.) | 3,6 MPa (bar) |

Max. pressure of the air filling in the storage tank | 0.18 - 0.2 (1.8 - 2.0) MPa (bar) |

Max. permissible inner pressure in the storage tank | 0.50 (5.0) MPa (bar) |

Delivery height (max.) | 28 m |

Dimensions and weights | |

Weight (without accessories) | 10,5 kg |

Mains voltage | 230-240 V |

Power frequency | 50 Hz |

Nominal power | 1150 W |

Device performance data | |

Maximum flow rate | 4900 l/h |

Suction height (max.) | 8 m |

Pressure (max.) | 5,0 MPa (bar) |

Max. pressure of the air filling in the storage tank | 0.18 - 0.2 (1.8 - 2.0) MPa (bar) |

Max. permissible inner pressure in the storage tank | 0.50 (5.0) MPa (bar) |

Delivery height (max.) | 35 m |

Dimensions and weights | |

Weight (without accessories) | 13,9 kg |

EU Declaration of Conformity |

We hereby declare that the machine described below complies with the relevant basic safety and health requirements in the EU Directives, both in its basic design and construction as well as in the version placed in circulation by us. This declaration is invalidated by any changes made to the machine that are not approved by us.

Product: Pump

Type: 1.645-xxx

Currently applicable EU Directives2014/35/EU

2014/30/EU

2011/65/EU

2009/125/EC

Commission Regulation(s)(EU) 2019/1781

Harmonised standards usedEN 60335-1

EN 60335-2-41

EN 62233: 2008

EN 55014-1: 2017 + A11: 2020

EN 55014-2: 1997+A1: 2001+A2: 2008

EN 61000-3-2: 2014

EN 61000-3-3: 2013

EN IEC 63000: 2018

The signatories act on behalf of and with the authority of the company management.

Documentation supervisor:

S. Reiser

Alfred Kärcher SE & Co. KG

Alfred-Kärcher-Str. 28 - 40

71364 Winnenden (Germany)

Ph.: +49 7195 14-0

Fax: +49 7195 14-2212

Winnenden, 2021/06/01

Declaration of Conformity (UK) |

We hereby declare that the product described below complies with the relevant provisions of the following UK Regulations, both in its basic design and construction as well as in the version put into circulation by us. This declaration shall cease to be valid if the product is modified without our prior approval.

Product: Pump

Type: 1.645-xxx

Currently applicable UK RegulationsS.I. 2016/1101 (as amended)

S.I. 2016/1091 (as amended)

S.I. 2012/3032 (as amended)

S.I. 2010/2617 (as amended)

Commission Regulation(s)(EU) 2019/1781

Designated standards usedEN 60335-1

EN 60335-2-41

EN 62233: 2008

EN 55014-1: 2017 + A11: 2020

EN 55014-2: 1997+A1: 2001+A2: 2008

EN 61000-3-2: 2014

EN 61000-3-3: 2013

EN IEC 63000: 2018

The signatories act on behalf of and with the authority of the company management.

Documentation supervisor:

S. Reiser

Alfred Kärcher SE & Co. KG

Alfred-Kärcher-Str. 28 - 40

71364 Winnenden (Germany)

Ph.: +49 7195 14-0

Fax: +49 7195 14-2212

Winnenden, 2021/06/01