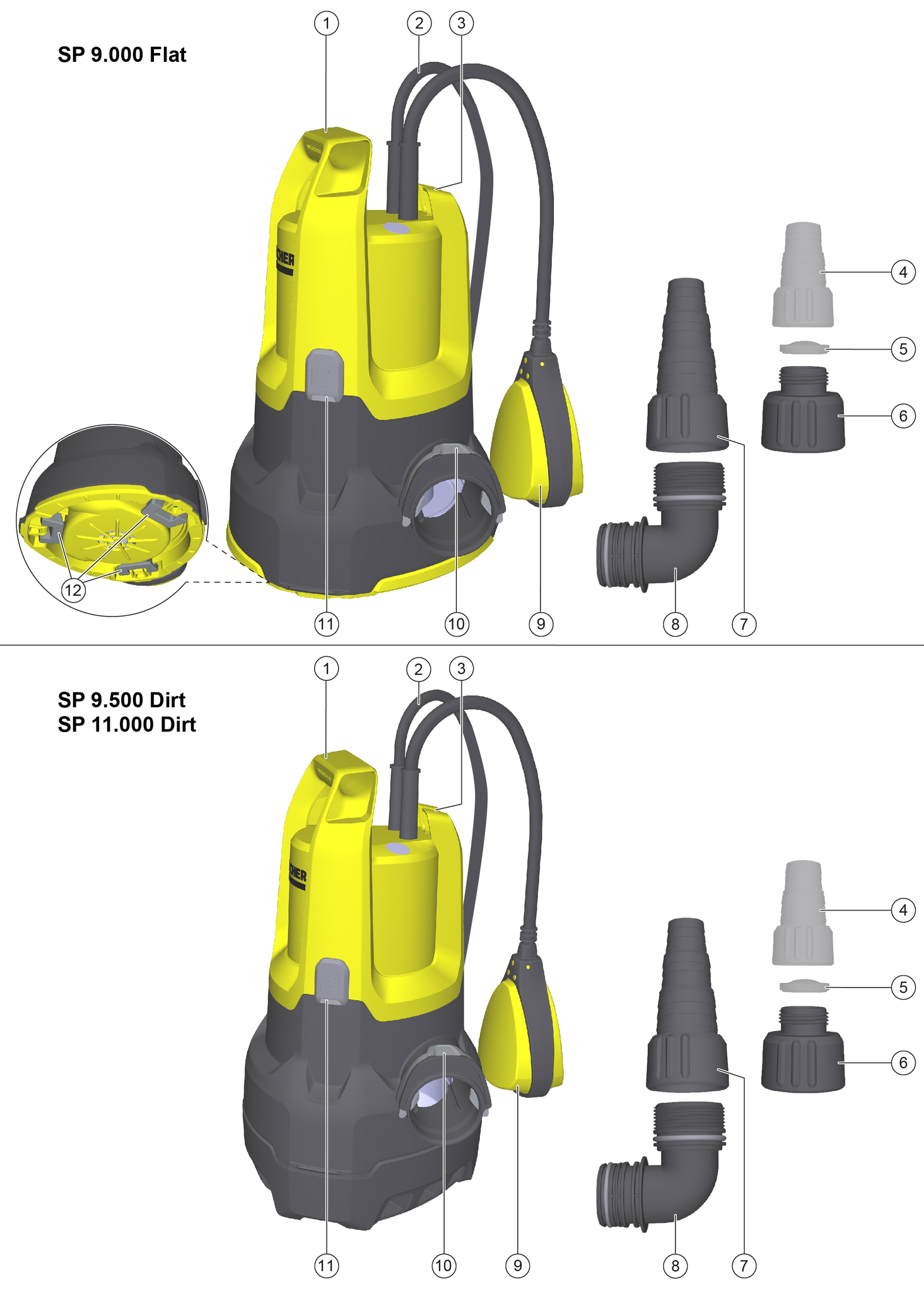

SP 9.000 FlatSP 9.500 DirtSP 11.000 Dirt

5.991-036.0 (07/22)

5.991-036.0 (07/22)

Read these original operating instructions and the enclosed safety instructions before using the device for the first time. Proceed accordingly.

Read these original operating instructions and the enclosed safety instructions before using the device for the first time. Proceed accordingly.

Keep both books for future reference or for future owners.

Only use the device in private households.

Intended use:

Removal of water from building sections in the event of flooding

Transferring and pumping water from containers

Water removal from wells and shafts

Pumping fresh water out of boats and yachts

For notes on functional principle, see chapter Operation.

Danger of death and risk of damage when pumping explosive, flammable or unsuitable substances!

Flammable or explosive substances may ignite or explode.

Unsuitable substances can damage the pump.

Do not pump explosive, flammable or corrosive liquids or gases (e.g. fuels, petroleum, nitro thinner) and do not pump fats, oils, salt water or waste water from sanitary facilities or water that has a lower flowing ability than clean water.

Permissible feed fluids:

Fresh water up to the specified degree of contamination

SP 9,500 Dirt and SP 11,000 Dirt (dirty water pump):

Water with a degree of contamination up to a diameter of 20 mm

SP 9,000 Flat (clean water pump):

Water with a degree of contamination up to a diameter of 5 mm

Swimming pool water with intended dosage of additives

Washing lye, e.g. from leaking washing machines. Afterwards, rinse and clean the pump with clear fresh water, see chapter Rinsing and cleaning.

The temperature of the feed fluids should lie between 5 °C and 35 °C

Risk of damage due to frost!

Operation during frost may damage the device.

An incompletely emptied device can be damaged by frost.

Do not operate the device during frost.

Protect the device from frost.

Risk of damage during continuous operation!

The device is not suitable for continuous operation.

Do not operate the device continuously for long periods (e.g. continuous circulation operation in ponds) or as a stationary installation (e.g. as a water lifting system, fountain pump).

The manufacturer accepts no liability for possible damage caused by improper use or incorrect operation.

Indication of an imminent threat of danger that will lead to severe injuries or even death.

Indication of a potentially dangerous situation that may lead to severe injuries or even death.

Indication of a potentially dangerous situation that may lead to minor injuries.

Indication of a potentially dangerous situation that may lead to damage to property.

The packing materials can be recycled. Please dispose of packaging in accordance with the environmental regulations.

The packing materials can be recycled. Please dispose of packaging in accordance with the environmental regulations.

Electrical and electronic appliances contain valuable, recyclable materials and often components such as batteries, rechargeable batteries or oil, which - if handled or disposed of incorrectly - can pose a potential threat to human health and the environment. However, these components are required for the correct operation of the appliance. Appliances marked by this symbol are not allowed to be disposed of together with the household rubbish.

Electrical and electronic appliances contain valuable, recyclable materials and often components such as batteries, rechargeable batteries or oil, which - if handled or disposed of incorrectly - can pose a potential threat to human health and the environment. However, these components are required for the correct operation of the appliance. Appliances marked by this symbol are not allowed to be disposed of together with the household rubbish.

Current information on content materials can be found at: www.kaercher.com/REACH

Only use original accessories and original spare parts. They ensure that the appliance will run fault-free and safely.

Information on accessories and spare parts can be found at www.kaercher.com.

The scope of delivery for the appliance is shown on the packaging. Check the contents for completeness when unpacking. If any accessories are missing or in the event of any shipping damage, please notify your dealer.

The warranty conditions issued by our sales company responsible apply in all countries. We shall remedy possible malfunctions on your device within the warranty period free of cost, provided that a material or manufacturing defect is the cause. In a warranty case, please contact your dealer (with the purchase receipt) or the next authorised customer service site.

(See overleaf for the address)

*Not included in the scope of delivery.

Risk of electric shock and risk of injury!

The device contains electrical and mechanical components.

Always disconnect the device from the power supply before assembling, disassembling or cleaning.

The shorter the hose length and larger the hose diameter, the higher the pump capacity.

To avoid clogging the pump, use a pre-filter for hose diameters smaller than 1 ¼″.

The pump connection is equipped with a plug-in system (Quick-Connect).

The pipe union with pump connecting piece G 1 ½ and the G 1 threaded connection are supplied unassembled with the device.

Hoses with a diameter of 1″, 1 ¼″ and 1 ½″ can be connected to the pump connecting piece G 1 ½.

A sufficiently large hose diameter must be selected and the pump connecting piece G 1 ½ must be shortened according to the grooves so that the required particle size can be used. A large hose diameter is also recommended for smaller particle sizes to allow a high flow volume.

Connect hose to pump if using a 1″, 1 ¼″ or 1 ½″ hose:

Screw the pump connecting piece G 1 ½ onto the pipe union.

Push the hose clamp onto the hose.

Push the hose onto the pump connecting piece G 1 ½ and fasten it with a hose clamp.

Push the pipe union into the Quick-Connect.

Connect hose to pump if using a ¾″ or 1″ hose:

Screw the G1 threaded connection onto the pipe union.

Fit the special accessory pump connecting piece G 1 (6.997-359.0 pump connecting piece G 1 (33.3 mm) incl. check valve - not included in the scope of delivery) onto the G 1 threaded connection:

Place the check valve on the G 1 threaded connection so that the lettering ‘UP’ is legible.

Screw the pump connecting piece G 1 onto the G 1 threaded connection.

Push the hose clamp onto the hose.

Push the hose onto the pump connecting piece G 1 and fasten it with a hose clamp.

Push the pipe union into the Quick-Connect.

Setting up / immersing the pump:

Fold out or in the feet (SP 9,000 Flat).

Place the pump securely on solid ground in the feed fluid or immerse it by means of a rope attached to the carrying handle.

The suction area must not be blocked by contamination. If the ground is muddy, place the pump on a brick or something similar. Make sure that the pump is horizontal. Do not carry the pump using the cable or hose.

Danger of death from electric shock.

Danger of death from electric shock if live parts are touched.

During operation, do not touch the rope attached to the carrying handle or any objects that are in contact with the pumped liquid (e.g. pipelines protruding into the pumped liquid, railings) and do not reach into the pumped liquid.

If the fluid level is low, any sucked-in air, or air present in the pump, may escape via the automatic venting device. Fluid can also leak along with air.

If the pump has problems with suction when the fluid level is low, unplug and plug in the mains plug repeatedly to assist the suction process.

If necessary, fold out the feet, see chapter Initial startup (SP 9,000 Flat).

Folding out the feet is not absolutely necessary, but it does increase the pump capacity.

Plug the mains plug into a mains socket.

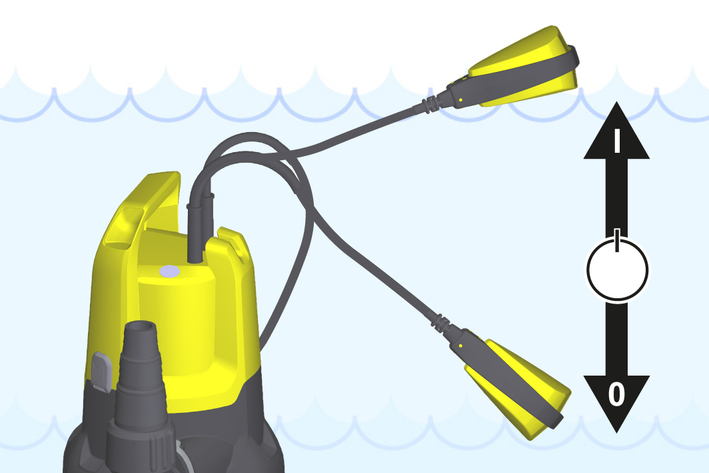

In automatic mode, the float switch controls the pumping process automatically.

The pump switches on as soon as the float switch has reached the switch-on height caused by the rising fluid level.

The pump switches off as soon as the float switch has reached the switch-off height caused by the sinking fluid level.

The float switch must be able to move freely.

Min / Max | SP 9,000 Flat | SP 9,500 Dirt | SP 11,000 Dirt |

|---|---|---|---|

Switch-on height cm* | 36 / 44 | 43 / 50 | 43 / 50 |

Switch-off height cm* | 15 / 24 | 18 / 30 | 18 / 30 |

* The switching heights vary depending on the position of the float switch.

In manual operation, the pump stays switched on continuously. For the pump to suction itself in manual mode, the fluid level must be at least 60 mm (SP 9,500 Dirt and SP 11,000 Dirt) or 7 mm (SP 9,000 Flat).

The pump can pump up to a residual fluid height of 25 mm (SP 9,500 Dirt and SP 11,000 Dirt) or 1 mm (SP 9,000 Flat).

The specified residual fluid heights are only achieved in manual operation.

The float switch must be able to move freely.

Fold in the feet, see chapter Initial startup (SP 9,000 Flat).

By folding in the feet, flat suction of the fluid up to 1 mm residual fluid height is possible in manual operation.

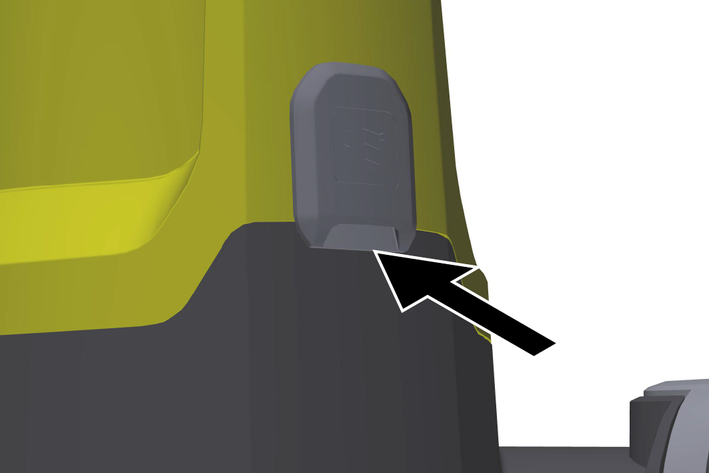

Fasten the float switch in the lock so it points upwards.

Risk of damage from dry running!

Dry running leads to increased wear on the pump.

Do not leave the pump unattended in manual operation.

In case of dry running, immediately pull the mains plug out of the socket.

Plug the mains plug into a mains socket.

Pull the mains plug out of the socket.

The device stops.

Risk of damage!

Risk of damage due to dried soiling or additives.

Rinse and clean the device immediately after each use.

If dirty liquids or liquids with additives have been pumped, rinse and clean the device immediately after finishing operation, see chapter Rinsing and cleaning.

Drain the device and accessories and let them dry.

Risk of electric shock and risk of injury!

The device contains electrical and mechanical components.

Cleaning and user maintenance may not be carried out by children.

Risk of damage!

Risk of damage due to dried soiling or additives.

Rinse and clean the device immediately after each use.

If dirty liquids or liquids with additives have been pumped, the device must be rinsed afterwards: Use the device to pump clear fresh water without additives until all soiling or additives have been flushed out of the device.

Risk of electric shock and risk of injury!

The device contains electrical and mechanical components.

Always disconnect the device from the power supply before assembling, disassembling or cleaning.

Pull the mains plug out of the socket.

Press the Quick-Connect button and remove the connection nozzle.

Where necessary, remove residue from the hose and on Quick-Connect.

Clean the outside of the device with a soft, clean cloth and clear fresh water.

Drain the device and accessories and let them dry.

The device is maintenance-free.

Manual transport

Risk of injury from tripping!

There is a risk of injury from tripping on loose cables and hoses.

Be careful of cables and hoses when moving the device.

Lift and carry the device by the carrying handle.

Transport in vehicles

Risk of injury, risk of damage!

Note the weight of the device during transport.

Store or secure the device in accordance with applicable guidelines so that it cannot slip or be thrown around during transport.

When transporting the device in vehicles, secure it to prevent it from slipping or overturning in accordance with the respectively applicable guidelines.

Risk of damage due to frost!

An incompletely emptied device can be damaged by frost.

Completely empty the device and accessories before storing them.

Protect the device from frost.

Store the device in a frost-free place and not outdoors.

Risk of injury and damage!

The device may tip over on sloping surfaces.

Be aware of the weight of the device during storage.

Completely empty the pump and accessories.

Allow the pump and accessories to dry out.

Store the pump in a frost-protected place.

Malfunctions often have simple causes that you can remedy yourself using the following overview. When in doubt, or in the case of malfunctions not mentioned here, please contact your authorised Customer Service.

Pump is running, but not delivering

Cause:

Air is in the pump.

Remedy:

Check for correct startup (see chapter Initial startup and Operation).

Cause:

Dirt particles block the suction area.

Remedy:

Pull the mains plug out of the socket.

Clean the suction area.

Cause:

The fluid level is too low (manual operation), see chapter Technical data.

Remedy:

Immerse the pump deeper into the feed fluid, see chapter Manual operation .

The pump does not start or stops during operation

Cause:

The power supply is disconnected.

Remedy:

Check the fuses and the electrical connections.

Cause:

The thermal protection switch has switched off the pump because of overheating.

Remedy:

Pull the mains plug out of the socket.

Allow the pump to cool down.

Clean the suction area.

Prevent the pump from running dry.

Cause:

Dirt particles are trapped in the suction area.

Remedy:

Pull the mains plug out of the socket.

Clean the suction area.

Cause:

The float switch switches the pump off.

Remedy:

Automatic mode: Check the position and free movement of the float switch and correct if necessary, see chapter Automatic mode .

Manual operation: Attach the float switch correctly, see chapter Manual operation .

The pump capacity drops or is too low

Cause:

The suction area is clogged.

Remedy:

Pull the mains plug out of the mains socket and clean the suction area.

Cause:

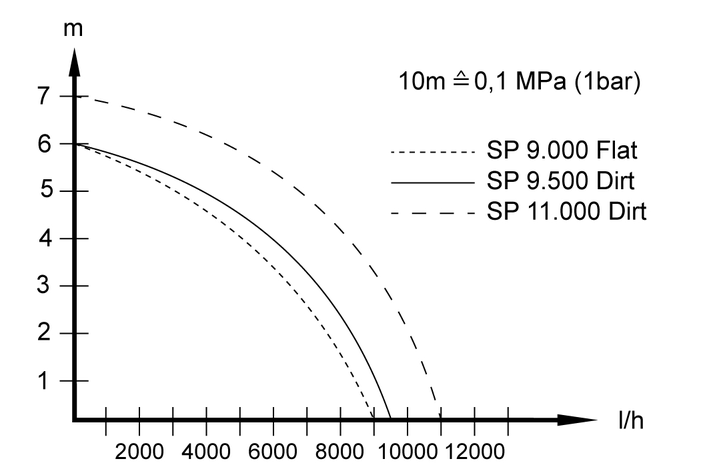

The delivery rate of the pump depends on the delivery head and the connected periphery.

Remedy:

Observe the maximum delivery height, see chapter Technical data. If necessary, select a larger hose diameter or shorter hose length.

Cause:

The cross-section on the pressure side is narrowed, e.g. due to the valve/ball tap not being fully open.

Remedy:

Fully open the valve / ball tap.

Cause:

The pressure side hose is kinked.

Remedy:

Eliminate the kink points in the hose.

Quick-Connect cannot be opened

Cause:

The Quick-Connect plug system is blocked by contamination.

Remedy:

Remove the clip and clean it.

Device performance data | |

Mains voltage | 230-240 V |

Power frequency | 50 Hz |

Nominal power | 280 W |

Maximum flow rate | 9.000 l/h |

Pressure (max.) | 0,06 (0,6) MPa (bar) |

Delivery height (max.) | 6 m |

Immersion depth (max.) | 7 m |

Perm. temp. feed fluid | 5...35 °C |

Particle size (max.) of permissible feed fluids | 5 mm |

Minimum fluid level (manual mode) | 7 mm |

Residual fluid height | 1 mm |

Weight (without accessories) | 3,7 kg |

Device performance data | |

Mains voltage | 230-240 V |

Power frequency | 50 Hz |

Nominal power | 280 W |

Maximum flow rate | 9.500 l/h |

Pressure (max.) | 0,06 (0,6) MPa (bar) |

Delivery height (max.) | 6 m |

Immersion depth (max.) | 7 m |

Perm. temp. feed fluid | 5...35 °C |

Particle size (max.) of permissible feed fluids | 20 mm |

Minimum fluid level (manual mode) | 60 mm |

Residual fluid height | 25 mm |

Weight (without accessories) | 3,8 kg |

Mains voltage | 230-240 V |

Power frequency | 50 Hz |

Nominal power | 400 W |

Maximum flow rate | 11.000 l/h |

Pressure (max.) | 0,07 (0,7) MPa (bar) |

Delivery height (max.) | 7 m |

Immersion depth (max.) | 7 m |

Perm. temp. feed fluid | 5...35 °C |

Particle size (max.) of permissible feed fluids | 20 mm |

Minimum fluid level (manual mode) | 60 mm |

Residual fluid height | 25 mm |

Weight (without accessories) | 4,4 kg |

The flow rate is further increased:

The lower the delivery height is.

The greater the diameter of the hose used is.

The shorter the hose used is.

The smaller the pressure loss caused by the connected up accessories.

EU Declaration of Conformity |

We hereby declare that the machine described below complies with the relevant basic safety and health requirements in the EU Directives, both in its basic design and construction as well as in the version placed in circulation by us. This declaration is invalidated by any changes made to the machine that are not approved by us.

Product: Pump

Type: 1.645-xxx

Currently applicable EU Directives2014/35/EU

2014/30/EU

2011/65/EU

2009/125/EC

Commission Regulation(s)(EU) 2019/1781

Harmonised standards usedEN 60335-1

EN 60335-2-41

EN 62233: 2008

EN 55014-1: 2017 + A11: 2020

EN 55014-2: 2015

EN 61000-3-2: 2014

EN 61000-3-3: 2013

EN IEC 63000: 2018

The signatories act on behalf of and with the authority of the company management.

Documentation supervisor:

S. Reiser

Alfred Kärcher SE & Co. KG

Alfred-Kärcher-Str. 28 - 40

71364 Winnenden (Germany)

Ph.: +49 7195 14-0

Fax: +49 7195 14-2212

Winnenden, 2021/06/01

Declaration of Conformity (UK) |

We hereby declare that the product described below complies with the relevant provisions of the following UK Regulations, both in its basic design and construction as well as in the version put into circulation by us. This declaration shall cease to be valid if the product is modified without our prior approval.

Product: Pump

Type: 1.645-xxx

Currently applicable UK RegulationsS.I. 2016/1101 (as amended)

S.I. 2016/1091 (as amended)

S.I. 2012/3032 (as amended)

S.I. 2010/2617 (as amended)

Commission Regulation(s)(EU) 2019/1781

Designated standards usedEN 60335-1

EN 60335-2-41

EN 62233: 2008

EN 55014-1: 2017 + A11: 2020

EN 55014-2: 2015

EN 61000-3-2: 2014

EN 61000-3-3: 2013

EN IEC 63000: 2018

The signatories act on behalf of and with the authority of the company management.

Documentation supervisor:

S. Reiser

Alfred Kärcher SE & Co. KG

Alfred-Kärcher-Str. 28 - 40

71364 Winnenden (Germany)

Ph.: +49 7195 14-0

Fax: +49 7195 14-2212

Winnenden, 2021/06/01

4-2-SC-A5-GS-12579