HD 4/8 Classic HD 4/10 X Classic

97687300 (01/22)

97687300 (01/22)

Read these safety instructions and the original instructions before using the device for the first time. Act in accordance with them. Keep the two booklets for future reference or for future owners.

Read these safety instructions and the original instructions before using the device for the first time. Act in accordance with them. Keep the two booklets for future reference or for future owners.

In addition to the notes in the operating instructions, you also need to take into consideration the general safety regulations and accident prevention guidelines applicable by law.

Warnings and information notices attached to the device provide important information for hazard-free operation.

Indication of an imminent threat of danger that will lead to severe injuries or even death.

Indication of a potentially dangerous situation that may lead to severe injuries or even death.

Indication of a potentially dangerous situation that may lead to minor injuries.

Indication of a potentially dangerous situation that may lead to damage to property.

Wear suitable gloves when working with the device.

Aerosols can be formed when using high-pressure cleaners. Inhaling aerosols can be harmful for your health. Employers are obliged to perform a hazard assessment in order to define, depending on the surface to be cleaned and the environment, protective measures necessary to prevent inhalation of aerosols. Respiratory protection masks of class FFP 2 or above are suitable for protection against aqueous aerosols.

Wear suitable personal protective equipment when working, as specified in the EC Directive 89/686/EC: Hard hat, safety goggles, face protection, encapsulated hearing protection, protective gloves, protective gloves, protective trousers (protective overalls), safety boots. The protective clothing only provides protection from spray water and flying particles. It does not protect you from direct contact with the high-pressure jet.

Risk of asphyxiation. Keep packaging film out of the reach of children.

Only use the device for its proper use. Take into account the local conditions and beware of third parties, in particular children, when working with the device.

The device is not intended for use by persons with restricted physical, sensory or mental abilities or those lacking in experience and / or lacking in knowledge.

Only people who have been instructed on how to use the device, or have proven their ability to operate it, and have been explicitly instructed to use it, must use the device.

Children must be supervised to prevent them from playing with the appliance.

Children and minors must not use the device.

Safety devices are provided for your own protection. Never modify or bypass safety devices.

Only connect protection class I devices to properly earthed power sources.

The voltage indicated on the type plate must match the voltage of the power source.

Take into account the minimum protection required for the socket, see chapter Technical data in the operating instructions.

Only operate the device via a fault current protection switch (maximum 30 mA).

Use a plug to connect the device to the mains grid. Permanent connection to the mains grid is prohibited. The plug is used for disconnection from the mains.

Never touch the mains plug and socket with wet hands.

The mains plug and coupling of the extension cable must be water tight and may not be placed in water. The coupling may not be on the floor. Use cable drums to ensure that the sockets are at least 60 mm above the floor.

All live parts in the work area must be protected against water jets.

Only connect the device to an electrical connection which has been set up by a qualified electrician as per IEC 60364‑1.

Check the power supply cable with mains plug for damage before operation each time. Do not put the device into operation with a damaged power supply cable. Have a damaged power supply cable replaced immediately by the authorised customer service / qualified electrician.

Do not damage the power supply and extension cable by running over it, crushing or yanking it or similar. Protect the power supply cable from heat, oil and sharp edges.

Only use the mains connection cable prescribed by the manufacturer, including when replacing the cable. For order no. and type see operating instructions.

Unsuitable electrical extension cables can be dangerous. Only use approved and appropriately marked electrical extension cables with a sufficient cable cross section for outdoors.

Use only a splash-protected extension cable with the cross-section specified in the operating instructions. Prevent any connections from lying in water.

Only replace couplings on the power supply or extension cable using those with the same water density and the same mechanical strength.

Do not clean the device with a high pressure water jet or low pressure water stream.

In case of longer breaks in operation and after use, switch off the device at the main switch / device switch and pull the mains plug.

Switch-on procedures will generate short-term voltage drops.

Unfavourable mains conditions may cause other devices to be impaired.

In case of a network impedance of less than 0.15 ohms, no malfunctions are to be expected.

Use only hose lines rated for the operating pressure, mechanical loads and chemical loads present.

The screw connections of all connection hoses must be leak-tight.

Do not exceed the maximum permissible water supply temperature.

Route the hose lines in a safe manner.

Do not bend the hose lines beyond the minimum permissible bending radius.

Replace the hose lines at appropriate intervals, even when no defects are visible. Hose lines have a limited service life.

Observe the regulations at your water distribution company.

The device must not be started up if the high-pressure hose is damaged. Replace a damaged high-pressure hose at once. Only those hoses and connections recommended by the manufacturer may be used. For order no. see operating instructions.

Do not subject the hose lines to mechanical, chemical or thermal loads.

The screw connections of all high-pressure hoses must be leak-tight.

Tighten the screw connections to a maximum tightening torque of 20 Nm.

Use a hose catching fixture.

Use only high-pressure hoses and accessories having a rated operating pressure of at least the same as the device.

Check the high-pressure hoses daily.

Do not use kinked high-pressure hoses.

Do not use high-pressure hoses having a visible outer wire mesh.

Do not use high-pressure hoses having a damaged thread.

Do not use high-pressure hoses that have been driven over or subjected to impacts, even if no damage is visible.

Route high-pressure hoses so that they cannot be driven over.

Use hose sleeves, protective covers or shields to eliminate hazards presented by the hose lines.

Leaking fluid can cause injuries. Do not search for leaks with your bare hands.

Store the high-pressure hoses so that they are not subjected to any mechanical loads.

Incorrect initial startup of an ultra-high-pressure cleaner is dangerous and can to lead to severe injuries or death in some cases.

Observe the legislature’s national accident prevention regulations. Liquid jet cleaners must be tested regularly and the results of the test recorded in writing.

Observe the local accident prevention guidelines and the safety instructions.

Operate the device only when all hoods, covers and electrical cabinets are closed.

Never leave the device unsupervised while it is in operation.

In the case of an energy supply malfunction, switch off the device to prevent it from restarting uncontrollably when the malfunction has been corrected.

Secure the device to prevent unauthorised use during work breaks.

Eliminate dangerous situations immediately.

Do not work with the device when under the influence of medication of alcohol.

Secure the work area in a clearly visible manner against unauthorised access. Erect warning signs and cordon off the area. Only the operator is permitted to be present in the work area (within a radius of 10 m).

Take suitable measures to secure yourself against falling when working on scaffolding. The recoil forces occurring present a risk of falling.

Always stand on stable ground when working. You must always be standing securely.

Keep the work area clean and tidy.

Observe the applicable national work safety regulations when working in enclosed spaces.

Adjust the nozzle and operating pressure to suit each other so that the resulting recoil force can be kept under control by the operator. The recoil force must not exceed 250 N (25 kp).

Equip a manually held spray unit with a body support if the recoil force exceeds 150 N (15 kp).

Use only pipe cleaning accessories having a marking allowing timely recognition of the nozzle outlet. The clearance between the nozzle and marking should be 500 mm.

Insert pipe cleaning accessories at least 500 mm into the pipe to be cleaned before activating the high-pressure jet.

When using the device in hazard zones (e.g. service stations), adhere to the respective safety regulations.

Operation in explosive atmospheres is prohibited.

Never suction solvents, liquids containing solvents or undiluted acids. This includes e.g. petrol, paint thinner or heating oil. The spray mist is highly flammable, explosive and poisonous.

A recoil force will arise due to the water stream ejecting from the spray lance. An angular spray lance produces a force that acts in upward direction. Make sure you grip the gun and spray lance firmly.

Do not aim the high-pressure jet at yourself, e.g. to clean clothes or shoes.

Do not direct the high-pressure jet at persons, animals, live electrical equipment or at the device itself.

Do not spray any objects which contain harmful substances (e.g. asbestos).

Check the device and the accessories, such as the high-pressure hose, high-pressure gun and safety devices, to make sure they are in proper safe and reliable condition before each operation. Do not use the device if it is damaged. Replace damaged components immediately.

Never leave the device unsupervised while it is in operation.

Never open the cover while the motor is running.

Never clamp the lever of the high-pressure gun during operation.

The device must be placed on an even, firm subsurface.

Do not operate the device at temperatures below 0 °C.

Keep the detergent out of the reach of children.

When using detergents, observe the safety data sheet of the detergent manufacturer, in particular instructions on protective gear.

Only use the detergents supplied or specified by the manufacturer. The use of other detergents or chemicals can impair the safety of the device.

Never use the recommended detergents undiluted. These products are operationally safe since they do not contain any acids, alkali or substances that are harmful to the environment. Should detergents come into contact with eyes, rinse these out immediately and thoroughly using water and seek medical attention immediately. The same applies if detergents are swallowed.

Using the device for longer periods can cause poor circulation in the hands due to vibrations. A general period of use cannot be set, because this depends on several influencing factors:

Personal tendency to suffer from poor circulation (frequently cold fingers, tingling sensation in the fingers)

Low ambient temperature. Wear warm gloves to protect your hands.

Holding the device too tightly hindering blood circulation.

Continuous operation is more harmful than operation interrupted by work breaks.

You should see a doctor if using the device regularly and for lengthy periods of time, and in the event of repeated occurrences of symptoms such as tingling in the fingers or cold fingers.

In case of devices with screw-in wheel rims: Make sure that all wheel rim bolts are tightened securely before setting the tyre filling pressure.

Make sure that the pressure reducer is set correctly on the compressor before setting the tyre filling pressure.

Never exceed the maximum permissible tyre filling pressure. The tyre filling pressure needs to be read on the tyre and if necessary on the wheel rim. If these values differ, use the smaller value.

Explosion hazard due to unsuitable fuel. Only fill the fuel specified in the operating instructions.

Switch off the motor before refuelling.

Do not refuel in confined spaces.

Exhaust gases are toxic. Never breathe in the exhaust gases. Ensure rooms where the device is operated are sufficiently ventilated and that exhaust gases can be conducted away.

During tanking, make sure that no fuel gets on hot surfaces.

Clean up spilt fuel immediately.

Risk of burns. Never bend down over the exhaust gas opening and never reach inside it. Do not touch the heating boiler while the burner is in operation.

Never close off exhaust gas openings.

Make sure that no exhaust gases are emitted close to air vents.

Observe the safety instructions for petrol-driven devices in the operating instructions.

Prior to cleaning, maintenance and replacement of parts, the device needs to be switched off and the mains plug removed with mains operation devices.

Depressurise the high-pressure system prior to all work on the device or its accessories.

Repairs may only be carried out by approved customer service sites or staff qualified in this area who are familiar with all relevant safety instructions.

Do not operate the device again until all malfunctions have been eliminated.

Pay attention to the safety inspection for mobile devices for industrial use in accordance with the locally applicable regulations

Short-circuits or other damage. Do not clean the device with a hose or high-pressure water jet.

Do not use acetone, undiluted acids or solvents, as they corrode the materials used on the device.

Only use accessories and spare parts which are approved by the manufacturer. Only original accessories and original spare parts ensure that the appliance will run fault-free and safely.

Only have repairs and installation of spare parts performed by the approved Customer Service in order to prevent any hazards.

Switch off the device prior to transport. Secure the device, taking into account its weight. See chapter Technical Data in the operating instructions.

Risk of accidents and injuries. Take into account the weight of the device for transportation and storage. See chapter Technical data in the operating instructions.

Observe the applicable national road traffic regulations when transporting the device on public roads.

Use ropes, chains, tensioning devices and slinging gear equipped with retainers, conforming to the applicable regulations.

Read these original operating instructions and the enclosed safety instructions before using the device for the first time. Proceed accordingly.

Read these original operating instructions and the enclosed safety instructions before using the device for the first time. Proceed accordingly.

Keep both books for future reference or for future owners.

The high-pressure cleaner with high-pressure jet is intended only for the cleaning of objects, including:

Machines, vehicles, structures, tools, facades, terraces and garden equipment.

Detergent can be added with optional accessories. We recommend using a dirt blaster as a special accessory for stubborn soiling.

Dirty water

Premature wear and tear or deposits in the device

Supply the device using only clean water, or recycled water that does not exceed the specified limit values.

The following limit values apply to the water supply:

pH value: 6.5-9.5

Electrical conductivity: Conductivity of fresh water + 1200 µS/cm, maximum conductivity 2000 µS/cm

Settleable particles (sample volume 1 l, settling time 30 minutes): < 0.5 mg/l

Filterable particles: < 50 mg/l, no abrasive substances

Hydrocarbons: < 20 mg/l

Chloride: < 300 mg/l

Sulphate: < 240 mg/l

Calcium: < 200 mg/l

Total hardness: < 28 °dH, < 50° TH, < 500 ppm (mg CaCO3/l)

Iron: < 0.5 mg/l

Manganese: < 0.05 mg/l

Copper: < 2 mg/l

Active chloride: < 0.3 mg/l

Free of unpleasant odours

The packing materials can be recycled. Please dispose of packaging in accordance with the environmental regulations.

The packing materials can be recycled. Please dispose of packaging in accordance with the environmental regulations.

Electrical and electronic devices contain valuable, recyclable materials and often components such as batteries, rechargeable batteries or oil, which - if handled or disposed of incorrectly - can pose a potential danger to human health and the environment. However, these components are required for the correct operation of the device. Devices marked by this symbol are not allowed to be disposed of together with the household rubbish.

Electrical and electronic devices contain valuable, recyclable materials and often components such as batteries, rechargeable batteries or oil, which - if handled or disposed of incorrectly - can pose a potential danger to human health and the environment. However, these components are required for the correct operation of the device. Devices marked by this symbol are not allowed to be disposed of together with the household rubbish.

Current information on content materials can be found at: www.kaercher.de/REACH

Only use original accessories and original spare parts. They ensure that the appliance will run fault-free and safely.

Information on accessories and spare parts can be found at www.kaercher.com.

Check the contents for completeness when unpacking. If any accessories are missing or in the event of any shipping damage, please notify your dealer.

It is essential that you read the safety instructions 5.951-949.0 before initial start-up.

Observe the national regulations for liquid jet cleaners.

Observe the national accident prevention regulations. Liquid jet cleaners must be tested regularly. The test result must be recorded in writing.

Do not modify the device or accessories.

Missing or modified safety devices

Safety devices are provided for your own protection.

Never modify or bypass safety devices.

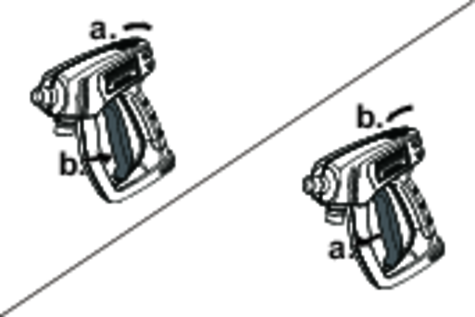

The safety lever on the high-pressure gun prevents the device from being switched on inadvertently.

If the high-pressure gun is closed, the overflow valve opens and the entire water volume will flow back to the pump suction side.

The overflow valve is set by the manufacturer and sealed. Setting shall only be carried out by Customer Service.

| Do not aim the high-pressure jet at persons, animals, live electrical equipment or the device itself. Protect the device against frost. |

| According to applicable regulations, the device must never be used with the drinking water network without a system separator. Ensure that the connection to your house water system, with which the high-pressure cleaner is operated, is equipped with a system separator according to EN 12729 type BA. Water that has flowed through a system separator is classified as undrinkable. Always connect the system separator to the water inlet and never directly to the device. |

| WARNINGThe high nozzle outlet speed of the high-pressure water jet results in a high noise level that can cause discomfort or hearing damage (e.g. tinnitus) to persons in the immediate vicinity. A continuously high noise level can result in deafness.

|

Danger of injury from electric shock

Only allow authorised technical specialists to install the water supply, electrical connections and high-pressure network.

Control elements for the cleaning process are yellow.

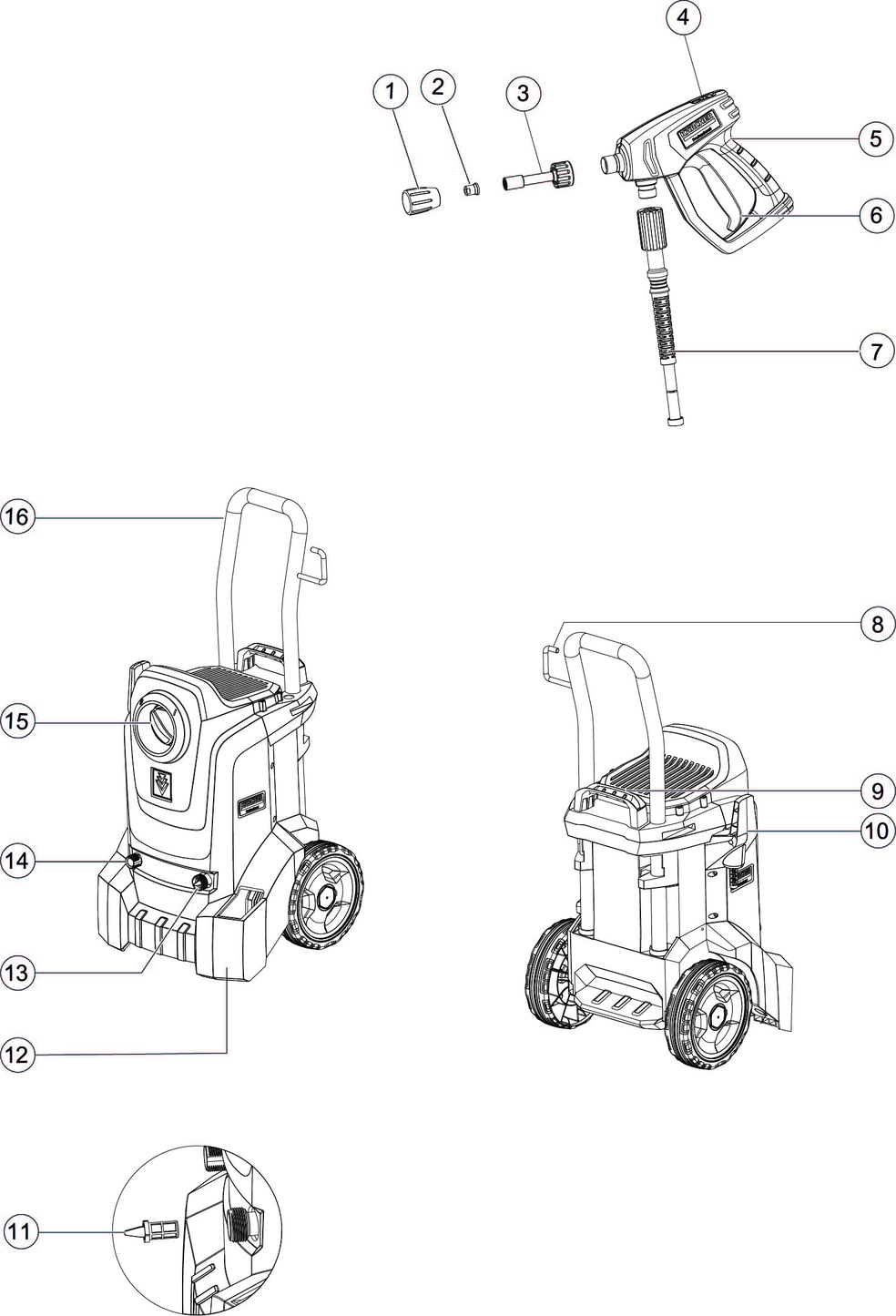

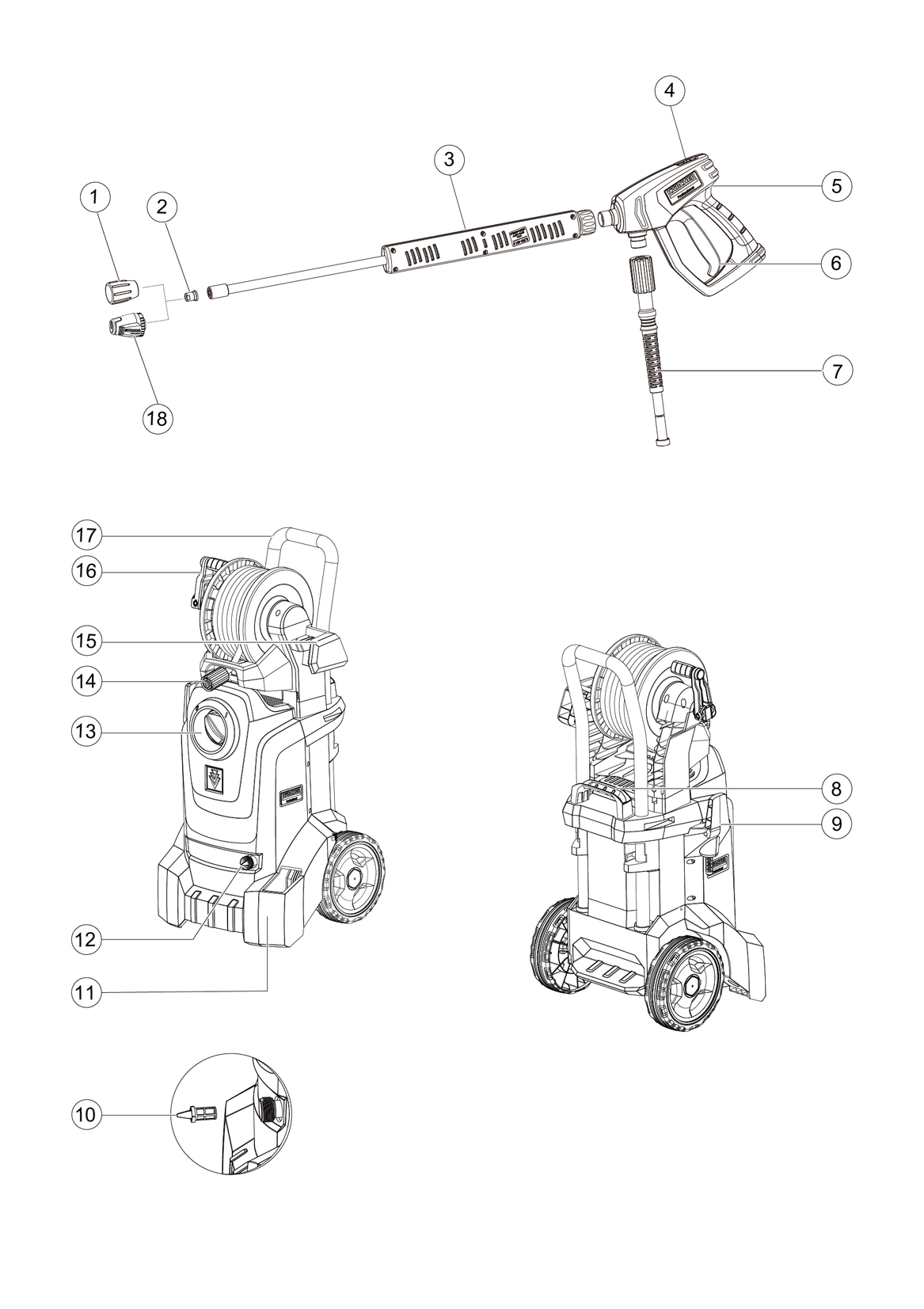

Check the contents of the package when unpacking.

Notify the dealer immediately in the case of shipping damage.

Install the nozzle with the nozzle screws at the spray lance.

Connect the spray lance to the high-pressure gun.

Screw the high-pressure hose to the high-pressure gun.

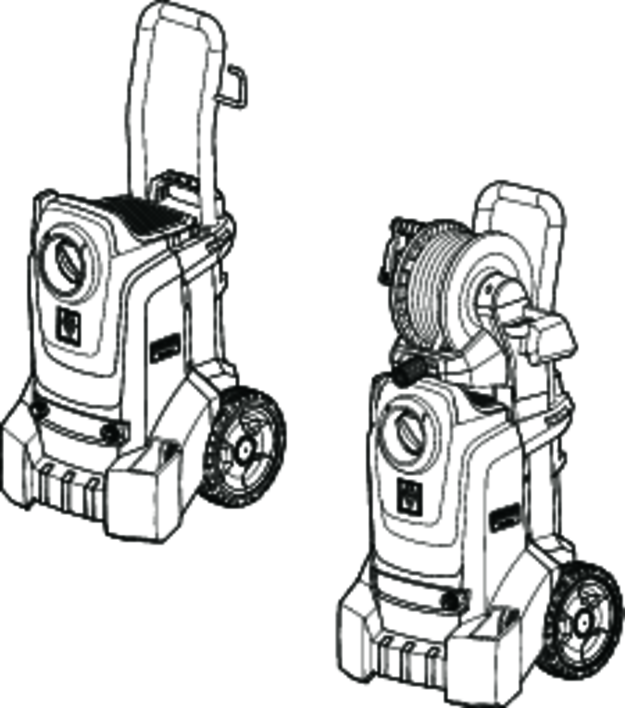

Only HD 4/8 Classic: Fasten the high-pressure hose to the water outlet.

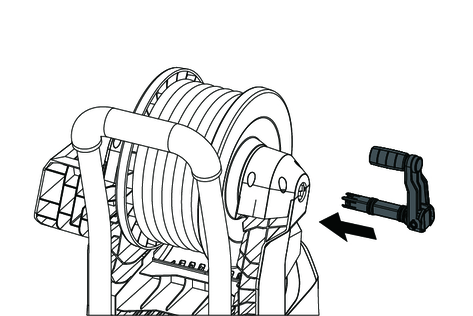

Only HD 4/10 X Classic: Push the hand crank into the hole of the hose reel and make sure the hand crank is secure.

Risk of injury from electric shock

Use a plug to connect the device to the mains grid. Permanent connection to the mains grid is prohibited. The plug is used for disconnection from the mains.

See the type plate or technical data for the connection values.

Unwind the mains cable and place it on the ground.

Plug the mains plug into the socket.

Health risk from return flow of contaminated water into the drinking water network.

Observe the regulations of your water supply company.

Check the feed pressure, input temperature and input amount of the water supply. See Chapter Technical data for the requirements.

Connect the system separator and water connection of the device with a hose (minimum length 7.5 m, minimum diameter 3/4”).

The supply hose is not included in the scope of delivery.

Open the water inlet.

Open the water inlet.

Remove the high-pressure nozzle.

Switch on the device.

Allow the device to run until the escaping water is free of air bubbles.

Switch off the device.

Fit the high-pressure nozzle.

Risk of explosion!

Do not spray flammable liquids.

If the device is used in hazardous areas (e.g. filling stations), the corresponding safety regulations must be observed.

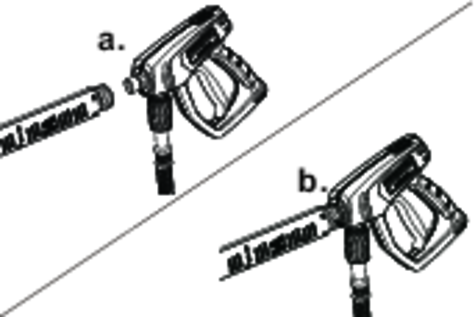

Push back the safety lock and actuate the trigger.

The high-pressure gun opens.

Release the trigger and push the safety lock forward.

Then the high-pressure gun closes.

The device can be operated vertically.

The device is equipped with a pressure switch. The motor only starts up when the high-pressure gun is open.

The high-pressure hose should be kept away from sharp edges.

For a device with the hose reel: unfold the high-pressure hose completely from the hose reel.

Open the water supply.

Set the power switch to "1".

Open the safety lock of the high-pressure gun.

Open the high-pressure gun.

Aim the high-pressure gun at the object to be cleaned and start the cleaning operation.

A foam lance (optional) is needed for operating with detergent.

Incorrect handling of detergents

Health risk

Adhere to the safety instructions stated on the detergent packaging.

Unsuitable detergents

Damage to the device and the objects to be cleaned

Use only detergents approved by KÄRCHER.

Observe the dosing recommendations and notes provided with the detergent.

Use detergents sparingly to help conserve the environment.

KÄRCHER detergents ensure fault-free operation. Please feel free to request a consultation, our catalogue or our detergent information sheets.

Fill the detergent into the container of the foam lance. (Follow the dosage instructions on the detergent bottle.)

Spray the detergent sparingly on the dry surface and let it work for a while (do not let it dry).

Rinse off the loosened dirt with the high-pressure jet.

Flush the foam lance with clear water for approx. 30 seconds.

Risk of injury!

Switch the device off prior to replacing nozzle and do not activate hand spray gun until the device is pressureless.

Secure the high-pressure gun. To do so, push the safety lever towards the front.

Unscrew nozzle screws and remove the nozzle.

Put on a new nozzle.

Screw on the nozzle screws and tighten them by hand.

When the device is shut down, the water pressure will be reduced, which can reduce the operating force of the high-pressure gun and improve the service life of the equipment.

Close the high-pressure gun, the device will interrupt.

Push the safety lock forward to close the safety lock of the high-pressure gun.

Push the safety lock back to open the safety lock of the high-pressure gun.

Open the high-pressure gun, the device will switch on again.

Shut off the water supply.

Open the high-pressure gun.

Set the power switch to "1" and let the device run for 5 to 10 seconds.

Set the power switch to "0" .

Close the high-pressure gun.

Unplug the power supply from the device with dry hands.

Remove water inlet.

Close the safety lever of the high-pressure gun and push the safety lock forward.

Failure to observe the weight

Risk of injury and damage

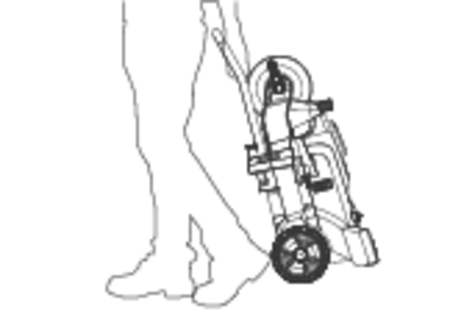

Be aware of the weight of the device during transportation.

Place the spray lance with the high-pressure gun on the hooks.

Wind the power cable around the cable hooks.

Without hose reel: Wind up the high-pressure hose and hang it over the hook.

With hose reel: Wind the high-pressure hose onto the hose reel.

When transporting the device in vehicles, secure the device against shifting and tipping over.

For short distance transportation, pull the telescopic handle to drag the device.

When going up stairs, hold the additional handle and lift the device up.

Failure to observe the weight

Risk of injury and damage

Be aware of the weight of the device during storage.

Store the device indoors only.

Frost destroys the device if it is not completely drained of water.

Store the device in a frost-free location.

If frost-free storage is not possible:

Drain excess water.

Pump commonly available anti-freeze through the device.

Allow the device to run for a maximum of 1 minute until the pump and lines are empty.

Use commonly available, Glycol-based vehicle anti-freeze. Observe the handling instructions of the anti-freeze manufacturer.

Inadvertently starting up the device

Risk of injury, electric shock

Switch off the device immediately and unplug the mains plug before performing work.

Old oil may only be disposed of at designated collection points. Please dispose of any old oil at these locations. Polluting the environment with old oil is punishable by law.

You can agree on regular safety inspections or close a maintenance contract with your dealer. Please seek advice on this.

Check the power cable for damage and have a damaged cable replaced immediately by the authorised Customer Service or a qualified electrician.

Check the high-pressure hose for damage and replace a damaged high-pressure hose immediately.

Check the device for leaks. 3 drops of water per minute are permissible. Contact Customer Service in the case of more serious leaks.

Clean the water filter, see ChapterCleaning the water filter.

Have the oil changed by Customer Service.

Damaged water filter in the water connection

Damage to the device through contaminated water

Check the water filter for damage before inserting it into the water connection.

Pull the water filter out.

Clean the water filter under running water.

Re-insert the water filter into the water connection.

Risk of injury due to inadvertently starting up device and also due to electric shock.

Switch off the device immediately and unplug the mains plug before performing work.

Have electrical components checked and repaired by the authorised Customer Service.

In case of any malfunctions not mentioned in this chapter, contact the authorised Customer Service when in doubt or when you have been explicitly advised to do so.

Device does not start

Remedy:

Check the power cable for damage.

Check the mains voltage.

If the device overheats:

Set the power switch to "0".

Allow the device to cool for at least 15 minutes.

Set the power switch to "1".

Contact Customer Service in case of electrical faults.

Device not building up pressure

Remedy:

Fit the standard nozzle (size specified, see Chapter Technical data).

Clean / replace the high-pressure nozzle.

Vent the device (see ChapterVenting the device).

Clean the water filter (see ChapterCleaning the water filter).

Clean all inlet pipes to the pump.

Check the water supply volume (see Chapter Technical data).

Pump leaking

Up to 3 drops of water per minute are permissible.

Remedy:

In case of more serious leaks, have the device checked by Customer Service.

Pump knocking

Remedy:

Clean the water filter.

Check the water supply line for leaks.

Vent the device (see Chapter Venting the device).

Contact Customer Service if necessary.

The warranty conditions issued by our sales company responsible apply in all countries. We shall remedy possible malfunctions on your device within the warranty period free of cost, provided that a material or manufacturing defect is the cause. In a warranty case, please contact your dealer (with the purchase receipt) or the next authorised customer service site.

You can find more detailed information at: www.kaercher.com/dealersearch

Electrical connection | |

Voltage | 220 - 240 V |

Phase | 1 ~ |

Frequency | 50 Hz |

Power rating | 1.4 kW |

Degree of protection | IPX5 |

Power protection (slow-blowing) | 10 A |

Extension cable, 30 m | 2.5 mm2 |

Water connection | |

Feed pressure (max.) | 1.0 (10) MPa (bar) |

Input temperature (max.) | 40 °C |

Input amount (min.) | 480 (8.0) l/h (l/min) |

Suction height (max.) | 1.0 m |

Device performance data | |

Nozzle size of standard nozzle | 33 |

Water flow rate | 400 (6.7) l/h (l/min) |

Operating pressure | 8 (80) MPa (bar) |

Operating pressure (max.) | 12 (120) MPa (bar) |

High-pressure gun recoil force | 14.2 N |

Dimensions and weights | |

Weight (without accessories) | 16 kg |

Length x width x height | 350 x 330 x 880 mm |

Determined values in acc. with EN 60335-2-79 | |

High-pressure gun hand-arm vibration value | 3.1 m/s2 |

Uncertainty K | 1.5 m/s2 |

Sound pressure level LpA | 77 dB(A) |

Uncertainty KpA | 2.5 dB(A) |

Sound power level LWA + uncertainty KWA | 92 dB(A) |

Electrical connection | |

Voltage | 220 - 240 V |

Phase | 1 ~ |

Frequency | 50 Hz |

Power rating | 1.8 kW |

Degree of protection | IPX5 |

Power protection (slow-blowing) | 10 A |

Extension cable, 30 m | 2.5 mm2 |

Water connection | |

Feed pressure (max.) | 1.0 (10) MPa (bar) |

Input temperature (max.) | 40 °C |

Input amount (min.) | 480 (8.0) l/h (l/min) |

Suction height (max.) | 1.0 m |

Device performance data | |

Nozzle size of standard nozzle | 28 |

Water flow rate | 400 (6.7) l/h (l/min) |

Operating pressure | 10 (100) MPa (bar) |

Operating pressure (max.) | 14.5 (145) MPa (bar) |

High-pressure gun recoil force | 15.4 N |

Dimensions and weights | |

Weight (without accessories) | 19 kg |

Length x width x height | 350 x 330 x 880 mm |

Determined values in acc. with EN 60335-2-79 | |

High-pressure gun hand-arm vibration value | 4.4 m/s2 |

Uncertainty K | 1.5 m/s2 |

Sound pressure level LpA | 78 dB(A) |

Uncertainty KpA | 2.5 dB(A) |

Sound power level LWA + uncertainty KWA | 93 dB(A) |

We hereby declare that the machine described below complies with the relevant basic safety and health requirements in the EU Directives, both in its basic design and construction as well as in the version placed in circulation by us. This declaration is invalidated by any changes made to the machine that are not approved by us.

Product: High-pressure cleaner

Type: 1.520-xxx

Currently applicable EU Directives2000/14/EC

2006/42/EC (+2009/127/EC)

2011/65/EU

2014/30/EU

2009/125/EC

Commission Regulation(s)(EU) 2019/1781

Harmonised standards usedEN 60335-1

EN 60335-2-79

EN IEC 63000: 2018

EN 55014-1: 2017 + A11: 2020

EN 55014-2: 1997+A1: 2001+A2: 2008

EN 61000-3-2: 2014

EN 61000-3-3: 2013

EN 62233: 2008

Applied conformity evaluation method2000/14/EG: Annex V

National standards used-

Sound power level dB(A)

Measured: 89.8

Guaranteed: 92

The signatories act on behalf of and with the authority of the company management.

Documentation supervisor:

S. Reiser

Alfred Kärcher SE & Co. KG

Alfred-Kärcher-Str. 28 - 40

71364 Winnenden (Germany)

Ph.: +49 7195 14-0

Fax: +49 7195 14-2212

Winnenden, /06/01

We hereby declare that the machine described below complies with the relevant basic safety and health requirements in the EU Directives, both in its basic design and construction as well as in the version placed in circulation by us. This declaration is invalidated by any changes made to the machine that are not approved by us.

Product: High-pressure cleaner

Type: 1.520-xxx

Currently applicable EU Directives2000/14/EC

2006/42/EC (+2009/127/EC)

2011/65/EU

2014/30/EU

2009/125/EC

Commission Regulation(s)(EU) 2019/1781

Harmonised standards usedEN 60335-1

EN 60335-2-79

EN IEC 63000: 2018

EN 55014-1: 2017 + A11: 2020

EN 55014-2: 2015

EN 62233: 2008

EN 61000-3-2: 2019

EN 61000-3-3: 2013 + A1: 2019

Applied conformity evaluation method2000/14/EG: Annex V

Sound power level dB(A)

Measured: 89.8

Guaranteed: 92

Measured:

Guaranteed:

Measured: 91.3

Guaranteed: 93

The signatories act on behalf of and with the authority of the company management.

Documentation supervisor:

S. Reiser

Alfred Kärcher SE & Co. KG

Alfred-Kärcher-Str. 28 - 40

71364 Winnenden (Germany)

Ph.: +49 7195 14-0

Fax: +49 7195 14-2212

Winnenden, /05/01