HD 9/20-4 S ST Classic HD 10/21-4 S ST Classic HD 10/25-4 S ST Classic HD 13/18-4 S ST Classic HD 17/15-4 S ST Classic

59800690 (01/23)

59800690 (01/23)

Read these original operating instructions and the enclosed safety instructions before using the device for the first time. Proceed accordingly.

Read these original operating instructions and the enclosed safety instructions before using the device for the first time. Proceed accordingly.

Keep both books for future reference or for future owners.

Use this high-pressure cleaner only for the following types of work:

Cleaning with the high-pressure jet without detergent (e.g. façades, terraces, garden machines)

Cleaning with the low-pressure jet and detergent (e.g. machines, vehicles, structures, tools)

Optional accessories required, e.g. dosing unit, detergent injector, cup foam lance.

For the most stubborn contamination, we recommend the dirt grinder accessory.

Risk of damage due to insufficient lubrication!

If the device stands or hangs at an angle, the high-pressure pump can be damaged by insufficient lubrication.

Only operate the device when it is standing horizontally with the feet on level ground or in the same orientation after wall mounting.

Do not operate the device with servo control accessories.

Risk of damage due to unsuitable inlet water!

Supply water whose properties and content materials exceed the permissible limit values causes premature wear or deposits in the device.

Only use clean inlet water (also recycled water) whose properties and content materials are within the permissible limits.

The following limit values apply to the inlet water:

pH value: 6.5-9.5

Electrical conductivity: Conductivity of fresh water + 1200 µS/cm, maximum conductivity 2000 µS/cm

Settleable particles (sample volume 1 l, settling time 30 minutes): < 0.5 mg/l

Filterable particles: < 50 mg/l, no abrasive substances

Hydrocarbons: < 20 mg/l

Chloride: < 300 mg/l

Sulphate: < 240 mg/l

Calcium: < 200 mg/l

Total hardness: < 28 °dH, < 50° TH, < 500 ppm (mg CaCO3/l)

Iron: < 0.5 mg/l

Manganese: < 0.05 mg/l

Copper: < 2 mg/l

Active chloride: < 0.3 mg/l

Free of unpleasant odours

The packing materials can be recycled. Please dispose of packaging in accordance with the environmental regulations.

The packing materials can be recycled. Please dispose of packaging in accordance with the environmental regulations.

Electrical and electronic devices contain valuable, recyclable materials and often components such as batteries, rechargeable batteries or oil, which - if handled or disposed of incorrectly - can pose a potential danger to human health and the environment. However, these components are required for the correct operation of the device. Devices marked by this symbol are not allowed to be disposed of together with the household rubbish.

Electrical and electronic devices contain valuable, recyclable materials and often components such as batteries, rechargeable batteries or oil, which - if handled or disposed of incorrectly - can pose a potential danger to human health and the environment. However, these components are required for the correct operation of the device. Devices marked by this symbol are not allowed to be disposed of together with the household rubbish.

Current information on content materials can be found at: www.kaercher.de/REACH

Only use original accessories and original spare parts. They ensure that the appliance will run fault-free and safely.

Information on accessories and spare parts can be found at www.kaercher.com.

Check the contents for completeness when unpacking. If any accessories are missing or in the event of any shipping damage, please notify your dealer.

It is essential that you read the safety instructions 5.951-949.0 before initial startup.

Observe the national regulations for liquid jet cleaners.

Observe the national accident prevention regulations. Liquid jet cleaners must be tested regularly. The test result must be recorded in writing.

Do not modify the device or accessories.

The device may not be connected to the public drinking water network.

The device may not be connected to the public drinking water network.

The high-pressure jet must not be directed at persons, animals, live electrical equipment or at the device itself. Protect the device from frost.

The high-pressure jet must not be directed at persons, animals, live electrical equipment or at the device itself. Protect the device from frost.

Missing or modified safety devices

Safety devices are provided for your own protection.

Never modify or bypass safety devices.

The safety devices are set and sealed by the manufacturer. Adjustments are performed only by customer service.

When the trigger on the high-pressure gun is released, the pressure switch switches off the high-pressure pump and the high-pressure jet stops.

The pump switches on again when the trigger is pulled.

When the water quantity is reduced via the pressure and quantity regulator on the trigger gun, the overflow valve opens and part of the water flows back to the suction side of the pump.

The motor circuit breaker shuts off the device if power consumption it too high.

The winding protection contact in the motor winding of the pump drive switches off the motor in the case of a thermal overload.

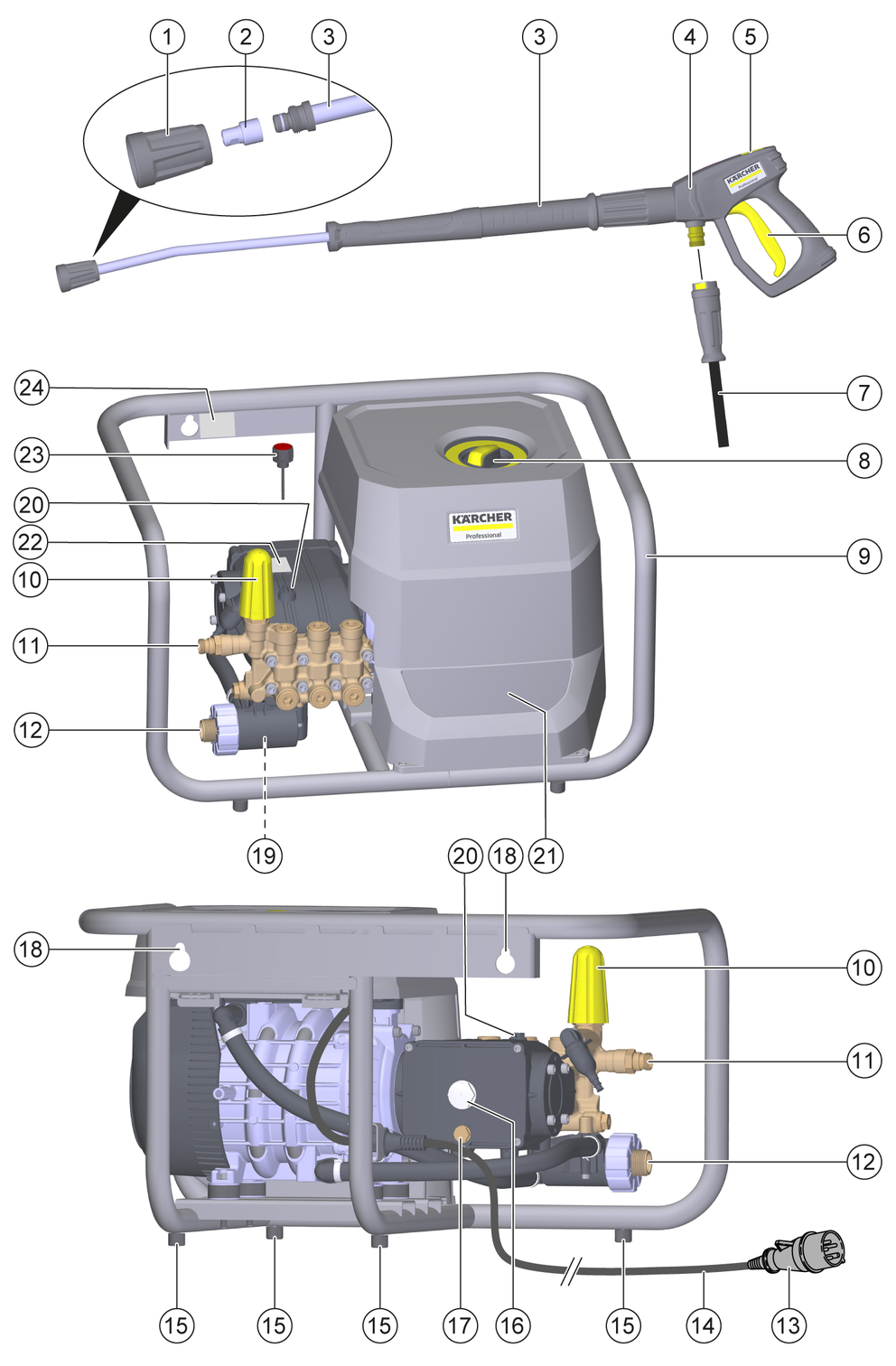

Control elements for the cleaning process are yellow.

Control elements for maintenance and servicing are light grey.

The device is suitable for wall mounting or as a stand-alone device.

Wall mounting

Risk of death and damage due to the device falling down!

There is a risk of death and damage if the device falls.

Only mount the device on suitable, load-bearing walls.

Be aware of the weight of the device during installation. Use suitable lifting equipment or enlist the help of assistants.

Use suitable fasteners and ensure professional installation.

If in doubt, leave the installation to a person with specialist knowledge.

Risk of damage due to frost!

An incompletely emptied device can be damaged by frost.

Protect the device from frost.

Operate or store the device in a frost-free place.

Completely empty the device and accessories before storing them.

Check the load-bearing capacity of the wall, taking into account the weight of the device, see chapter Technical data.

Check the space conditions, taking into account the dimensions of the device and appropriate clearances on all sides, see chapter Technical data.

Select suitable fasteners and mount the device horizontally on a vertical wall.

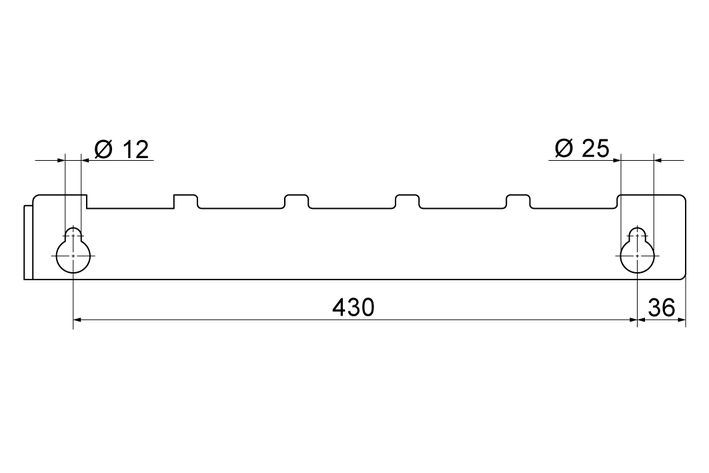

For dimensions and distances of the suspension eyes, see sketch.

Upright machine

Place the device on a level, horizontal and solid surface on the four feet.

The applicable national regulations for permanently installed high-pressure cleaning systems must be observed.

During installation, the specifications of the VDMA standard sheet 24416 "High-pressure cleaners; permanently installed high-pressure cleaning systems; terms, requirements, installation, testing" must be observed (available from Beuth Verlag, Cologne, www.beuth.de).

Risk of damage due to pressure loss!

If the pressure loss in the high-pressure pipeline network is greater than in the 10 m standard high-pressure hose, the high-pressure pump can be damaged by overloading.

Fit a correspondingly larger high-pressure nozzle to compensate for the greater pressure loss.

Lay the pipeline network to be permanently installed with as few changes of direction as possible.

Observe the minimum cross-section of the pipelines: DN 15 (½″).

Route the pipeline network using padded loose and fixed clips to compensate for pressure and thermal expansion.

Risk of damage due to vibration!

If the device is connected to the high-pressure pipeline network with a rigid pipe, vibrations may cause damage to the device or the high-pressure pipeline network.

Only connect the device to the high-pressure pipeline network using a high-pressure hose line.

Connect the device to the pipeline network with a high-pressure hose line.

Observe the minimum cross-section of the high-pressure hose line:

Device | Min. Ø high pressure hose line nominal width DN (in) |

HD9/20-4 S ST Classic HD10/21-4 S ST Classic HD10/25-4 S ST Classic HD13/18-4 S ST Classic | DN 8 (¼”) |

HD17/15-4 S ST Classic | DN 10 (⅜″) |

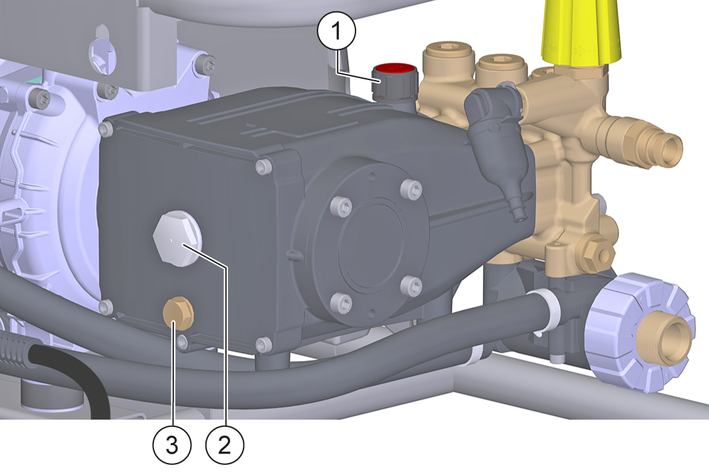

Risk of damage due to under- or overpressure!

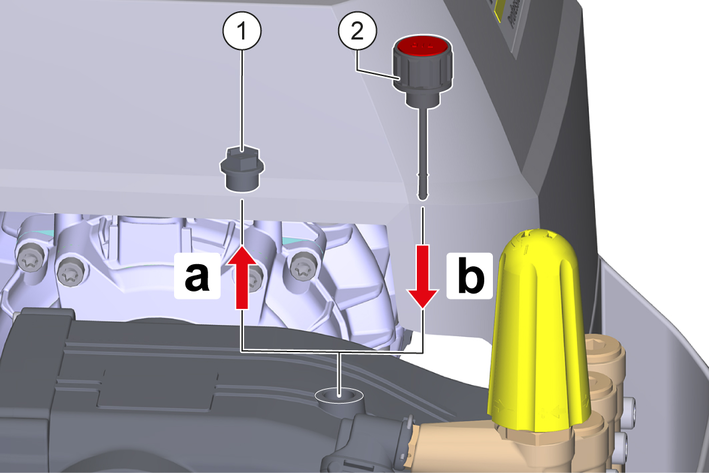

If the plug is not replaced with the dipstick with breather valve before the initial startup, the high-pressure pump may be damaged.

Be sure to replace the plug with the dipstick with breather valve.

Unscrew the plug and dispose of it.

Screw in the dipstick with breather valve and tighten.

Risk of damage due to insufficient lubrication or unsuitable lubricants!

Too little oil or the use of unsuitable lubricants can damage the high-pressure pump.

Before the initial startup, ensure that the oil level in the high-pressure pump is sufficient and only fill with suitable lubricants.

Risk of damage due to water in the oil!

If the oil is milky, there is water in the oil, which damages the high-pressure pump.

Do not operate the device with milky oil.

Contact Kärcher Service.

Set up the device horizontally, see chapter Attach or set up the device.

Check the high-pressure pump oil level at the oil level indicator

Check the oil level on the oil level indicator, it must be in the middle of the sight glass.

If necessary, slowly top up oil, for specifications see chapter Technical data.

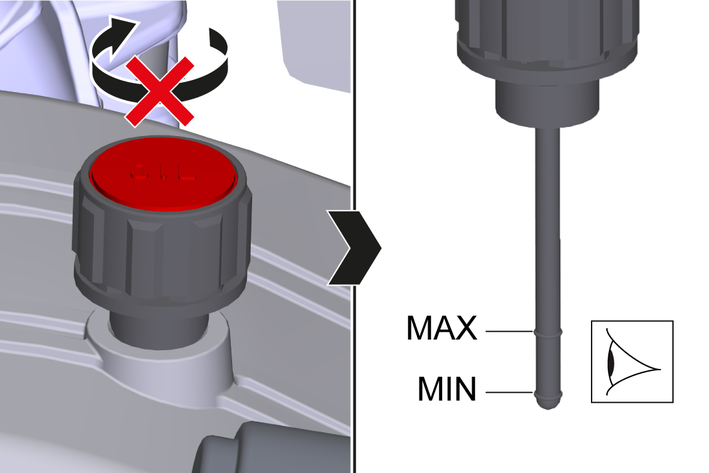

Check the high-pressure pump oil level with the dipstick with breather valve

Unscrew the dipstick with breather valve and wipe with a clean, lint-free cloth.

Insert the dipstick with the breather valve into the bore, do not screw it in.

Pull out the dipstick with the breather valve and read the oil level, it must be between the MIN and MAX marks.

If necessary, slowly top up oil, for specifications see chapter Technical data.

Wash your hands thoroughly with soap and water after each contact with oil.

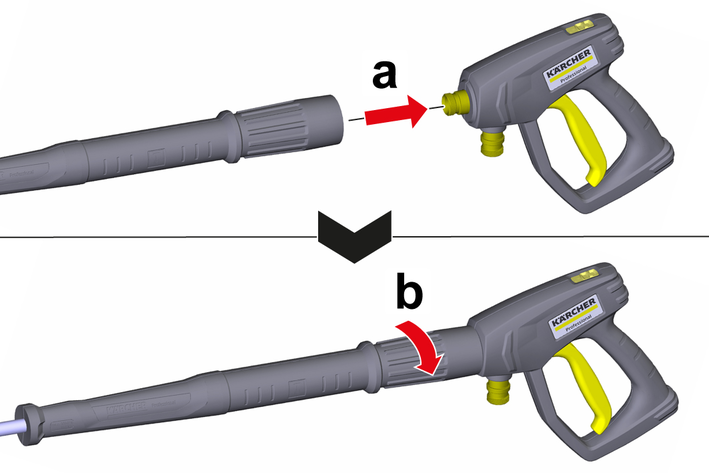

The EASY!Lock system connects components quickly and safely via a single turn of the quick-release thread.

Connect the spray lance to the high-pressure gun and teh union nut and hand-tighten (EASY!Lock).

Plug the high-pressure nozzle onto the spray lance.

Fit the union nut and hand-tighten (EASY!Lock).

Connect the high-pressure hose to the high-pressure gun and high-pressure connection of the device and tighten hand-tight (EASY!Lock).

Risk of injury from electric shock

Use a plug to connect the device to the mains grid. Permanent connection to the mains grid is prohibited. The plug is used for mains isolation.

Only connect the device to an AC power source.

Use an extension cable with sufficient diameter (see "Technical data").

Unwind the extension cable completely from the cable drum.

Unwind the mains cable and place on the ground.

Plug the mains plug into the socket.

Health risk when operating without system separator!

When operating without an upstream system separator, there is a health risk due to backflow of contaminated water into the drinking water network.

Observe the regulations of your water supply company.

Do not operate the device on the drinking water network without a system separator.

Use a system separator from KÄRCHER or a system separator as per EN 12729 Type BA. Water that has flowed through a system separator is classified as undrinkable.

Always connect the system separator to the water supply and never directly to the water connection on the device.

Check that the pressure, temperature and quantity of the inlet water as well as the dimensions of the water inlet hose meet the requirements, see chapter Technical data.

Connect the system separator and the water connection of the device with a water supply hose.

Open the water inlet.

Screw the suction hose with filter onto the water connection (for the order number see chapter Technical data).

Vent the device (see chapter Vent the device).

Unscrew the high-pressure nozzle from the spray lance.

Allow the device to run until the escaping water is free of air bubbles.

In the case of venting problems, allow the device to run for 10 seconds and then switch it off. Repeat the procedure several times.

Switch off the device.

Screw the high-pressure nozzle onto the spray lance.

Danger of death when touching damaged, live parts!

When using damaged mains plugs, mains cables and extension cables, there is a danger of death due to electric shock!

Check the mains plug, mains cable and extension cable for damage before each use and only use them if they are in perfect condition.

Have damaged parts replaced immediately by a person with specialist knowledge.

Risk of injury from high-pressure jet!

A high-pressure jet can escape from a defective device and accessories, or in the event of incorrect installation, and cause serious injuries.

Check the device and accessories for damage and faults in the installation before each use.

Have any damage repaired immediately and only use the device and accessories if they are in perfect condition and correctly installed.

Risk of injury from high-pressure jet!

A high-pressure jet can escape from the pressurised device and accessories and cause serious injuries.

Hold the high-pressure gun and spray lance tight with both hands.

Do not fasten the trigger in the actuated position.

Depressurise the device and disconnect the mains plug from the mains socket before releasing, dismantling or fitting the high-pressure hose or the high-pressure gun or carrying out work on the device or accessories.

Push the safety latch on the high-pressure gun forwards before releasing, dismantling or fitting the spray lance, jet nozzle or accessories (e.g. T-Racer, cup foam lance).

The device is equipped with a pressure switch. The motor only starts when the trigger is pulled.

Before each operation, check the device for damage and leaks, see chapter Each time before use.

Set the trigger to the "I/ON" position.

Push the safety latch backwards.

The high-pressure gun is unlocked.

Pull the trigger.

Adjust (infinitely adjustable) the working pressure and water quantity by turning the pressure and quantity regulator (+/-).

Health risk when incorrectly handling detergents!

Incorrect handling of detergents can endanger your health and the health of others.

Observe the safety and application instructions of the detergent manufacturers and act accordingly.

Risk of damage when incorrectly handling detergents!

Incorrect handling of detergents can damage the device, accessories and treated objects.

Use only detergents approved by KÄRCHER.

Observe the safety and application instructions of the detergent manufacturers and act accordingly.

Follow the instructions on dosing and contact time.

Use detergents sparingly to help conserve the environment.

KÄRCHER detergents ensure fault-free operation. Ask us for a consultation, request our catalogue or our detergent information sheets.

The application of detergents with the device is possible with optional accessories, e.g. dosing unit, cleaning agent injector, cup foam lance.

Please educate yourself or ask for advice.

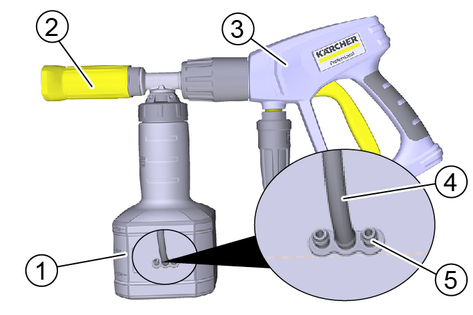

Unscrew the container.

Plug the desired gate into the suction hose.

Fill the detergent into the container.

Screw the container onto the foam nozzle.

Disconnect the spray lance from the high-pressure gun.

Connect the cup foam lance to the high-pressure gun and hand-tighten.

Start up the high-pressure cleaner.

Spray the detergent sparingly on the dry surface and let it work for a while (do not let it dry).

Rinse off the loosened dirt with the high-pressure jet.

The cup foam lance must be flushed after use to prevent the formation of detergent deposits.

Unscrew the container.

Pour the remaining detergent back into the original packaging.

Fill the container with clear water.

Screw the container onto the cup foam lance nozzle.

Operate the cup foam lance for approx. 1 minute to flush the detergent residue.

Empty the container.

Release the trigger.

The device switches off.

Push the safety latch forwards.

The high-pressure gun is secured.

Push the safety latch backwards.

The high-pressure gun is unlocked.

Actuate the trigger.

The device switches on.

Close the water inlet.

Actuate the trigger.

Set the trigger to "I/ON" and allow the device to run for 5-10 seconds.

Release the trigger.

Set the power switch to "0/OFF".

Pull the mains plug out of the socket only when your hands are dry.

Dismantle the water supply hose on the water connection of the device.

Actuate the trigger until the device is completely depressurised.

Push the safety latch forwards.

The high-pressure gun is secured.

Risk of injury or damage due to non-observance of the weight!

When transporting and storing the device, there is a risk of injury and damage due to its weight.

Take into account the weight of the device for transportation and storage, see chapter Technical data.

At least one helper is required to lift or carry the device.

Transporting the device:

Lift up and carry the device by the device's frame.

Place the device on a suitable means of transport (e.g. platform truck) and secure it against slipping and tipping.

When transporting in vehicles, secure the device against rolling away, slipping and tipping according to the respectively applicable guidelines.

Risk of injury or damage due to non-observance of the weight!

When transporting and storing the device, there is a risk of injury and damage due to its weight.

Take into account the weight of the device for transportation and storage, see chapter Technical data.

Risk of damage due to frost!

Water that is not completely drained can damage the device and accessories during freezing.

Empty the water completely from the device and accessories.

Protect the device and accessories from frost.

Finish operation, see chapter Ending operation.

Dismantle the high-pressure hose or the high-pressure hose line at the high-pressure connection of the device, see chapter Installing accessories.

Remove the high-pressure hose from the high-pressure gun, see chapter Installing accessories.

Allow the water to drain completely from the high-pressure hose and the high-pressure gun with spray lance.

Pull the mains plug out of the socket only when your hands are dry.

Store the device and accessories in a frost-protected interior space.

If frost-free storage is not possible:

Close the water inlet.

Dismantle the water supply hose on the water connection of the device.

Let the water run out of the device.

Pump commonly available anti-freeze through the device.

Use commonly available, Glycol-based vehicle anti-freeze. Observe the handling instructions of the anti-freeze manufacturer.

Turn the power switch to the “I/ON” position.

Operate the trigger lever for max. 1 min until the anti-freeze is expelled from the device.

Turn the power switch to the "0/OFF” position.

Dismantle the high-pressure hose or the high-pressure hose line at the high-pressure connection of the device, see chapter Installing accessories.

Remove the high-pressure hose from the high-pressure gun, see chapter Installing accessories.

Allow the water to drain completely from the high-pressure hose and the high-pressure gun with spray lance.

Pull the mains plug out of the socket only when your hands are dry.

Store the appliance and accessories in an interior space.

Inadvertently starting up device

Risk of injury, electric shock

Switch off the device immediately and unplug the mains plug before performing work.

Old oil may only be disposed of at designated collection points. Please dispose of any old oil at these locations. Polluting the environment with old oil is punishable by law.

You can agree on regular safety inspections or close a maintenance contract with your dealer. Please seek advice on this.

Check the mains plug, the mains cable and the extension cables for damage.

Have damaged parts replaced immediately by the authorised Customer Service or a qualified electrician.

Check the high-pressure hose, high-pressure gun, jet pipe and accessories for damage.

Replace damaged parts immediately.

Check the device for leaks.

3 drops of water loss per minute are permissible. Contact Customer Service in the case of more serious leaks.

Risk of damage due to water in the oil!

If the oil is milky, there is water in the oil, which damages the high-pressure pump.

Do not operate the device with milky oil.

Contact Kärcher Service.

Check the oil level of the high-pressure pump, see chapter Checking / correcting the high-pressure pump oil level.

Clean the fine filter, see chapter Cleaning the fine filter.

Have the device serviced by Customer Service.

Change the high-pressure pump oil, see chapter Change high pressure pump oil.

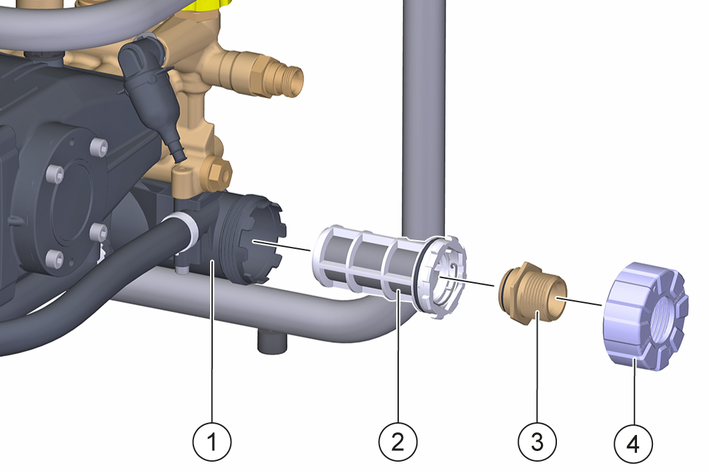

Close the water inlet.

Depressurise the device, see chapter Ending operation.

Unscrew the union nut.

Pull out the connection nozzle.

Pull the fine filter out of the fine filter housing.

Rinse the fine filter with clear water or blow it out with compressed air.

Insert the fine filter into the filter housing.

Attach the connection nozzle.

Tighten the union nut hand-tight.

Risk of damage when draining the high-pressure pump oil!

Draining the oil during operation damages the high-pressure pump.

Do not unscrew the oil drain screw while the device is in operation.

Set the power switch to "0/OFF".

Risk of scalding!

The high-pressure pump oil can be very hot and cause scalding.

Allow the device to cool down before draining the high-pressure pump oil.

Allow the device to cool down.

Place a suitable container (oil-resistant, capacity min. 1.5 l) under the oil drain screw.

The device must stand horizontally, see chapter Attach or set up the device.

Unscrew the oil drain screw counter-clockwise using a ring or socket spanner with a spanner.

Allow the high-pressure pump oil to drain completely.

Replace the sealing ring on the drain screw.

Turn the drain screw clockwise and tighten it.

Filling new oil, see chapter Checking / correcting the high-pressure pump oil level.

Dispose of the old oil in accordance with the environmental and local regulations.

Wash your hands thoroughly with soap and water after each contact with oil.

Inadvertently starting up device, touching live components

Risk of injury, electric shock

Switch off the device before performing any work on the device.

Remove the mains plug.

Have all checks and work on electrical parts performed by a qualified electrician.

In case of any malfunctions not mentioned in this chapter, contact the authorised Customer Service.

The device cannot be started

Remedy:

Check the mains cable for damage.

Check the mains voltage.

If the device overheats:

Set the power switch to "0/OFF".

Allow the device to cool for at least 15 minutes.

Set the trigger to the "I/ON" position.

Contact Customer Service in the case of electrical faults.

Device does not reach required pressure

Remedy:

Check that the high-pressure nozzle is the right size (see chapter "Technical data").

Clean or replace the nozzle.

Vent the device (see chapter "Venting the water connection/device.").

Clean the fine filter, replace if necessary (see chapter "Care and Maintenance/Weekly").

Check the water supply volume (compare with the required volume specified in the "Technical data" chapter).

Contact Customer Service if necessary.

The water quantity is too low

Remedy:

When using a long high-pressure hose or a high-pressure hose with a small diameter, fit a larger high-pressure nozzle to the spray lance.

The pump is leaking.

Up to 3 drops of water per minute are permissible.

Remedy:

In case of more serious leaks, have the device checked by Customer Service.

The pump knocks

Remedy:

Check the water supply volume (compare with the required volume specified in the "Technical data" chapter).

Vent the device (see chapter "Venting the water connection/device.").

Clean the fine filter, replace if necessary (see chapter "Care and Maintenance/Weekly").

Contact Customer Service if necessary.

The detergent dosing volume is too low

Remedy:

Check that the cup foam lance used matches the flow rate of the device.

Refill the cup of the cup foam lance.

Plug a larger gate onto the suction hose.

Check the suction hose and cup foam nozzle for detergent deposits. Remove deposits using lukewarm water.

Contact Customer Service if necessary.

The foam formation is too low

Remedy:

Check that the cup foam lance used matches the flow rate of the device.

Check the suction hose and cup foam lance for detergent deposits. Remove deposits using lukewarm water.

Contact Customer Service if necessary.

The warranty conditions issued by our sales company responsible apply in all countries. We shall remedy possible malfunctions on your device within the warranty period free of cost, provided that a material or manufacturing defect is the cause. In a warranty case, please contact your dealer (with the purchase receipt) or the next authorised customer service site.

You can find more detailed information at: www.kaercher.com/dealersearch

Country variant | |

Country | EU |

Electrical connection | |

Voltage | 400 V |

Phase | 3 ~ |

Frequency | 50 Hz |

Maximum permissible mains grid impedance | - Ω |

Power rating | 7 kW |

Degree of protection | IPX5 |

Power protection (slow-blow, char. C) | 16 A |

Extension cable, 10 m | 2,5 mm2 |

Extension cable, 30 m | 4 mm2 |

Water connection | |

Feed pressure (max.) | 1 MPa |

Input temperature (max.) | 60 °C |

Input amount (min.) | 18 l/min |

Suction height (max.) | 0,5 m |

Minimum water supply hose length | 7,5 m |

Minimum water supply hose diameter | 1 in |

Suction filter order number | 4.730-012.0 |

Device performance data | |

Nozzle size of standard nozzle | 047 |

Water operating pressure with standard nozzle | 20 MPa |

Operating pressure (max.) | 26 MPa |

Water flow rate | 15 l/min |

High-pressure gun recoil force | 50 N |

High-pressure pump | |

Oil type | Engine oil |

SAE viscosity grade | 15W-40 |

Filling quantity | 0,65 l |

Dimensions and weights | |

Typical operating weight | 44,8 kg |

Length | 720 mm |

Width | 522 mm |

Height | 418 mm |

Determined values in acc. with EN 60335-2-79 | |

Hand-arm vibration value | 2,6 m/s2 |

Uncertainty K | 0,8 m/s2 |

Sound pressure level LpA | 71 dB(A) |

Uncertainty KpA | 3 dB(A) |

Sound power level LWA + uncertainty KWA | 88 dB(A) |

Country variant | |

Country | EU |

Electrical connection | |

Voltage | 400 V |

Phase | 3 ~ |

Frequency | 50 Hz |

Maximum permissible mains grid impedance | - Ω |

Power rating | 8 kW |

Degree of protection | IPX5 |

Power protection (slow-blow, char. C) | 16 A |

Extension cable, 10 m | 2,5 mm2 |

Extension cable, 30 m | 4 mm2 |

Water connection | |

Feed pressure (max.) | 1 MPa |

Input temperature (max.) | 60 °C |

Input amount (min.) | 20 l/min |

Suction height (max.) | 0,5 m |

Minimum water supply hose length | 7,5 m |

Minimum water supply hose diameter | 1 in |

Suction filter order number | 4.730-012.0 |

Device performance data | |

Nozzle size of standard nozzle | 050 |

Water operating pressure with standard nozzle | 21 MPa |

Operating pressure (max.) | 27 MPa |

Water flow rate | 16,67 l/min |

High-pressure gun recoil force | 57 N |

High-pressure pump | |

Oil type | Engine oil |

SAE viscosity grade | 15W-40 |

Filling quantity | 0,65 l |

Dimensions and weights | |

Typical operating weight | 48,4 kg |

Length | 720 mm |

Width | 522 mm |

Height | 418 mm |

Determined values in acc. with EN 60335-2-79 | |

Hand-arm vibration value | 2,8 m/s2 |

Uncertainty K | 0,8 m/s2 |

Sound pressure level LpA | 69 dB(A) |

Uncertainty KpA | 3 dB(A) |

Sound power level LWA + uncertainty KWA | 86 dB(A) |

Country variant | |

Country | EU |

Electrical connection | |

Voltage | 400 V |

Phase | 3 ~ |

Frequency | 50 Hz |

Maximum permissible mains grid impedance | 0.0452 +j0.0283 Ω |

Power rating | 8,8 kW |

Degree of protection | IPX5 |

Power protection (slow-blow, char. C) | 16 A |

Extension cable, 10 m | 2,5 mm2 |

Extension cable, 30 m | 4 mm2 |

Water connection | |

Feed pressure (max.) | 1 MPa |

Input temperature (max.) | 60 °C |

Input amount (min.) | 20 l/min |

Suction height (max.) | 0,5 m |

Minimum water supply hose length | 7,5 m |

Minimum water supply hose diameter | 1 in |

Suction filter order number | 4.730-012.0 |

Device performance data | |

Nozzle size of standard nozzle | 045 |

Water operating pressure with standard nozzle | 25 MPa |

Operating pressure (max.) | 31 MPa |

Water flow rate | 16,67 l/min |

High-pressure gun recoil force | 63 N |

High-pressure pump | |

Oil type | Engine oil |

SAE viscosity grade | 15W-40 |

Filling quantity | 0,65 l |

Dimensions and weights | |

Typical operating weight | 54,4 kg |

Length | 720 mm |

Width | 522 mm |

Height | 418 mm |

Determined values in acc. with EN 60335-2-79 | |

Hand-arm vibration value | 3,7 m/s2 |

Uncertainty K | 0,9 m/s2 |

Sound pressure level LpA | 74 dB(A) |

Uncertainty KpA | 3 dB(A) |

Sound power level LWA + uncertainty KWA | 91 dB(A) |

Country variant | |

Country | EU |

Electrical connection | |

Voltage | 400 V |

Phase | 3 ~ |

Frequency | 50 Hz |

Maximum permissible mains grid impedance | 0.0452 +j0.0283 Ω |

Power rating | 8,8 kW |

Degree of protection | IPX5 |

Power protection (slow-blow, char. C) | 16 A |

Extension cable, 10 m | 2,5 mm2 |

Extension cable, 30 m | 4 mm2 |

Water connection | |

Feed pressure (max.) | 1 MPa |

Input temperature (max.) | 60 °C |

Input amount (min.) | 25 l/min |

Suction height (max.) | 0,5 m |

Minimum water supply hose length | 7,5 m |

Minimum water supply hose diameter | 1 in |

Suction filter order number | 4.730-012.0 |

Device performance data | |

Nozzle size of standard nozzle | 075 |

Water operating pressure with standard nozzle | 18 MPa |

Operating pressure (max.) | 24 MPa |

Water flow rate | 21,67 l/min |

High-pressure gun recoil force | 69 N |

High-pressure pump | |

Oil type | Engine oil |

SAE viscosity grade | 15W-40 |

Filling quantity | 0,65 l |

Dimensions and weights | |

Typical operating weight | 54,4 kg |

Length | 720 mm |

Width | 522 mm |

Height | 418 mm |

Determined values in acc. with EN 60335-2-79 | |

Hand-arm vibration value | 2,9 m/s2 |

Uncertainty K | 0,8 m/s2 |

Sound pressure level LpA | 74 dB(A) |

Uncertainty KpA | 3 dB(A) |

Sound power level LWA + uncertainty KWA | 91 dB(A) |

Country variant | |

Country | EU |

Electrical connection | |

Voltage | 400 V |

Phase | 3 ~ |

Frequency | 50 Hz |

Maximum permissible mains grid impedance | 0.0452 +j0.0283 Ω |

Power rating | 9 kW |

Degree of protection | IPX5 |

Power protection (slow-blow, char. C) | 16 A |

Extension cable, 10 m | 2,5 mm2 |

Extension cable, 30 m | 4 mm2 |

Water connection | |

Feed pressure (max.) | 1 MPa |

Input temperature (max.) | 60 °C |

Input amount (min.) | 31,6 l/min |

Suction height (max.) | 0,5 m |

Minimum water supply hose length | 7,5 m |

Minimum water supply hose diameter | 1 in |

Suction filter order number | 4.730-012.0 |

Device performance data | |

Nozzle size of standard nozzle | 105 |

Water operating pressure with standard nozzle | 15 MPa |

Operating pressure (max.) | 21 MPa |

Water flow rate | 28,33 l/min |

High-pressure gun recoil force | 85 N |

High-pressure pump | |

Oil type | Engine oil |

SAE viscosity grade | 15W-40 |

Filling quantity | 1,2 l |

Dimensions and weights | |

Typical operating weight | 59,2 kg |

Length | 720 mm |

Width | 522 mm |

Height | 418 mm |

Determined values in acc. with EN 60335-2-79 | |

Hand-arm vibration value | 3,0 m/s2 |

Uncertainty K | 0,8 m/s2 |

Sound pressure level LpA | 76 dB(A) |

Uncertainty KpA | 3 dB(A) |

Sound power level LWA + uncertainty KWA | 93 dB(A) |

EU Declaration of Conformity |

We hereby declare that the machine described below complies with the relevant basic safety and health requirements in the EU Directives, both in its basic design and construction as well as in the version placed in circulation by us. This declaration is invalidated by any changes made to the machine that are not approved by us.

Product: High-pressure cleaner

Type: 1.367-xxx.x

Currently applicable EU Directives2000/14/EC

2006/42/EC (+2009/127/EC)

2011/65/EU

2014/30/EU

2009/125/EC

Commission Regulation(s)(EU) 2019/1781

Harmonised standards usedEN 60335-1

EN 60335-2-79

EN IEC 63000: 2018

EN 55014-1: 2017 + A11: 2020

EN 55014-2: 1997+A1: 2001+A2: 2008

EN 61000-3-2: 2014

EN 61000-3-3: 2013

HD 9/20-4 S St Classic

HD 10/21-4 S St Classic

EN 61000-3-11: 2000

HD 10/25-4 S St Classic

HD 13/18-4 S St Classic

HD 17/15-4 S St Classic

EN 62233: 2008

National standards used-

Sound power level dB(A)HD 9/20-4 S St Classic

Measured: 85

Guaranteed: 88

HD 10/21-4 S St Classic

Measured: 84

Guaranteed: 86

HD 10/25-4 S St Classic

Measured: 89

Guaranteed: 91

HD 13/18-4 S St Classic

Measured: 89

Guaranteed: 91

HD 17/15-4 S St Classic

Measured: 91

Guaranteed: 93

The signatories act on behalf of and with the authority of the company management.

Documentation supervisor:

S. Reiser

Alfred Kärcher SE & Co. KG

Alfred-Kärcher-Str. 28 - 40

71364 Winnenden (Germany)

Ph.: +49 7195 14-0

Fax: +49 7195 14-2212

Winnenden, 2023/02/01

Declaration of Conformity (UK) |

We hereby declare that the product described below complies with the relevant provisions of the following UK Regulations, both in its basic design and construction as well as in the version put into circulation by us. This declaration shall cease to be valid if the product is modified without our prior approval.

Product: High-pressure cleaner

Type: 1.367-xxx.x

Currently applicable UK RegulationsS.I. 2001/1701 (as amended)

S.I. 2008/1597 (as amended)

S.I. 2012/3032 (as amended)

S.I. 2016/1091 (as amended)

S.I. 2010/2617 (as amended)

Commission Regulation(s)(EU) 2019/1781

Designated standards usedEN 60335-1

EN 60335-2-79

EN IEC 63000: 2018

EN 55014-1: 2017 + A11: 2020

EN 55014-2: 1997+A1: 2001+A2: 2008

EN 61000-3-2: 2014

EN 61000-3-3: 2013

HD 9/20-4 S St Classic

HD 10/21-4 S St Classic

EN 61000-3-11: 2000

HD 10/25-4 S St Classic

HD 13/18-4 S St Classic

HD 17/15-4 S St Classic

EN 62233: 2008

National standards used-

Sound power level dB(A)HD 9/20-4 S St Classic

Measured: 85

Guaranteed: 88

HD 10/21-4 S St Classic

Measured: 84

Guaranteed: 86

HD 10/25-4 S St Classic

Measured: 89

Guaranteed: 91

HD 13/18-4 S St Classic

Measured: 89

Guaranteed: 91

HD 17/15-4 S St Classic

Measured: 91

Guaranteed: 93

The signatories act on behalf of and with the authority of the company management.

Documentation supervisor:

S. Reiser

Alfred Kärcher SE & Co. KG

Alfred-Kärcher-Str. 28 - 40

71364 Winnenden (Germany)

Ph.: +49 7195 14-0

Fax: +49 7195 14-2212

Winnenden, 2023/02/01

2-2-SC-A5-GS-17339