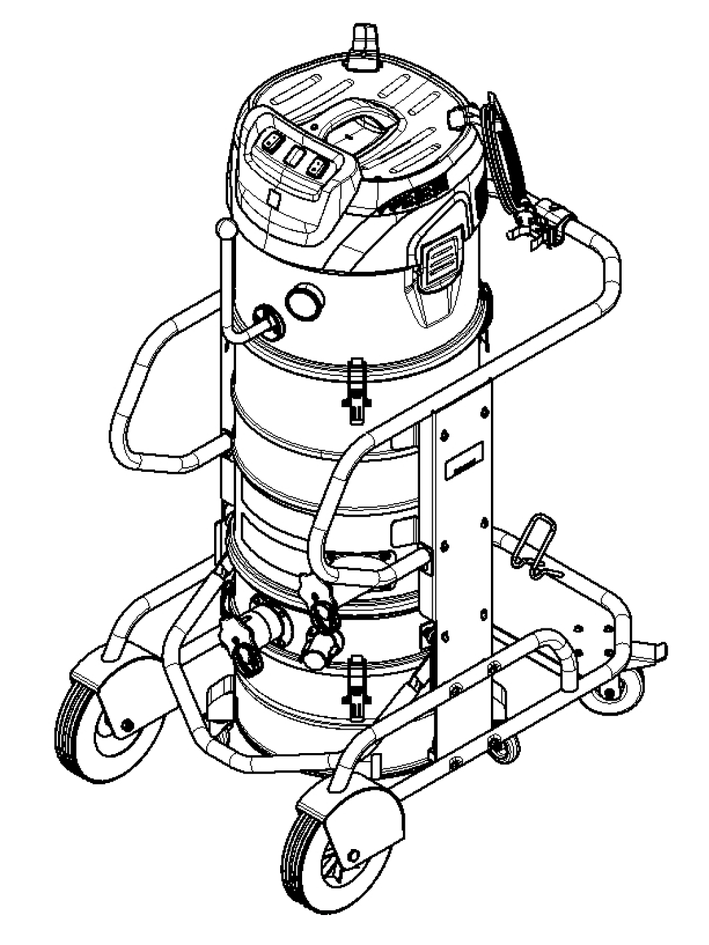

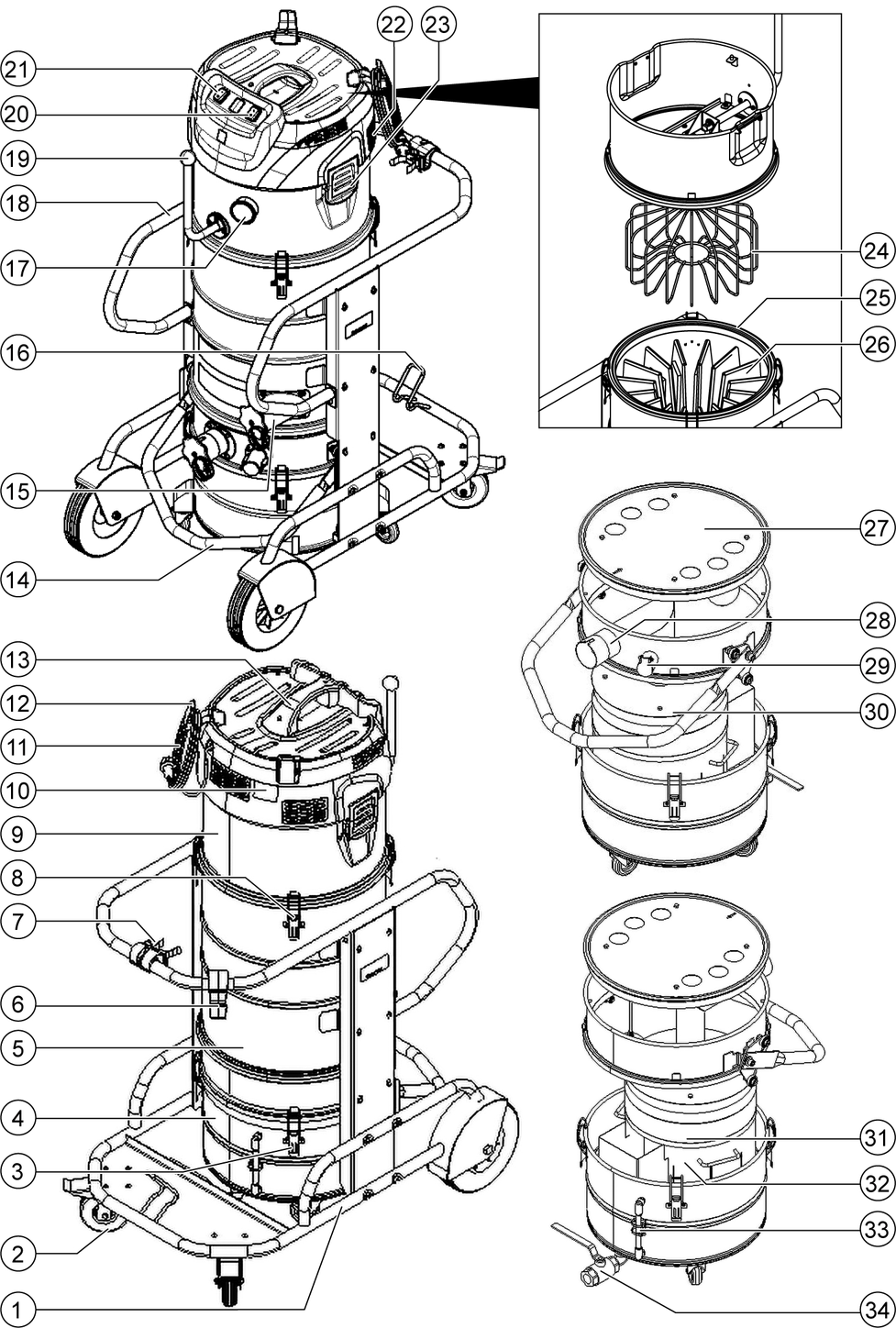

IVM 60/24-2 M ACD WS

99902620 (04/24)

99902620 (04/24)

Read these original instructions before using your device for the first time, adhere to the instructions contained therein and store them for later reference or subsequent owners.

Read these original instructions before using your device for the first time, adhere to the instructions contained therein and store them for later reference or subsequent owners.

Be sure to read the safety instructions no. 5.956-249.0 prior to the initial startup.

If the operating instructions and safety instructions are not observed, the device can be damaged and dangers could arise for users and other persons.

Notify the dealer immediately in the case of shipping damage.

Indication of an imminent threat of danger that will lead to severe injuries or even death.

Indication of a potentially dangerous situation that may lead to severe injuries or even death.

Indication of a potentially dangerous situation that may lead to minor injuries.

Indication of a potentially dangerous situation that may lead to damage to property.

Only trained personnel are permitted to use the device and the substances for which it is to be used, including the safe procedure for disposing of the vacuumed material.

An air exchange rate L must be present in the room when the exhaust gas is returned into the room. To remain within the required limit values, the volume flow of returned air must be no greater than 50% of the fresh air volume (room volume VR x air exchange rate LW). Without special ventilation measures, the following applies: LW=1h-1.

This device contains dust that is harmful to your health. Emptying and maintenance, including removal of the dust bag, may only be performed by technical specialists wearing suitable personal protective equipment.

Do not operate the device without the complete filtration system.

Observe the applicable safety instructions for the materials being vacuumed.

The simultaneous collection of different combustible dusts in the collection container can lead to fires or explosion.

Make sure that the correct liquid for collecting metal dust is used in the liquid container in order to avoid dangerous reactions. To avoid the formation of hydrogen gas with metal dusts, the use of oil instead of water is recommended.

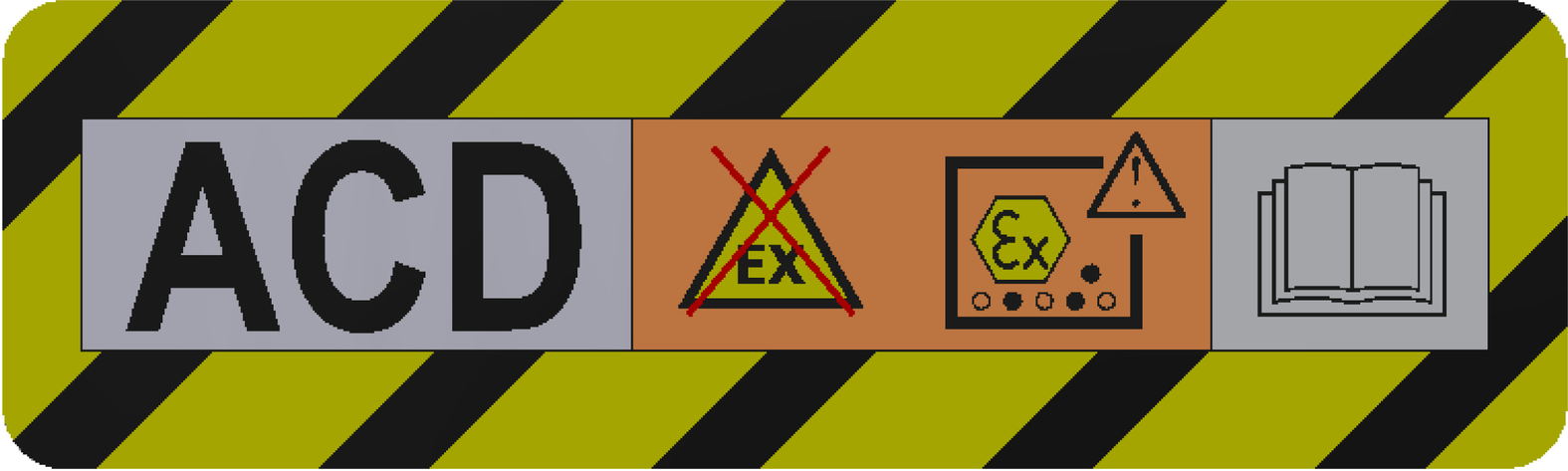

You must not set up or operate the device in areas where there is a risk of dust or gas explosion. A dust explosive atmosphere inside the device is only allowed in front of the filter. Gas explosive atmospheres are prohibited inside the device.

The device is not suitable for the suctioning or vacuuming of flammable liquids (flammable, easily flammable, highly flammable according to Dangerous Substances Directive 67/548/EEC) (flash point below 55 °C) and mixtures of flammable dusts and liquids.

The device is not suitable for sucking up ignition sources and dusts with a glow temperature ≤ 190 °C.

Every time before use, check whether the equipotential bonding conductors (earthing conductors) are connected.

The device must not be used or stored outdoors in wet conditions.

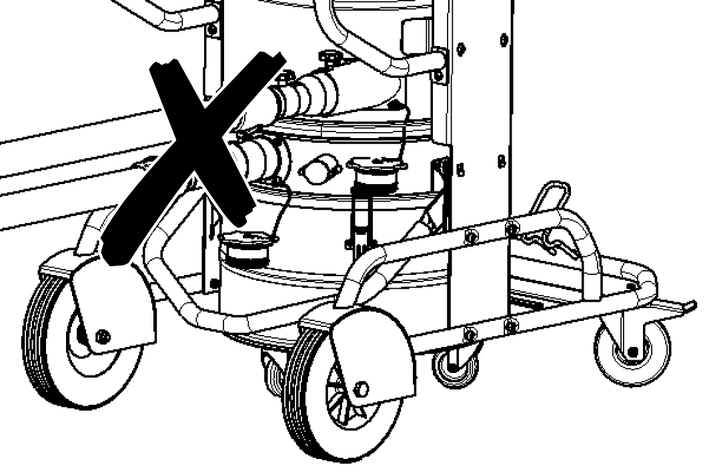

Apply the parking brake at the steering roller to ensure a secure footing for the device. The device may move uncontrollably if the parking brake is open.

Fill the liquid container only with the liquids recommended by the manufacturer.

In case of longer breaks in operation and after use, switch off the device at the power switches and unplug the mains plug.

Only use the device indoors.

Risk of crushing! Wear gloves when removing or installing the suction head, filter inlay or collection container.

Risk of damage! Never vacuum without a filter or with a damaged filter.

Wear safety shoes when operating the device.

Only move the device at walking speed, and to move down a decline, have two workers steady the device as necessary.

Be careful to ensure that there is no dust spillage when replacing accessories.

Surface temperatures can rise to 135° C during normal operation.

Avoid kinking the suction hose unit.

Carry out a regular visual inspection of the hoses.

Take appropriate precautions for removal, handling, storage and disposal of the sludge, such as mixing with inert liquids according to local regulations.

Hydrogen gas is flammable and can be produced by extracting up certain materials such as aluminium, magnesium, etc. The valve prevents the accumulation of hydrogen gas inside the liquid container. Clean and inspect the valve regularly and check for signs of damage.

Ensure adequate ventilation of the installation site to reduce the hydrogen concentration.

Empty the dirt receptacle after each use and when it is full of sludge to reduce the formation of hydrogen gas.

The device may only be connected to an electrical connection which has been set up by a qualified electrician as per IEC 60364. For connected loads seeTechnical data and type plate.

Danger of electric shock

Danger of death

Avoid damaging the power cables by driving over them or otherwise crushing them, or by jerking them.

Protect the cables from heat, oil and sharp edges.

Check the mains connection of the device for damage every time before operation. Do not operate the device using a damaged cable. Have any damaged cables replaced by a qualified electrician.

Risk of injury and damage in the event of a short-circuit or other electrical faults

Danger of electric shock, danger of burns

Switch off the device and unplug the mains plug.

Behaviour in case of filter breakage / leakage:

Switch off the unit immediately.

The unit may not be operated without the fresh water filter.

Replace the filter.

The device is intended for:

Wet and dry cleaning of floor and wall surfaces

Vacuuming of dry, flammable, deposited dusts hazardous to health; dust class M according to EN 60335‑2‑69

Vacuuming of non-explosive substances

Vacuuming of flammable dusts of all dust explosion classes

Vacuuming of dusts and coarse dirt

Vacuuming of flammable dusts from a zone 22 if the device is installed outside of potentially explosive areas

Vacuuming moist and liquid substances

Vacuuming of the following substances only when using inert liquid:

Titanium dust

Explosive and conductive dust

Magnesium dust or powder

Condensate dusts and explosive metal powders from additive manufacturing (3D printing)

Industrial usee.g. in storage and production areas

Commercial use, e.g. in hotels, schools, hospitals, factories, shops, offices, and rental companies.

A corresponding Ex device must be used if there is a classified Ex zone at the device installation location.

The device’s correct function is only guaranteed when using suction hose nominal widths of DN40 and DN50.

Any other use constitutes improper use.

The device is not suitable for:

Vacuuming of ignition sources and dusts with a glow temperature ≤ 190 °C

Vacuuming of explosive substances or substances classified as such in the sense of §1 German Explosives Law "Explosive vapour-air mixtures" (§1 SprengG, explosiver Dampf-Luftgemische)

vacuuming of mixtures of flammable liquids and flammable dust

Vacuuming of smouldering or hot particles where this could otherwise result in a fire or an explosion

Vacuuming of toxic substances

Connection to a dust-generating machine

The packing materials can be recycled. Please dispose of packaging in accordance with the environmental regulations.

The packing materials can be recycled. Please dispose of packaging in accordance with the environmental regulations.

Electrical and electronic devices contain valuable, recyclable materials and often components such as batteries, rechargeable batteries or oil, which - if handled or disposed of incorrectly - can pose a potential danger to human health and the environment. However, these components are required for the correct operation of the device. Devices marked by this symbol are not allowed to be disposed of together with the household rubbish.

Electrical and electronic devices contain valuable, recyclable materials and often components such as batteries, rechargeable batteries or oil, which - if handled or disposed of incorrectly - can pose a potential danger to human health and the environment. However, these components are required for the correct operation of the device. Devices marked by this symbol are not allowed to be disposed of together with the household rubbish.

Current information on content materials can be found at: www.kaercher.de/REACH

Risk of explosion when used with non-permitted accessories

Only use accessories permitted by the manufacturer and with the Ex label for type 22 usage.

Only use original accessories and original spare parts. They ensure that the appliance will run safely and fault-free.

Information on accessories and spare parts can be found at www.kaercher.com.

No accessories are included in the scope of delivery. The accessories must be ordered separately depending on the application.

Check the contents for completeness when unpacking. In the event of shipping damage, please notify your dealer.

The device is suitable for vacuuming dusts up to dust class M.

Damage to the skin, lungs and eyes

Expulsion of fine dust during emptying and maintenance work and disposal

Wear the prescribed personal protective gear when performing during emptying and maintenance work, including disposal of the dust bag.

The device is suitable for vacuuming flammable dusts, installation outside zone 22.

WARNING: This device must not be placed in any zone 22. If a zone 22 is present, an EX-device must be used.

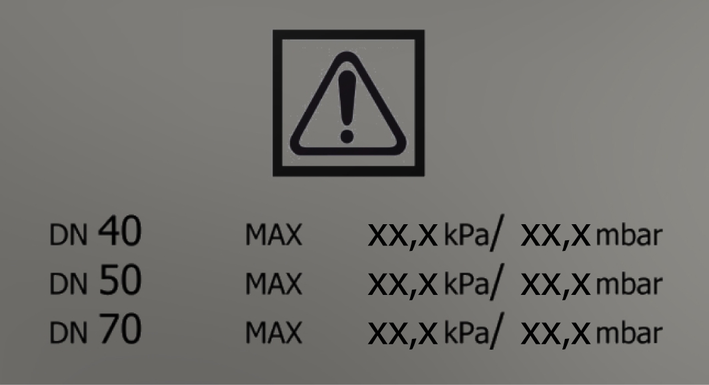

The maximum vacuum value in relation to the hose cross-section is specified on the label. The actual value can be read on the pressure gauge. For the values applicable to this device, see chapter Reading the minimum volumetric flow. If this value is not reached, the filter must be replaced, (see chapter Replacing the main filter). The various different hose cross-sections allow adaptation to the various different connection cross-sections of the accessories.

| Micro-fleece (Order no. 9.990-103.0) |

| Main filter (Order no. 9.439-542.0) |

Potential equalisation line not connected correctly

Electric shock

Every time before use, check whether the equipotential bonding conductor (earthing conductors) are connected.

Danger from dust that is harmful to your health

Respiratory sicknesses through inhalation of dust.

Do not vacuum without correctly installed filter elements, otherwise a danger to health from increased fine dust emission is present.

Improper handling when locking the dirt receptacle

Risk of crushing

Under no circumstances should you hold your hands between the dirt receptacle and filter ring or allow them to come close to the lifting mechanism while locking it.

Lock the dirt receptacle by operating the bow handle with both hands.

Missing filter element

Damage to the suction motor

Do not vacuum without a filter element.

Static charge of the dirt receptacle

Ignition of dusts

Make sure that the grounding on the chassis is in contact with the dirt receptacle.

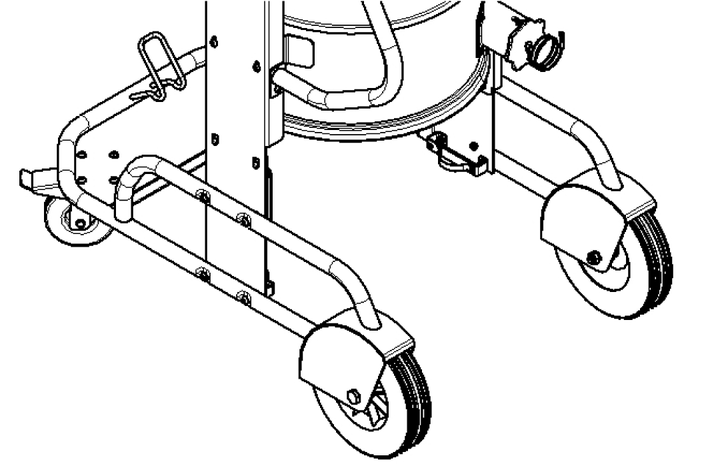

Bring the device into the working position.

Secure the device with the parking brakes.

Ensure that the suction head is fitted correctly.

Fill the dirt receptacle with water or oil (order no. 9.990-272.0) up to the mark (see chapter Fill the dirt receptacle with inert liquid).

Clamp the earth terminal to the external equipotential bonding.

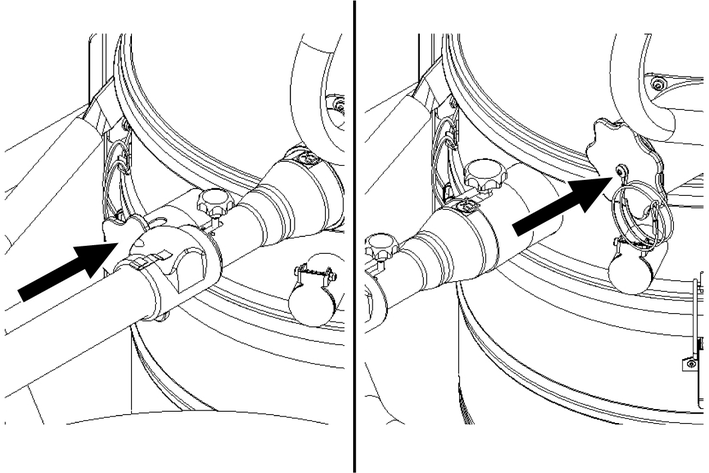

Remove the sealing plug on the collection container (see chapter Selecting the suction connection).

Insert the suction hose into the suction connection.

Ensure that the suction connection on the filter ring is tightly sealed with a sealing plug (see chapter Closing the suction connection).

Check the filling level in the dirt receptacle (see chapter Check the dirt receptacle filling level).

Empty the dirt receptacle if necessary (see chapter Emptying the dirt receptacle).

Plug the desired accessories (not included in the scope of delivery) onto the suction hose.

Ensure that the dirt receptacle is correctly fitted.

The device is equipped with 2 suction hose ports.

Suction hose port on the dirt receptacle

Dry vacuuming with wet separator: Fine dust, powder

The dirt receptacle with wet separation function must be filled with the inert liquid water or oil. Oil with order no. 9.990-272.0 is recommended.

Suction hose port on the filter ring

Is tightly sealed with a sealing plug when used as intended.

| Two suction hoses must not be connected to the vacuum cleaner at the same time. Only the lower suction hose port may be used when used as intended. |

| The upper suction hose port must be tightly closed when using the wet separator. |

Risk of injury

Damage to the skin, lungs and eyes through fine dust

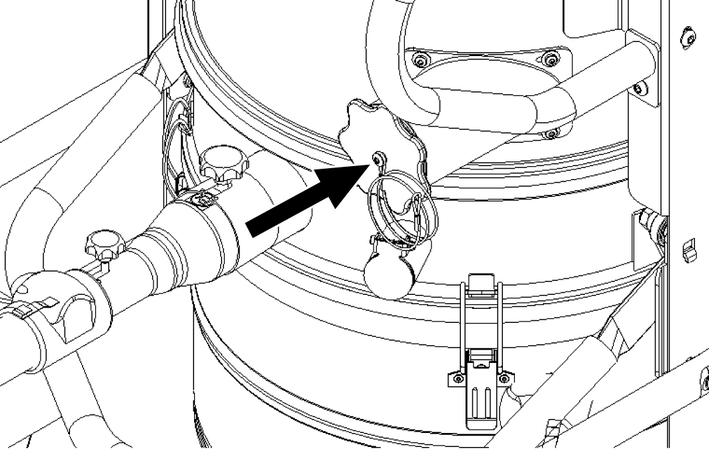

The suction connection must be closed using the sealing plug after removing the suction hose.

Insert the sealing plug precisely into the suction connection.

Push the sealing plug in all the way to the end stop.

Turn the sealing plug to the right until the suction connection is tightly closed.

If a dirt receptacle with wet separator is used, the dirt receptacle must be filled with inert liquid before use.

Moving parts

Risk of crushing

Be careful of moving parts when removing or inserting the upper part of the dirt receptacle.

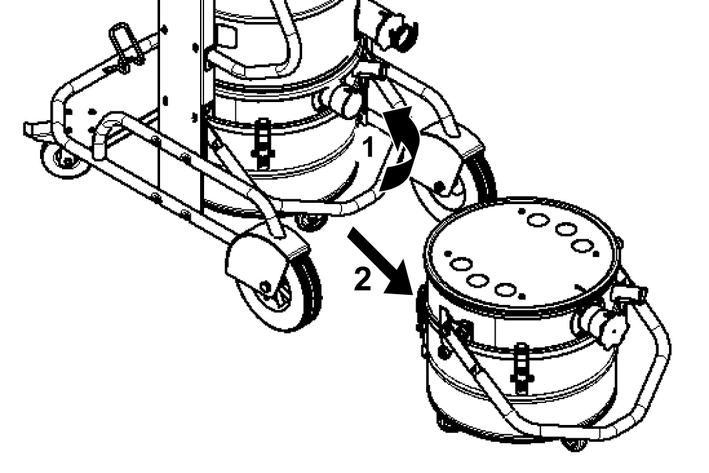

Secure the device with the parking brakes.

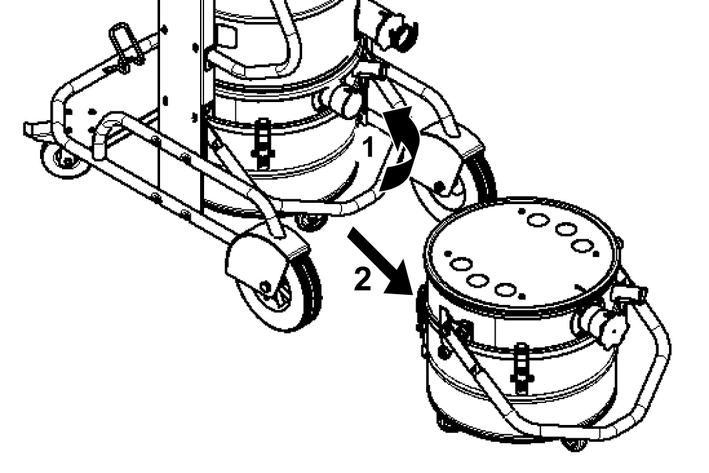

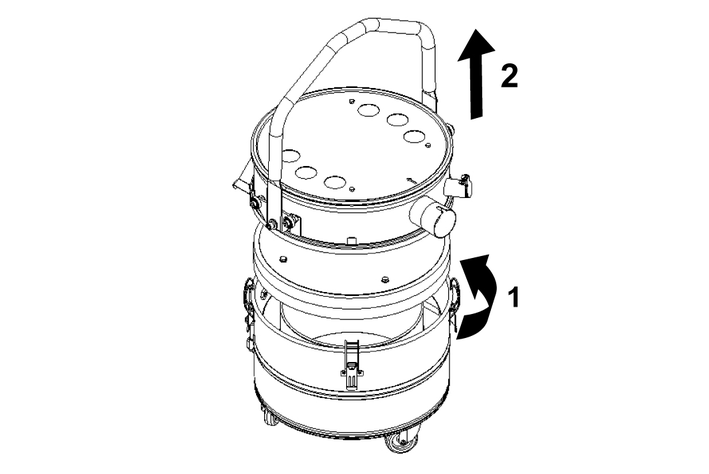

Pull the bow handle up.

The dirt receptacle is unlocked and lowered.

Pull the dirt receptacle out of the device by the bow handle.

Loosen the clamping straps on the dirt receptacle.

Remove the upper part of the dirt receptacle by the bow handle.

Fill the inert liquid water or oil into the dirt receptacle until the filling level reaches the mark on the filling level indicator.

When fitting the upper part of the dirt receptacle, make sure that the float ball is inserted into the corresponding guide.

Improper handling when locking the dirt receptacle

Risk of crushing

Under no circumstances should you hold your hands between the dirt receptacle and filter ring or allow them to come close to the lifting mechanism while locking it.

Lock the dirt receptacle by operating the bow handle with both hands.

Static charge of the dirt receptacle

Ignition of dusts

Make sure that the grounding on the chassis is in contact with the dirt receptacle.

Fit the dirt receptacle in the reverse sequence and lock it with the bow handle.

The dirt receptacle must be emptied when filled up to the mark. The device does not switch off automatically when the maximum filling level is exceeded.

Check the dirt receptacle filling level regularly.

Make sure that no more than 8 litres of material are sucked in during vacuuming.

Suction of explosive and conductive metal dust without inert liquid

Explosion hazard, heat generation

Never vacuum explosive and conductive suction material without inert liquid.

Danger from dust that is harmful to your health

Respiratory sicknesses through inhalation of dust.

Do not vacuum without correctly installed filter elements, otherwise a danger to health occurs from increased fine dust emission.

Before each use, check that both filter elements are correctly installed.

Danger due to fine dust entering

Risk of damage to the suction motor.

Never remove the main filter element when vacuuming.

Lack of inert liquid

Damage to the wet separator

Never vacuum without inert liquid when using the suction hose port on the wet separator.

Plug the mains plug into the socket.

Switch on the device via the suction turbine power switches.

Always switch the suction turbines on and off one after the other. For the correct function of the pressure gauge for monitoring the minimum volume flow, all suction turbines must be switched on.

In most application cases it is sufficient that you vacuum with one suction turbine. If necessary, switch on the 2nd suction turbine. However, do not operate the device with both suction turbines for longer than 15 min. This can cause too much humid air to prematurely wet the main filter. If necessary, let the main filter dry afterwards or replace it (see chapter Replacing the main filter).

Start the vacuuming process.

Regularly check the filling level in the dirt receptacle, since the device does not switch off automatically.

The device is equipped with a mechanical monitoring unit. This monitoring unit interrupts the airflow when the inert liquid falls below the minimum filling level. Refill with inert liquid to continue the vacuuming process (see chapter Fill the dirt receptacle with inert liquid).

Make sure that no more than 8 litres of material are sucked in during vacuuming.

If necessary, empty the dirt receptacle (see chapter Emptying the dirt receptacle).

If necessary, replace the main filter (see chapter Replacing the main filter).

If the dirt receptacle is filled with an inert liquid, moist air may flow through the main filter during suction and soak it. Check the main filter for moisture after the vacuuming process. If necessary, let the main filter dry or replace it (see chapter Replacing the main filter).

A pressure gauge showing the vacuum inside the device is mounted on the front of the device. The main filter must be cleaned when the maximum vacuum (see table) is reached, see chapter Replacing the main filter). This value depends on the device performance and the suction hose used. If the vacuum is not significantly reduced by replacing the filter, there must be another problem (see chapter Troubleshooting guide).

Exceeding the maximum vacuum

Suction loss

If the specified value is exceeded, the air speed in the suction hose drops below 20 m/s. Replace the filter.

Nominal width of the suction hose | Maximum vacuum |

|---|---|

DN40 | 16.4 kPa (164 mbar) |

DN50 | 12.9 kPa (129 mbar) |

DN70 | --- |

Switch off the device via the suction turbine power switches.

Pull out the mains plug.

Disconnect the earth terminal from the external equipotential bonding.

Remove the accessories.

Close the suction connection (see chapter Closing the suction connection).

Remove the accessories and, if necessary, flush with water and allow to dry.

Empty the dirt receptacle (see chapter Emptying the dirt receptacle).

Vacuum the inside and outside of the device and clean with a moist cloth.

The dirt receptacle must be emptied if necessary and after each use.

The inlet opening or the suction hose are closed.

Regularly check the filling level in the dirt receptacle, since the device does not switch off automatically.

Switch off the device.

Secure the device with the parking brakes.

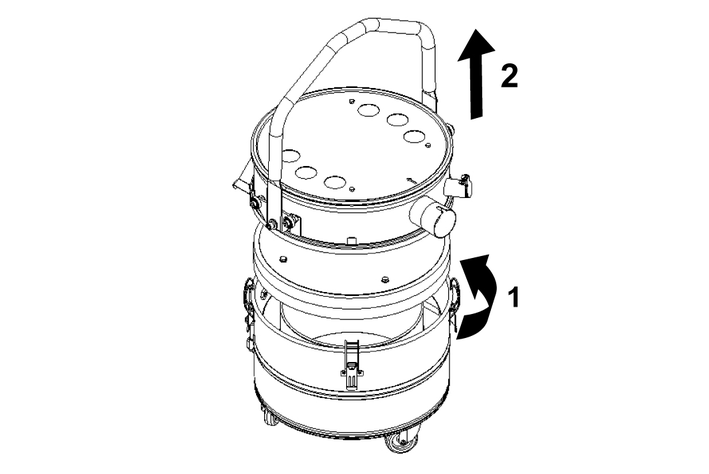

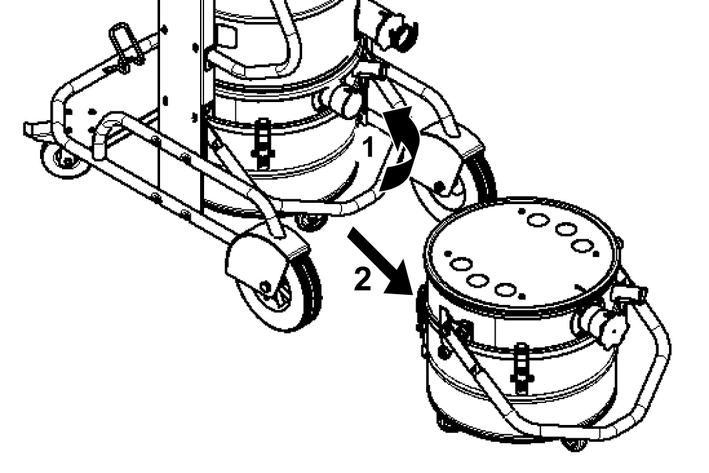

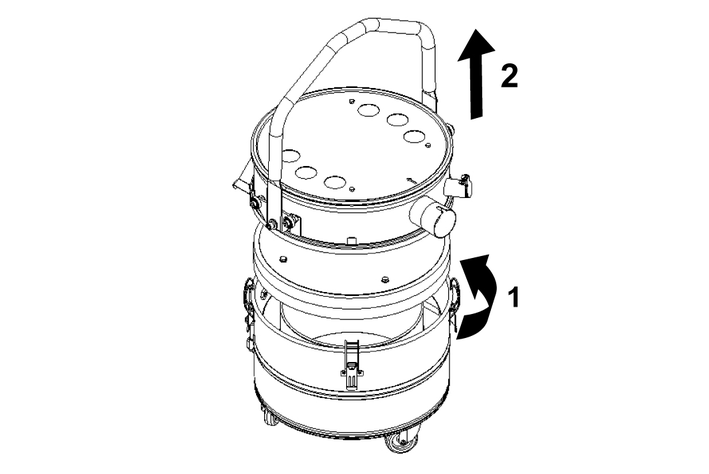

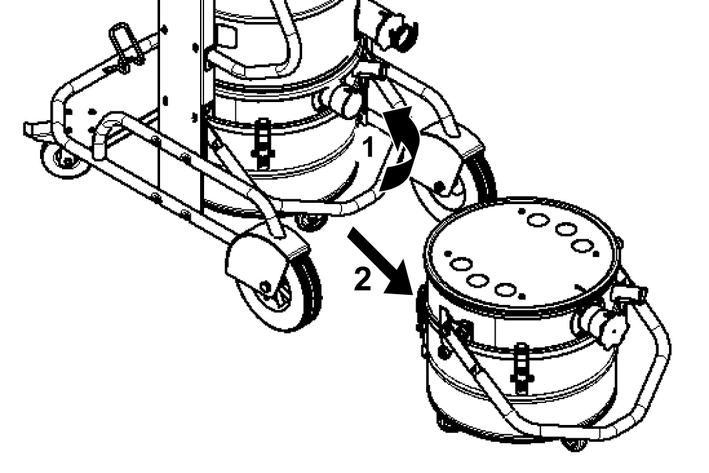

Pull the bow handle up.

The dirt receptacle is unlocked and lowered.

Pull the dirt receptacle out of the device by the bow handle.

Loosen the clamping straps on the dirt receptacle.

Remove the upper part of the dirt receptacle by the bow handle.

Remove the foam element from the lower part of the dirt receptacle.

Remove the strainer basket with the micro-fleece.

Remove the micro-fleece from the strainer basket.

Dispose of the micro-fleece in accordance with statutory regulations.

If necessary, drain the inert liquid from the dirt receptacle (see chapter Drain the inert liquid from the dirt receptacle).

You can use the inert liquid several times if necessary.

When fitting the upper part of the dirt receptacle, make sure that the float ball is inserted into the corresponding guide.

Improper handling when locking the dirt receptacle

Risk of crushing

Under no circumstances should you hold your hands between the dirt receptacle and filter ring or allow them to come close to the lifting mechanism while locking it.

Lock the dirt receptacle by operating the bow handle with both hands.

Static charge of the dirt receptacle

Ignition of dusts

Make sure that the grounding on the chassis is in contact with the dirt receptacle.

Fit the dirt receptacle in the reverse sequence and lock it with the bow handle.

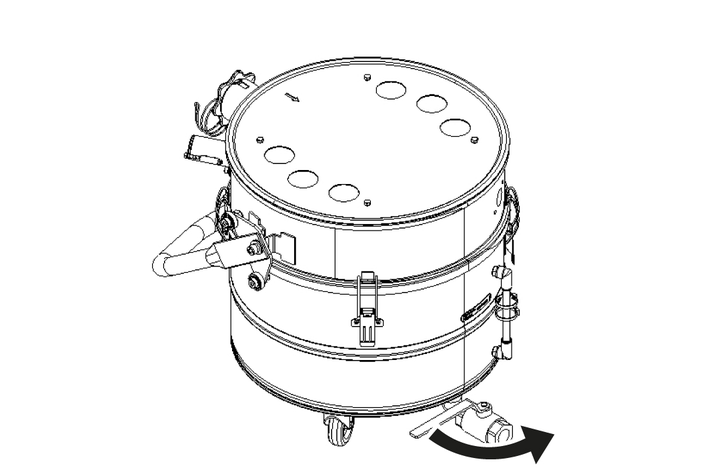

Switch off the device.

Secure the device with the parking brakes.

Close the suction connection (see chapter Closing the suction connection).

Pull the bow handle up.

The dirt receptacle is unlocked and lowered.

Pull the dirt receptacle out of the device by the bow handle.

Turn the lever on the ball tap by 90°.

Turn the lever to the original position when the collection container is completely empty.

Improper handling when locking the dirt receptacle

Risk of crushing

Under no circumstances should you hold your hands between the dirt receptacle and filter ring or allow them to come close to the lifting mechanism while locking it.

Lock the dirt receptacle by operating the bow handle with both hands.

Static charge of the dirt receptacle

Ignition of dusts

Make sure that the grounding on the chassis is in contact with the dirt receptacle.

Fit the dirt receptacle and lock it with the bow handle.

Improper disposal of waste water

Environmental pollution

Observe the local waste water treatment regulations.

Vacuum the inside and outside of the device and clean with a moist cloth.

A vacuum cleaner with the same or better classification must be used for vacuuming the device.

If necessary, rinse the accessories (not included in the scope of delivery) with water and dry them.

Wind the mains cable onto the cable holders.

Store the device in a dry room and secure it against unauthorised use.

Failure to observe the weight

Risk of injury and damage

Be aware of the weight of the device during transportation.

The dirt receptacle is emptied.

Close both suction connections for dust-free transport (see chapter Closing the suction connection).

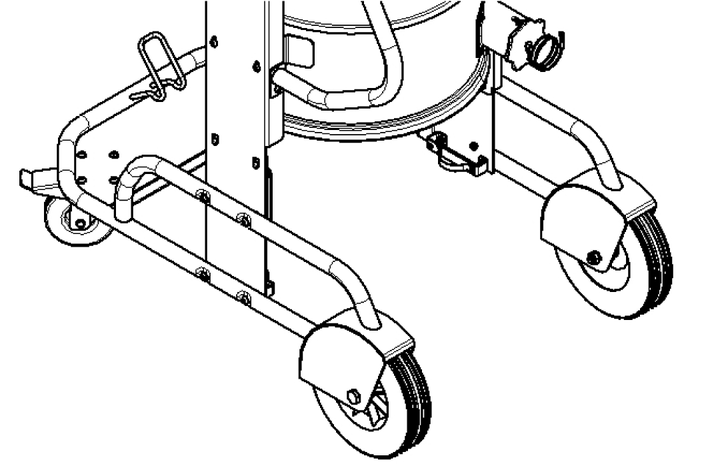

Release the parking brakes and push the device by the push handle.

Grasp the device by the chassis and the push handle for loading.

Secure the device against slipping and tipping over when transporting in vehicles.

Failure to observe the weight

Risk of injury and damage

Be aware of the weight of the device during storage.

The dirt receptacle is emptied.

Store the device indoors only.

Inadvertently starting up device, touching live components

Risk of injury, electric shock

Switch off the device before performing any work on the device.

Remove the mains plug.

Danger from dust that is harmful to your health

Respiratory sicknesses through inhalation of dust.

Wear a breathing protection mask of class P2 or higher and disposable clothing when performing maintenance work (e.g. filter change).

Danger from dust that is harmful to your health

Respiratory sicknesses through inhalation of dust.

Safety devices providing hazard protection must be checked for correct safety-related functionality at least annually by the manufacturer or an appropriately instruction person, e.g. absence of leaks, filter damage, functionality of the monitoring devices.

Care agents containing silicone

These can attach plastic components.

Do not use care agents containing silicone for cleaning.

Dust extraction machines are safety devices for the prevention or elimination of hazards according to the German BGV A1.

For servicing performed by the user, the device must be disassembled, cleaned and maintained only to the degree that this is possible without presenting a danger to the maintenance personnel and other persons. Suitable precautionary measures include detoxification before disassembly. Make provisions for local forced ventilation at the location where the device is to be disassembled, for cleaning the maintenance surface and to ensure adequate protection for the personnel.

The exterior of the device should be detoxified by vacuuming and wiped clean, or treated with sealant before being removed from the hazardous area. All device parts must be regarded as contaminated when they are taken from the hazardous area. Suitable measures must be taken to prevent distribution of the dust.

All contaminated objects resulting from maintenance and repair work that cannot be satisfactorily cleaned must be correctly disposed of. Such objects must be disposed of in sealed bags in accordance with the applicable regulations for the disposal of this type of waste.

The suction hose ports are to be closed using the sealing plugs during transport and maintenance of the device.

Note that you can carry out simple maintenance and care work yourself.

Clean the surface of the device and the interior of the container regularly with a moist cloth.

Carry out a regular visual inspection for clogging of the hoses.

Have the device regularly inspected according to the respective national accident prevention regulations. Maintenance work as specified by the manufacturer must be performed by a technically qualified person at the specified regular intervals and in accordance with the applicable regulations and safety requirements. Work on electrical components may only be performed by a qualified electrician. Please contact a KÄRCHER branch office if you have any questions.

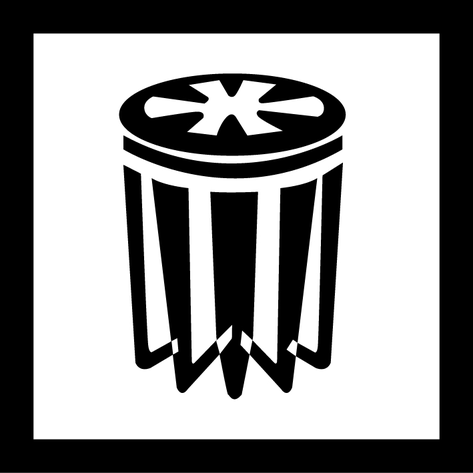

Switch off the device.

Pull out the mains plug.

Unlock and remove the suction head.

Unlock and remove the spacer.

Remove the contaminated star pleated filter.

Immediately after removing the contaminated star pleated filter from the unit, place it in a bag and seal the bag tightly.

Dispose of the contaminated star pleated filter according to legal requirements.

Remove any dirt deposits from the clean air side.

Check the sealing ring for damage.

Insert the new star pleated filter:

Pull the new star pleated filter over the filter vibrator on the spacer such that the vibrating elements are aligned centrally in the filter bags.

Place the spacer with star pleated filter and filter vibrator on the filter ring.

Lock the spacer.

Fit and lock the suction head.

Switch off the device.

Secure the device with the parking brakes.

Pull the bow handle up.

The dirt receptacle is unlocked and lowered.

Pull the dirt receptacle out of the device by the bow handle.

Loosen the clamping straps on the dirt receptacle.

Remove the upper part of the dirt receptacle by the bow handle.

Remove the foam element from the lower part of the dirt receptacle.

Remove the strainer basket with the micro-fleece.

Remove the micro-fleece from the strainer basket.

Dispose of the micro-fleece in accordance with statutory regulations.

Insert the new micro-fleece.

When fitting the upper part of the dirt receptacle, make sure that the float ball is inserted into the corresponding guide.

Improper handling when locking the dirt receptacle

Risk of crushing

Under no circumstances should you hold your hands between the dirt receptacle and filter ring or allow them to come close to the lifting mechanism while locking it.

Lock the dirt receptacle by operating the bow handle with both hands.

Static charge of the dirt receptacle

Ignition of dusts

Make sure that the grounding on the chassis is in contact with the dirt receptacle.

Fit the dirt receptacle in the reverse sequence and lock it with the bow handle.

Unintentional start-up of the device / electric shock

Unintentional start-up of the suction motor can cause injuries. Voltage present on electrical parts can cause an electric shock.

Switch off the device and unplug the mains plug before performing any work on the device.

Have all checks and work on electrical parts performed by an qualified technician.

The device must be switched off immediately in the event of a malfunction. The malfunction must be eliminated before switching the device on again.

If the malfunction cannot be corrected, the device must be checked by the Customer Service department.

Suction turbine does not start up

Remedy:

Check the socket and the power supply fuse.

Check the mains cable and the mains plug of the device.

Switch the device on.

Suction power decreases

Remedy:

Close the unsealed suction connection (see chapter Closing the suction connection).

Remove the blockages from the suction nozzle, the suction pipe or the suction hose.

Check that the suction head and the dirt receptacle are correctly seated.

Empty the dirt receptacle (see chapter Emptying the dirt receptacle).

Check the seating of the filter and correct if necessary.

Replace the main filter (see chapter Replacing the main filter).

Replace the micro-fleece (see chapter Replacing the micro-fleece).

Check the condition of the inert liquid.

Check the filling level of the inert liquid, top up the inert liquid if necessary (see chapter Fill the dirt receptacle with inert liquid).

Check the quality of the inert liquid, replace the inert liquid if necessary (see chapter Drain the inert liquid from the dirt receptacle and chapter Fill the dirt receptacle with inert liquid).

Suction power not present

Cause:

The mechanical switch-off interrupts the volume flow because there is too little inert liquid in the dirt receptacle.

Remedy:

Top up the inert liquid (see chapter Fill the dirt receptacle with inert liquid).

Escaping dust when vacuuming

Remedy:

Check the seating of the dirt receptacle.

Check the seating of the filter and correct if necessary.

Replace the main filter (see chapter Replacing the main filter).

Top up with inert liquid when using the device with a wet separator (see chapter Fill the dirt receptacle with inert liquid).

At the end of its service life, the device is to be disposed of in accordance with statutory regulations.

The warranty conditions issued by our relevant sales company apply in all countries. We shall remedy possible malfunctions on your appliance within the warranty period free of cost, provided that a material or manufacturing flaw is the cause. In a warranty case, please contact your dealer (with the purchase receipt) or the next authorised customer service site.

Further information can be found at: www.kaercher.com/dealersearch

Further warranty information (if available) can be found in the service area of your local Kärcher website under "Downloads".

Electrical connection | |

Mains voltage | 220-240 V |

Phase | 1 ~ |

Power frequency | 50-60 Hz |

Nominal power | 2100 W |

Maximum power | 2400 W |

Protection type | IPX4 |

Protection class | I* |

Maximum permissible mains grid impedance | 0.195+j0.122 Ω |

Dimensions and weights | |

Typical operating weight | 108 kg |

Length x width x height | 1020 x 680 x 1490 mm |

Filter area | 2.24 m2 |

Ambient conditions | |

Storage temperature | -10-40 °C |

Device performance data | |

Container capacity | 60 l |

Inert liquid container capacity | 20 l |

Suction material container capacity | 8 l |

Vacuum (with pressure relief valve) | 25.4 kPa |

Air quantity | 2x 74 l/s |

Suction hose connection | DN70 |

Nominal width of the suction hose | DN40/50 |

Filter order number | 9.439-542.0 |

Determined values in acc. with EN 60335-2-69 | |

Hand-arm vibration value | <2.5 m/s2 |

K uncertainty | 0.2 m/s2 |

Sound pressure level LpA | 79 dB(A) |

Uncertainty KpA | 2 dB(A) |

Mains cable | |

Type | H07RN-F 3G1.5 mm2 |

Part number | 6.650-035.0 |

Cable length | 10 m |

EU Declaration of Conformity |

We hereby declare that the machine described below complies with the relevant basic safety and health requirements in the EU Directives, both in its basic design and construction as well as in the version placed in circulation by us. This declaration is invalidated by any changes made to the machine that are not approved by us.

Product: Dry vacuum cleaner

Product: Wet/dry vacuum cleaner

Type: 9.990-xxx

Currently applicable EU Directives2006/42/EC (+2009/127/EC)

2014/30/EU

2011/65/EU

Harmonised standards usedEN 60335-1

EN 60335-2-69

EN 55014-1: 2017 + A11: 2020

EN 55014-2: 2015

EN IEC 61000-3-2: 2019

EN 61000-3-3: 2013 + A1: 2019

EN 61000-3-11: 2000

EN 62233: 2008

EN IEC 63000: 2018

Non-harmonised standards usedIEC 60335-1

IEC 60335-2-69

National standards used-

The signatories act on behalf of and with the authority of the Executive Board.

Documentation supervisor:

A. Haag

Kärcher Industrial Vacuuming GmbH

Robert-Bosch-Straße 4-8

73550 Waldstetten (Germany)

Ph.: +49 7171 94888-0

Fax: +49 7171 94888-528

Waldstetten, 24/04/01

Declaration of Conformity (UK) |

We hereby declare that the product described below complies with the relevant provisions of the following UK Regulations, both in its basic design and construction as well as in the version put into circulation by us. This declaration shall cease to be valid if the product is modified without our prior approval.

Product: Dry vacuum cleaner

Product: Wet/dry vacuum cleaner

Type: 9.990-xxx

Currently applicable UK RegulationsS.I. 2008/1597 (as amended)

S.I. 2016/1091 (as amended)

S.I. 2012/3032 (as amended)

Designated standards usedEN 60335-1

EN 60335-2-69

EN 55014-1: 2017 + A11: 2020

EN 55014-2: 2015

EN IEC 61000-3-2: 2019

EN 61000-3-3: 2013 + A1: 2019

EN 61000-3-11: 2000

EN 62233: 2008

EN IEC 63000: 2018

Non-designated standards usedIEC 60335-1

IEC 60335-2-69

National standards used-

The signatories act on behalf of and with the authority of the Executive Board.

Documentation supervisor:

A. Haag

Kärcher Industrial Vacuuming GmbH

Robert-Bosch-Straße 4-8

73550 Waldstetten (Germany)

Ph.: +49 7171 94888-0

Fax: +49 7171 94888-528

Waldstetten, 24/04/01

2-2-HC-A5-GS-awx2508