BDP 43/400 C

59563040 (01/21)

59563040 (01/21)

Read these original operating instructions and the enclosed safety instructions before using the device for the first time. Proceed accordingly.

Read these original operating instructions and the enclosed safety instructions before using the device for the first time. Proceed accordingly.

Keep both books for future reference or for future owners.

Use the device only in accordance with the information in these operating instructions.

This device is suitable for commercial use, e.g. in hotels, schools, hospitals, factories, shops, offices, and rental companies.

Only use the device for cleaning hard surfaces that are not sensitive to moisture and not sensitive to polishing.

Use the device only at an ambient temperature between +5°C and +40°C.

Do not use the device for cleaning frozen floors (e.g. in cold stores).

Only equip the device with original accessories and spare parts.

Only use the device for cleaning indoor floors or covered areas.

Do not use the device for cleaning public traffic routes.

The device must not be used outdoors.

Do not use the device in a corrosive environment.

Never use the device in potentially explosive atmospheres.

Only use the device on surfaces up to the maximum gradient specified in the “Technical data” section.

Only connect accessories to the socket in the device that are listed in the “Accessories” chapter.

Before using the device for the first time, read and observe these operating instructions and the accompanying brochure: Safety information for single disc machines, No. 5.956-659.0.

Missing or modified safety devices!

Safety devices are provided for your own protection.

Do not bypass, remove or render ineffective any safety devices.

The device cannot be started if the unlocking button is not pressed.

The packing materials can be recycled. Please dispose of packaging in accordance with the environmental regulations.

The packing materials can be recycled. Please dispose of packaging in accordance with the environmental regulations.

Electrical and electronic devices contain valuable, recyclable materials and often components such as batteries, rechargeable batteries or oil, which - if handled or disposed of incorrectly - can pose a potential danger to human health and the environment. However, these components are required for the correct operation of the device. Devices marked by this symbol are not allowed to be disposed of together with the household rubbish.

Electrical and electronic devices contain valuable, recyclable materials and often components such as batteries, rechargeable batteries or oil, which - if handled or disposed of incorrectly - can pose a potential danger to human health and the environment. However, these components are required for the correct operation of the device. Devices marked by this symbol are not allowed to be disposed of together with the household rubbish.

Current information on content materials can be found at: www.kaercher.de/REACH

Only use original accessories and original spare parts. They ensure that the appliance will run fault-free and safely.

Information on accessories and spare parts can be found at www.kaercher.com.

Description | Order no. |

|---|---|

ABS tank complete BDP 43/400 C | 2.644-237.0 |

ABS suction complete BDP 43/400 C | 2.644-238.0 |

ABS spray bottle complete BDP 43/400 C | 2.644-239.0 |

Impact protection ring, rubber | 6.994-155.0 |

Brush for polishing D 430 | 6,370-044.0 |

Brush, Palmyra | 6,370-046.0 |

Brush for scrubbing D 430 | 6,370-047.0 |

Pad drive board, pad D 430 | 6,370-063.0 |

Pad, red | 6.369-470.0 |

Polishing pad, white | 6.369-469.0 |

Polishing pad, beige, with natural hair | 6.371-149.0 |

Polishing pad, beige | 6.371-081.0 |

Diamond pad, green, 5 pieces | 6.371-238.0 |

Diamond pad, white, 5 pieces | 6.371-256.0 |

Diamond pad, yellow, 5 pieces | 6.371-257.0 |

Check the contents for completeness when unpacking. If any accessories are missing or in the event of any shipping damage, please notify your dealer.

* only with ABS tank

** only with ABS spray bottle

*** only with ABS suction

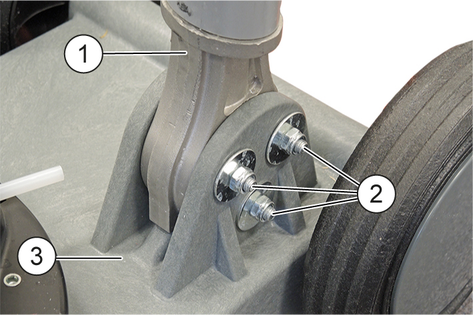

Align the holes in the push rod with the holes on the cleaning head.

Insert the screws with washers, and tighten using stop nuts with washers (tightening torque: 25 Nm).

Do not overtighten the stop nuts. The push rod must not jam in the mount, and must be tiltable without effort after unlocking.

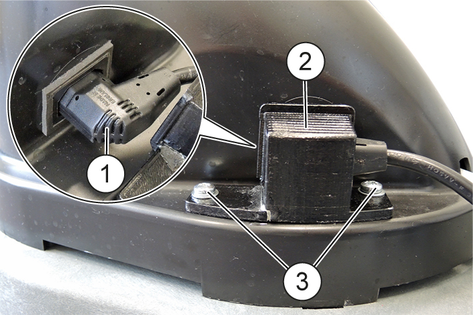

Insert the plug into the socket on the cleaning head.

Install the bar cover and tighten using screws with washers.

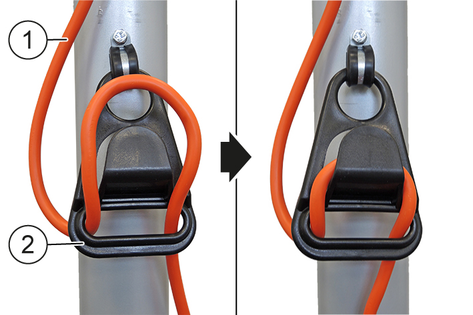

Attach the mains cable to the strain relief from below as shown.

Select the brush suitable for the cleaning task or the corresponding pad with the pad drive board.

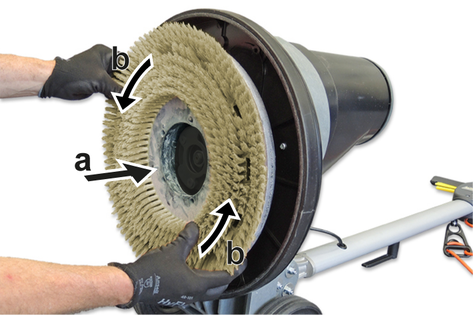

Make sure that the mains plug is unplugged.

Tilt the device backwards and place it carefully on the handle.

Place the brush or the pad drive board on the device and turn it 45° anticlockwise.

After installing a pad drive board: Centre and press the pad onto the pad drive board.

Erect the device.

Unsuitable detergents

Health risk, damage to the device

Use only recommended detergents. The operator carries all increased risks relating to operational safety and increased risk of accidents if using other detergents.

Use only detergents free of solvents, salt and hydrofluoric acid.

Adhere to the safety instructions stated on the detergent packaging.

Risk of damage

A cleaning solution with a temperature above 50°C can damage the device.

Only pour the cleaning solution into the detergent tank or the spray bottle at a maximum temperature of 50°C.

Pour in the cleaning solution.

Devices with ABS tank: Fill up to the MAX mark in the tank.

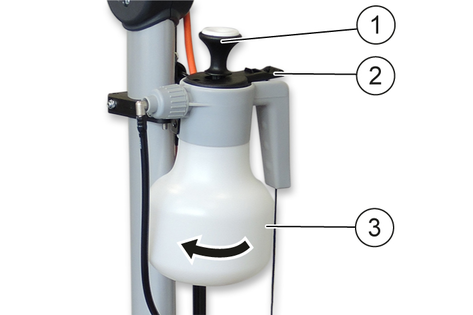

Devices with ABS spray bottle: Unscrew the spray bottle container, fill up to the MAX mark and screw it back on. Operate the pump rod several times to build up pressure in the spray bottle.

Danger of accident

The device can move uncontrollably if the push rod is adjusted while the motor is running.

Only adjust the push rod when the device is switched off.

Pull the tilt adjustment lever and hold it in position.

Bring the push rod into a comfortable position (about waist height).

Release the tilt adjustment lever.

Move the push rod up and down slightly until it latches into place.

Risk of injury

The maximum permissible mains grid impedance at the electrical connection point (see Technical data) must not be exceeded.

In the absence of ground friction, the brush or pad can reach very high speeds. They can be hurled away and cause injury.

Do not switch on the device when the cleaning head is swung up.

Contact your electricity supplier in the case of any uncertainties regarding the mains grid impedance at your electrical connection point.

Risk of damage

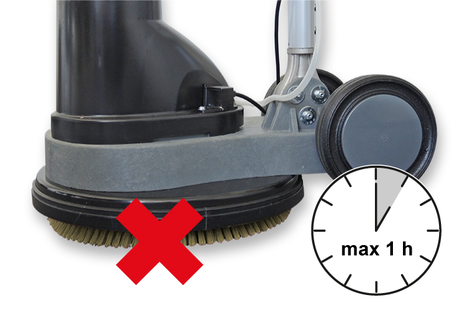

The floor covering can be damaged if the device is operated on the same spot for a long time.

Always move the device when it is switched on.

Turn the cable hook upwards, and unwind the mains cable completely.

Insert the mains plug into a mains socket.

The "Mains voltage" indicator light lights up.

Hold the handles firmly with both hands.

Press and hold the left or right unlocking button.

The unlocking buttons can only be pressed when the push rod is not vertical.

Pull the ON / OFF lever on the same side - the device starts.

Release the unlocking button.

Release the ON / OFF lever to interrupt operation.

Switch the device on.

Devices with ABS tank: Hook the pull rod into the inner or outer catch on the cleaning solution lever.

Inner catch: When operating the cleaning solution lever, a reduced amount of cleaning solution is added.

Outer catch: When operating the cleaning solution lever, the maximum amount of cleaning solution is added.

Release the cleaning solution lever 30 seconds before switching off the machine, as a certain amount of cleaning solution runs on.

Devices with ABS spray bottle: If necessary, add cleaning solution by pulling the cleaning solution lever.

Push or pull the device over the surface to be cleaned.

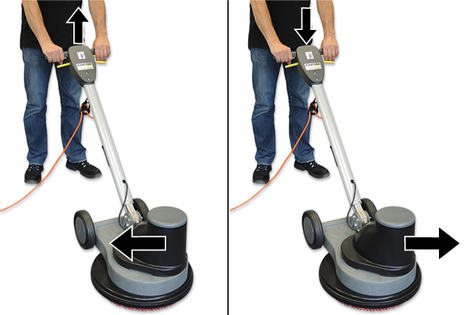

For lateral control, pull the handles slightly upwards - the device moves to the right.

Push the handles slightly down - the device moves to the left.

If the area is very dirty, run over it several times.

Then remove the waste water with a wet vacuum cleaner, or wipe it up with a cloth.

Risk of damage when vacuuming up liquids and damp dirt

The suction unit will be damaged if liquids and damp dirt are sucked up.

Only vacuum dry dirt, never liquids or damp dirt.

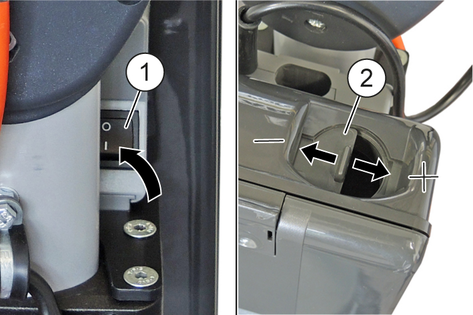

Press the suction ON / OFF switch to the ON position.

Switch on the device and move it over the surface to be vacuumed.

To change the suction power, move the suction power regulation slider sideways.

Pull the mains plug out of the socket.

Pull the tilt adjustment lever and hold it in position.

Bring the push rod into a vertical position.

Release the tilt adjustment lever.

Slightly move the push rod back and forth until it clicks into place.

Devices with ABS tank or ABS spray bottle: Remove the remaining cleaning solution from the tank or spray bottle.

Devices with ABS tank: Rinse and empty the tank with clear water.

Devices with ABS spray bottle: Rinse and empty the spray system with clear water.

Turn the cable hook down, and wrap the mains cable around the handle and cable hook.

Remove the brush or the pad drive board with pad.

Clean the device with a moist cloth.

Failure to observe the weight

Risk of injury and damage

Be aware of the weight of the device during transportation.

Pull the tilt adjustment lever and position the handle vertically.

Release the tilt adjustment lever.

Tilt the device back and transport to the destination.

When transporting in vehicles, secure the device against rolling away, slipping and tipping according to the respectively applicable guidelines.

Danger of electric shock, danger of frost

Water entering the device can cause electric shock.

Water in the device can freeze and cause damage.

Only store the device indoors.

Failure to observe the weight

Risk of injury and damage

Be aware of the weight of the device during transport and storage.

Store the device indoors only.

Remove brush or pad / pad drive board.

When the work is interrupted, do not place the device on the brush or the pad / pad drive board for longer than 1 hour, otherwise the brush or the pad / pad drive board will be damaged.

Risk of injury

The device may start up unexpectedly.

Be sure to pull the mains plug out of the socket before you start working on the device.

Wash dirty pads at a maximum of 60 °C.

Clean the casing of the device with a damp cloth and then rub dry.

Check the mains cable and mains plug for damage, have damaged parts replaced by an electrician.

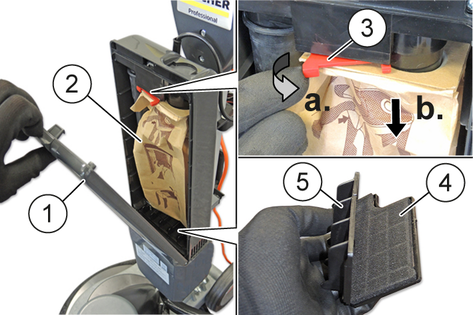

Make sure that the mains plug is unplugged.

Unlock the lid and remove.

Move the holder anticlockwise and remove the filter bag downwards.

At the latest, after changing the filter bag 5 times: Pull out the exhaust filter holder and open it.

Replace the exhaust filter.

Install the exhaust filter and filter bag in the reverse order.

Risk of injury

The device may start up unexpectedly.

Be sure to pull the mains plug out of the socket before you start working on the device.

In the event of malfunctions that cannot be remedied using the following information, please contact customer service.

Unsatisfactory cleaning results

Remedy:

Replace a dirty brush or pad.

Replace a worn brush or pad.

Check the suitability of the detergent used for the application.

Check the suitability of the brush or pad used for the application.

The device vibrates strongly

Remedy:

Check the brush or pad for damage, replace if necessary.

Check the central position of the pad on the pad drive board, if necessary attach the pad centred.

Check attachment of the pad, replace pad or pad drive board if necessary.

The brush or the pad do not turn

Remedy:

Check whether foreign objects block the brush or the pad drive board, remove foreign objects if necessary.

Plug the mains plug into the socket.

The overload protection has triggered, let the device cool down for 30 minutes.

Discharge of cleaning solution too low

Remedy:

Fill the tank with cleaning solution.

Attach the pull rod to the cleaning solution lever.

Check the hose of the cleaning solution for kinks, eliminate kinks if necessary.

Spray system does not spray or does not spray enough

Remedy:

Pour cleaning solution into the spray bottle.

Operate the pump rod several times to build up enough pressure.

Clean the spray nozzle.

Flush the spray system with clean water.

Suction does not work or suction power is too low

Remedy:

Plug the mains plug into the socket.

Insert the mains plug for suction on the device.

Close the suction power regulation slider.

Check the suction hose for correct seating on the suction unit and the suction skirt, attach it correctly if necessary.

If the suction warning light lights up red:

Check the suction hose for blockage, remove blockage if necessary

Check the filter bag and the exhaust filter for contamination/blockage, replace if necessary.

Check that the suction skirt is correctly seated on the cleaning head, attach correctly if necessary.

Check the suction skirt for wear and damage, and replace if necessary.

Discharge of cleaning solution too low

Remedy:

Fill the tank with cleaning solution.

Attach the pull rod to the cleaning solution lever.

Check the hose of the cleaning solution for kinks, eliminate kinks if necessary.

Spray system does not spray or does not spray enough

Remedy:

Pour cleaning solution into the spray bottle.

Operate the pump rod several times to build up enough pressure.

Clean the spray nozzle.

Flush the spray system with clean water.

Suction does not work or suction power is too low

Remedy:

Plug the mains plug into the socket.

Insert the mains plug for suction on the device.

Close the suction power regulation slider.

Check the suction hose for correct seating on the suction unit and the suction skirt, attach it correctly if necessary.

If the suction warning light lights up red:

Check the suction hose for blockage, remove blockage if necessary

Check the filter bag and the exhaust filter for contamination/blockage, replace if necessary.

Check that the suction skirt is correctly seated on the cleaning head, attach correctly if necessary.

Check the suction skirt for wear and damage, and replace if necessary.

The warranty conditions issued by our sales company responsible apply in all countries. We shall remedy possible malfunctions on your device within the warranty period free of cost, provided that a material or manufacturing defect is the cause. In a warranty case, please contact your dealer (with the purchase receipt) or the next authorised customer service site.

You can find more detailed information at: www.kaercher.com/dealersearch

Device performance data | |

Voltage | 220-240 V |

Phase | 1 ~ |

Frequency | 50 Hz |

Maximum permissible mains grid impedance | 0.401 Ω |

Power rating | 1300 W |

Suction connection output max. | 1500 W |

Fresh water tank capacity | 12 l |

Max. working area slope | 2 % |

Surface performance | 475 m2/h |

Pad | |

Brush / pad diameter | 430 mm |

Brush / pad speed | 380 1/min |

Brush / pad contact pressure | 22 g/cm² |

Dimensions and weights | |

Length | 650 mm |

Width | 470 mm |

Height | 1210 mm |

Weight | 32 kg |

Cable length | 15 m |

Determined values in acc. with EN 60335-2-67 | |

Hand-arm vibration value | <2,5 m/s2 |

Uncertainty K | 0,3 dB(A) |

Sound pressure level LpA | 54,9 dB(A) |

Peak sound level LpCpeak | 73,4 dB(A) |

Sound power level LwA | 67,7 dB(A) |

Sound level with suction LpA | 72,7 dB(A) |

Peak sound level with suction LpCpeak | 87,2 dB(A) |

Sound power level with suction LwA | 86,9 dB(A) |

EU Declaration of Conformity |

We hereby declare that the machine described below complies with the relevant basic safety and health requirements in the EU Directives, both in its basic design and construction as well as in the version placed in circulation by us. This declaration is invalidated by any changes made to the machine that are not approved by us.

Product: Floor cleaner

Type: 1.291-xxx

Currently applicable EU Directives2006/42/EC (+2009/127/EC)

2014/30/EU

2011/65/EU

Commission Regulation(s)(EU) 2019/1781

Harmonised standards usedEN 60335-1

EN 60335-2-67

EN 55014-1: 2006+A1: 2009+A2: 2011

EN 55014-2: 1997+A1: 2001+A2: 2008

EN 61000-3-2: 2014

EN 61000-3-3: 2013

EN 62233: 2008

EN IEC 63000: 2018

EN 61000-3-11: 2000

Conformity evaluation procedure used2000/14/EC

National standards used-

The signatories act on behalf of and with the authority of the company management.

Documentation supervisor:

S. Reiser

Alfred Kärcher SE & Co. KG

Alfred-Kärcher-Str. 28 - 40

71364 Winnenden (Germany)

Ph.: +49 7195 14-0

Fax: +49 7195 14-2212

Winnenden, /09/01

Declaration of Conformity (UK) |

We hereby declare that the product described below complies with the relevant provisions of the following UK Regulations, both in its basic design and construction as well as in the version put into circulation by us. This declaration shall cease to be valid if the product is modified without our prior approval.

Product: Floor cleaner

Type: 1.291-xxx

Currently applicable UK RegulationsS.I. 2008/1597 (as amended)

S.I. 2016/1091 (as amended)

S.I. 2012/3032 (as amended)

Commission Regulation(s)(EU) 2019/1781

Designated standards usedEN 60335-1

EN 60335-2-67

EN 55014-1: 2006+A1: 2009+A2: 2011

EN 55014-2: 1997+A1: 2001+A2: 2008

EN 61000-3-2: 2014

EN 61000-3-3: 2013

EN 62233: 2008

EN IEC 63000: 2018

EN 61000-3-11: 2000

Applied conformity assessment procedureS.I. 2001/1701 (as amended)

National standards used-

The signatories act on behalf of and with the authority of the company management.

Documentation supervisor:

S. Reiser

Alfred Kärcher SE & Co. KG

Alfred-Kärcher-Str. 28 - 40

71364 Winnenden (Germany)

Ph.: +49 7195 14-0

Fax: +49 7195 14-2212

Winnenden, /09/01