HDS 8/18-4 C/CXA

59794650 (07/24)

59794650 (07/24)

Read these original instructions and the enclosed safety instructions before using the device for the first time. Act in accordance with them.

Read these original instructions and the enclosed safety instructions before using the device for the first time. Act in accordance with them.

Keep both books for future reference or for future owners.

If the operating instructions and safety instructions are not observed, the device can be damaged and dangers could arise for users and other persons.

Notify the dealer immediately in the case of shipping damage.

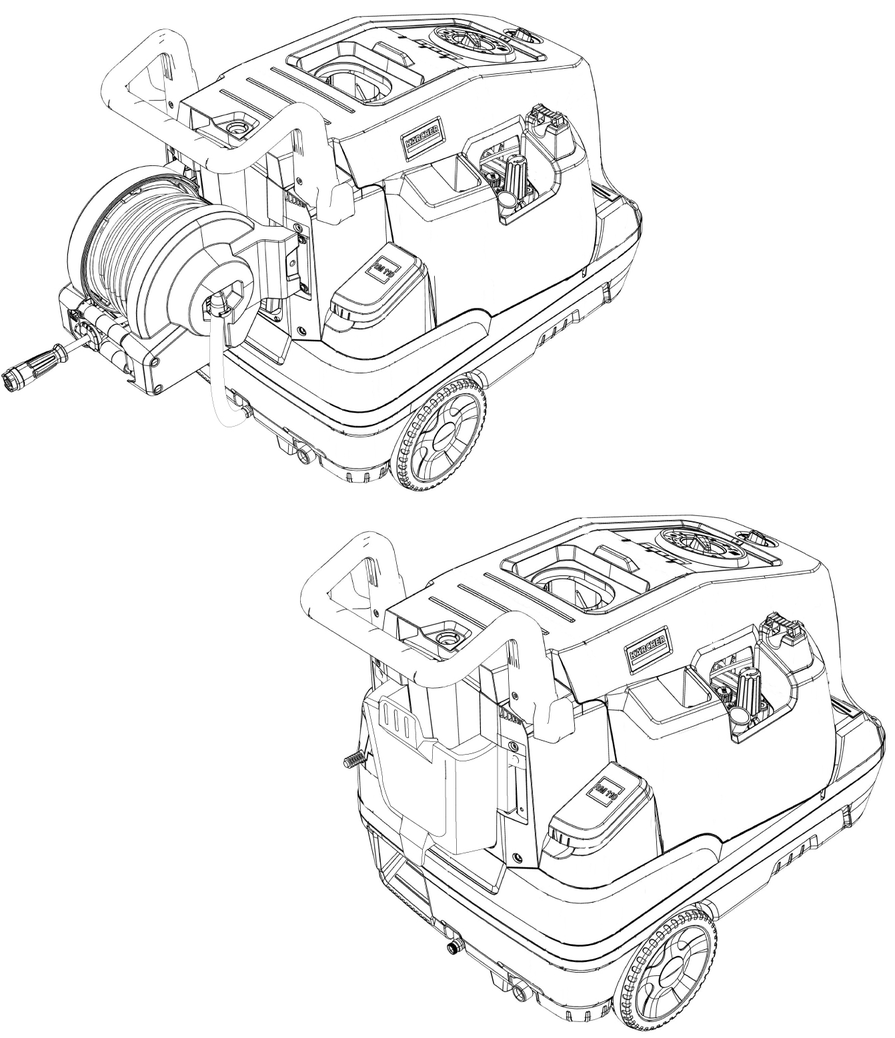

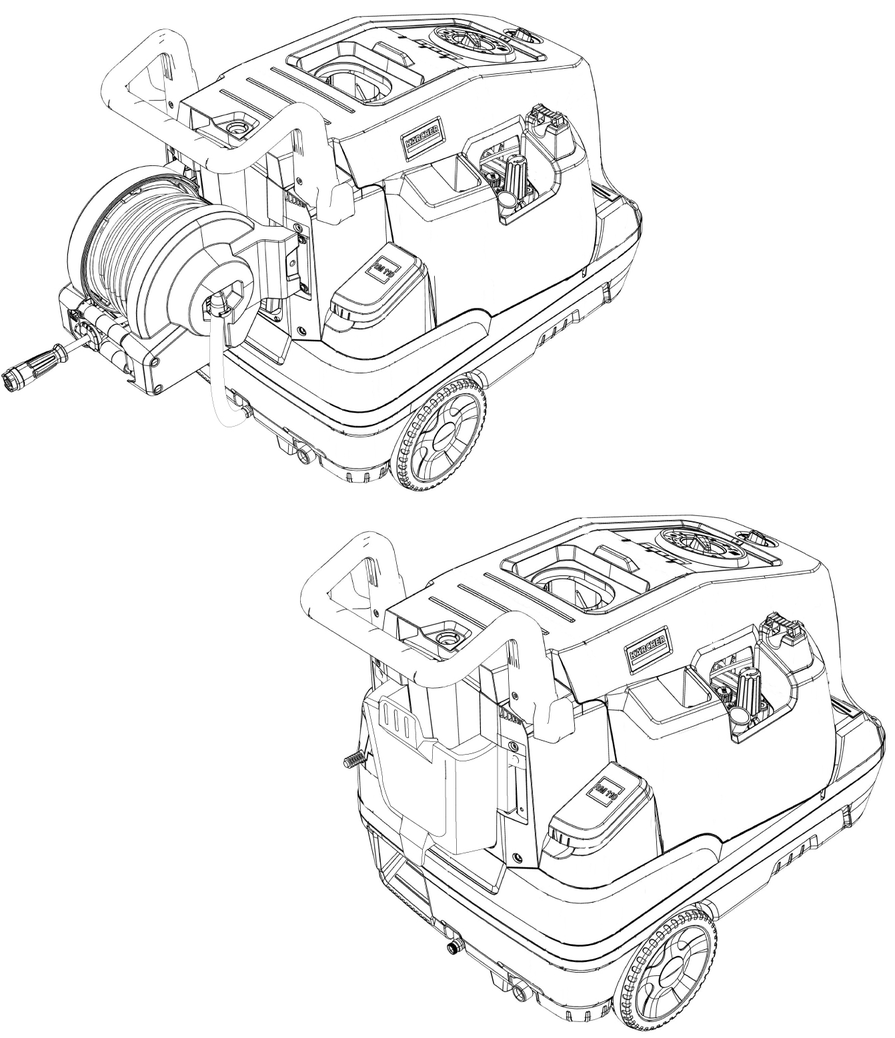

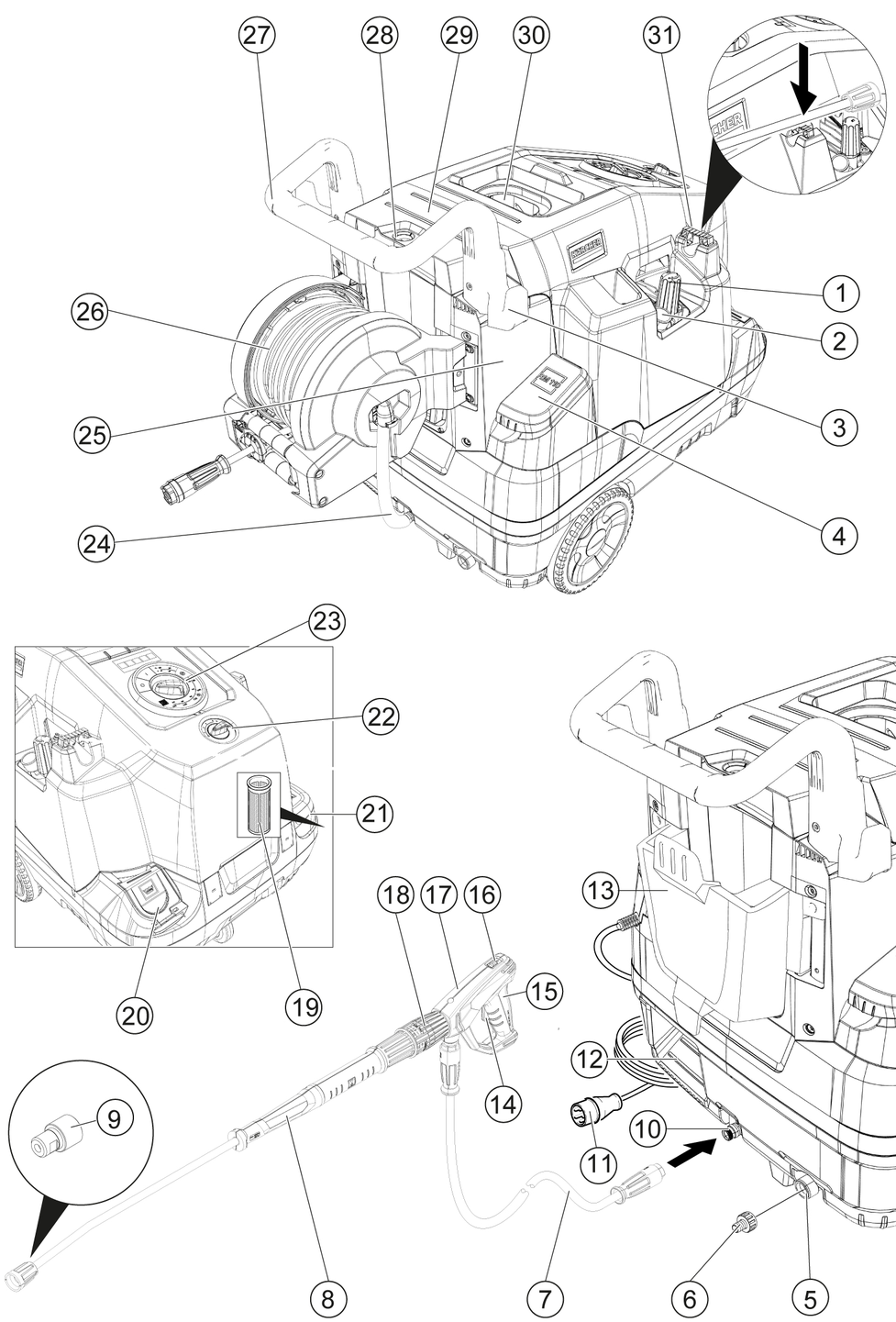

Check the package contents when unpacking for missing accessories or for damage. Scope of delivery see illustration A.

At operating elevations of approx. 800 m above sea level or higher, please contact your dealer to have the burner setting adjusted to the elevation and reduced oxygen content.

The following safety instructions apply to the device:

Observe the respectively applicable national regulations for liquid jet cleaners.

Observe the respectively applicable national accident prevention regulations. Liquid jet cleaners must be tested regularly and the results of the test recorded in writing.

Note that the heating system in the device is classified as a furnace. Furnaces must be inspected regularly according to the applicable national regulations.

According to the application national regulations, this device must be initially commissioned by a qualified person when used commercially. KÄRCHER has already performed and documented this initial commissioning for you. You can request the documentation for this from your KÄRCHER partner. Please provide the part number and works number of the device when requesting documentation.

We explicitly state that the application national regulations require that this device must be inspected regularly by a qualified person. Please contact your KÄRCHER partner for this.

No modifications may be made to the device or accessories.

Safety devices protect the user and may not be disabled or functionally circumvented.

When reducing the water volume at the pump head or with the pressure/quantity regulator on the high-pressure gun, the overflow valve opens and part of the water flows back to the pump suction side.

If the high-pressure gun is closed so that all the water flows back to the pump suction side, the pressure switch on the overflow valve switches off the pump.

If the high-pressure gun is opened again, the pressure switch on the cylinder head switches the pump on again.

The overflow valve is set and sealed at the factory. The adjustment is performed only by customer service.

The safety valve opens if the overflow valve or pressure switch is faulty.

The safety valve is adjusted and sealed at the factory. The adjustment is performed only by customer service.

The water shortage safeguard prevents the burner from switching on when there is a lack of water.

The exhaust gas thermostat switches the device off when the emission temperature is too high.

The packing materials can be recycled. Please dispose of packaging in accordance with the environmental regulations.

The packing materials can be recycled. Please dispose of packaging in accordance with the environmental regulations.

Electrical and electronic devices contain valuable, recyclable materials and often components such as batteries, rechargeable batteries or oil, which - if handled or disposed of incorrectly - can pose a potential danger to human health and the environment. However, these components are required for the correct operation of the device. Devices marked by this symbol are not allowed to be disposed of together with the household rubbish.

Electrical and electronic devices contain valuable, recyclable materials and often components such as batteries, rechargeable batteries or oil, which - if handled or disposed of incorrectly - can pose a potential danger to human health and the environment. However, these components are required for the correct operation of the device. Devices marked by this symbol are not allowed to be disposed of together with the household rubbish.

Current information on content materials can be found at: www.kaercher.de/REACH

Please do not allow engine oil, heating oil, diesel and petrol to enter the environment. Please protect the ground and dispose of old oil in an environmentally friendly manner.

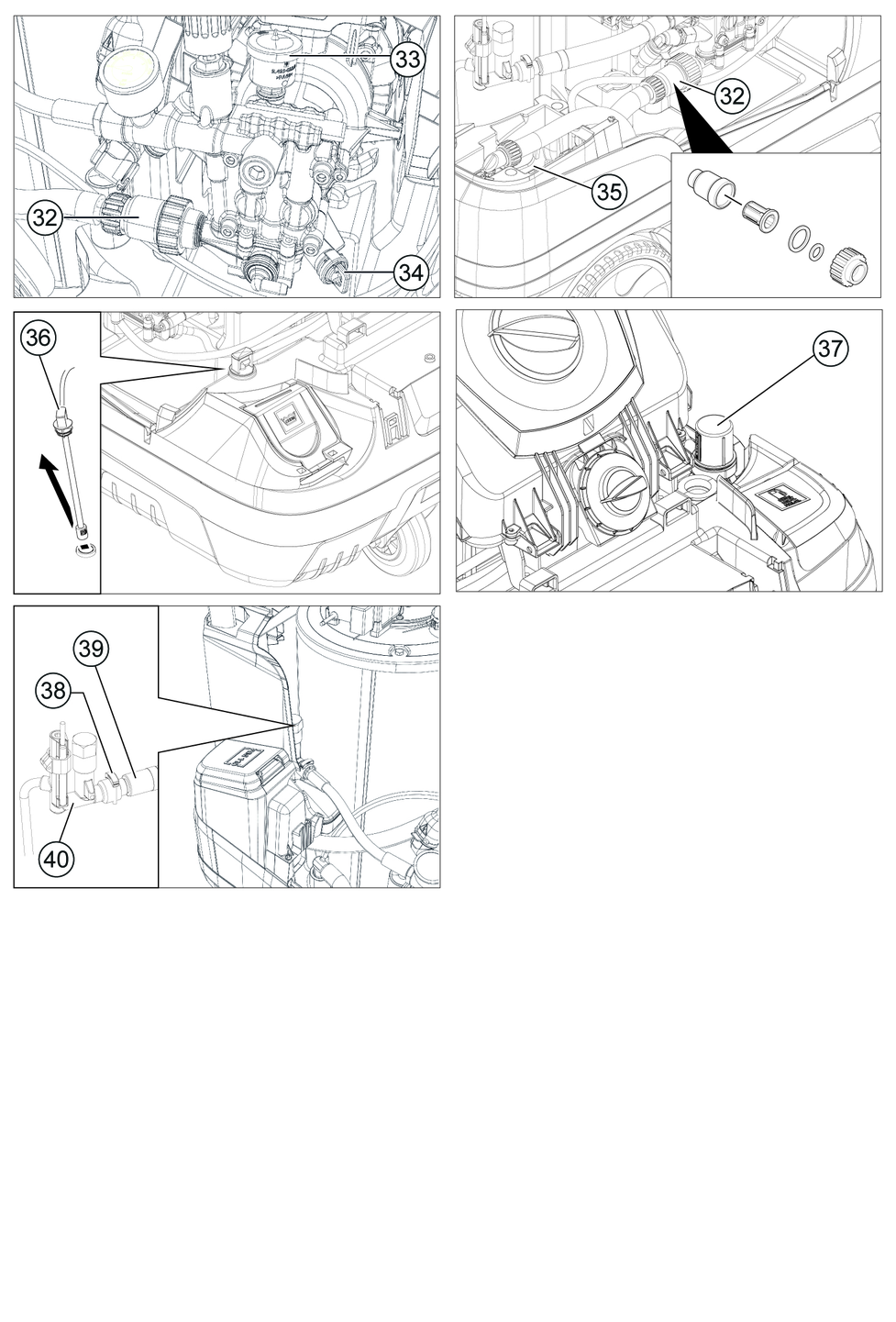

Only use the device for cleaning, e.g. machines, vehicles, buildings, tools, façades, terraces and garden equipment.

Use at petrol stations or other hazard zones

Risk of injury

Adhere to the respective safety regulations.Do not allow waste water containing mineral oil to penetrate soil, waterways or the sewage system. Only wash the motor or the undercarriage in suitable places with an oil separator.

Dirty water

Premature wear and tear or deposits in the device

Supply the device using only clean water, or recycled water that does not exceed the specified limit values.The following limit values apply to the water supply:

pH value: 6.5-9.5

Electrical conductivity: Conductivity of fresh water + 1200 µS/cm, maximum conductivity 2000 µS/cm

Settleable particles (sample volume 1 l, settling time 30 minutes): < 0.5 mg/l

Filterable particles: < 50 mg/l, no abrasive substances

Hydrocarbons: < 20 mg/l

Chloride: < 300 mg/l

Sulphate: < 240 mg/l

Calcium: < 200 mg/l

Total hardness: < 28 °dH, < 50° TH, < 500 ppm (mg CaCO3/l)

Iron: < 0.5 mg/l

Manganese: < 0.05 mg/l

Copper: < 2 mg/l

Active chloride: < 0.3 mg/l

Free of unpleasant odours

If the device is connected to a chimney or if the device cannot be seen, we recommend installing a flame monitor (option).

Only use original accessories and original spare parts. They ensure that the appliance will run safely and fault-free.

Information on accessories and spare parts can be found at www.kaercher.com.

The scope of delivery for the appliance is shown on the packaging. Check the contents for completeness when unpacking. If any accessories are missing or in the event of any shipping damage, please notify your dealer.

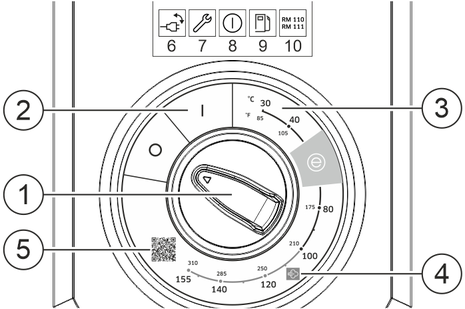

0 = off

Control elements for the cleaning process are yellow.

Control elements for maintenance and servicing are light grey.

Damaged components

Risk of injury

Check that the device, accessories, supply lines and connections are in perfect condition. If the condition is not perfect, you may not use the device.Apply the parking brake.

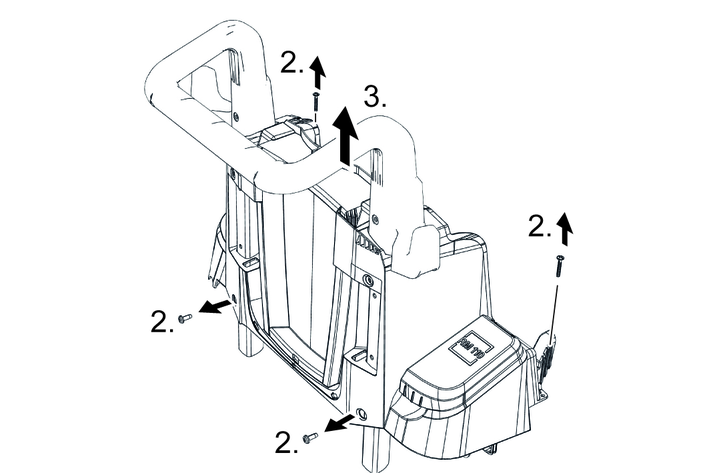

Mount the handlebar, observing the tightening torque of the screws (6.5-7.0 Nm).

Hang the tool bag on the upper latches on the device.

Fold the tool bag down and click into place.

Fasten the tool bag with 2 screws (tightening torque: 6.5-7.0 Nm).

2 screws remain left over.

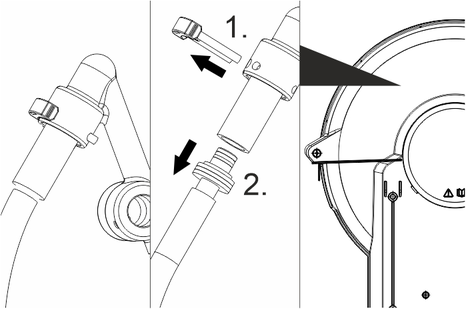

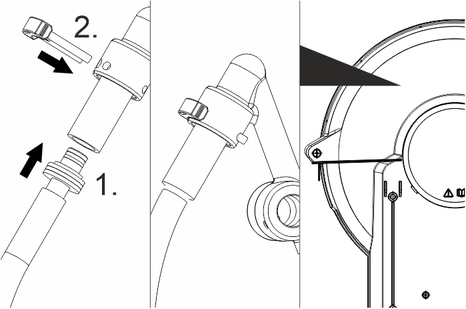

Device with ANTI!Twist: Attach the yellow high-pressure hose connection to the high-pressure gun.

The EASY!Lock system connects components quickly and safely via a single turn of the quick-release thread.

Connect the spray lance to the high-pressure gun and hand-tighten (EASY!Lock).

Plug the high-pressure nozzle onto the spray lance.

Fit the union nut and hand-tighten (EASY!Lock).

Device without a hose reel: Connect the high-pressure hose to the high-pressure gun and high-pressure connection of the device and tighten hand-tight (EASY!Lock).

Device with a hose reel: Connect the high-pressure hose to the high-pressure gun and hand-tighten (EASY!Lock).

Rolled-up high-pressure hose

Risk of damage

Fully unroll the high-pressure hose before starting operation.RM 110 prevents calcification of the heating coil in the presence of hard water.

RM 111 prevents the formation of black water and cares for the pump in the presence of soft water.

Water hardness (°dH) | System care products to be used |

<3 | RM 111 |

>3 | RM 110 |

Determine the local water hardness via the local supply company or with a hardness tester (order number 6.768-004.0).

A test container of system care is included in the scope of delivery.

System care is a highly effective agent for preventing calcification of the pump when operating with calcareous tap water. This is drip-fed dosed into the float tank.

The dosage is set to medium water hardness at the factory.

Fill up the system care.

Unsuitable fuel

Risk of explosion

Only use diesel fuel or light heating oil. Unsuitable fuels, such as petrol, must not be used.Operation with an empty fuel tank

Destruction of the fuel pump

Never operate the device with an empty fuel tank.Open the tank cap.

Refill the fuel.

Close the tank cap.

Wipe up the spilt fuel.

Unsuitable detergents

Risk of injury

Use only KÄRCHER products.Never fill with solvents (e.g. petrol, acetone, thinners).Avoid contact with eyes and skin.Observe the safety and handling instructions of the detergent manufacturer.Kärcher offers an individual range of cleaning and care products. Your dealer will be happy to advise you.

Fill with detergent.

See the "Technical data" for the connected loads.

The supply hose is not included in the scope of delivery.

Connect the supply hose (minimum length 7.5 m, minimum diameter 3/4") to the water connection of the device and to the water inlet (e.g. tap) using the water connection adapter.

Open the water inlet.

Risk of injury and damage, contamination of drinking water

The seals in the device are not resistant to solvents. The spray mist of solvents is highly flammable, explosive and toxic.

Never aspirate liquids containing solvents such as paint thinner, petrol, oil or unfiltered water. Never draw water from drinking water containers.If the device is to draw water from an external container, the following modification is required:

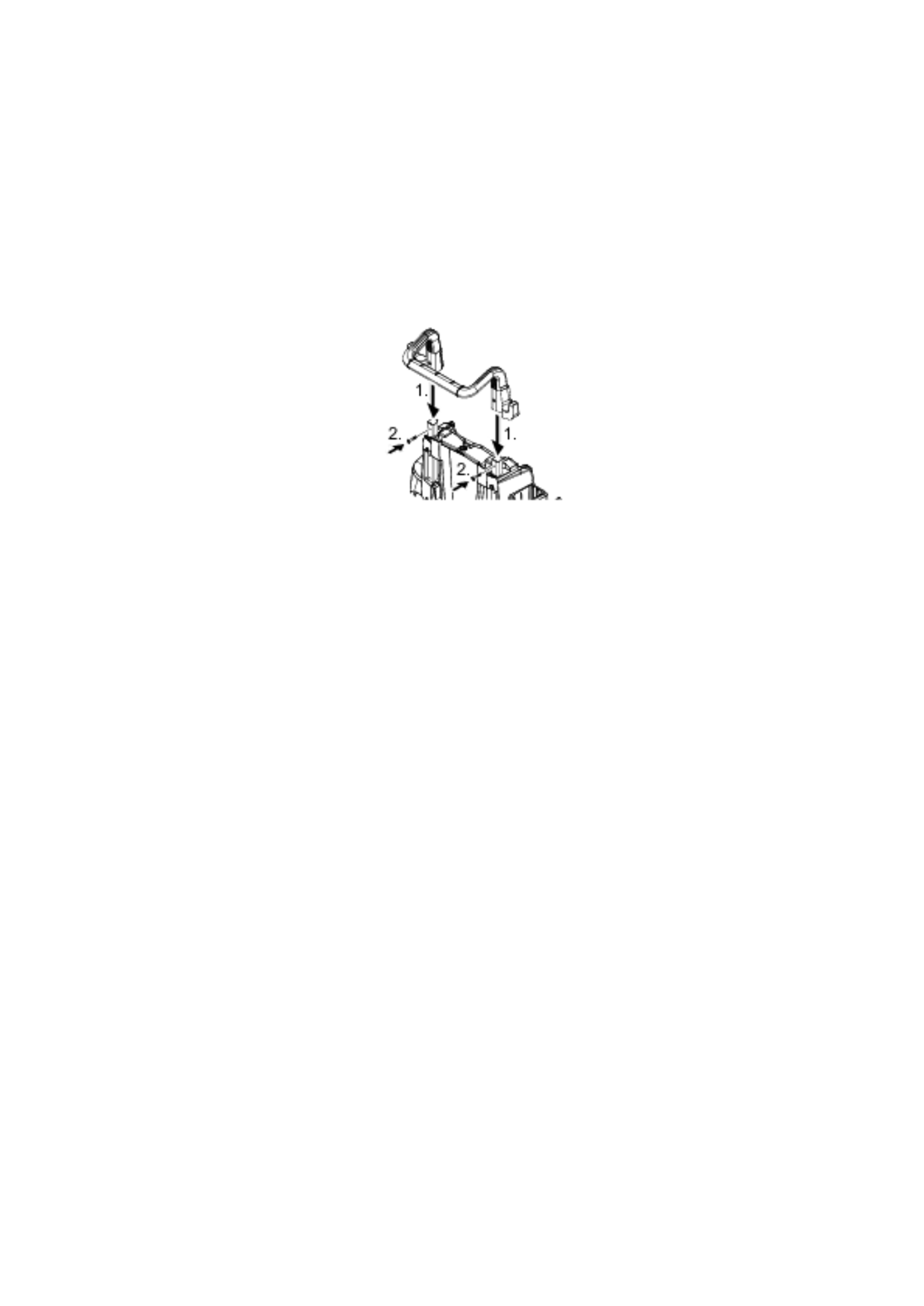

Open the filler opening for system care.

Unscrew and remove the system care cover.

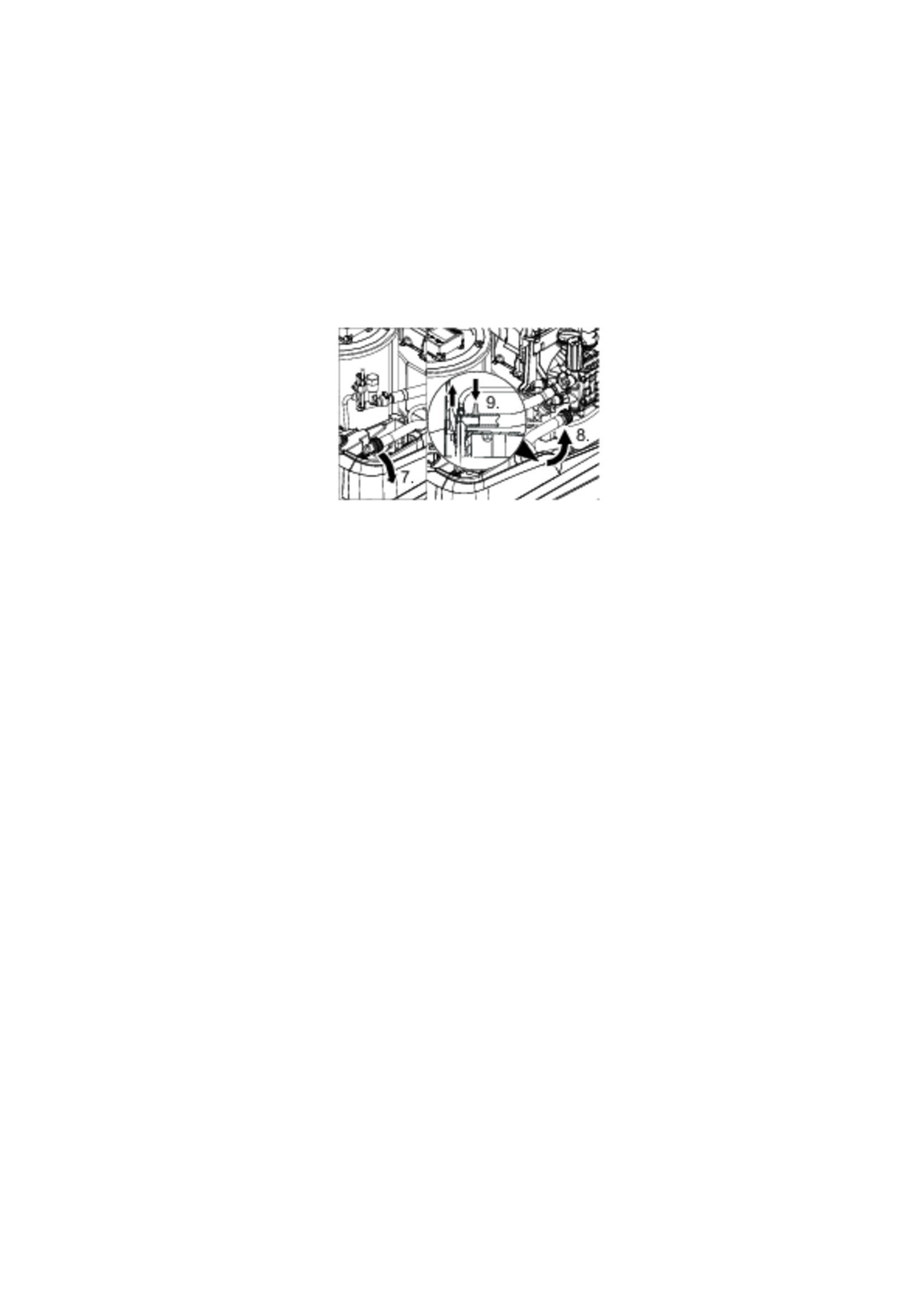

Only for devices with a hose reel: Remove the hose reel. To do this, release the 4 screws and place the hose reel next to the device.

Unscrew the 2 screws on the burner housing.

Unscrew and remove the rear wall.

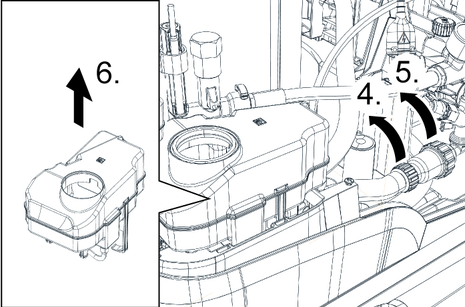

Remove the water connection on the fine filter.

Unscrew the fine filter on the pump head.

Remove the system care container.

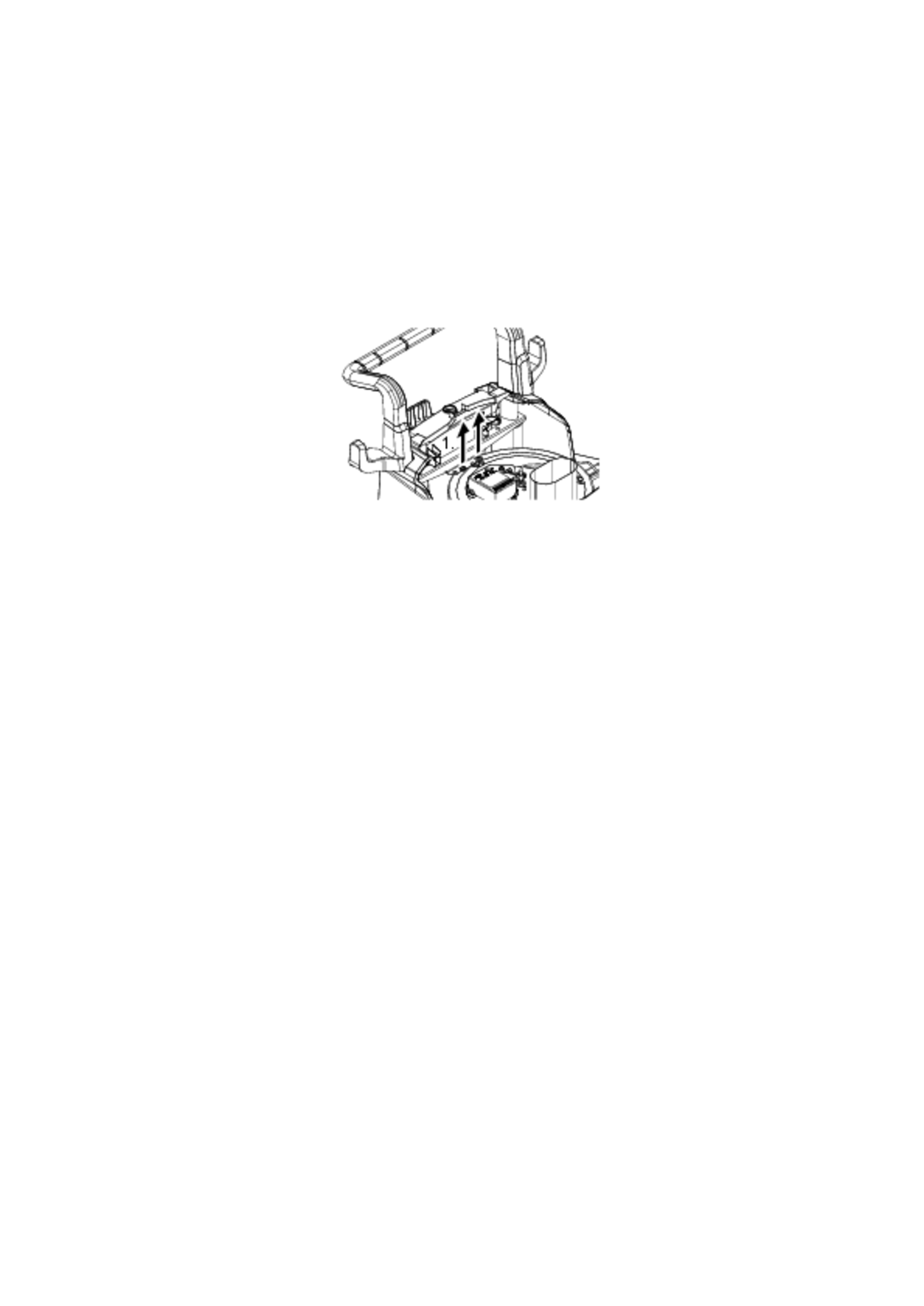

Unscrew the upper supply hose to the float tank.

Connect the upper supply hose to the pump head.

Plug the flushing line of the detergent dosing valve onto the blind plug.

Connect the suction hose (diameter at least 3/4") with filter (accessory) to the water connection.

Hang the suction hose in an external water source.

Maximum suction height: 0.5 m

Until the pump draws in water: Set the pressure/quantity regulator of the pump unit to the maximum value and close the detergent dosing valve.

Reinstall in the in the reverse order. Make sure that the solenoid valve cable is not pinched on the system care container.

Unsuitable electrical extension cables

Electric shock

Only use approved and appropriately marked electrical extension cables with a sufficient line cross section for outdoors.Make sure that the plug and coupling of an extension cable used are watertight.Always unroll extension cables completely.Exceeding the grid impedance

Electrical shock in the event of a short-circuit

The maximum permissible mains grid impedance at the electrical connection point (see Technical data) must not be exceeded.Contact your electricity supplier in the case of any uncertainties regarding the mains grid impedance at your electrical connection point.For connected loads, see technical data and type plate.

The electrical connection must be carried out by an electrician and comply with IEC 60364-1.

Flammable fluids

Risk of explosion

Do not spray inflammable liquids.Operation without spray lance

Risk of injury

Never operate the device without the spray lance installed.Before each use, check that the spray lance is firmly seated. The screw connection of the spray lance must be tightened hand tight.High-pressure water jet

Danger of injury

Never fasten the trigger and safety lever in the actuated position.Do not use the high-pressure gun when the safety lever is damaged.Push the safety latch of the high-pressure gun forwards every time before starting work with the device.Hold the high-pressure gun and spray lance with both hands.Operation with an empty fuel tank

Destruction of the fuel pump

Never operate the device with an empty fuel tank.Opening the high-pressure gun: Actuate the safety lever and trigger.

Closing the high-pressure gun: Release the safety lever and trigger.

Switch off the device and operate the high-pressure gun until the device is depressurized.

Lock the high-pressure gun by pushing the safety latch forwards.

Change the nozzle.

Set the trigger to the operating mode. The standby mode indicator light lights up. The device starts up briefly and switches off as soon as the working pressure is reached.

If the direction of rotation indicator light lights up during operation, switch off the device immediately and rectify the fault, see "Troubleshooting".

Unlock the high-pressure gun by pushing the safety latch to the rear. When the high-pressure gun is actuated, the device switches on again.

If no water comes out of the high-pressure nozzle, bleed the pump. See help in the event of malfunctions – device does not build up pressure.

30 °C to 98 °C: Clean with hot water.

100 °C to 150 °C: Clean with steam.

Set the power switch to the desired temperature.

During steam operation: Replace the high-pressure nozzle (stainless steel) with the steam nozzle (brass) (see Operation with steam).

Turn the regulating spindle clockwise: Increase the working pressure (MAX).

Turn the regulating spindle anticlockwise: Reduce the working pressure (MIN).

Danger of a loose spray lance

Risk of injury

Take care to ensure that the spray lance screw connection does not release when adjusting the pressure/quantity control.If you want to work with reduced pressure over the long term, set the pressure on the pressure/quantity regulator of the pump unit.

Set the power switch to max. 98 °C.

Set the working pressure on the pressure/quantity regulator of the pump unit to the maximum value.

Adjust the working pressure and flow rate by turning (variable) the pressure/quantity regulator on the high-pressure gun (+/-).

Use detergents sparingly to conserve the environment.

The detergent must be suitable for the surface to be cleaned.

The guide values on the control panel refer to the maximum working pressure.

If detergent is to be sucked in from an external container, route the detergent suction hose through the recess to the outside.

Set the concentration of the detergent via the detergent dosing valve according to the manufacturer's instructions.

Always initially direct the high-pressure jet at the object to be cleaned from a distance to avoid damage due to excessive pressure.

Set the working pressure, the cleaning temperature and the detergent concentration according to the surface to be cleaned.

Loosen dirt: Spray the detergent sparingly and let it take effect for 1... 5 minutes, but do not let it dry.

Remove dirt: Rinse off the loosened dirt with the high-pressure jet.

For removing light contamination and for rinsing, e.g. garden machines, terrace, tools.

Adjust the working pressure as required.

30-50 °C: Light soiling

Max. 60 °C: Soiling containing protein, e.g. in the food industry

60-90 °C: Car cleaning, machine cleaning

100-110 °C: Preservative removal, very greasy soiling

Up to 140 °C: Thawing aggregates, façade cleaning in some cases

Hot water

Risk of scalding

Avoid contact with hot water.Set the power switch to the desired temperature.

Hot steam

Risk of scalding

At work temperatures above 98 °C, the working pressure must not exceed 3.2 MPa (32 bar).It is therefore essential that the following measures are carried out:

Replace the high-pressure nozzle (stainless steel) with the steam nozzle (brass, part no. see Technical Data).

Completely open the pressure/quantity regulator on the high-pressure gun, towards + as far as it will go.

Set the working pressure on the pressure/quantity regulator of the pump unit to the minimum value.

Set the power switch to min. 100 °C.

The device works in the most economical temperature range (max. 60 °C).

Lock the high-pressure gun by pushing the safety latch forwards.

Set the detergent dosing valve to "0".

Set the power switch to level 1 (operation with cold water).

Flush the device clean for at least 1 minute with the high-pressure gun open.

Risk of injury from hot water or steam

Risk of scalding

After operation with hot water or steam, the device must be operated with the gun opened with cold water for at least two minutes to cool it down.Close the water inlet.

Open the high-pressure gun.

Switch on the pump with the power switch and let it run for 5-10 seconds.

Close the high-pressure gun.

Set the power switch to "0/OFF".

Only pull the mains plug out of the socket only when your hands are dry.

Remove the water connection.

Actuate the high-pressure gun until the device is completely depressurised.

Lock the high-pressure gun by pushing the safety latch forwards.

Frost hazard

Destruction of the device through freezing water

Store the device that has not been completely drained of water in a frost-free place.In the case of devices that are connected to a chimney, the ingress of cold air must be taken into account.

Cold air entering through the chimney

Risk of damage

When the exterior temperatures are below 0 °C, disconnect the device from the chimney.Shut down the device if frost-free storage is not possible.

For longer breaks in operation or when frost-free storage is not possible:

Drain the detergent tank.

Drain the water.

Flush the device with antifreeze.

Unscrew the water supply hose and the high-pressure hose.

Unscrew the supply line at the boiler base and allow the heating coil to drain.

Allow the device for run for a maximum of 1 minute until the pump and lines are empty.

Observe the handling instructions of the anti-freeze manufacturer.

Pour a commercially available antifreeze into the float tank.

Switch on the device (without burner) and allow it to run until the device is completely flushed.

This also provides a certain degree of corrosion protection.

Improper transport with a factory truck

Risk of damage

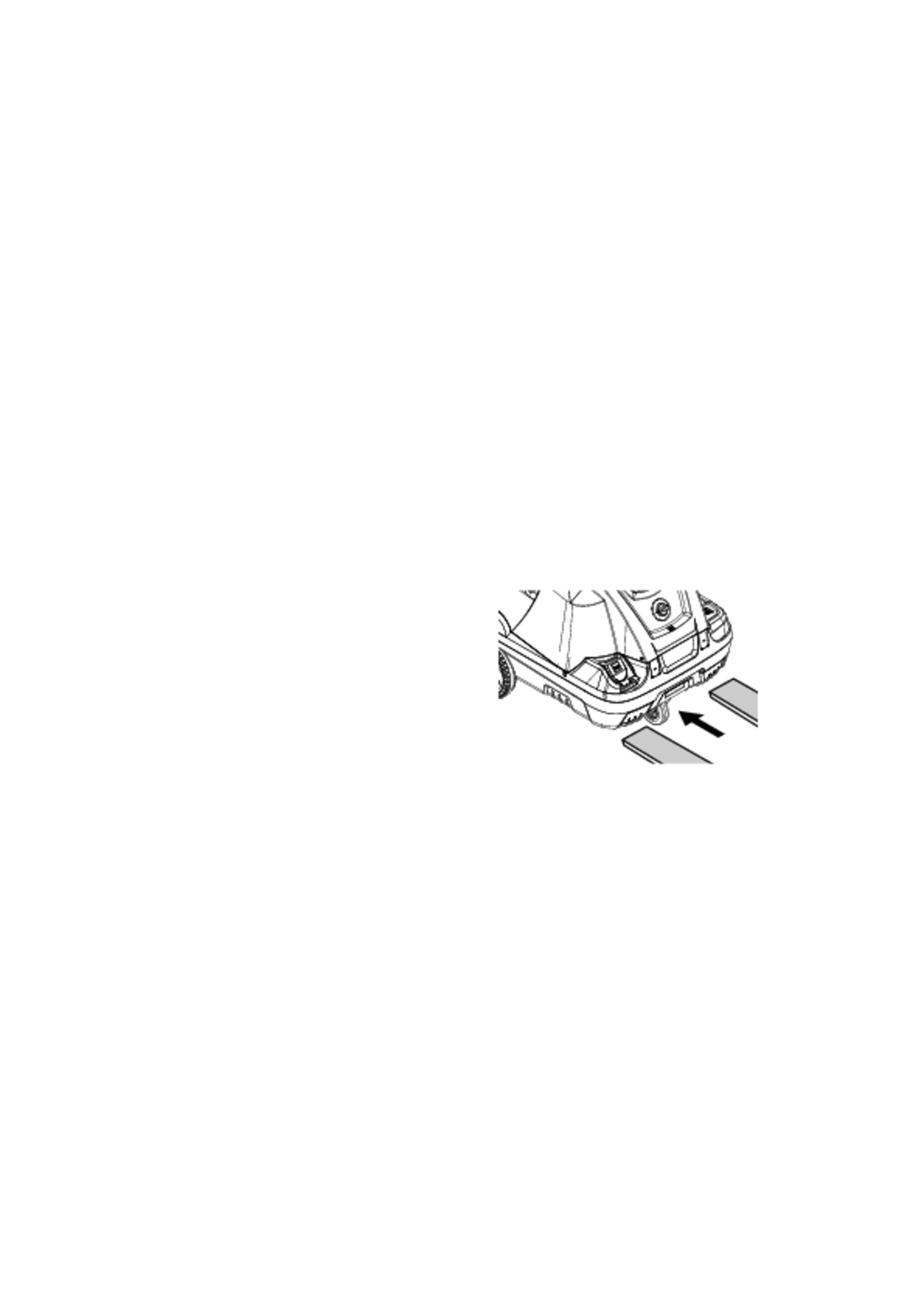

Pay attention to the orientation of the device when transporting it with a factory truck.

Improper transportation

Risk of damage

Protect the trigger of the high-pressure gun from damage.Failure to observe the weight

Risk of injury and damage

Be aware of the weight of the device during transportation.When transporting the device in vehicles, secure it to prevent it from slipping or overturning in accordance with the respectively applicable guidelines.

Failure to observe the weight

Risk of injury and damage

Be aware of the weight of the device during storage.Inadvertently starting up device, touching live components

Risk of injury, electric shock

Switch off the device before performing any work on the device.Remove the mains plug.Close the water inlet.

Open the high-pressure gun.

Switch on the pump with the power switch and let it run for 5-10 seconds.

Close the high-pressure gun.

Set the trigger to "0/OFF".

Only pull the mains plug out of the socket only when your hands are dry.

Remove the water connection.

Actuate the high-pressure gun until the device is completely depressurised.

Lock the high-pressure gun by pushing the safety latch forwards.

Allow the device to cool down.

You can agree on regular safety inspections or close a maintenance contract with your dealer. Please seek advice on this.

Risk of damage due to milky oil

Operation with milky oil can lead to damage to the device.

If the oil is milky, inform the authorised Customer Service immediately.Clean the fine filter.

Clean the fuel strainer.

Check the oil level.

Clean the sieve in the water shortage safeguard.

Clean the filter on the detergent suction hose.

Change the oil.

Have the device maintained by Customer Service.

Perform a pressure test according to the manufacturer's specifications.

Risk of injury

The hose reel may turn very fast unexpectedly if it is released.

Carefully follow the steps below and secure the hose reel as described.Only high-pressure hoses in the "Ultra Guard" version are suitable for this device.

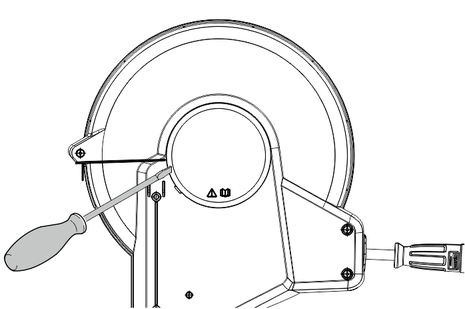

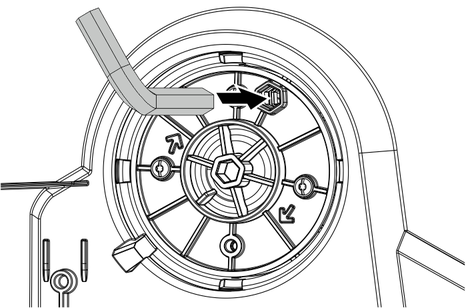

Lift off the cover on the hose reel with a flat-blade screwdriver.

Completely unroll the high-pressure hose from the hose reel.

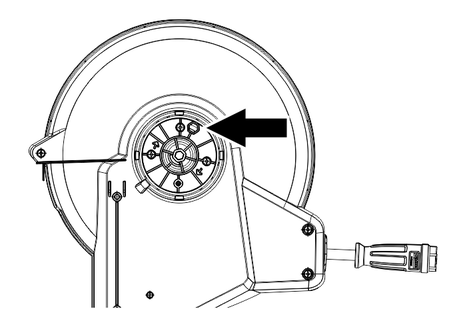

Insert a 10 mm Allen key through the hexagonal opening in the casing. Insert the key until the hose reel is blocked.

Unscrew the 2 screws.

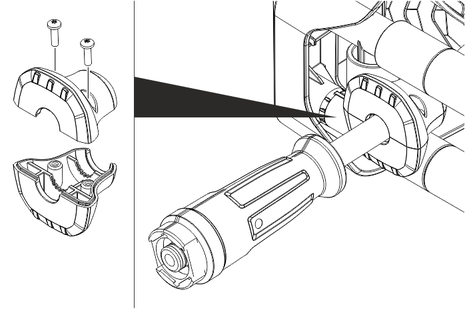

Remove the hose stopper from the high-pressure hose.

Pull out the locking hook.

Pull the high-pressure hose out of the hose connection.

Insert the new high-pressure hose through the hose guide rollers and insert it into the hose connection. Observe the direction of rotation of the hose reel.

Insert the locking hook into the hose connection.

Check that all washers are behind the locking hook.

Fit the hose stopper to the other end of the high-pressure hose. The distance to the end of the hose should be about 1 m (to the high-pressure gun).

Connect the device to the water supply and power supply, put it into operation and check the connection for leaks.

Tension the hose and keep it tensioned. Pull out the Allen key while the hose is taut.

Unlock the hose reel by pulling on the high-pressure hose and let the high-pressure hose slowly roll up. Control the reeling speed by holding the hose.

Replace the cover.

Depressurise the device.

Unscrew the fine filter on the pump head.

Dismantle the fine filter and take out the filter inlay.

Clean the filter inlay with clean water or compressed air.

Assemble in the reverse order.

Knock out the fuel sieve. Do not allow fuel to enter the environment.

Pull out the detergent suction hose port.

Clean the filter in water.

Fit the filter again.

See the "Technical data" section for the oil filling quantity and type.

Provide a catch pan for approx. 1 litre of oil.

Loosen the oil drain plug.

Drain the oil into the catch pan.

Dispose of the old oil in an environmentally friendly manner or hand it over to an authorised collection point.

Tighten the oil drain plug again.

Slowly fill with new oil until the "MAX" marking. The air bubbles must be able to escape.

Inadvertently starting up device, touching live components

Risk of injury, electric shock

Switch off the device before performing any work on the device.Remove the mains plug.Direction of rotation indicator light flashes (3-phase devices only)

The standby mode indicator light goes out or the device does not run

Device is leaking, water is dripping from the bottom of the device

The device switches on and off continuously when the high-pressure gun is locked

The set temperature is not reached when operating with hot water

Direction of rotation indicator light flashes (3-phase devices only)

Remedy:

Swap the pins on the power plug.

The standby mode indicator light goes out or the device does not run

Cause:

No mains voltage

Remedy:

Check the power supply and the supply line.

Service indicator light flashes 1x

Cause:

Water shortage

Remedy:

Check the water connection and the supply lines.

Cause:

Leak in the high-pressure system

Remedy:

Check the high-pressure system and the connections for leaks.

Service indicator light flashes 2x

Cause:

Fault in the voltage supply or current consumption of the motor too high

Remedy:

Check the power supply and the mains power supply circuit breaker.

Contact Customer Service.

Service indicator light flashes 3x

Cause:

Motor overloaded/overheated

Remedy:

Set the trigger to "0/OFF".

Allow the device to cool down.

Switch the device on.

Cause:

Malfunction occurs repeatedly

Remedy:

Contact Customer Service.

Service indicator light flashes 4x

Cause:

Exhaust gas thermostat has triggered

Remedy:

Set the trigger to "0/OFF".

Allow the device to cool down.

Switch the device on.

Cause:

Malfunction occurs repeatedly

Remedy:

Contact Customer Service.

Service indicator light flashes 5x

Cause:

Reed switch stuck in the water shortage safeguard or magnetic piston stuck

Remedy:

Contact Customer Service.

The service indicator light flashes 6x

Cause:

Flame sensor has switched off the burner

Remedy:

Contact Customer Service.

The fuel indicator light lights up

Cause:

Fuel tank is empty

Remedy:

Refill the fuel.

System care indicator light lights up

Cause:

System care container is empty

Remedy:

Fill up the system care.

Detergent indicator light lights up

Cause:

Detergent tank is empty

Remedy:

Fill with detergent.

Device not building up pressure

Cause:

Air in the system

Remedy:

Venting the pump:

Set the detergent dosing valve to "0".

With the high-pressure gun open, switch the device on and off several times via the power switch.

Open and close the pressure/quantity regulator of the pump unit with the high-pressure gun open.

The venting process is accelerated by removing the high-pressure hose from the high-pressure connection.

Top up the detergent if necessary.

Check connections and lines.

Cause:

Pressure is set to MIN

Remedy:

Set the pressure to "MAX".

Cause:

Fine filter dirty

Remedy:

Clean the fine filter, replace if necessary.

Cause:

Water supply volume too low

Remedy:

Check the water supply volume (see "Technical data").

Device is leaking, water is dripping from the bottom of the device

Cause:

Pump leaking

Remedy:

If there is a significant leak, have the device checked by Customer Service.

3 drops/minute are permitted.

The device switches on and off continuously when the high-pressure gun is locked

Cause:

Leak in the high-pressure system

Remedy:

Check the high-pressure system and the connections for leaks.

The device does not suck in any detergent

Remedy:

Let the device run with the detergent dosing valve open and the water inlet closed until the float tank has been sucked empty and the pressure drops to “0”.

Open the water inlet again.

Cause:

If the pump still does not suck in detergent, this can be due to the following reasons:

The filter in the detergent suction hose is dirty

Remedy:

Clean the filter.

Cause:

Check valve is stuck

Remedy:

Pull off the detergent hose and free up the check valve with a blunt object.

Burner not igniting

Cause:

Fuel tank is empty

Remedy:

Refill the fuel.

Cause:

Water shortage

Remedy:

Check the water connection and the supply lines.

Cause:

Fuel filter dirty

Remedy:

Change the fuel filter.

Cause:

No ignition spark

Remedy:

If no ignition spark is visible through the sight glass during operation, have the device checked by Customer Service.

The set temperature is not reached when operating with hot water

Cause:

Working pressure/flow rate too high

Remedy:

Reduce the working pressure/flow rate via the pressure/quantity regulator of the pump unit.

Cause:

Sooty heating coil

Remedy:

Have the soot removed from the device by Customer Service.

If the malfunction cannot be corrected, the device must be checked by the Customer Service department.

Direction of rotation indicator light flashes (3-phase devices only)

The standby mode indicator light goes out or the device does not run

Device is leaking, water is dripping from the bottom of the device

The device switches on and off continuously when the high-pressure gun is locked

The set temperature is not reached when operating with hot water

Direction of rotation indicator light flashes (3-phase devices only)

Remedy:

Swap the pins on the power plug.

The standby mode indicator light goes out or the device does not run

Cause:

No mains voltage

Remedy:

Check the power supply and the supply line.

Service indicator light flashes 1x

Cause:

Water shortage

Remedy:

Check the water connection and the supply lines.

Cause:

Leak in the high-pressure system

Remedy:

Check the high-pressure system and the connections for leaks.

Service indicator light flashes 2x

Cause:

Fault in the voltage supply or current consumption of the motor too high

Remedy:

Check the power supply and the mains power supply circuit breaker.

Contact Customer Service.

Service indicator light flashes 3x

Cause:

Motor overloaded/overheated

Remedy:

Set the trigger to "0/OFF".

Allow the device to cool down.

Switch the device on.

Cause:

Malfunction occurs repeatedly

Remedy:

Contact Customer Service.

Service indicator light flashes 4x

Cause:

Exhaust gas thermostat has triggered

Remedy:

Set the trigger to "0/OFF".

Allow the device to cool down.

Switch the device on.

Cause:

Malfunction occurs repeatedly

Remedy:

Contact Customer Service.

Service indicator light flashes 5x

Cause:

Reed switch stuck in the water shortage safeguard or magnetic piston stuck

Remedy:

Contact Customer Service.

The service indicator light flashes 6x

Cause:

Flame sensor has switched off the burner

Remedy:

Contact Customer Service.

The fuel indicator light lights up

Cause:

Fuel tank is empty

Remedy:

Refill the fuel.

System care indicator light lights up

Cause:

System care container is empty

Remedy:

Fill up the system care.

Detergent indicator light lights up

Cause:

Detergent tank is empty

Remedy:

Fill with detergent.

Device not building up pressure

Cause:

Air in the system

Remedy:

Venting the pump:

Set the detergent dosing valve to "0".

With the high-pressure gun open, switch the device on and off several times via the power switch.

Open and close the pressure/quantity regulator of the pump unit with the high-pressure gun open.

The venting process is accelerated by removing the high-pressure hose from the high-pressure connection.

Top up the detergent if necessary.

Check connections and lines.

Cause:

Pressure is set to MIN

Remedy:

Set the pressure to "MAX".

Cause:

Fine filter dirty

Remedy:

Clean the fine filter, replace if necessary.

Cause:

Water supply volume too low

Remedy:

Check the water supply volume (see "Technical data").

Device is leaking, water is dripping from the bottom of the device

Cause:

Pump leaking

Remedy:

If there is a significant leak, have the device checked by Customer Service.

3 drops/minute are permitted.

The device switches on and off continuously when the high-pressure gun is locked

Cause:

Leak in the high-pressure system

Remedy:

Check the high-pressure system and the connections for leaks.

The device does not suck in any detergent

Remedy:

Let the device run with the detergent dosing valve open and the water inlet closed until the float tank has been sucked empty and the pressure drops to “0”.

Open the water inlet again.

Cause:

If the pump still does not suck in detergent, this can be due to the following reasons:

The filter in the detergent suction hose is dirty

Remedy:

Clean the filter.

Cause:

Check valve is stuck

Remedy:

Pull off the detergent hose and free up the check valve with a blunt object.

Burner not igniting

Cause:

Fuel tank is empty

Remedy:

Refill the fuel.

Cause:

Water shortage

Remedy:

Check the water connection and the supply lines.

Cause:

Fuel filter dirty

Remedy:

Change the fuel filter.

Cause:

No ignition spark

Remedy:

If no ignition spark is visible through the sight glass during operation, have the device checked by Customer Service.

The set temperature is not reached when operating with hot water

Cause:

Working pressure/flow rate too high

Remedy:

Reduce the working pressure/flow rate via the pressure/quantity regulator of the pump unit.

Cause:

Sooty heating coil

Remedy:

Have the soot removed from the device by Customer Service.

The warranty conditions issued by our relevant sales company apply in all countries. We shall remedy possible malfunctions on your appliance within the warranty period free of cost, provided that a material or manufacturing flaw is the cause. In a warranty case, please contact your dealer (with the purchase receipt) or the next authorised customer service site.

Further information can be found at: www.kaercher.com/dealersearch

Further warranty information (if available) can be found in the service area of your local Kärcher website under "Downloads".

EU Declaration of Conformity |

We hereby declare that the product named below complies with the relevant provisions of the directives and regulations listed. This declaration is invalidated by any changes made to the product that are not approved by us.

Product: High-pressure cleaner

Type: 1.174-xxx

Type:

Directives and Regulations2000/14/EC

2006/42/EC (+2009/127/EC)

2014/30/EU

2014/53/EU

2014/68/EU

2011/65/EU

2009/125/EC

Commission Regulation(s)(EU) 2019/1781

Category of the assemblyII

Conformity processModule H

Heating coilModule H conformity evaluation

Control blockModule H conformity evaluation

Various pipelinesConformity evaluation Art. 4 Para. 3

Harmonised standards usedEN 60335-1

EN 60335-2-79

EN 55014-1: 2017 + A11: 2020

EN 55014-2: 2015

EN 61000-3-2: 2014

EN IEC 63000: 2018

EN 62233: 2008

EN 61000-3-3: 2013

EN 61000-3-11: 2000

Applied specifications:AD 2000 based on

TRD 801 based on

Name of notified body:For 2014/68/EUTÜV Rheinland Industrie Service GmbH

Am Grauen Stein

51105 Köln

Identification no. 0035

Certificate No .:Conformity evaluation procedure used

2000/14/EC: Annex V

Sound power level dB(A)HDS 8/18-4

Measured: 90

Guaranteed: 93

Measured:

Guaranteed:

Measured:

Guaranteed:

Measured:

Guaranteed:

Measured:

Guaranteed:

Name and addressDocumentation supervisor:

S. Reiser

Alfred Kärcher SE & Co. KG

Alfred-Kärcher-Str. 28 - 40

71364 Winnenden (Germany)

Tel.: +49 7195 14-0

Fax: +49 7195 14-2212

Winnenden, 2024/07/01

The undersigned act on behalf of and with the authority of the Board of Directors.

Alfred Kärcher SE & Co. KG

Alfred-Kärcher-Str. 28 - 40

71364 Winnenden (Germany)

Ph.: +49 7195 14-0

Fax: +49 7195 14-2212

Declaration of Conformity (UK) |

We hereby declare that the product named below complies with the relevant provisions of the directives and regulations listed. This declaration is invalidated by any changes made to the product that are not approved by us.

Product: High-pressure cleaner

Type: 1.174-xxx

Type:

Directives and RegulationsS.I. 2001/1701 (as amended)

S.I. 2008/1597 (as amended)

S.I. 2016/1091 (as amended)

S.I. 2017/1206 (as amended)

2014/68/EU

S.I. 2012/3032 (as amended)

S.I. 2010/2617 (as amended)

Commission Regulation(s)(EU) 2019/1781

Category of the assemblyII

Conformity processModule H

Heating coilModule H conformity evaluation

Control blockModule H conformity evaluation

Various pipelinesConformity evaluation Art. 4 Para. 3

Designated standards usedEN 60335-1

EN 60335-2-79

EN 55014-1: 2017 + A11: 2020

EN 55014-2: 2015

EN 61000-3-2: 2014

EN IEC 63000: 2018

EN 62233: 2008

EN 61000-3-3: 2013

EN 61000-3-11: 2000

Applied specifications:AD 2000 based on

TRD 801 based on

Name of stated position:For 2014/68/EUTÜV Rheinland Industrie Service GmbH

Am Grauen Stein

51105 Köln

ID no. 0035

Certificate No .:Applied conformity assessment procedure

S.I. 2001/1701 (as amended): Schedule 8

Sound power level dB(A)HDS 8/18-4

Measured: 90

Guaranteed: 93

Measured:

Guaranteed:

Measured:

Guaranteed:

Measured:

Guaranteed:

Measured:

Guaranteed:

Name and addressDocumentation supervisor:

S. Reiser

Alfred Kärcher SE & Co. KG

Alfred-Kärcher-Str. 28 - 40

71364 Winnenden (Germany)

Tel.: +49 7195 14-0

Fax: +49 7195 14-2212

Winnenden, 2024/07/01

The undersigned act on behalf of and with the authority of the Board of Directors.

Alfred Kärcher SE & Co. KG

Alfred-Kärcher-Str. 28 - 40

71364 Winnenden (Germany)

Ph.: +49 7195 14-0

Fax: +49 7195 14-2212

Electrical connection | |

Mains voltage | 400 V |

Phase | 3 ~ |

Power frequency | 50 Hz |

Degree of protection | IPX5 |

Protection class | I |

Power rating | 6,0 kW |

Power protection (slow-blowing) | 16 A |

Water connection | |

Feed pressure (max.) | 1 (10) MPa (bar) |

Input temperature (max.) | 30 °C |

Input amount (min.) | 1000(13,7) l/h (l/min) |

Suction height (max.) | 0,5 m |

Device performance data | |

Water flow rate | 300-800 (5,0-13,3) l/h (l/min) |

Water operating pressure with standard nozzle | 3-18 (30-180) MPa (bar) |

Excess operating pressure safety valve (maximum) | 22 (220) MPa (bar) |

Steam operation flow rate | 340 (5,7) l/h (l/min) |

Steam operation operating pressure with steam nozzle (max.) | 3,2 (32) MPa (bar) |

Part no. of steam nozzle | 2.114-002.0 |

Hot water operating temperature (maximum) | 98 °C |

Steam operation working temperature | 155 °C |

Detergent flow rate | 51 (8,5) l/h (l/min) |

Burner output | 61 kW |

Heating oil consumption (max.) | 5,2 kg/h |

High-pressure gun recoil force | 42 N |

Nozzle size of standard nozzle | 43 |

Dimensions and weights | |

Typical operating weight | 130 kg |

Length x width x height | 1060 x 650 x 920 mm |

Fuel tank | 15,5 l |

Detergent tank | 15,5 l |

High-pressure pump | |

Oil volume | 0,46 l |

Oil type | SAE90 |

Burner | |

Fuel | EL heating oil or diesel |

Determined values in acc. with EN 60335-2-79 | |

Sound pressure level LpA | 74 dB(A) |

Uncertainty KpA | 3 dB(A) |

Sound power level LWA + uncertainty KWA | 93 dB(A) |

Hand-arm vibration value | 3,2 m/s2 |

Uncertainty K | 0,8 m/s2 |

Electrical connection | |

Mains voltage | 400 V |

Phase | 3 ~ |

Power frequency | 50 Hz |

Degree of protection | IPX5 |

Protection class | I |

Power rating | 6,0 kW |

Power protection (slow-blowing) | 16 A |

Water connection | |

Feed pressure (max.) | 1 (10) MPa (bar) |

Input temperature (max.) | 30 °C |

Input amount (min.) | 1000 (16,7) l/h (l/min) |

Suction height (max.) | 0,5 m |

Device performance data | |

Water flow rate | 300-800 (5,5-13,3) l/h (l/min) |

Water operating pressure with standard nozzle | 3-18 (30-180) MPa (bar) |

Excess operating pressure safety valve (maximum) | 22 (220) MPa (bar) |

Steam operation flow rate | 340 (5,7) l/h (l/min) |

Steam operation operating pressure with steam nozzle (max.) | 3,2 (32) MPa (bar) |

Part no. of steam nozzle | 2.114-002.0 |

Hot water operating temperature (maximum) | 98 °C |

Steam operation working temperature | 155 °C |

Detergent flow rate | 51 (8,5 l/h (l/min) |

Burner output | 61 kW |

Heating oil consumption (max.) | 5,2 kg/h |

High-pressure gun recoil force | 42 N |

Nozzle size of standard nozzle | 43 |

Dimensions and weights | |

Typical operating weight | 138 kg |

Length x width x height | 1060 x 650 x 920 mm |

Fuel tank | 15,5 l |

Detergent tank | 15,5 l |

High-pressure pump | |

Oil volume | 0,46 l |

Oil type | SAE90 |

Burner | |

Fuel | EL heating oil or diesel |

Determined values in acc. with EN 60335-2-79 | |

Sound pressure level LpA | 75 dB(A) |

Uncertainty KpA | 3 dB(A) |

Sound power level LWA + uncertainty KWA | 93 dB(A) |

Hand-arm vibration value | 4,1 m/s2 |

Uncertainty K | 0,9 m/s2 |