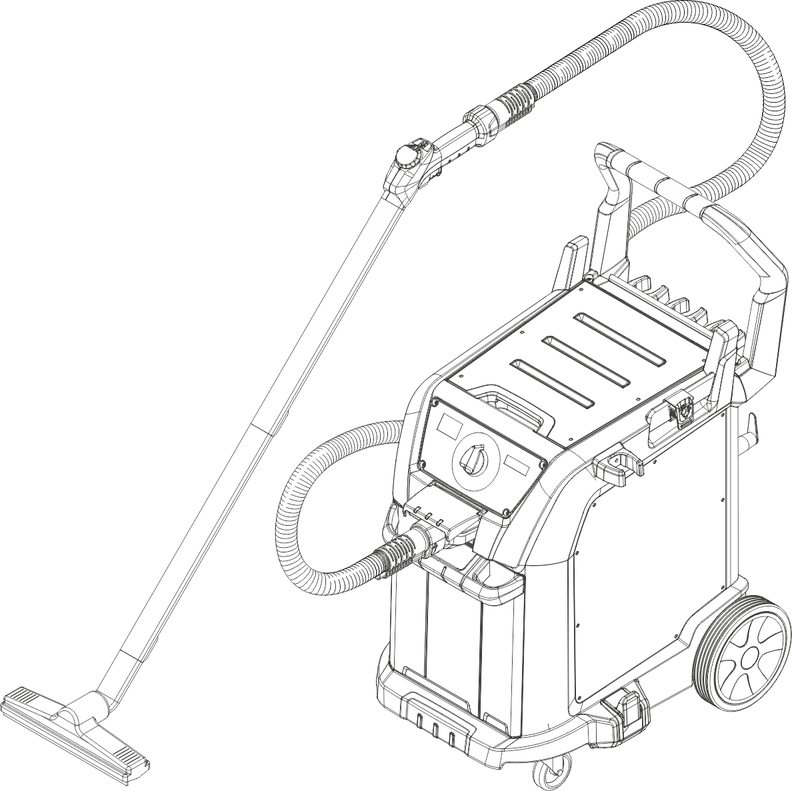

SGV 8/5 ClassicSGV 8/5

59991520 (09/23)

59991520 (09/23)

Read these original instructions and the enclosed safety instructions before using the device for the first time. Act in accordance with them.

Read these original instructions and the enclosed safety instructions before using the device for the first time. Act in accordance with them.

Keep both books for future reference or for future owners.

If the operating instructions and safety instructions are not observed, the device can be damaged and dangers could arise for users and other persons.

Notify the dealer immediately in the case of shipping damage.

Check the package contents when unpacking for missing accessories or for damage.

The packing materials can be recycled. Please dispose of packaging in accordance with the environmental regulations.

The packing materials can be recycled. Please dispose of packaging in accordance with the environmental regulations.

Electrical and electronic devices contain valuable, recyclable materials and often components such as batteries, rechargeable batteries or oil, which - if handled or disposed of incorrectly - can pose a potential danger to human health and the environment. However, these components are required for the correct operation of the device. Devices marked by this symbol are not allowed to be disposed of together with the household rubbish.

Electrical and electronic devices contain valuable, recyclable materials and often components such as batteries, rechargeable batteries or oil, which - if handled or disposed of incorrectly - can pose a potential danger to human health and the environment. However, these components are required for the correct operation of the device. Devices marked by this symbol are not allowed to be disposed of together with the household rubbish.

Current information on content materials can be found at: www.kaercher.de/REACH

Health risk

Inhalation of dusts that are harmful to health

Do not use the device for vacuuming up dusts that are harmful to health.

The device is intended for generating steam and sucking up spilled liquids and solid particles as described in these operating instructions.

This device is suitable for commercial use,e.g. in hotels, schools, hospitals, factories, shops, offices, and rental companies.

| Steam ATTENTION - risk of scalding |

Safety devices protect the user and may not be disabled or functionally circumvented.

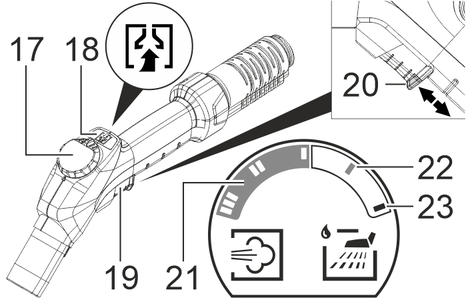

The handle has a safety latch on the steam switch to prevent accidental release of steam flow.

If the steam suction hose is unattended for a short time during operation, it is recommended to activate the fuse (pull out the fuse catch). To release the steam flow again, deactivate the fuse (push in the fuse catch).

Before treating leather, special fabrics and wooden surfaces, read the manufacturer's instructions and always make a test on a hidden spot or sample. Allow the steam treated surface to dry to check if any colour or shape changes have occurred.

When cleaning wooden surfaces (furniture, doors, etc.), it is recommended to be particularly careful, as steam treatment for too long can damage the wax coatings, the gloss or the colour of the surfaces. Therefore, it is recommended to use steam only in short intervals for these surfaces, or to clean them with a previously steamed cloth.

For particularly sensitive surfaces (e.g. synthetic materials, painted surfaces, etc.) it is recommended to use the steam function with minimum thickness.

Cleaning stainless steel: Avoid the use of abrasive brushes. Use the manual nozzle with rubber lip or spotlight nozzle without round brush.

Always check the compatibility of the textiles at a concealed point before using the device on textiles: First steam the textile, allow it to dry and then check it for any change in colour or shape.

Wax, furniture polish, plastic coatings or paint can come off or stains may occur when cleaning painted or plastic-coated surfaces such as e.g. kitchen and living room furniture, doors, parquet or linoleum. To clean these surfaces, steam a cloth briefly and wipe it over the surfaces.

Danger from detergents

Health risk, risk of damage

Observe all instructions that are included with the detergents used.

Danger from detergent solutions

Risk of damage

Do not use detergent solutions with a pH value greater than 13 (alkaline) and less than 2 (acidic), as these can cause damage to the device.

Use detergents sparingly to conserve the environment.

Kitchen area | Fat and protein solvent RM 731 (alkaline) |

Floor coverings,e.g. Safety tiles | Universal floor cleaner RM 743 (alkaline) |

Fine stone cleaner RM 753 (alkaline) | |

Sanitary area,e.g. Shower, floor coverings with lime deposits | Floor precleaner CA 20C (acidic) |

For further information, please request the product information sheet and the EU safety data sheet for the relevant cleaning agent.

SGV 8/5 Classic only:

The spray bottle supplied is empty.

Fill the spray bottle with detergent.

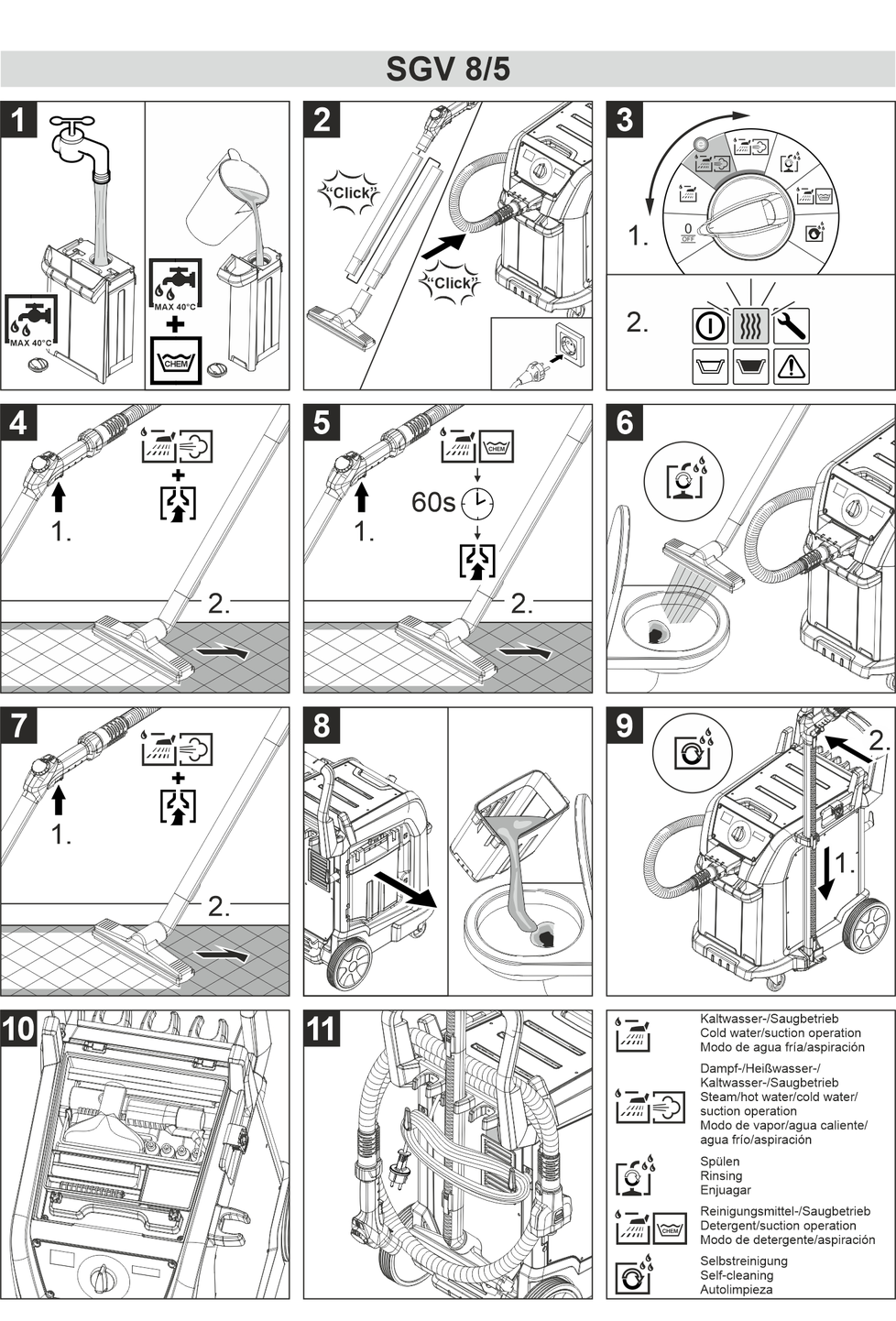

SGV 8/5 only:

Mix the fresh water (max. 40 °C) and the detergent in a clean container (concentration as specified for the detergent).

SGV 8/5 only:

Pull out the detergent container.

Unscrew the twist lock of the detergent container.

For technical reasons (automatic venting of the pumps), there may be water in the detergent tank.

Fill the detergent tank with cleaning solution.

Screw in the twist lock of the detergent container.

Push the detergent container in as far as it will go.

Danger due to unsuitable fluids

Risk of damage

Never fill the fresh water reservoir with demineralised water or detergent. This can lead to malfunctions and damage to the device.

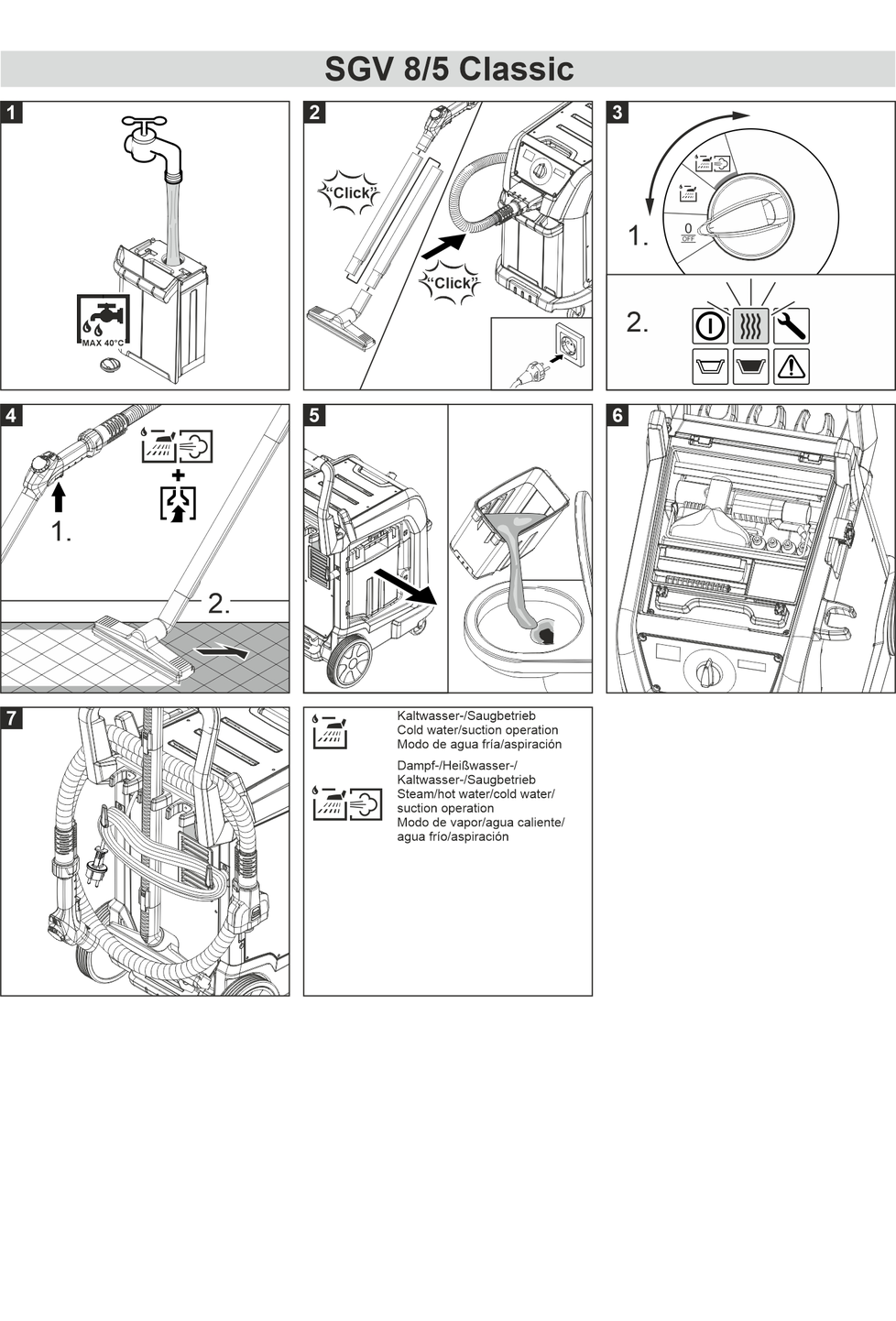

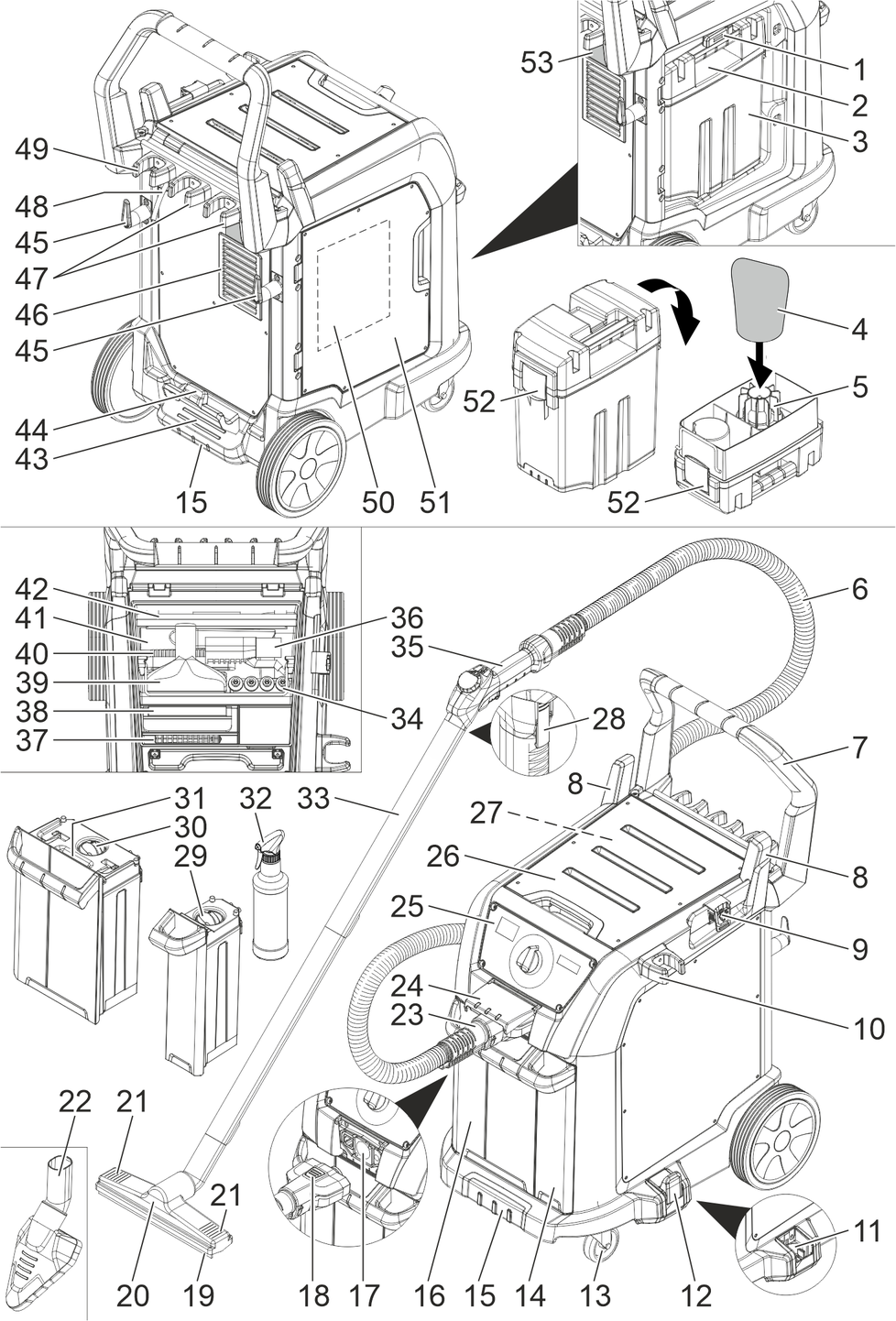

Pull out the fresh water reservoir.

Unscrew the twist lock of the fresh water reservoir.

Fill the fresh water reservoir with at least 3 litres of water.

Normal tap water can be used.

Screw in the twist lock of the fresh water reservoir.

Push the fresh water reservoir in as far as it will go.

Danger from steam

Danger of scalding

Pull out the safety latch on the steam switch to prevent steam from escaping when disconnecting accessories.

Check the accessories for secure connection before use.

Open the cover of the accessory socket, insert the accessory plug into the accessory socket and audibly click it into place.

Connecting accessories: Connect the handle or the steam suction pipe to the desired accessory. Push the parts into each other until the accessory lock engages.

Disconnecting accessories: Hold down the accessory lock and pull the accessories apart.

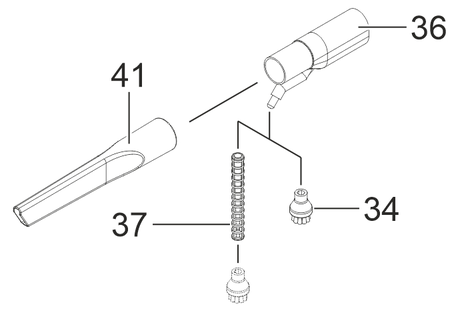

Connect the screwable accessories and tighten them hand-tight.

During operation it is necessary to place the device horizontally.

SGV 8/5 only:

The display shows either text or a dash/bar representation.

The line/bar display represents a certain period of time. At the beginning of the time span, 10 bars are displayed, which are replaced by dashes from right to left until 10 dashes are displayed at the end.

text # # # # _ _ _ _ _ _ |

EU/CH: English

GB: English

Users whose national language is not available as a display language:

Select English as the display language.

Available display languages:

English

English

French

Spanish

Japanese

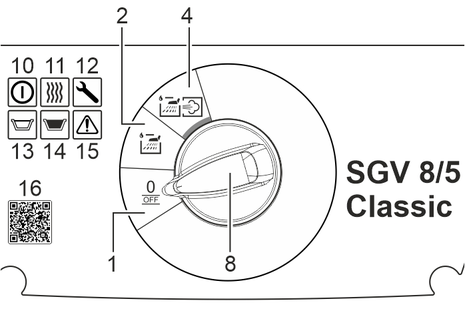

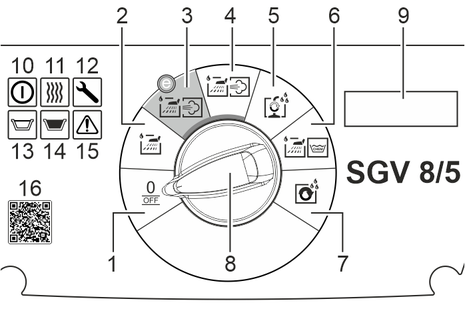

Set the turn switch on the device to "0/OFF".

Set the handwheel on the handle to cold water.

Press the suction button and the steam switch.

Set the turn switch to cold water/vacuuming operations.

Language German |

The bottom line flashes because the display language has not yet been saved.

Release the suction button and the steam switch.

Select the language using the handwheel.

Press the steam switch to save the display language. The bottom line stops flashing.

Danger due to the device tipping over

Risk of damage

Do not tilt the device when it is switched on.

Connect the mains plug.

Set the turn switch to the operating mode.

Filling process Please wait |

In this operating mode, the handwheel has the function "Apply cold water" in every position. Steam/hot water operation is deactivated.

Set the turn switch to cold water/vacuuming operations.

Cold water _ |

Press the steam switch. The cold water is dispensed as long as the button is pressed.

Start vacuuming operations: Press the suction button briefly.

End vacuuming operations: Press the suction button again briefly.

Press the steam switch and briefly press the suction button at the same time. Vacuuming operations start and cold water is dispensed at the same time.

Danger from steam

Danger of scalding

Pull out the safety latch on the steam switch to prevent unintentional steam from escaping.

Set the turn switch to steam / hot water / cold water / vacuuming operations.

Danger from steam

Danger of scalding

avoid contact with steam.

The heating process starts and the indicator light "Heating on" flashes green.

Heating # # # # _ _ _ _ _ _ |

After approx. 7 minutes, the heating process is finished. The "heating on" indicator light lights up green.

The heating switches on periodically during use (indicator light flashes green) to maintain the pressure in the boiler.

Steam/hot water ready |

-Display is alternating-

Steam/hot water Steam maximum |

The display shows the following depending on the steam stage set: Steam Maximum or Steam Medium or Steam Minimum

Press the steam switch. The steam is dispensed as long as the button is pressed.

Light steam (stage I): For minor contamination.

Medium steam (stage II): For medium contamination.

Strong steam (stage III): For removing stubborn dirt.

Set the steam volume control on the handwheel to the desired steam stage.

Hot water

Risk of scalding

Avoid contact with hot water.

Hot water (approx. 70 °C) increases the cleaning effect. Check the temperature resistance of the surface to be cleaned.

Set the handwheel to hot water.

Hot water _ |

Press the steam switch. The hot water is dispensed as long as the button is pressed.

Set the handwheel to cold water.

Cold water _ |

Press the steam switch. The cold water is dispensed as long as the button is pressed.

Start vacuuming operations: Press the suction button briefly.

End vacuuming operations: Press the suction button again briefly.

Press the steam switch and briefly press the suction button at the same time. Vacuuming operations start and steam or hot/cold water is dispensed at the same time.

SGV 8/5 only:

In eco!efficiency operating mode, the device works with reduced suction performance and volume.

Set the turn switch to steam / hot water / cold water / vacuuming operations (eco!efficiency).

SGV 8/5 only:

Check the detergent resistance of the surface to be cleaned.

In this operating mode, the handwheel has the function "Apply cleaning solution" in every position. The steam/hot water/cold water mode is deactivated.

Set the turn switch to detergent/vacuuming operations.

Detergent _ |

Press the steam switch. The cleaning solution is dispensed as long as the button is pressed.

Start vacuuming operations: Press the suction button briefly.

End vacuuming operations: Press the suction button again briefly.

As soon as the entire contents of the detergent tank have been applied and sucked out again, the wastewater container must be emptied to avoid excessive foaming.

Press the steam switch and briefly press the suction button at the same time. Vacuuming operations start and the cleaning solution is dispensed at the same time.

SGV 8/5 only:

After operating with detergent, the device must be rinsed clear.

If the turn switch is not set to rinse after operation with detergent, the following message appears in the display:

Rinse programme select |

Set the turn switch to rinse.

Rinse start |

Press and hold the steam switch. The rinse starts. Hold the floor nozzle over a drain or start the vacuuming operations.

Rinse # # # # _ _ _ _ _ _ |

The rinse is running. The running time is displayed. |

NoteWhen the steam switch is released, the rinsing process stops. Press the steam switch again to continue the rinsing process. |

Rinse finished |

NoteThe rinsing process can be extended by pressing the steam switch longer. |

Open the cover of the wastewater container.

Press the lock of the wastewater container upwards.

Remove the wastewater container.

Unlock the wastewater container lock and remove the cover.

Empty the wastewater container.

When there is a short interruption in the work, the floor nozzle can be put in the parking position and the steam suction pipe can be engaged.

Set the turn switch on the device to "0/OFF".

Pull out the mains plug.

SGV 8/5 only:

Set the turn switch on the device to self-cleaning.

Self-cleaning Preparation |

-Display is alternating- |

Self-cleaning See Quickstart |

Fold out the floor nozzle holder (parking position).

Remove the floor nozzle from the steam suction pipe.

Snap the steam suction pipe into the holder (bottom) and into the holder (top) so that the handle points outwards.

Self-cleaning start |

Press the steam switch briefly. The self-cleaning starts.

Self-cleaning # # # # _ _ _ _ _ _ |

Self-cleaning runs automatically. The running time is displayed. |

Self-cleaning finished |

Danger from spores

Health risk

Select the cleaning location of the device in such a way that contamination of the surroundings, food and food processing tools and machines,e.g. by spray water, is excluded.

Empty the fresh water reservoir and dry it.

Empty the detergent tank (SGV 8/5) and dry it.

Drain and clean the wastewater container and dry it.

Clean the accessories thoroughly: Clean the handle, steam suction hose and accessory plug with a damp cloth. Clean the remaining accessories with hot water and dry them.

Clean the exterior of the device with a damp cloth.

Clean the device with a warm damp cloth and detergent if it is visibly contaminated, or disinfect it if necessary.

Always let the brushes cool down to prevent deformation of the bristles.

Press the accessory plug lock and pull the accessory plug out of the accessory socket.

Allow the accessories to dry sufficiently and place them in the accessory tray.

Empty the fresh water reservoir.

SGV 8/5 only: Empty the detergent tank and clean it.

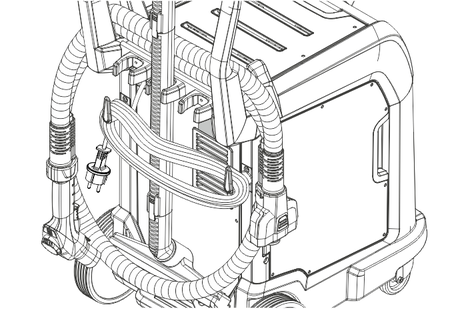

Store the floor nozzle, steam suction pipes, steam suction hose and the mains cable as shown in the illustration.

To avoid unpleasant smells, remove all water from the device before long downtimes.

Allow the device to dry sufficiently: Pull out the waste water tank, the fresh water reservoir and the detergent tank a little and open the accessory tray cover.

Store the device in a dry room and secure it against unauthorised use.

Detergent residues or care emulsions on the surface to be cleaned can cause streaks during steam cleaning, but these disappear after repeated use.

Eliminate odours and creases from hanging clothes by steaming them at a distance of 10-20 cm.

The cleaning effect increases the closer the nozzle is held to the dirty area, since the temperature and pressure of the steam are greatest at the emission point.

Use of the spotlight nozzle is recommended for hard-to-reach areas.

The cleaning of stainless steel, window panes, mirrors and enamel surfaces.

The cleaning of corners on stairs, window frames, door jambs and aluminium profiles.

The cleaning of fittings.

The cleaning of shutters and radiators. The interior cleaning of vehicles.

Round brush: Suitable for stubborn dirt on particularly small surfaces such as cooker tops, roller shutters, tile grout, sanitary facilities, etc.

The round brush is not suitable for cleaning sensitive surfaces.

Extension: With this accessory, optimal cleaning is possible for particularly inaccessible places. Ideal for cleaning heaters, door jambs, windows, shutters and sanitary installations.

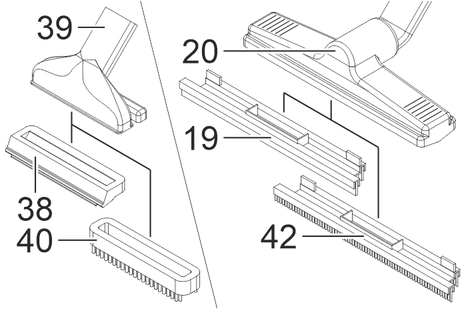

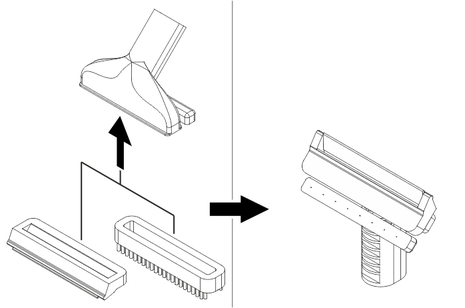

The cleaning of large surfaces, floors made of ceramics, marble, etc.

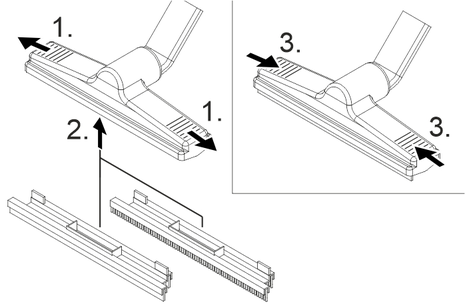

Floor nozzle with rubber lip insert: For absorbing liquids on smooth surfaces.

Floor nozzle with brush strip insert: For dissolving and scrubbing off stubborn contamination.

Cleaning large glass and mirror surfaces, smooth surfaces in general or fabric surfaces such as sofas, etc.

Squeegee: For smaller surfaces,e.g. Muntin windows and mirrors. For window panes and larger surfaces,e.g. Wall tiles, working areas and stainless steel surfaces.

Brush crown: For stairs, automobile interiors, fabric surfaces in general (after testing on a concealed area). For abrasive cleaning and scrubbing.

Preheat the window pane in seasons with particularly low temperatures. To do this, lightly steam the entire glass surface at a distance of approx. 50 cm. This avoids tension on the surface that can lead to glass breakage.

Steam the glass surface evenly at a distance of approx. 20 cm to remove the dirt.

Switch off the steam supply.

Pull off the glass surface in strips from top to bottom with the squeegee and vacuum.

Wipe the squeegee and the lower edge of the window dry if needed.

The triangle nozzle may only be used in conjunction with the vacuum function.

Failure to observe the weight

Risk of injury and damage

Be aware of the weight of the device during transportation.

Place the floor nozzle in the tray at the back of the device and engage the steam suction pipe. Separate the steam suction pipes.

Release the parking brakes and push the device by the push handle.

To load the device, grasp it by the recessed grip and the push handle.

Pull the device behind you via the push handle for transporting over longer distances.

When transporting in vehicles, secure the device against rolling away, slipping and tipping according to the respectively applicable guidelines. Empty all containers beforehand.

Failure to observe the weight

Risk of injury and damage

Be aware of the weight of the device during storage.

The device may only be operated indoors.

Danger of electric shock

Injuries due to touching live parts

Switch off the device.

Remove the mains plug.

Danger from hot water, steam and hot surfaces

Risk of scalding and burns

Allow the device to cool down prior to all work on the device.

Damaged or missing O-rings can be the cause of increased temperatures in the handle.

Regularly check the condition of the seals (2x O-ring) in the accessory plug, in the handle and in the steam suction pipes. If necessary, replace the seals.

Open the cover of the wastewater container.

Press the lock of the wastewater container upwards.

Remove the wastewater container.

Unlock the wastewater container lock and remove the cover.

Turn the cover 180° and set it down.

Pull the coarse dirt filter off the filter holder and replace it.

Have the device descaled by Customer Service.

Danger of electric shock

Injuries due to touching live parts

Switch off the device.

Remove the mains plug.

Danger from hot water, steam and hot surfaces

Risk of scalding and burns

Allow the device to cool down prior to all work on the device.

Danger from improper repair work

Risk of injury and damage

ave repair work carried out by the authorised customer service only.

Display without indicator light

Cause:

Detergent refill |

Remedy:

Refill the detergent.

Insert the detergent container correctly, push it in as far as it will go.

"Service" indicator light flashes yellow

Cause:

Service Error: E07 |

Remedy:

Switch off the device, wait briefly, switch the device on again.

If the indicator light does not go out, repeat the procedure (max. 4 times).

Cause:

Service Error: E14 |

Pre-warning for descaling (still 100h)

Remedy:

Have the device descaled by Customer Service.

"Service" indicator light lights up yellow

Cause:

Service Error: E15 |

Descaling

Remedy:

Have the device descaled by Customer Service.

"Fresh water reservoir empty" indicator light lights up red

Cause:

Fresh water refill |

Remedy:

Refill with fresh water.

Correctly insert the fresh water reservoir, push it in as far as it will go.

"Wastewater container full" indicator light lights up red

Cause:

Waste water drain |

Remedy:

Drain the waste water.

Fit and lock the wastewater container correctly.

"Malfunction" indicator light flashes red

Cause:

Service Error: E01 |

Remedy:

Switch off the device.

Check the fresh water tank for a correct fit.

Switch the device on again.

If the indicator light does not go out, repeat the procedure (max. 4 times).

The "Service" indicator lamp lights up yellow and the "Malfunction" indicator lamp lights up red at the same time.

Cause:

Service Error: E01 |

Remedy:

Contact Customer Service.

Cause:

Service Error: E07 |

Remedy:

Contact Customer Service.

Cause:

Service Error: E09 |

Remedy:

Contact Customer Service.

Cause:

Service Error: E16 |

Remedy:

Contact Customer Service.

"Malfunction" indicator light lights up red

Cause:

Service Error: E12 |

Remedy:

Check the accessory plug for a correct fit.

Switch off the device, wait briefly, switch the device on again.

If the error occurs repeatedly, notify Customer Service.

Cause:

Service Error: E13 |

Remedy:

Check the accessory plug for a correct fit.

If water enters the handle, ensure that it is completely dry.

Switch off the device, wait briefly, switch the device on again.

If the error occurs repeatedly, notify Customer Service.

Poor suction performance

Remedy:

Remove blockages from the floor nozzle, the steam suction pipe, the handle and the steam suction hose.

Remove the blockage from the accessory.

Increased temperatures in the handle

Remedy:

Check the seals (2x O-ring) in the handle and in the steam suction pipes.

If the malfunction cannot be corrected, the device must be checked by the Customer Service department.

Display without indicator light

Cause:

Detergent refill |

Remedy:

Refill the detergent.

Insert the detergent container correctly, push it in as far as it will go.

"Service" indicator light flashes yellow

Cause:

Service Error: E07 |

Remedy:

Switch off the device, wait briefly, switch the device on again.

If the indicator light does not go out, repeat the procedure (max. 4 times).

Cause:

Service Error: E14 |

Pre-warning for descaling (still 100h)

Remedy:

Have the device descaled by Customer Service.

"Service" indicator light lights up yellow

Cause:

Service Error: E15 |

Descaling

Remedy:

Have the device descaled by Customer Service.

"Fresh water reservoir empty" indicator light lights up red

Cause:

Fresh water refill |

Remedy:

Refill with fresh water.

Correctly insert the fresh water reservoir, push it in as far as it will go.

"Wastewater container full" indicator light lights up red

Cause:

Waste water drain |

Remedy:

Drain the waste water.

Fit and lock the wastewater container correctly.

"Malfunction" indicator light flashes red

Cause:

Service Error: E01 |

Remedy:

Switch off the device.

Check the fresh water tank for a correct fit.

Switch the device on again.

If the indicator light does not go out, repeat the procedure (max. 4 times).

The "Service" indicator lamp lights up yellow and the "Malfunction" indicator lamp lights up red at the same time.

Cause:

Service Error: E01 |

Remedy:

Contact Customer Service.

Cause:

Service Error: E07 |

Remedy:

Contact Customer Service.

Cause:

Service Error: E09 |

Remedy:

Contact Customer Service.

Cause:

Service Error: E16 |

Remedy:

Contact Customer Service.

"Malfunction" indicator light lights up red

Cause:

Service Error: E12 |

Remedy:

Check the accessory plug for a correct fit.

Switch off the device, wait briefly, switch the device on again.

If the error occurs repeatedly, notify Customer Service.

Cause:

Service Error: E13 |

Remedy:

Check the accessory plug for a correct fit.

If water enters the handle, ensure that it is completely dry.

Switch off the device, wait briefly, switch the device on again.

If the error occurs repeatedly, notify Customer Service.

Poor suction performance

Remedy:

Remove blockages from the floor nozzle, the steam suction pipe, the handle and the steam suction hose.

Remove the blockage from the accessory.

Increased temperatures in the handle

Remedy:

Check the seals (2x O-ring) in the handle and in the steam suction pipes.

The warranty conditions issued by our sales company responsible apply in all countries. We shall remedy possible malfunctions on your device within the warranty period free of cost, provided that a material or manufacturing defect is the cause. In a warranty case, please contact your dealer (with the purchase receipt) or the next authorised customer service site.

You can find more detailed information at: www.kaercher.com/dealersearch

Only use original accessories and original spare parts. They ensure that the appliance will run fault-free and safely.

Information on accessories and spare parts can be found at www.kaercher.com.

EU Declaration of Conformity |

We hereby declare that the machine described below complies with the relevant basic safety and health requirements in the EU Directives, both in its basic design and construction as well as in the version placed in circulation by us. This declaration is invalidated by any changes made to the machine that are not approved by us.

Product: Steam vacuum cleaner

Type: 1.092-xxx

Currently applicable EU Directives2006/42/EC (+2009/127/EC)

2009/125/EC

2011/65/EU

2014/30/EU

Harmonised standards usedEN IEC 63000: 2018

EN 55014-1: 2017 + A11: 2020

EN 55014-2: 2015

EN 60335-1

EN 60335-2-54

EN 60335-2-68

EN 61000-3-2: 2014

EN 61000-3-3: 2013

EN 62233: 2008

National standards used-

The signatories act on behalf of and with the authority of the company management.

Documentation supervisor:

S. Reiser

Alfred Kärcher SE & Co. KG

Alfred-Kärcher-Str. 28 - 40

71364 Winnenden (Germany)

Ph.: +49 7195 14-0

Fax: +49 7195 14-2212

Winnenden, 2022/10/01

Declaration of Conformity (UK) |

We hereby declare that the product described below complies with the relevant provisions of the following UK Regulations, both in its basic design and construction as well as in the version put into circulation by us. This declaration shall cease to be valid if the product is modified without our prior approval.

Product: Steam vacuum cleaner

Type: 1.092-xxx

Currently applicable UK RegulationsS.I. 2008/1597 (as amended)

S.I. 2010/2617 (as amended)

S.I. 2012/3032 (as amended)

S.I. 2016/1091 (as amended)

Designated standards usedEN IEC 63000: 2018

EN 55014-1: 2017 + A11: 2020

EN 55014-2: 2015

EN 60335-1

EN 60335-2-54

EN 60335-2-68

EN 61000-3-2: 2014

EN 61000-3-3: 2013

EN 62233: 2008

National standards used-

The signatories act on behalf of and with the authority of the company management.

Documentation supervisor:

S. Reiser

Alfred Kärcher SE & Co. KG

Alfred-Kärcher-Str. 28 - 40

71364 Winnenden (Germany)

Ph.: +49 7195 14-0

Fax: +49 7195 14-2212

Winnenden, 2022/10/01

Electrical connection | |

Mains voltage | 220-240 V |

Phase | 1 ~ |

Power frequency | 50 Hz |

Tension in the handle | 5 V |

Degree of protection | IPX4 |

Protection class | I |

Nominal power of device (total) | 3400 W |

Nominal power of blower | 1200 W |

Steam boiler intake performance | 3000 W |

Main pump power | 48 W |

Water pump power | 28 W |

Device performance data | |

Steam boiler | 3,4 l |

Fresh water reservoir filling quantity | 5,6 l |

Wastewater container filling quantity | 5 l |

Air quantity (max.) | 74 l/s |

Vacuum (max.) | 25,4 (254) kPa (mbar) |

Working pressure | 0,8 MPa |

Steam pressure (max.) | 1,2 MPa |

Steam volume (max.) - constant | 75 g/min |

Heating-up time | 7,0 min |

Hot water operating temperature (maximum) | 70 °C |

Working temperature of steam operation (max.) | 173 °C |

Water flow rate | 550 ml/min |

Dimensions and weights | |

Typical operating weight | 39 kg |

Length x width x height | 640 x 495 x 965 mm |

Tilt angle (max.) | 10 ° |

Determined values in acc. with EN 60335-2-68 | |

Sound pressure level LpA | 67 dB(A) |

Uncertainty KpA | 1 dB(A) |

Hand-arm vibration value | <2,5 m/s2 |

Uncertainty K | 0,2 m/s2 |

Mains cable | |

Power cord type | H07RN-F 3G 1,5 mm2 |

Part number (EU) | 6.648-098.0 |

Cable length | 7,5 m |

Electrical connection | |

Mains voltage | 220-240 V |

Phase | 1 ~ |

Power frequency | 50 Hz |

Tension in the handle | 5 V |

Degree of protection | IPX4 |

Protection class | I |

Nominal power of device (total) | 3400 W |

Nominal power of blower | 1200 W |

Steam boiler intake performance | 3000 W |

Main pump power | 48 W |

Water pump power | 28 W |

Device performance data | |

Steam boiler | 3,4 l |

Fresh water reservoir filling quantity | 5,6 l |

Wastewater container filling quantity | 5 l |

Detergent container filling quantity | 2 l |

Air quantity (max.) | 74 l/s |

Vacuum (max.) | 25,4 (254) kPa (mbar) |

Working pressure | 0,8 MPa |

Steam pressure (max.) | 1,2 MPa |

Steam volume (max.) - constant | 75 g/min |

Heating-up time | 7,0 min |

Hot water operating temperature (maximum) | 70 °C |

Working temperature of steam operation (max.) | 173 °C |

Water flow rate | 550 ml/min |

Detergent flow rate | 550 ml/min |

Dimensions and weights | |

Typical operating weight | 40 kg |

Length x width x height | 640 x 495 x 965 mm |

Tilt angle (max.) | 10 ° |

Determined values in acc. with EN 60335-2-68 | |

Sound pressure level LpA | 67 dB(A) |

Uncertainty KpA | 1 dB(A) |

Hand-arm vibration value | <2,5 m/s2 |

Uncertainty K | 0,2 m/s2 |

Mains cable | |

Power cord type | H07RN-F 3G 1,5 mm2 |

Part number (EU) | 6.648-098.0 |

Cable length | 7,5 m |

Electrical connection | |

Mains voltage | 220-240 V |

Phase | 1 ~ |

Power frequency | 50 Hz |

Tension in the handle | 5 V |

Degree of protection | IPX4 |

Protection class | I |

Nominal power of device (total) | 2900 W |

Nominal power of blower | 1200 W |

Steam boiler intake performance | 2700 W |

Main pump power | 48 W |

Water pump power | 28 W |

Device performance data | |

Steam boiler | 3,4 l |

Fresh water reservoir filling quantity | 5,6 l |

Wastewater container filling quantity | 5 l |

Detergent container filling quantity | 2 l |

Air quantity (max.) | 74 l/s |

Vacuum (max.) | 25,4 (254) kPa (mbar) |

Working pressure | 0,8 MPa |

Steam pressure (max.) | 1,2 MPa |

Steam volume (max.) - constant | 65 g/min |

Heating-up time | 8,0 min |

Hot water operating temperature (maximum) | 70 °C |

Working temperature of steam operation (max.) | 173 °C |

Water flow rate | 550 ml/min |

Detergent flow rate | 550 ml/min |

Dimensions and weights | |

Typical operating weight | 40 kg |

Length x width x height | 640 x 495 x 965 mm |

Tilt angle (max.) | 10 ° |

Determined values in acc. with EN 60335-2-68 | |

Sound pressure level LpA | 67 dB(A) |

Uncertainty KpA | 1 dB(A) |

Hand-arm vibration value | <2,5 m/s2 |

Uncertainty K | 0,2 m/s2 |

Mains cable | |

Power cord type | H07RN-F 3G 1,5 mm2 |

Part number (GB) | 6.648-102.0 |

Cable length | 7,5 m |