HDS 8/18-4 STHDS 10/21-4 STHDS 13/20-4 ST

59795330 (08/24)

59795330 (08/24)

Read these original operating instructions and the enclosed safety instructions before using the device for the first time. Proceed accordingly.

Read these original operating instructions and the enclosed safety instructions before using the device for the first time. Proceed accordingly.

Keep both books for future reference or for future owners.

Risk of injury due to missing or modified safety devices!

Safety devices are provided for your own protection.

Do not bypass, remove or render ineffective any safety devices.The safety devices are set and sealed by the manufacturer. Adjustments are performed only by customer service.

The water shortage safeguard (flow switch) prevents the burner from overheating and dry running of the HP-pump in the case of a water shortage. If the water supply is insufficient, the device switches off.

The pressure switch switches the device off if the maximum working pressure is exceeded.

If the maximum permissible system pressure is exceeded, the safety valve opens to relieve the pressure in the system. The safety valve is adjusted and sealed at the factory. The adjustment is performed only by customer service.

The flame monitoring system monitors the brightness of the flame on the burner and switches the burner off in the event of a fault.

The motor of the high-pressure pump is protected by the electronics and a winding circuit breaker.

If the emission temperature rises above the permissible value, the emission temperature limiter switches the burner off and locks it.

The temperature limiter switches the burner off when the temperature is too high.

The air pressure switch switches off the burner as soon as the fan fails to generate air pressure.

The emission pressure switch switches off the burner if an impermissibly high back pressure is created in the emission system, e.g. in the event of a blockage.

After switching off the device via the high-pressure gun, a solenoid valve located in the high-pressure system opens after the operating standby time has elapsed. This reduces the pressure built up in the high-pressure system.

The safety catch on the high-pressure gun prevents the device from being switched on inadvertently.

If the device is not used for 30 minutes, the device switches off. The readiness time can be activated and deactivated by customer service via the service menu.

The packing materials can be recycled. Please dispose of packaging in accordance with the environmental regulations.

The packing materials can be recycled. Please dispose of packaging in accordance with the environmental regulations.

Electrical and electronic devices contain valuable, recyclable materials and often components such as batteries, rechargeable batteries or oil, which - if handled or disposed of incorrectly - can pose a potential danger to human health and the environment. However, these components are required for the correct operation of the device. Appliances marked by this symbol are not allowed to be disposed of together with the household rubbish.

Electrical and electronic devices contain valuable, recyclable materials and often components such as batteries, rechargeable batteries or oil, which - if handled or disposed of incorrectly - can pose a potential danger to human health and the environment. However, these components are required for the correct operation of the device. Appliances marked by this symbol are not allowed to be disposed of together with the household rubbish.

Kärcher detergents are separator-friendly (ASF). That means the function of an oil separator is not impaired. A list of recommended detergents can be found in Chapter Accessories and spare parts.

Notes on the content materials (REACH)Current information on content materials can be found at: www.kaercher.de/REACH

The device is used to remove dirt from surfaces using a free-flowing water stream. It is used in particular for cleaning machines, vehicles and facades.

The system must be installed so that the rear opening is closed, for example by a wall.

Only clean water may be used as a high-pressure medium. Contamination leads to premature wear and tear or deposits in the device.

Use at petrol stations or other hazard zones

Risk of injury

Adhere to the respective safety regulations.Do not allow waste water containing mineral oil to penetrate soil, waterways or the sewage system. Only wash the motor or the undercarriage in suitable places with an oil separator.

Dirty water

Premature wear and tear or deposits in the device

Supply the device using only clean water, or recycled water that does not exceed the specified limit values.The following limit values apply to the water supply:

pH value: 6.5-9.5

Electrical conductivity: Conductivity of fresh water + 1200 µS/cm, maximum conductivity 2000 µS/cm

Settleable particles (sample volume 1 l, settling time 30 minutes): < 0.5 mg/l

Filterable particles: < 50 mg/l, no abrasive substances

Hydrocarbons: < 20 mg/l

Chloride: < 300 mg/l

Sulphate: < 240 mg/l

Calcium: < 200 mg/l

Total hardness: < 28 °dH, < 50° TH, < 500 ppm (mg CaCO3/l)

Iron: < 0.5 mg/l

Manganese: < 0.05 mg/l

Copper: < 2 mg/l

Active chloride: < 0.3 mg/l

Free of unpleasant odours

Only use original accessories and original spare parts. They ensure that the appliance will run fault-free and safely.

Information on accessories and spare parts can be found at www.kaercher.com.

Detergents make cleaning tasks easier and a selection of detergents is shown in the table. The instructions on the packaging must be observed before using the detergents.

Area of application | Contamination, type of application | Detergent | Kärcher designation | Dosing |

|---|---|---|---|---|

Automotive industry, petrol stations, haulage companies, vehicle fleets | Dust, road dirt, mineral oils (on painted surfaces) | Active cleaner, neutral * | RM 55 * | 0,5-8% |

Active cleaner, alkaline | RM 81* | 0,25-1,25% | ||

Natural active cleaner, alkaline | RM 82N | |||

RM 803* | ||||

Foam cleaner | RM 838 direct | |||

RM 806 | ||||

Vehicle preservation | Hot wax | RM 41 | ||

Hot wax | RM 820* | |||

Spray wax | RM 821* | |||

Super pearl wax | RM 824* | |||

Metalworking industry | Oils, grease, dust and similar soiling | Active cleaner, neutral * | RM 55 * | 0,5-8% |

Active cleaner, alkaline | RM 81* | 0,25-1,25% | ||

RM 803* | ||||

RM 806 | ||||

For heavy soiling | RM 31* | 0,375-2,5% | ||

Liquid (with corrosion protection) | RM 39 | |||

Food processing companies | Light to medium soiling, grease/oil, large surfaces | Parts cleaner | RM 39 | |

Active cleaner, neutral * | RM 55 * | 0,5-8% | ||

Active cleaner, alkaline | RM 81* | 0,25-1,25% | ||

Natural active cleaner, alkaline | RM 82N | |||

Foam cleaner, neutral | RM 57 | |||

Foam cleaner | RM 58* | |||

Gel foam OSC | RM 882 | |||

RM 31*/** | 0,375-2,5% | |||

Smoke resin | Smoke resin remover | RM 33** | ||

Cleaning and disinfection | RM 732 | |||

Disinfection | RM 735 | |||

Limescale, mineral deposits | RM 25** | |||

Foam cleaner | RM 59* | |||

Sanitary area | Limescale, urine scale, soaps etc. | Basic cleaner | RM 25* | |

Foam cleaner | RM 59 |

* Separator-friendly

** only for short use, two-step method, rinse with clear water.

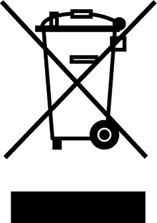

During unpacking, check the contents for completeness. In the event of shipping damage, please notify your dealer.

No accessories are included in the scope of delivery.

The following attachment kits are available separately:

Remote control (not shown)

Pressure relief (not shown)

Second detergent + dosage

Steel floor structure (not shown)

Water inlet solenoid valve (not shown)

Operating hours counter + pressure gauge

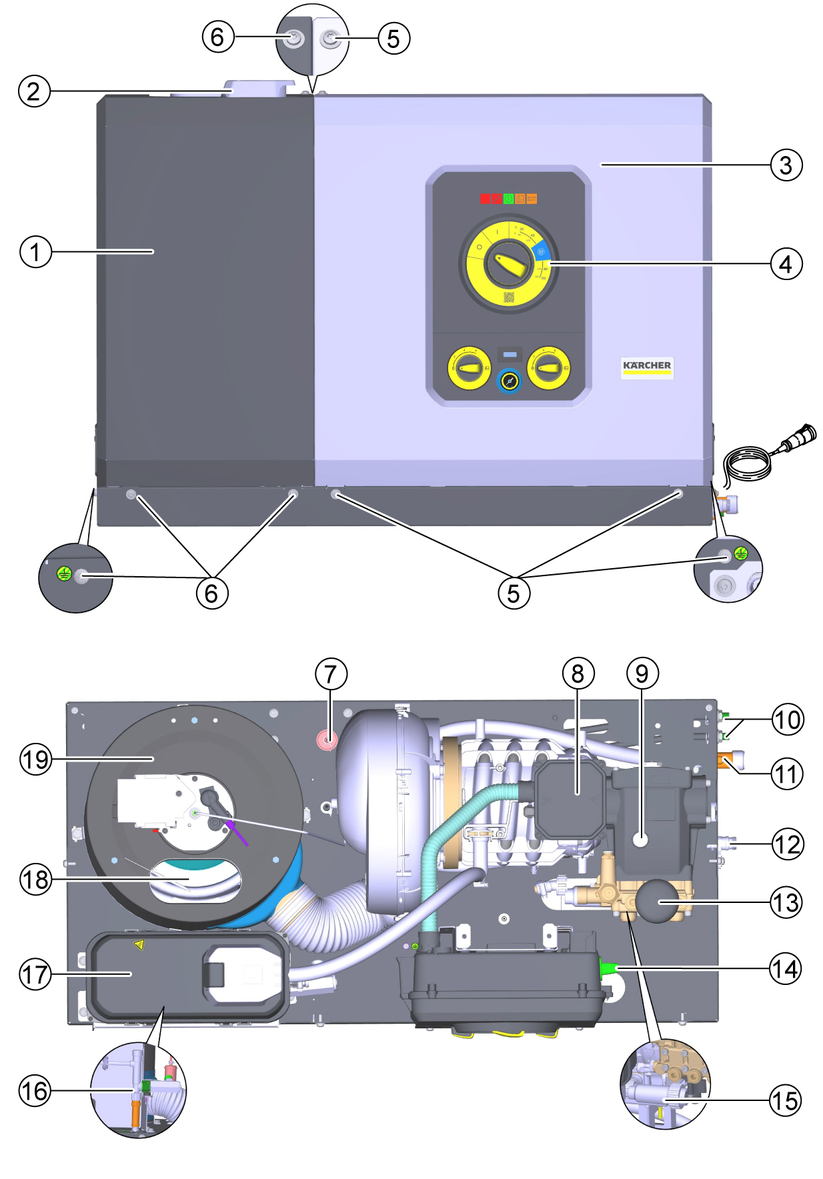

Indicator light | Blink code | Meaning |

|---|---|---|

Indicator lightService menu (red) | - | This indicator light is only relevant for service technicians. |

Indicator light Service (red) | lights up | Carry out service/maintenance after 600 h pump operation after 400 h burner operation |

flashes 1x | Leakage on the device The device switches off. | |

flashes 2x | Current/voltage fault:

The device switches off. | |

flashes 3x | Winding protection contact fault The device switches off. | |

flashes 4x | Exhaust gas fault The device switches off. | |

flashes 5x | Water shortage / dry running The device switches off. | |

flashes 6x | Flame sensor LED too bright / too dark The device switches off. | |

flashes 7x | Water outlet temperature sensor fault The device switches off. | |

flashes 8x | Communication fault The device switches off. | |

Indicator light Operation (green) | lights up | Normal operation without faults |

flashes 1x | Pump has been running continuously for 30 minutes | |

flashes 2x | Pump has been continuously inactive for 30 minutes | |

Detergent indicator light (orange) | lights up | Detergent 1 empty |

flashes 1x | Detergent 2 empty | |

System care indicator light (orange) | lights up | System care empty |

No accessories are included in the scope of delivery.

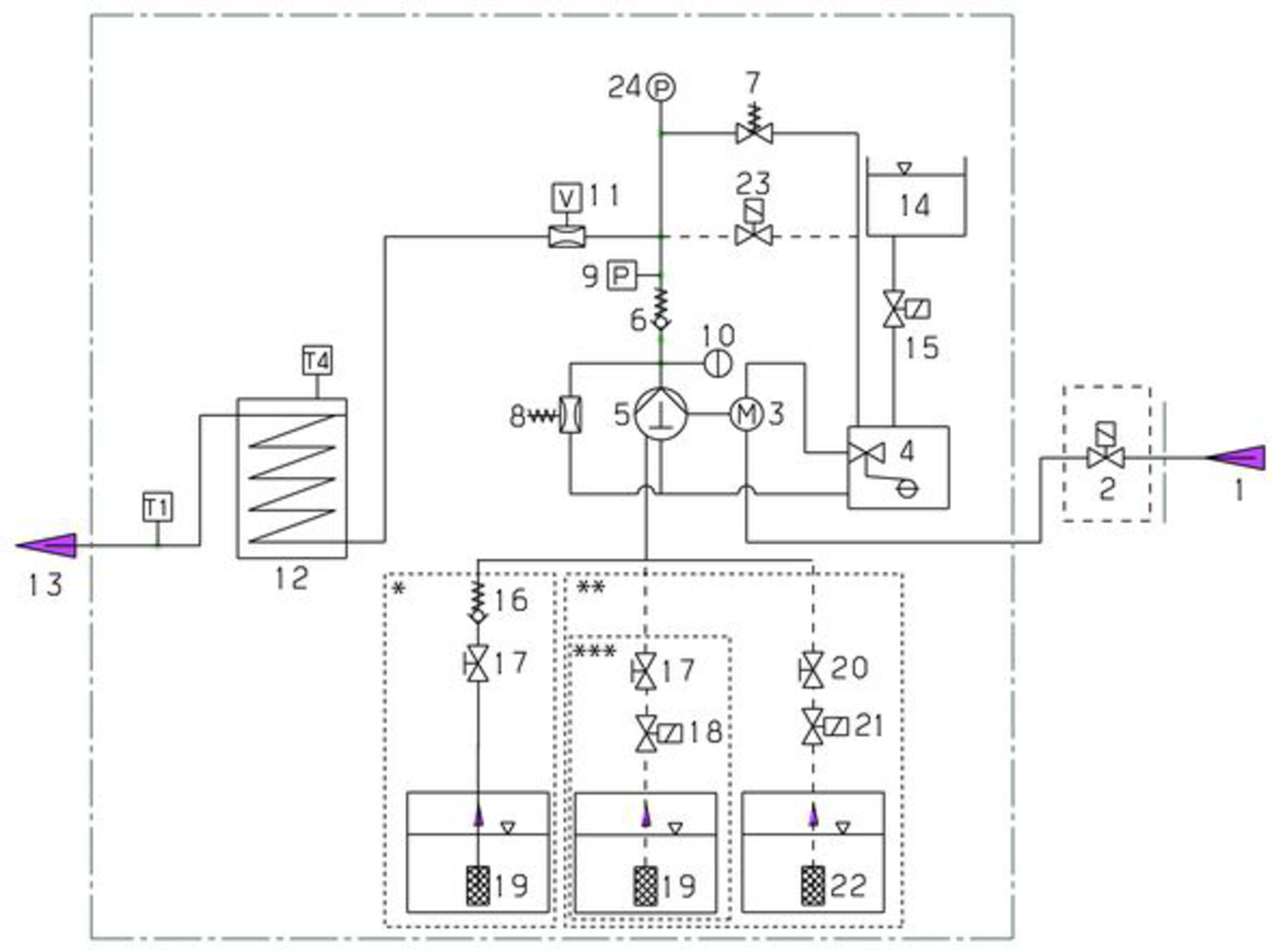

The cold water reaches the suction side of the high-pressure pump via the motor cooling coil and the float tank. System car (RM 110) is dosed into the float tank. Depending on the water hardness, this can be adjusted by customer service as required. The pump conveys water and detergent sucked in through the instantaneous water heater. The proportion of detergent in the water can be adjusted using a dosing valve. The instantaneous water heater is heated by a burner.

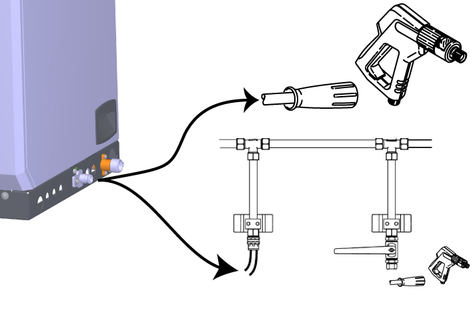

The high-pressure outlet is connected directly to a high-pressure hose or to an existing high-pressure network in the building. The high-pressure gun is connected to the tapping points of this network using a high-pressure hose.

Water outlet temperature sensor T1

T4 exhaust gas temperature monitor

* Flow chart with 1 detergent without remote control (delivery status)

** Flow chart with 2 detergents and remote control (optional)

*** Flow chart with 1 detergent and remote control (optional)

Installation may only be carried out by authorised specialist personnel!

The heating equipment in the device is a firing system. The locally applicable regulations must be observed during installation.

Only use tested chimneys and exhaust gas pipes.

When installing a fuel oil tank in the device installation room, observe the regulations on the storage of flammable liquids.

Provide a two-pipe system with supply and return lines for the fuel lines.

Maximum heating oil pre-pressure: 0.05 MPa (0.5 bar)

Maximum negative pressure between heating oil filter and pump: 0.04 MPa (0.4 bar)

Before the initial startup of the device, connect the external fuel lines to the device and supply them with fuel. This also applies to cold water operation, as otherwise the fuel pump will no longer be lubricated and will fail after a short time.

The components for air/exhaust gas system are not included with the device. Observe the local regulations for building installation.

Each device must be connected to its own chimney.

Carry out the exhaust gas routing in accordance with local regulations and in consultation with the responsible chimney sweep.

Check the load capacity of the wall before installation. Use suitable plugs and screws for concrete, cavity block, brick and aerated concrete walls,e.g. an injection anchor.

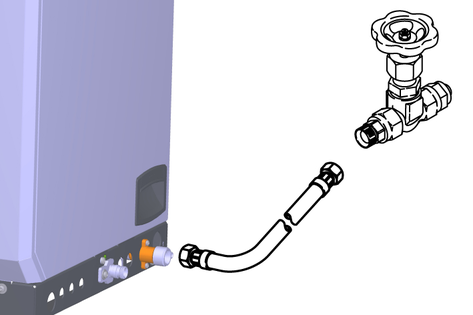

The device must not be rigidly connected to the water supply or high-pressure pipework. The connecting hoses must always be fitted.

Provide a stopcock between the water pipe network and the connecting hose.

Observe the relevant national regulations when installing the high-pressure lines.

The pressure drop in the pipework must be less than 1.5 MPa.

The finished pipework must be tested at 32 MPa.

The insulation of the pipework must be temperature-resistant up to 100°C.

Set up the containers so that the lower level of the detergent is not more than 1.5 m below the base of the device and the upper level is not above the base of the device.

Remote controls can be connected between the device and the tapping points. These allow the device to be operated directly at the tapping point.

Various mounting kits for remote controls are available depending on the application.

Function | Description | |

|---|---|---|

| Reset | After the standby time has elapsed, the device can be restarted directly at the tapping point. |

| Emergency off | |

| On/Off + detergent (turn switch) Single workstation | Switching the device on and off at the tapping point. Activation of the hot water function (burner switches on). Selection of whether detergent should be added: No admixture, admixture RM 1 or admixture RM 2, as set on the device. |

| On/Off + detergent (push buttons) up to 5 spots | Switching the device on and off at the tapping point. Activation of the hot water function (burner switches on). Selection of whether detergent should be added: No admixture, admixture RM 1 or admixture RM 2 (option), as set on the device. |

Connect the water inlet to the water pipe network using a suitable hose.

The capacity of the water supply must be at least 1300 l/h at a minimum of 0.15 MPa.

The water temperature must be under 30 °C.

If the "Solenoid valve water inlet" attachment kit is installed, the valve blocks the water inlet until water is required at a tapping point or the device is switched on.

Switch-on procedures will generate short-term voltage drops. Unfavourable mains conditions may cause other devices to be impaired.

Exceeding the grid impedance

Electrical shock in the event of a short-circuit

The maximum permissible mains grid impedance at the electrical connection point (see Technical data) must not be exceeded.Contact your electricity supplier in the case of any uncertainties regarding the mains grid impedance at your electrical connection point.For connected loads, see technical data and type plate.

The electrical connection must be carried out by an electrician and comply with IEC 60364-1.

All live parts, cables and devices in the work area must be in proper condition and be protected against water jets.

Danger of death from electric shock.

If the device is operated at a socket without an error current circuit breaker or without a protective contact (earthing), there is a danger of death from electric shock in the event of a fault!

Only operate the device at sockets with an earthing contact and with an error current circuit breaker with a nominal fault current of max. 30 mA.Device with ANTI!Twist: Attach the yellow high-pressure hose connection to the high-pressure gun.

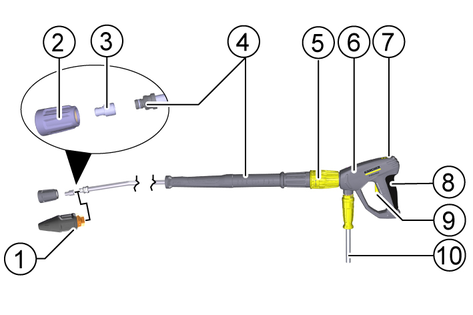

The EASY!Lock system connects components quickly and safely via a single turn of the quick-release thread.

Connect the spray lance to the high-pressure gun and hand-tighten (EASY!Lock).

Plug the high-pressure nozzle onto the spray lance.

Fit the union nut and hand-tighten (EASY!Lock).

Device without a hose reel: Connect the high-pressure hose to the high-pressure gun and high-pressure connection of the device and tighten hand-tight (EASY!Lock).

Device with a hose reel: Connect the high-pressure hose to the high-pressure gun and hand-tighten (EASY!Lock).

Rolled-up high-pressure hose

Risk of damage

Fully unroll the high-pressure hose before starting operation.

Risk of injury

Damaged components can lead to injuries when operating the device.

Check that the device, accessories, supply lines and connections are in perfect condition. Do not use the device if it is not in perfect condition.Ensure the water inlet is OK.

Remove the detergent suction from the device.

Connect the heating oil.

Ensure the power supply is OK.

RM 110 prevents calcification of the heating coil, device and pipework in the presence of hard water.

RM 111 prevents the formation of black water and cares for the pump in the presence of soft water.

Water hardness (°dH) | Scale on the turn switch (1-10) | System care products to be used |

<3 | 3 | RM 111 |

3...7 | 1 | RM 110 |

7...14 | 2 | RM 110 |

14...21 | 3 | RM 110 |

>21 | 4 | RM 110 |

Determine the local water hardness via the local supply company or with a hardness tester (order number 6.768-004.0).

Set the system care dosage using the turn switch on the control panel.

The system care is a highly effective agent for preventing calcification of the heating coil when operating with calcareous tap water. This is drip-fed dosed into the float container.

The dosage is set to medium water hardness at the factory and can be adjusted to the water hardness on site if necessary.

Refill the system care.

If the high-pressure gun is closed during operation, the device will switch off.

If the gun is opened again within the activatable standby time (30 minutes), the device restarts automatically.

If the operating standby time is exceeded, the safety timer switches off the pump and burner.

To restart the device, set the device switch to the "0" position, then switch it on again. If the device is controlled by a remote control, it can be restarted using the corresponding switch on the remote control.

Risk of injury

Risk of injury from escaping, possibly hot water stream!

Check the device for damage each time before use.Check the high-pressure hose, the pipework, the fittings and the spray lance for damage before each use.

Replace leaking components immediately and seal leaking joints.

Check the hose coupling for tight fit and leaks.

Check the filling level of the detergent container and top up with detergent if necessary.

Check the filling level of the system care and top up if necessary.

Risk of damage as a result of incorrect nozzle

Vehicle tyres can be damaged when cleaning with a round jet.

Always clean vehicle tyres with a flat jet nozzle (25°) and a spray distance of at least 30 cm.We recommend the following nozzles, depending on the device and the cleaning task:

Nozzle | Spray angle | Pressure (MPa) |

|---|---|---|

HDS 8/18-4 St | ||

043 | 40° | 18 |

043 | 25° | 18 |

043 | 0° | 18 |

HDS 10/21-4 St | ||

050 | 40° | 21 |

050 | 25° | 21 |

050 | 0° | 21 |

HDS 13/20-4 St | ||

070 | 40° | 20 |

070 | 25° | 20 |

070 | 0° | 20 |

Risk of injury!

Switch off the device and actuate the high-pressure gun until the device is depressurised before changing the nozzle.Secure the high-pressure gun by pushing the safety latch forwards.

Change the nozzle.

For removing light contamination and for rinsing,e.g. garden machines, terrace, tools.

Set the power switch to "I".

Hot water

Risk of scalding

Avoid contact with hot water.Set the power switch to the desired temperature.

The device works in the most economical temperature range (max. 60 °C).

Risk of injury from detergent

Serious damage to health due to improper use of detergents.

Observe the detergent manufacturer's safety data sheet.Wear the prescribed personal protective gear.KÄRCHER detergents ensure fault-free operation. Ask us for advice, request our catalog or our detergent information sheets.

Hang the detergent suction hose in a container with detergent.

Set the detergent dosing valve to the desired dosage. The dosage is set in stages from 0 (no detergent) to 6 (highest dosage).

Spray the detergent sparingly on the dry surface and let it work for a while (do not let it dry).

Rinse off the loosened dirt with the high-pressure jet.

Immerse the filter in clear water.

Turn the dosing valve to the highest detergent concentration.

Start the device and rinse clear for one minute.

As an alternative to dosing detergent at the device, detergent can also be added directly at the dispensing points.

Various options are available for this, e.g.a cup foam lance.

Risk of injury from detergent

Health risk due to incorrect handling of detergents.

Adhere to the safety instructions stated on the detergent packaging.Risk of damage from unsuitable detergents

Using unsuitable detergents may damage the device and the item being cleaned.

Use only detergents approved by KÄRCHER.Observe the dosing recommendations and notes provided with the detergent.Use detergents sparingly to help conserve the environment.KÄRCHER detergents ensure fault-free operation. Ask us for a consultation, request our catalogue or our detergent information sheets.

Unscrew the container.

Plug the desired gate into the suction hose.

Fill the detergent into the container.

Screw the container onto the foam nozzle.

Disconnect the spray lance from the high-pressure gun.

Connect the cup foam lance to the high-pressure gun and hand-tighten.

Start up the high-pressure cleaner.

The cup foam lance must be flushed after use to prevent the formation of detergent deposits.

Unscrew the container.

Pour the remaining detergent back into the original packaging.

Fill the container with clear water.

Screw the container onto the cup foam lance nozzle.

Operate the cup foam lance for approx. 1 minute to flush the detergent residue.

Empty the container.

Actuate the safety lever and trigger.

The high-pressure gun opens.

Release the safety lever and trigger.

The high-pressure gun closes.

Danger of a loose spray lance

Risk of injury

Take care to ensure that the spray lance screw connection does not release when adjusting the pressure/quantity control.Set the power switch to max. 98 °C.

Adjust the working pressure and flow rate by turning (variable) the pressure/quantity regulator on the high-pressure gun (+/-).

Danger of scalding from hot water

Contact with hot water can lead to scald injuries.

After operation with hot water, the device must be operated with an opened gun with cold water for at least 2 minutes.Close the water inlet.

Open the high-pressure gun.

Switch on the pump with the power switch and let it run for 5-10 seconds.

Close the high-pressure gun.

Set the trigger to "0/OFF".

Close the stopcock on the water inlet and, if necessary, also close other stopcocks at the tapping points

Remove the water connection.

Actuate the high-pressure guns at the tapping points until the system is depressurised.

Lock the high-pressure guns by pushing the safety latch forwards.

Turn the main switch to position “0”.

Close the water inlet.

Actuate the high-pressure gun until the device is completely depressurised.

Risk of injury, risk of damage

Be aware of the weight of the device during transportation.When transporting in vehicles, secure the device against slipping and tipping over according to the applicable guidelines.

Risk of injury or damage due to non-observance of the weight!

When transporting and storing the device, there is a risk of injury and damage due to its weight.

Take into account the weight of the device for transportation and storage, see chapter Technical data.Risk of damage due to frost!

Water that is not completely drained can damage the device and accessories during freezing.

Empty the water completely from the device and accessories.Protect the device and accessories from frost.We recommend that you choose a service contract to ensure reliable operation of the device. Please contact your KÄRCHER customer service department responsible.

Check the high-pressure gun.

Check the mains cable.

Check the filling level of the detergent containers.

Check the filling level of the system care.

Check the high-pressure hoses.

Risk of damage due to milky oil

Operation with milky oil can lead to damage to the device.

If the oil is milky, inform the authorised Customer Service immediately.Check the system for leaks.

Check the appearance and level of the pump oil.

Check the vibration dampener.

Check the pump for leaks.

Check the system for internal deposits. To do this, start up the system with a spray lance without a high-pressure nozzle. If the operating pressure on the device pressure gauge (optional) rises above 3 MPa, the system must be descaled.

Clean the fresh water filter.

Clean the fuel filter.

Change the oil in the high-pressure pump.

Have the entire system checked and cleaned by customer service.

Replace the fuel filter (earlier if necessary).

Perform the safety test.

Perform the pressure test according to the manufacturer's specifications.

See the "Technical data" section for the oil volume and type.

Provide a catch pan for approx. 1 litre of oil.

Loosen the oil drain plug.

Drain the oil into the catch pan.

Dispose of the old oil in an environmentally friendly manner or hand it over to an authorised collection point.

Tighten the oil drain plug again.

Slowly fill with new oil up to the centre of the sight glass or between the "Min" and "Max" markings on the dipstick.

Switch the device on "I/ON".

Unlock the lever of the high-pressure gun.

Press the lever of the high-pressure gun.

The device switches on.

Allow the device for run a maximum of 2 minutes until the water escaping from the high-pressure gun is free of air bubbles.

Release the lever of the high-pressure gun.

Lock the lever of the high-pressure gun.

Close the water inlet.

Release the screws of the cover and remove the cover.

Unscrew the filter casing in front of the pump and remove the water filter.

Clean the filter and replace if necessary

Mount the device in reverse order.

Deposits accumulating in the pipework increase the flow resistance and the motor load becomes too high.

Hazard due to inflammable gases

Risk of explosion

Do not smoke during the descaling process. Ensure good ventilation.Acid danger

Risk of acid burns

Wear safety goggles and protective gloves.Execution:

According to legal regulations, only approved boiler solvents with a test certificate may be used for removing deposits.

RM 101; Dissolves descaling and detergent residues.

Fill a 20 litre container with 15 litres of water.

Add 1 litre of scale solvent.

Connect the water hose directly to the pump head and hang the free end into the container.

Place the connected spray lance in the container without a nozzle.

Start the motor according to the operating instructions of the motor manufacturer.

Open the high-pressure gun and do not close it again during descaling.

Set the temperature controller to a work temperature of 40 °C.

Let the device run until the work temperature is reached.

Switch the device off and allow it to stand for 20 minutes. The high-pressure gun must remain open.

Then pump the device empty.

For the purposes of corrosion protection and neutralising acid residues, we recommend then pumping an alkaline solution (e.g. RM 81) through the device via the detergent container.

The device should be installed in a frost-protected room. If there is a risk of frost,e.g. when installed in an outside area, the device must be drained and flushed with antifreeze.

Unscrew the water supply hose and the high-pressure hose.

Allow the device for run for a maximum of 1 minute until the pump and lines are empty.

Unscrew the supply line at the boiler base and allow the heating coil to drain.

Pour a commercially available antifreeze into the float tank. Observe the handling instructions of the anti-freeze manufacturer when doing this.

Place a catch pan under the high-pressure outlet.

Switch on the device (without burner) until the device is completely flushed.

The antifreeze also provides a certain degree of corrosion protection.

Inadvertently starting up device, touching live components

Risk of injury, electric shock

Switch off the device before performing any work on the device.Remove the mains plug.Have all checks and work on electrical parts performed by a qualified electrician.In case of any malfunctions not mentioned in this chapter, contact the authorised Customer Service.Operator: Work labelled with "Operator" may only be performed by instructed persons capable of operating and maintaining high-pressure systems.

Qualified electrician: Work labelled with "Electrician" may only be performed by qualified electricians.

Customer Service: Work labelled with "Customer service" may only be performed by KÄRCHER customer service technicians or KÄRCHER-authorised technicians.

Device is not running

Cause:

There is no voltage in the machine.

Remedy:

Operator, qualified electrician

Check the plug and socket.

Check if the voltage specified on the type plate matches the voltage of the power source.

Check the mains connection for damage.

Cause:

Safety timer active.

Remedy:

Operator

Briefly switch off the device at the trigger an then on again.

Cause:

Fuse blown in the control circuit.

Remedy:

Customer Service department

Insert new fuse. Eliminate the reason for the overload if it burns out again.

Cause:

HP pressure switch (high pressure) faulty.

Remedy:

Customer Service department

Check the pressure switch.

Burner does not ignite or flame goes out during operation

Cause:

Temperature controller set too low.

Remedy:

Operator

Set the temperature regulator higher.

Cause:

Power switch is not set to warm water.

Remedy:

Operator

Set the device to a higher temperature.

Cause:

Low water cut-out in the safety block has switched off (Service indicator light flashes 5x).

Remedy:

Operator

Ensure sufficient water supply.

Check the device for leaks.

Cause:

No fuel.

Remedy:

Operator

Check the fuel supply.

Cause:

Exhaust gas thermostat has triggered (Service indicator light flashes 4x)

Remedy:

Operator

Set the power switch to "0".

Allow the device to cool down.

Switch the device on.

Cause:

Malfunction occurs repeatedly.

Remedy:

Operator

Contact Customer Service.

Service indicator light flashes 1x

Cause:

Leak in the high-pressure system.

Remedy:

Operator

Check the high-pressure system and the connections for leaks.

Service indicator light flashes 2x

Cause:

Fault in the voltage supply or current consumption of the motor too high.

Remedy:

Operator

Check the power supply and the mains power supply circuit breaker.

Contact Customer Service.

Service indicator light flashes 3x

Cause:

Motor overloaded or overheated.

Remedy:

Operator

Set the power switch to "0".

Allow the device to cool down.

Switch the device on.

Cause:

Malfunction occurs repeatedly.

Remedy:

Customer Service

Contact Customer Service.

Service indicator light flashes 4x

Cause:

Exhaust gas thermostat has triggered.

Remedy:

Operator

Set the power switch to "0".

Allow the device to cool down.

Switch the device on.

Cause:

Malfunction occurs repeatedly.

Remedy:

Customer Service

Contact Customer Service.

Service indicator light flashes 5x

Cause:

Water shortage.

Remedy:

Operator

Check the water connection and the supply lines.

Cause:

Reed switch stuck in the water shortage safeguard or magnetic piston stuck.

Remedy:

Customer Service

Contact Customer Service.

The service indicator light flashes 6x

Cause:

Flame sensor has switched off the burner.

Remedy:

Customer Service

Contact Customer Service.

Service indicator light flashes 7x

Cause:

Water outlet temperature sensor fault.

Remedy:

Customer Service

Contact Customer Service.

Service indicator light flashes 8x

Cause:

Communication fault.

Remedy:

Customer Service

Contact Customer Service.

Service indicator light lights up

Cause:

Maintenance required.

The device continues running.Remedy:

Customer Service department

Contact Customer Service.

Cause:

Dosage set too low.

Remedy:

Operator

Increase the dosage.

Cause:

Detergent filter clogged or tank empty (detergent LED lights up or flashes).

Remedy:

Operator

Clean the filter.

Fill with detergent.

Cause:

Detergent suction hoses, dosing valve or solenoid valve leaking or blocked.

Remedy:

Operator, customer service

Check the detergent supply.

Replace the defective or leaking parts.

Cause:

Malfunction occurs repeatedly.

Remedy:

Operator

Contact Customer Service.

System care LED lights up

Cause:

System care used up.

Remedy:

Operator

Refill the system care.

Cause:

Flushed the nozzle.

Remedy:

Operator

Replace the nozzle.

Cause:

Detergent tank is empty.

Remedy:

Operator

Top up detergent or close the dosing valve.

Cause:

Not enough water.

Remedy:

Operator

Ensure for sufficient water supply.

Cause:

Fresh water filter contaminated.

Remedy:

Operator

Clean the fresh water filter.

Cause:

Detergent dosing valve is leaking.

Remedy:

Operator

Check and seal the valve.

Cause:

Detergent hoses are leaking.

Remedy:

Operator

Replace the detergent hoses.

Cause:

Float valve is jammed.

Remedy:

Operator

Check the valve for free movement.

Cause:

Safety valve is leaky.

Remedy:

Customer Service department

Check the setting.

Install new seal, if required.

Cause:

Flow control valve is leaking or set too low.

Remedy:

Customer Service department

Check the valve parts.

Replace the parts if damaged, clean if dirty.

Cause:

Solenoid valve for pressure relief is defective.

Remedy:

Customer Service department

Replace the solenoid valve.

Cause:

Vibration dampener is defective.

Remedy:

Customer Service department

Replace the vibration dampener.

Cause:

High-pressure pump draws in a small amount of air.

Remedy:

Customer Service department

Check the suction system and eliminate any leaks.

Cause:

Detergent container empty and detergent dosing activated.

Remedy:

Operator

Top up detergent or set detergent dosage to 0.

Cause:

Not enough water, water inlet/fresh water filter blocked.

Remedy:

Operator

Check the water inlet.

Clean the fresh water filter.

Cause:

Nozzle in the spray lance is clogged.

Remedy:

Operator

Check the nozzle and clean it.

Cause:

Device is scaled.

Remedy:

Operator/customer service

Descale the device (see Descale the device)

Cause:

The switching point of the overflow valve has become misaligned.

Remedy:

Customer Service department

Reset the overflow valve.

Cause:

Air in the pump.

Remedy:

Operator

Vent the device.

Cause:

Safety valve or safety valve seal is defective.

Remedy:

Customer Service

Replace the safety valve or the seal.

Cause:

Pressure switch faulty.

Remedy:

Customer Service

Contact Customer Service.

Device is not running

Cause:

There is no voltage in the machine.

Remedy:

Operator, qualified electrician

Check the plug and socket.

Check if the voltage specified on the type plate matches the voltage of the power source.

Check the mains connection for damage.

Cause:

Safety timer active.

Remedy:

Operator

Briefly switch off the device at the trigger an then on again.

Cause:

Fuse blown in the control circuit.

Remedy:

Customer Service department

Insert new fuse. Eliminate the reason for the overload if it burns out again.

Cause:

HP pressure switch (high pressure) faulty.

Remedy:

Customer Service department

Check the pressure switch.

Burner does not ignite or flame goes out during operation

Cause:

Temperature controller set too low.

Remedy:

Operator

Set the temperature regulator higher.

Cause:

Power switch is not set to warm water.

Remedy:

Operator

Set the device to a higher temperature.

Cause:

Low water cut-out in the safety block has switched off (Service indicator light flashes 5x).

Remedy:

Operator

Ensure sufficient water supply.

Check the device for leaks.

Cause:

No fuel.

Remedy:

Operator

Check the fuel supply.

Cause:

Exhaust gas thermostat has triggered (Service indicator light flashes 4x)

Remedy:

Operator

Set the power switch to "0".

Allow the device to cool down.

Switch the device on.

Cause:

Malfunction occurs repeatedly.

Remedy:

Operator

Contact Customer Service.

Service indicator light flashes 1x

Cause:

Leak in the high-pressure system.

Remedy:

Operator

Check the high-pressure system and the connections for leaks.

Service indicator light flashes 2x

Cause:

Fault in the voltage supply or current consumption of the motor too high.

Remedy:

Operator

Check the power supply and the mains power supply circuit breaker.

Contact Customer Service.

Service indicator light flashes 3x

Cause:

Motor overloaded or overheated.

Remedy:

Operator

Set the power switch to "0".

Allow the device to cool down.

Switch the device on.

Cause:

Malfunction occurs repeatedly.

Remedy:

Customer Service

Contact Customer Service.

Service indicator light flashes 4x

Cause:

Exhaust gas thermostat has triggered.

Remedy:

Operator

Set the power switch to "0".

Allow the device to cool down.

Switch the device on.

Cause:

Malfunction occurs repeatedly.

Remedy:

Customer Service

Contact Customer Service.

Service indicator light flashes 5x

Cause:

Water shortage.

Remedy:

Operator

Check the water connection and the supply lines.

Cause:

Reed switch stuck in the water shortage safeguard or magnetic piston stuck.

Remedy:

Customer Service

Contact Customer Service.

The service indicator light flashes 6x

Cause:

Flame sensor has switched off the burner.

Remedy:

Customer Service

Contact Customer Service.

Service indicator light flashes 7x

Cause:

Water outlet temperature sensor fault.

Remedy:

Customer Service

Contact Customer Service.

Service indicator light flashes 8x

Cause:

Communication fault.

Remedy:

Customer Service

Contact Customer Service.

Service indicator light lights up

Cause:

Maintenance required.

The device continues running.Remedy:

Customer Service department

Contact Customer Service.

Cause:

Dosage set too low.

Remedy:

Operator

Increase the dosage.

Cause:

Detergent filter clogged or tank empty (detergent LED lights up or flashes).

Remedy:

Operator

Clean the filter.

Fill with detergent.

Cause:

Detergent suction hoses, dosing valve or solenoid valve leaking or blocked.

Remedy:

Operator, customer service

Check the detergent supply.

Replace the defective or leaking parts.

Cause:

Malfunction occurs repeatedly.

Remedy:

Operator

Contact Customer Service.

System care LED lights up

Cause:

System care used up.

Remedy:

Operator

Refill the system care.

Cause:

Flushed the nozzle.

Remedy:

Operator

Replace the nozzle.

Cause:

Detergent tank is empty.

Remedy:

Operator

Top up detergent or close the dosing valve.

Cause:

Not enough water.

Remedy:

Operator

Ensure for sufficient water supply.

Cause:

Fresh water filter contaminated.

Remedy:

Operator

Clean the fresh water filter.

Cause:

Detergent dosing valve is leaking.

Remedy:

Operator

Check and seal the valve.

Cause:

Detergent hoses are leaking.

Remedy:

Operator

Replace the detergent hoses.

Cause:

Float valve is jammed.

Remedy:

Operator

Check the valve for free movement.

Cause:

Safety valve is leaky.

Remedy:

Customer Service department

Check the setting.

Install new seal, if required.

Cause:

Flow control valve is leaking or set too low.

Remedy:

Customer Service department

Check the valve parts.

Replace the parts if damaged, clean if dirty.

Cause:

Solenoid valve for pressure relief is defective.

Remedy:

Customer Service department

Replace the solenoid valve.

Cause:

Vibration dampener is defective.

Remedy:

Customer Service department

Replace the vibration dampener.

Cause:

High-pressure pump draws in a small amount of air.

Remedy:

Customer Service department

Check the suction system and eliminate any leaks.

Cause:

Detergent container empty and detergent dosing activated.

Remedy:

Operator

Top up detergent or set detergent dosage to 0.

Cause:

Not enough water, water inlet/fresh water filter blocked.

Remedy:

Operator

Check the water inlet.

Clean the fresh water filter.

Cause:

Nozzle in the spray lance is clogged.

Remedy:

Operator

Check the nozzle and clean it.

Cause:

Device is scaled.

Remedy:

Operator/customer service

Descale the device (see Descale the device)

Cause:

The switching point of the overflow valve has become misaligned.

Remedy:

Customer Service department

Reset the overflow valve.

Cause:

Air in the pump.

Remedy:

Operator

Vent the device.

Cause:

Safety valve or safety valve seal is defective.

Remedy:

Customer Service

Replace the safety valve or the seal.

Cause:

Pressure switch faulty.

Remedy:

Customer Service

Contact Customer Service.

The warranty conditions issued by our relevant sales company apply in all countries. We shall remedy possible malfunctions on your appliance within the warranty period free of cost, provided that a material or manufacturing flaw is the cause. In a warranty case, please contact your dealer (with the purchase receipt) or the next authorised customer service site.

Further information can be found at: www.kaercher.com/dealersearch

Further warranty information (if available) can be found in the service area of your local Kärcher website under "Downloads".

EU Declaration of Conformity |

We hereby declare that the machine described below complies with the relevant basic safety and health requirements in the EU Directives, both in its basic design and construction as well as in the version placed in circulation by us. This declaration is invalidated by any changes made to the machine that are not approved by us.

Product: High-pressure cleaner

Type: 1.698-xxx

Type: 1.699-xxx

Currently applicable EU Directives2006/42/EC (+2009/127/EC)

2014/30/EU

2014/68/EU

2011/65/EU

2009/125/EC

Commission Regulation(s)(EU) 2019/1781

Harmonised standards usedEN 60335-1

EN 60335-2-79

EN 55014-1: 2017 + A11: 2020

EN 61000-3-2: 2014

EN 55014-2: 1997 + A1: 2001 + A2: 2008

EN IEC 63000: 2018

HDS 8/18-4 ST; HDS 10/21-4 ST

EN 61000-3-3: 2013

HDS 13/20-4 ST

EN 61000-3-11: 2000

Applied specifications:-

The signatories act on behalf of and with the authority of the company management.

Documentation supervisor:

S. Reiser

Alfred Kärcher SE & Co. KG

Alfred-Kärcher-Str. 28 - 40

71364 Winnenden (Germany)

Ph.: +49 7195 14-0

Fax: +49 7195 14-2212

Winnenden, 2024/08/01

Declaration of Conformity (UK) |

We hereby declare that the product described below complies with the relevant provisions of the following UK Regulations, both in its basic design and construction as well as in the version put into circulation by us. This declaration shall cease to be valid if the product is modified without our prior approval.

Product: High-pressure cleaner

Type: 1.698-xxx

Type: 1.699-xxx

Currently applicable UK RegulationsS.I. 2008/1597 (as amended)

S.I. 2016/1091 (as amended)

S.I. 2016/1105 (as amended)

S.I. 2012/3032 (as amended)

S.I. 2010/2617 (as amended)

Commission Regulation(s)(EU) 2019/1781

Designated standards usedEN 60335-1

EN 60335-2-79

EN 55014-1: 2017 + A11: 2020

EN 61000-3-2: 2014

EN 55014-2: 1997 + A1: 2001 + A2: 2008

EN IEC 63000: 2018

HDS 8/18-4 ST; HDS 10/21-4 ST

EN 61000-3-3: 2013

HDS 13/20-4 ST

EN 61000-3-11: 2000

Applied specifications:-

The signatories act on behalf of and with the authority of the company management.

Documentation supervisor:

S. Reiser

Alfred Kärcher SE & Co. KG

Alfred-Kärcher-Str. 28 - 40

71364 Winnenden (Germany)

Ph.: +49 7195 14-0

Fax: +49 7195 14-2212

Winnenden, 2024/08/01

Electrical connection | |

Mains voltage | 400 V |

Phase | 3 ~ |

Power frequency | 50 Hz |

Power rating | 5,5 kW |

Power protection (C-type, gL/gG) | 16 A |

Degree of protection | IPX5 |

Protection class | I |

Water connection | |

Input amount (min.) | 1000 (16,7) l/h (l/min) |

Feed pressure (max.) | 1 (10) MPa (bar) |

Input temperature (max.) | 30 °C |

Device performance data | |

Water flow rate | 800 (13,3) l/h (l/min) |

Water operating pressure with standard nozzle | 18 (180) MPa (bar) |

Excess operating pressure safety valve (maximum) | 21,5 (215) MPa (bar) |

Hot water operating temperature (maximum) | 98 °C |

Detergent flow rate | 0-45 (0-0,75) l/h (l/min) |

Burner output | 61 kW |

Total water temperature increase under full load | 65 K |

Heating oil consumption (max.) | 5,1 kg/h |

High-pressure gun recoil force | 65 N |

Nozzle size of standard nozzle | 043 |

Dimensions and weights | |

Typical operating weight | 134 kg |

Length | 1141 mm |

Width | 577 mm |

Height with chimney adapter | 936 mm |

High-pressure pump | |

Filling quantity | 0,5 l |

Oil type | SAE 15W-40 |

Burner | |

Fuel | EL heating oil or diesel |

Determined values in acc. with EN 60335-2-79 | |

Sound pressure level LpA | 78 dB(A) |

Uncertainty KpA | 3 dB(A) |

Sound power level LWA + uncertainty KWA | 95 dB(A) |

Hand-arm vibration value | 3,9 m/s2 |

Uncertainty K | 0,9 m/s2 |

Electrical connection | |

Mains voltage | 400 V |

Phase | 3 ~ |

Power frequency | 50 Hz |

Power rating | 8 kW |

Power protection (C-type, gL/gG) | 25 A |

Degree of protection | IPX5 |

Protection class | I |

Water connection | |

Input amount (min.) | 1300 (21,7) l/h (l/min) |

Feed pressure (max.) | 1 (10) MPa (bar) |

Input temperature (max.) | 30 °C |

Device performance data | |

Water flow rate | 1000 (16,7) l/h (l/min) |

Water operating pressure with standard nozzle | 21 (210) MPa (bar) |

Excess operating pressure safety valve (maximum) | 23,5 (235) MPa (bar) |

Hot water operating temperature (maximum) | 98 °C |

Detergent flow rate | 0-58 (0-0,97) l/h (l/min) |

Burner output | 77 kW |

Total water temperature increase under full load | 65 K |

Heating oil consumption (max.) | 6,5 kg/h |

High-pressure gun recoil force | 57 N |

Nozzle size of standard nozzle | 050 |

Dimensions and weights | |

Typical operating weight | 143 kg |

Length | 1141 mm |

Width | 577 mm |

Height with chimney adapter | 936 mm |

High-pressure pump | |

Filling quantity | 0,65 l |

Oil type | SAE 15W-40 |

Burner | |

Fuel | EL heating oil or diesel |

Determined values in acc. with EN 60335-2-79 | |

Sound pressure level LpA | 78 dB(A) |

Uncertainty KpA | 3 dB(A) |

Sound power level LWA + uncertainty KWA | 95 dB(A) |

Hand-arm vibration value | 3,8 m/s2 |

Uncertainty K | 1,3 m/s2 |

Electrical connection | |

Mains voltage | 400 V |

Phase | 3 ~ |

Power frequency | 50 Hz |

Power rating | 9,5 kW |

Power protection (C-type, gL/gG) | 25 A |

Degree of protection | IPX5 |

Protection class | I |

Maximum permissible mains grid impedance | 0,0607 Ω |

Water connection | |

Input amount (min.) | 1500 (25) l/h (l/min) |

Feed pressure (max.) | 1 (10) MPa (bar) |

Input temperature (max.) | 30 °C |

Device performance data | |

Water flow rate | 1300 (21,7) l/h (l/min) |

Water operating pressure with standard nozzle | 20 (200) MPa (bar) |

Excess operating pressure safety valve (maximum) | 23,5 (235) MPa (bar) |

Hot water operating temperature (maximum) | 98 °C |

Detergent flow rate | 0-45 (0-0,75) l/h (l/min) |

Burner output | 108 kW |

Total water temperature increase under full load | 65 K |

Heating oil consumption (max.) | 9,1 kg/h |

High-pressure gun recoil force | 72 N |

Nozzle size of standard nozzle | 070 |

Dimensions and weights | |

Typical operating weight | 168 kg |

Length | 1141 mm |

Width | 577 mm |

Height with chimney adapter | 940 mm |

High-pressure pump | |

Filling quantity | 0,65 l |

Oil type | SAE 15W-40 |

Burner | |

Fuel | EL heating oil or diesel |

Determined values in acc. with EN 60335-2-79 | |

Sound pressure level LpA | 78 dB(A) |

Uncertainty KpA | 3 dB(A) |

Sound power level LWA + uncertainty KWA | 95 dB(A) |

Hand-arm vibration value | 4,8 m/s2 |

Uncertainty K | 1 m/s2 |

System type: | Manufacturer no: | Initial startup on: |

Test performed on: | ||

Findings: | ||

Signature | ||

Test performed on: | ||

Findings: | ||

Signature | ||

Test performed on: | ||

Findings: | ||

Signature | ||

Test performed on: | ||

Findings: | ||

Signature |

2-2-NN-A4-GS-20906