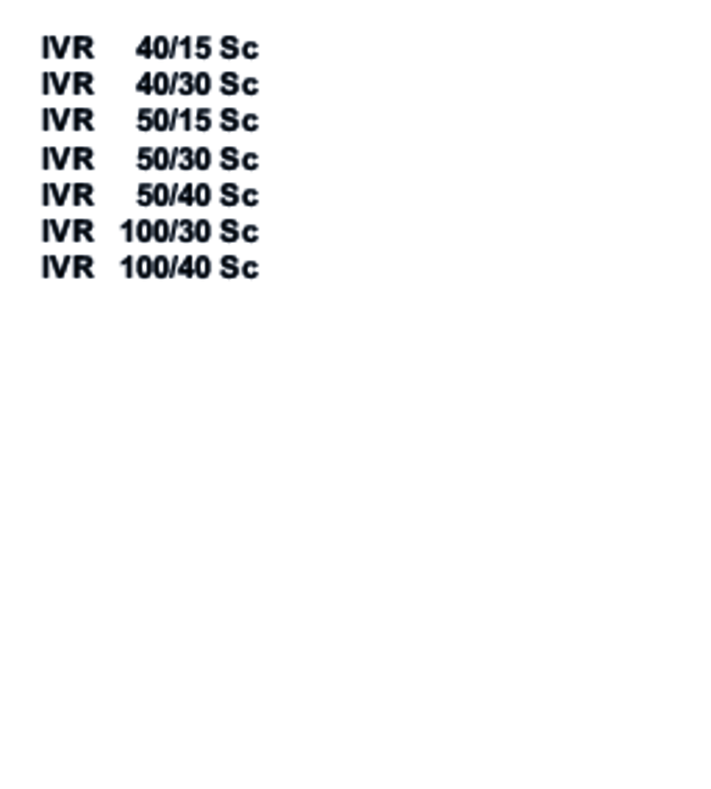

99907540 (05/24)

99907540 (05/24)

Read these original operating instructions and the enclosed safety instructions before using the device for the first time. Proceed accordingly.

Read these original operating instructions and the enclosed safety instructions before using the device for the first time. Proceed accordingly.

Keep both books for future reference or for future owners.

Inhalation of dusts posing a health hazard

Health hazard

Never use the appliance to vacuum up dusts which pose a health hazard.Short-circuit due to high levels of humidity

Damage to the device

Only use the device indoors.The device is intended for:

the vacuuming of non-flammable and non-explosive substances.

the vacuuming of flammable dusts of all dust explosion classes (excluding dusts with a minimum ignition energy ME < 1 mJ).

the vacuuming of dusts and coarse dirt.

the vacuuming of flammable dusts from a zone 22 if the device is installed outside of potentially explosive areas.

the vacuuming of moist and liquid substances.

industrial usee.g. in storage and production areas

commercial use, e.g. in hotels, schools, hospitals, factories, shops, offices, and rental companies.

Any other use will be regarded as improper use.

The packing materials can be recycled. Please dispose of packaging in accordance with the environmental regulations.

The packing materials can be recycled. Please dispose of packaging in accordance with the environmental regulations.

Electrical and electronic devices contain valuable, recyclable materials and often components such as batteries, rechargeable batteries or oil, which - if handled or disposed of incorrectly - can pose a potential danger to human health and the environment. However, these components are required for the correct operation of the device. Devices marked by this symbol are not allowed to be disposed of together with the household rubbish.

Electrical and electronic devices contain valuable, recyclable materials and often components such as batteries, rechargeable batteries or oil, which - if handled or disposed of incorrectly - can pose a potential danger to human health and the environment. However, these components are required for the correct operation of the device. Devices marked by this symbol are not allowed to be disposed of together with the household rubbish.

Current information on content materials can be found at: www.kaercher.de/REACH

Risk of explosion when used with non-permitted accessories

Only use original accessories and original spare parts. They ensure that the appliance will run safely and fault-free.

Information on accessories and spare parts can be found at www.kaercher.com.

Check the contents for completeness when unpacking. If any accessories are missing or in the event of any shipping damage, please notify your dealer.

Indication of an imminent threat of danger that will lead to severe injuries or even death.

Indication of a potentially dangerous situation that may lead to severe injuries or even death.

Indication of a potentially dangerous situation that may lead to minor injuries.

Indication of a potentially dangerous situation that may lead to damage to property.

You must not set up or operate the device in areas where there is a risk of dust or gas explosion. A dust explosive atmosphere inside the device is only allowed in front of the filter. Gas explosive atmospheres are prohibited inside the device.

The device is not suitable for vacuuming up dusts that are harmful to human health.

The device is not suitable for sucking up ignition sources and dusts with a glow temperature ≤ 190 °C.

The device is not suitable for the suction of explosive or equivalent substances within the meaning of §1 SprengG, explosive steam-air mixtures, as well as Al and Mg dusts.

The device is not suitable for the suctioning or vacuuming of flammable liquids (flammable, easily flammable, highly flammable according to Dangerous Substances Directive 67/548/EEC) (flash point below 55 °C) and mixtures of flammable dusts and liquids.

The device is not suitable for the vacuuming of dusts with extremely low minimum ignition energy (ME <1 mJ), e.g. toner, mesh, aluminium powder, lead acid suitable.

Protect the device from rain. Do not store the device outdoors.

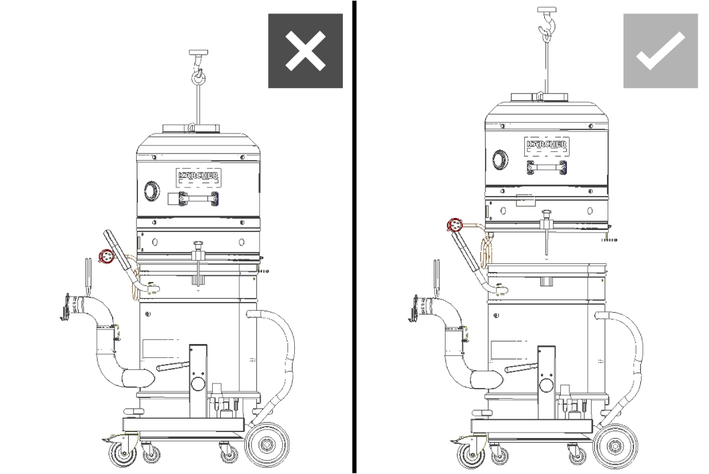

Every time before use, check whether the equipotential bonding conductors (earthing conductors) are connected.

Switch off the device after each use and remove the mains plug.

Only use the device indoors.

Risk of crushing! Wear gloves when removing or installing the suction head, filter inlay or collection container.

Risk of damage! Never vacuum without a filter or with a damaged filter.

Wear safety shoes when operating the device.

Only move the device at walking speed, and to move down a decline, have two workers steady the device as necessary.

Be careful to ensure that there is no dust spillage when replacing accessories.

Surface temperatures can rise to 100 °C during normal operation.

Risk of injury and material damage when vacuuming inflammable materials, or in the case of a short-circuit or other electrical faults

Danger of inhalation of gases hazardous to health, danger of electric shock, danger of burns.

In the event of an emergency, switch off the device and unplug the mains plug.The device may only be connected to an electrical connection which has been set up by a qualified electrician as per IEC 60364. For the connection values seeTechnical data and type plate. Use of an extension cable is prohibited.

Danger of electric shock

Danger of death

Avoid damaging the power cables by driving over them or otherwise crushing them, or by jerking them.Protect the cables from heat, oil and sharp edges.Check the mains connection of the device for damage every time before operation. Do not operate the device using a damaged cable. Have any damaged cables replaced by a qualified electrician. | Observe the warning sign on the device! |

The device is not suitable for:

Intake of liquids with high risk of explosion and for mixtures of flammable dusts and liquids.

Connection to dust-producing machines.

Absorption of glowing dust or other ignition sources.

The device is not suitable for:

Operation in potentially explosive atmospheres.

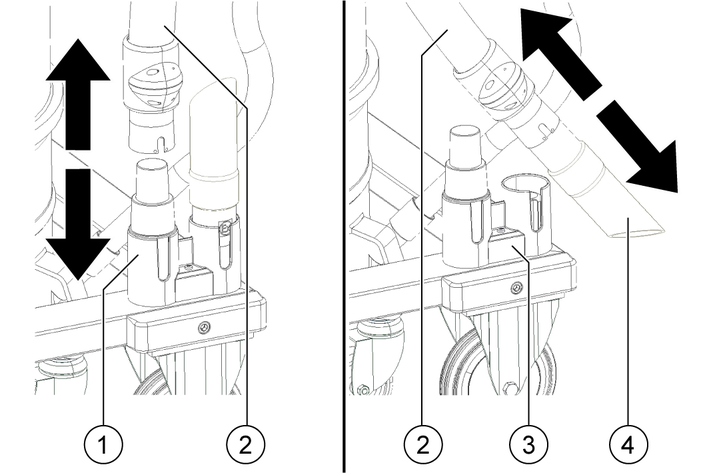

Bring the device into the working position.

If necessary, secure the device using the parking brake.

Ensure that the suction head is fitted correctly.

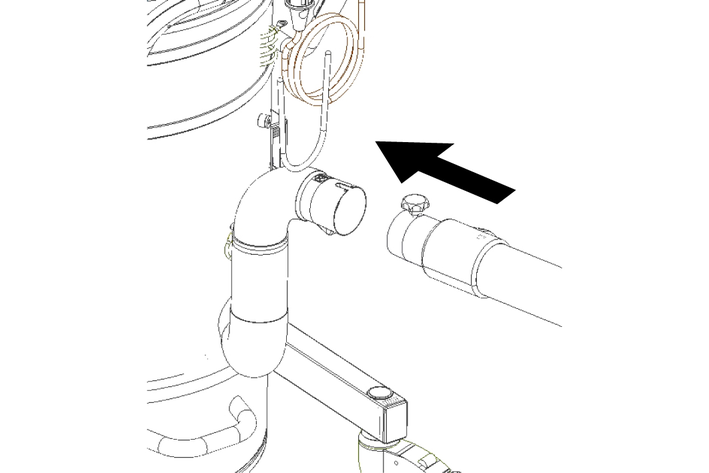

Insert the suction hose into the suction hose connection.

The hose diameter DN50 is only permitted for devices with power variants 3.0 kW and 4.0 kW, and 1.5 kW hose diameter DN40.

Plug the desired accessory onto the suction hose.

Plug the mains plug into the socket.

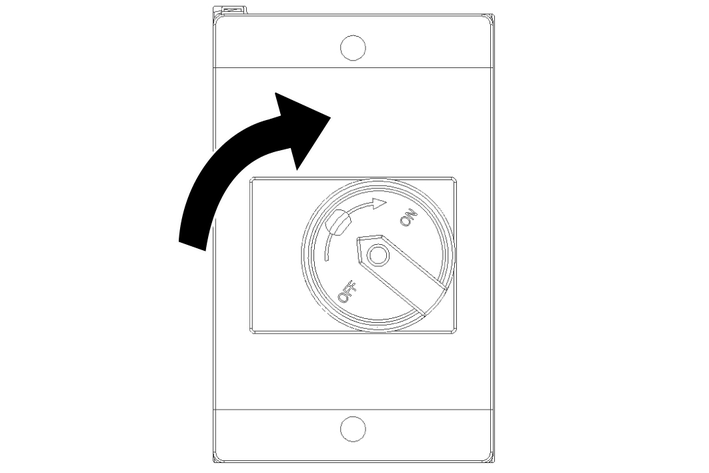

Switch on the device at the trigger.

Start vacuuming.

Switch the device on.

Remove the suction hose from the holder.

Take the desired nozzle out of the accessory holder and attach it to the suction hose.

Vacuum up the desired material.

Take the nozzle off the suction hose and place it into the accessory holder.

Place the suction hose on the holder.

Switch off the device.

Clean the filter regularly to avoid declining suction power.

Move the filter cleaning handle back and forth several times to clean the filter.

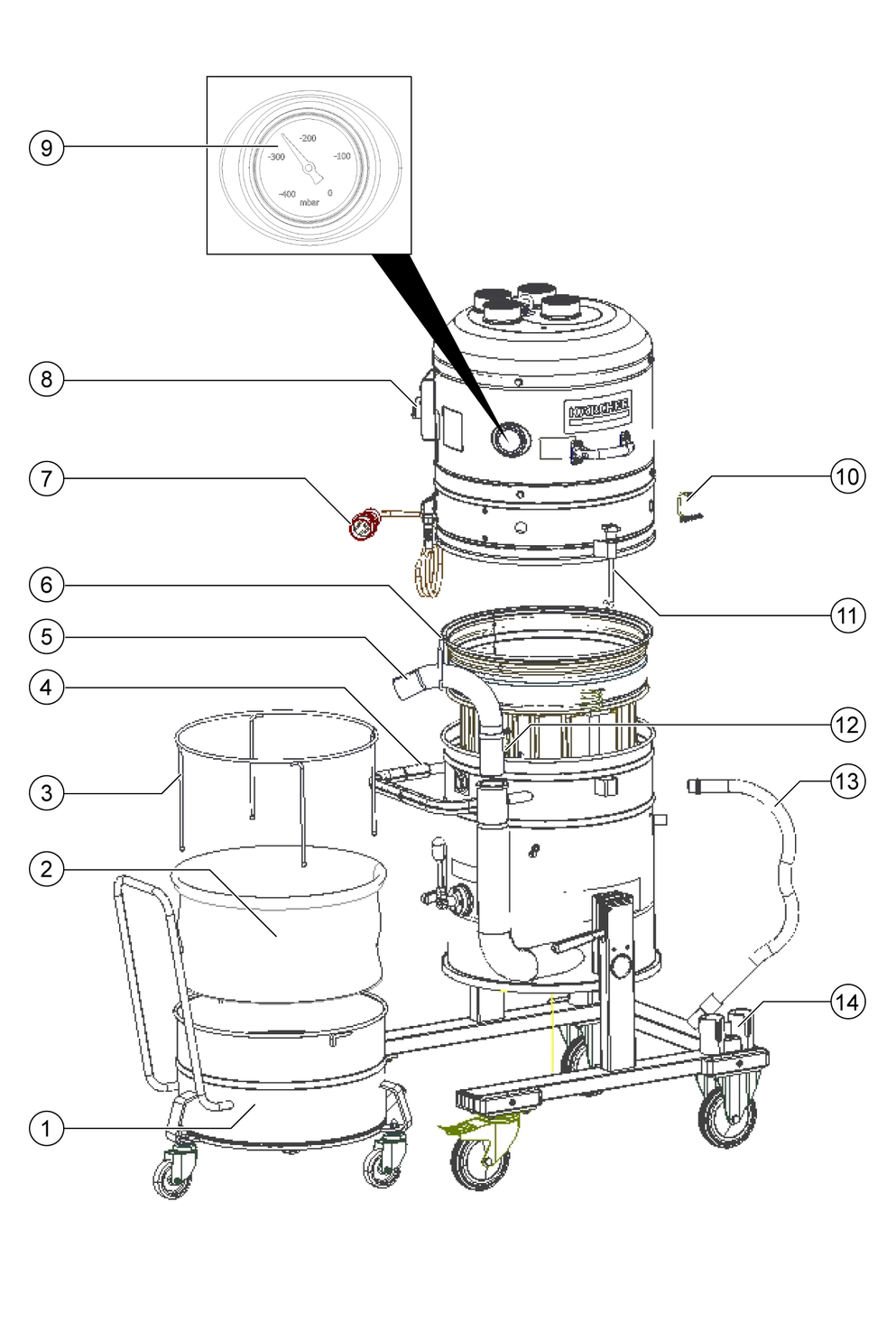

A gauge is mounted on the front of the device that shows the vacuum intensity.

(see chapter Device description)

The table shows the maximum vacuum intensity value. This value depends on the unit performance and the suction hose used.

Suction loss

If the specified value is exceeded, the air speed in the suction hose drops below 20 m/s.

Clean the bag filter when the value is reached, or sooner.If cleaning does not significantly lower the value, change out the bag filter.(see chapterReplacing the pocket filter)Power | Hose diameter | Value |

|---|---|---|

1.5 kW | DN40 | 126 mbar (12.6 kPA) |

3.0 kW | DN40 | 200 mbar (20 kPA) |

3.0 kW | DN50 | 150 mbar (15 kPA) |

4.0 kW | DN40 | 226 mbar (22.6 kPA) |

4.0 kW | DN50 | 216 mbar (21.6 kPA) |

Clean the filter before or when the specified value is reached.

Switch the device off and disconnect it from the power supply.

Clean the dust filter.

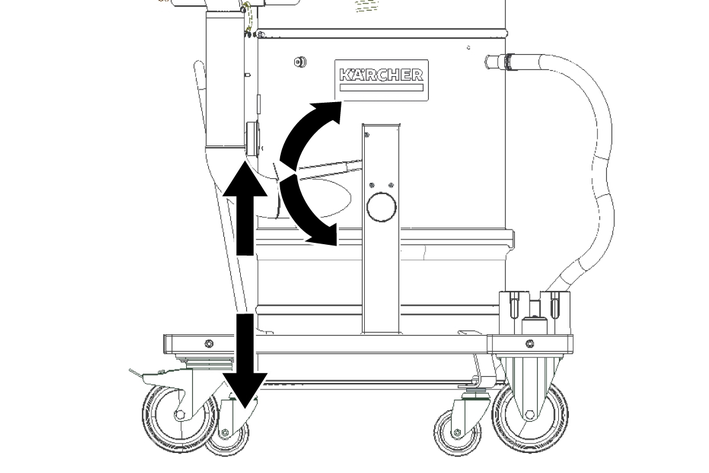

Push down the lever to lower the collection container.

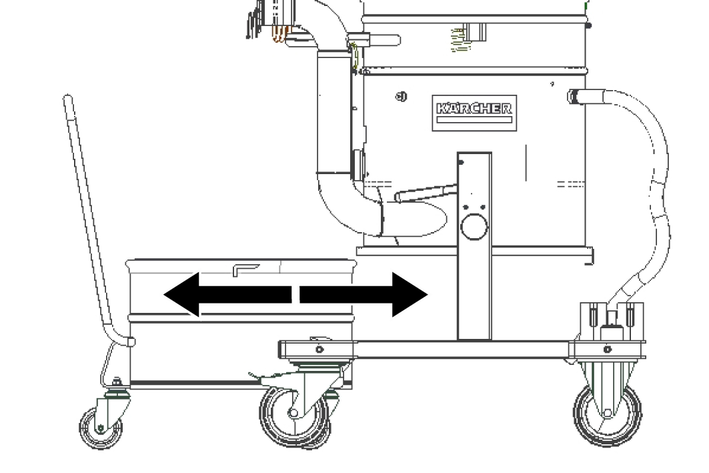

Pull the collection container out of the device.

Empty the collection container into the waste container.

Dispose of or reuse the contents in accordance with applicable law.

Empty the collection container after each use and otherwise as needed.

Only move the collection container only on its rollers. Do not use a crane, forklift or similar means.

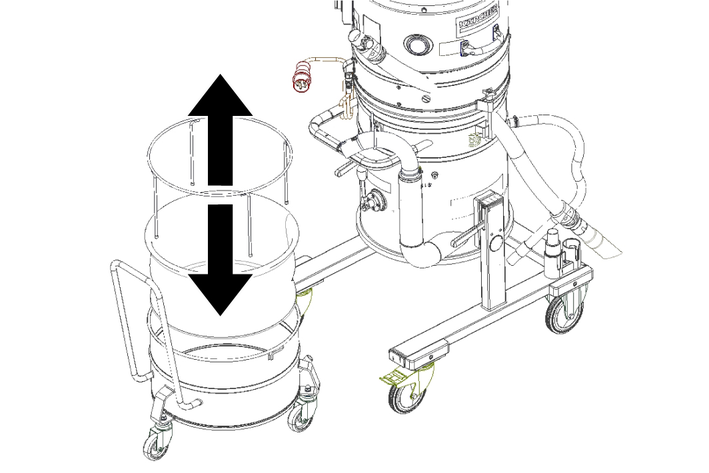

Disconnect the pressure equalisation hose from the collection container.

Take the collection container out of the device.

Remove the fastener from the PE dust bag.

Close the PE dust bag using a cable tie or adhesive tape.

Dispose of the dust bag in accordance with statutory regulations.

Insert the new dust bag into the collection container.

Place the fastener inside.

Ensure that the PE dust bag is not damaged.

Insert the collection container into the device and connect the pressure equalisation hose.

Failure to observe the weight

Risk of injury and damage

Only lift the suction head. Because of its weight, do not remove the suction head by hand.Failure to observe the weight

Risk of injury from falling device

Observe the applicable accident prevention guidelines and safety instructions.Every time before lifting, check to ensure correct functioning of the lifting device.Only lift the device via the provided crane grommet.Ensure that there will be no unintentional unhooking of the lifted load.The crane may exclusively be operated by qualified staff.No people may be located within the hazard zone of the crane.Do not leave the device hanging unattended on the crane.

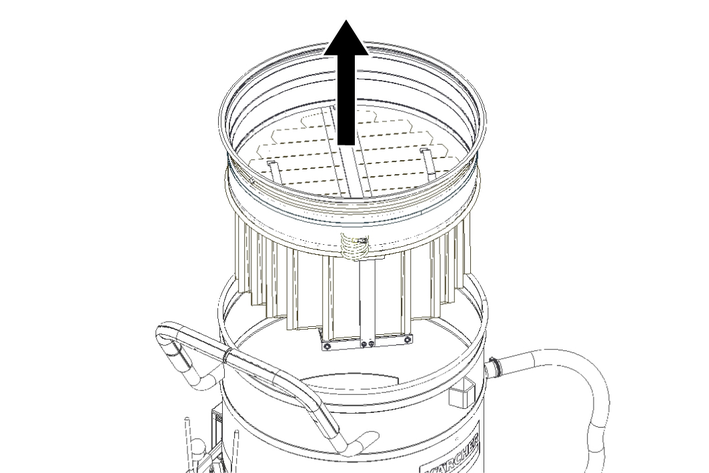

Switch off the device and disconnect from the power supply.

Open the suction head lock.

Attach a suitable hoist to the crane grommet.

Use the crane to lift the suction head and place it on a suitable surface.

Switch off the device using the on/off switch

Empty and clean the collection container.

Remove the accessories and clean and dry them as necessary.

Failure to observe the weight

Risk of injury and damage

Be aware of the weight of the device during transport and storage.When transporting in vehicles, secure the device against slipping and tipping over according to the applicable guidelines.

Failure to observe the weight

Risk of injury and damage

Be aware of the weight of the device during transport and storage.Store the device indoors only.

Rinse off the device and accessories at regular intervals using a suitable liquid and allow to dry.

Check the bag filter regularly for damage. Replace the bag filter if damaged.

Failure to observe the weight

Risk of injury and damage

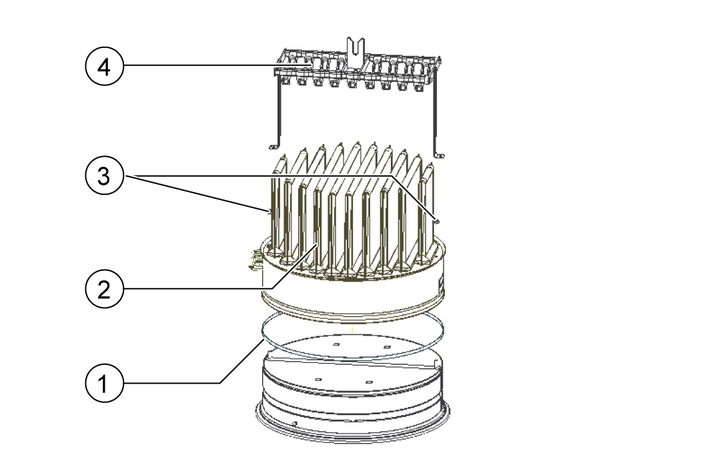

Use suitable lifting gear for lifting the suction head.Remove the suction head (see chapter Removing the suction head).

Remove the filter unit from the device using the handles and turn it over.

Remove the screws and remove the cleaning fixture.

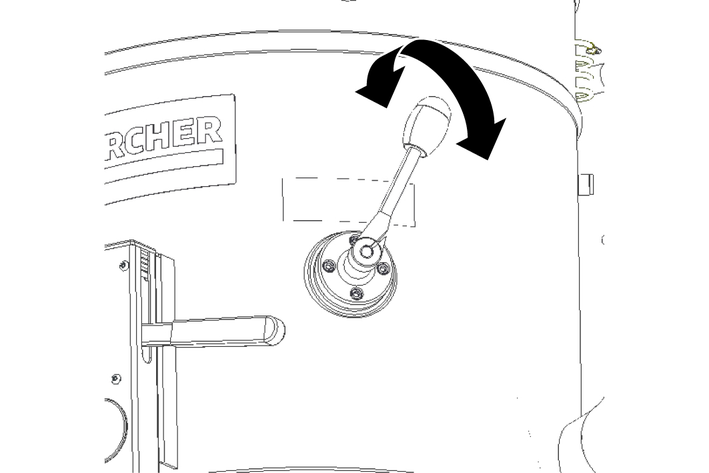

Loosen the clamping ring screw connection.

Remove the pocket filter.

Dispose of the foam filter.

Insert the new bag filter.

Insert the new foam filter.

Fit the tensioning ring and screw it in place.

Fit the cleaning device and screw it on.

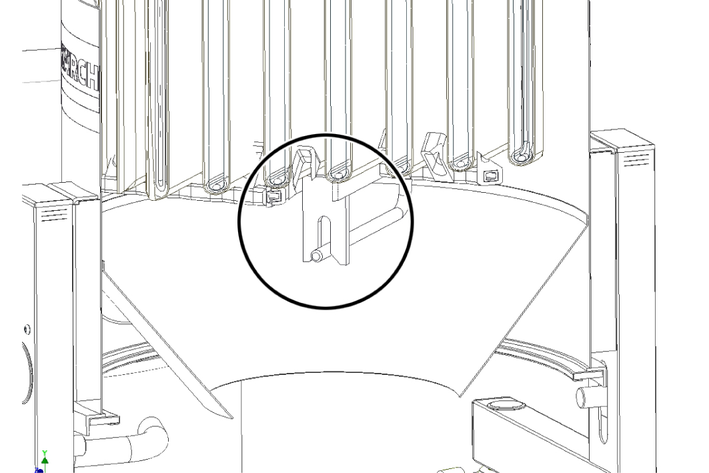

Insert the filter inlay.

In doing so, make sure the tab on the filter inlay fits into the shaft.

Risk of injury

Danger of the device unintentionally starting and danger of electric shock

Switch off the device and unplug the mains plug before performing any work on the device.Have all checks and work on electrical parts performed by an qualified technician.The motor (suction turbine) does not start up

Cause:

No electrical voltage present

Remedy:

Check the socket and the power supply fuse.

Check the mains cable and the mains plug of the device.

The suction power decreases

Cause:

Nozzle, suction hose or suction pipe clogged.

Remedy:

Check the nozzle, the suction hose and the suction pipe and clean if necessary.

Cause:

The filter is dirty.

Remedy:

Clean the filter.

If the malfunction cannot be corrected, the device must be checked by the Customer Service department.

The motor (suction turbine) does not start up

Cause:

No electrical voltage present

Remedy:

Check the socket and the power supply fuse.

Check the mains cable and the mains plug of the device.

The suction power decreases

Cause:

Nozzle, suction hose or suction pipe clogged.

Remedy:

Check the nozzle, the suction hose and the suction pipe and clean if necessary.

Cause:

The filter is dirty.

Remedy:

Clean the filter.

The warranty conditions issued by our relevant sales company apply in all countries. We shall remedy possible malfunctions on your appliance within the warranty period free of cost, provided that a material or manufacturing flaw is the cause. In a warranty case, please contact your dealer (with the purchase receipt) or the next authorised customer service site.

Further information can be found at: www.kaercher.com/dealersearch

Further warranty information (if available) can be found in the service area of your local Kärcher website under "Downloads".

Electrical connection | |

Mains voltage | 400 V |

Phase | 3 ~ |

Power frequency | 50 Hz |

Degree of protection | IPX4 |

Protection class | I |

Nominal power | 1500 W |

Power protection (slow-blowing) | 16 A |

Dimensions and weights | |

Typical operating weight | 116 kg |

Length x width x height | 855 x 715 x 1530 mm |

Ambient conditions | |

Ambient temperature | +40 °C |

Device performance data | |

Tank content | 40 l |

Air quantity | 58 l/s |

Air flow volume during operation | 37.5 l/s |

Vacuum | 20 (200) kPa (mbar) |

Operating pressure | 16 (160) kPa (mbar) |

Nominal width of the suction hose | DN50 |

Determined values in acc. with EN 60335-2-69 | |

Hand-arm vibration value | < 2.5 m/s2 |

Uncertainty K | 0.2 m/s2 |

Sound pressure level LpA | 57 dB(A) |

Uncertainty KpA | 2 dB(A) |

Mains cable | |

Mains cable H07BQ-F | 4 x 2.5 mm2 |

Part number (EU) | 9.979-856.0 |

Cable length | 7.5 m |

Electrical connection | |

Mains voltage | 400 V |

Phase | 3 ~ |

Power frequency | 50 Hz |

Degree of protection | IPX4 |

Protection class | I |

Nominal power | 3000 W |

Power protection (slow-blowing) | 16 A |

Dimensions and weights | |

Typical operating weight | 131 kg |

Length x width x height | 855 x 715 x 1530 mm |

Ambient conditions | |

Ambient temperature | +40 °C |

Device performance data | |

Tank content | 40 l |

Air quantity | 87.5 l/s |

Air flow volume during operation | 56.5 l/s |

Vacuum | 26 (260) kPa (mbar) |

Operating pressure | 21 (210) kPa (mbar) |

Nominal width of the suction hose | DN50 |

Determined values in acc. with EN 60335-2-69 | |

Hand-arm vibration value | < 2.5 m/s2 |

Uncertainty K | 0.2 m/s2 |

Sound pressure level LpA | 62 dB(A) |

Uncertainty KpA | 2 dB(A) |

Mains cable | |

Mains cable H07BQ-F | 4 x 2.5 mm2 |

Part number (EU) | 9.979-856.0 |

Cable length | 7.5 m |

Electrical connection | |

Mains voltage | 400 V |

Phase | 3 ~ |

Power frequency | 50 Hz |

Degree of protection | IPX4 |

Protection class | I |

Nominal power | 1500 W |

Power protection (slow-blowing) | 16 A |

Dimensions and weights | |

Typical operating weight | 139 kg |

Length x width x height | 855 x 760 x 1675 mm |

Ambient conditions | |

Ambient temperature | +40 °C |

Device performance data | |

Tank content | 50 l |

Air quantity | 58 l/s |

Air flow volume during operation | 37.5 l/s |

Vacuum | 20 (200) kPa (mbar) |

Operating pressure | 16 (160) kPa (mbar) |

Nominal width of the suction hose | DN50 |

Determined values in acc. with EN 60335-2-69 | |

Hand-arm vibration value | < 2.5 m/s2 |

Uncertainty K | 0.2 m/s2 |

Sound pressure level LpA | 57 dB(A) |

Uncertainty KpA | 2 dB(A) |

Mains cable | |

Mains cable H07BQ-F | 4 x 2.5 mm2 |

Part number (EU) | 9.979-856.0 |

Cable length | 7.5 m |

Electrical connection | |

Mains voltage | 400 V |

Phase | 3 ~ |

Power frequency | 50 Hz |

Degree of protection | IPX4 |

Protection class | I |

Nominal power | 3000 W |

Power protection (slow-blowing) | 16 A |

Dimensions and weights | |

Typical operating weight | 154 kg |

Length x width x height | 855 x 760 x 1675 mm |

Ambient conditions | |

Ambient temperature | +40 °C |

Device performance data | |

Tank content | 50 l |

Air quantity | 87.5 l/s |

Air flow volume during operation | 56.5 l/s |

Vacuum | 26 (260) kPa (mbar) |

Operating pressure | 21 (210) kPa (mbar) |

Nominal width of the suction hose | DN50 |

Determined values in acc. with EN 60335-2-69 | |

Hand-arm vibration value | < 2.5 m/s2 |

Uncertainty K | 0.2 m/s2 |

Sound pressure level LpA | 62 dB(A) |

Uncertainty KpA | 2 dB(A) |

Mains cable | |

Mains cable H07BQ-F | 4 x 2.5 mm2 |

Part number (EU) | 9.979-856.0 |

Cable length | 7.5 m |

Electrical connection | |

Mains voltage | 400 V |

Phase | 3 ~ |

Power frequency | 50 Hz |

Degree of protection | IPX4 |

Protection class | I |

Nominal power | 4700 W |

Power protection (slow-blowing) | 32 A |

Dimensions and weights | |

Typical operating weight | 179 kg |

Length x width x height | 855 x 760 x 1795 mm |

Ambient conditions | |

Ambient temperature | +40 °C |

Device performance data | |

Tank content | 50 l |

Air quantity | 137.5 l/s |

Air flow volume during operation | 88.5 l/s |

Vacuum | 14 (140) kPa (mbar) |

Operating pressure | 11.5 (115) kPa (mbar) |

Nominal width of the suction hose | DN50 |

Determined values in acc. with EN 60335-2-69 | |

Hand-arm vibration value | < 2.5 m/s2 |

Uncertainty K | 0.2 m/s2 |

Sound pressure level LpA | 71 dB(A) |

Uncertainty KpA | 2 dB(A) |

Mains cable | |

Mains cable H07BQ-F | 4 x 2.5 mm2 |

Part number (EU) | 9.981-557.0 |

Cable length | 7.5 m |

Electrical connection | |

Mains voltage | 400 V |

Phase | 3 ~ |

Power frequency | 50 Hz |

Degree of protection | IPX4 |

Protection class | I |

Nominal power | 3000 W |

Power protection (slow-blowing) | 16 A |

Dimensions and weights | |

Typical operating weight | 159 kg |

Length x width x height | 915 x 760 x 1975 mm |

Ambient conditions | |

Ambient temperature | +40 °C |

Device performance data | |

Tank content | 100 l |

Air quantity | 87.5 l/s |

Air flow volume during operation | 56.5 l/s |

Vacuum | 26 (260) kPa (mbar) |

Operating pressure | 21 (210) kPa (mbar) |

Nominal width of the suction hose | DN50 |

Determined values in acc. with EN 60335-2-69 | |

Hand-arm vibration value | < 2.5 m/s2 |

Uncertainty K | 0.2 m/s2 |

Sound pressure level LpA | 62 dB(A) |

Uncertainty KpA | 2 dB(A) |

Mains cable | |

Mains cable H07BQ-F | 4 x 2.5 mm2 |

Part number (EU) | 9.979-856.0 |

Cable length | 7.5 m |

Electrical connection | |

Mains voltage | 400 V |

Phase | 3 ~ |

Power frequency | 50 Hz |

Degree of protection | IPX4 |

Protection class | I |

Nominal power | 4700 W |

Power protection (slow-blowing) | 32 A |

Dimensions and weights | |

Typical operating weight | 184 kg |

Length x width x height | 915 x 760 x 2095 mm |

Ambient conditions | |

Ambient temperature | +40 °C |

Device performance data | |

Tank content | 100 l |

Air quantity | 137.5 l/s |

Air flow volume during operation | 88.5 l/s |

Vacuum | 14 (140) kPa (mbar) |

Operating pressure | 11.5 (115) kPa (mbar) |

Nominal width of the suction hose | DN50 |

Determined values in acc. with EN 60335-2-69 | |

Hand-arm vibration value | < 2.5 m/s2 |

Uncertainty K | 0.2 m/s2 |

Sound pressure level LpA | 71 dB(A) |

Uncertainty KpA | 2 dB(A) |

Mains cable | |

Mains cable H07BQ-F | 4 x 2.5 mm2 |

Part number (EU) | 9.981-557.0 |

Cable length | 7.5 m |

EU Declaration of Conformity |

We hereby declare that the machine described below complies with the relevant basic safety and health requirements in the EU Directives, both in its basic design and construction as well as in the version placed in circulation by us. This declaration is invalidated by any changes made to the machine that are not approved by us.

Product: Dry vacuum cleaner

Product: Wet/dry vacuum cleaner

Type: 9.986-xxx

Type: 9.989-xxx

Currently applicable EU Directives2006/42/EC (+2009/127/EC)

2014/30/EU

2011/65/EU

Harmonised standards usedEN 55014-2: 2015

EN 55014-1: 2017 + A11: 2020

EN 60335-1

EN 60335-2-69

EN IEC 61000-3-2: 2019

EN 61000-3-3: 2013 + A1: 2019

EN 61000-3-11: 2000

EN 62233: 2008

EN IEC 63000: 2018

The signatories act on behalf of and with the authority of the Executive Board.

Documentation supervisor:

A. Haag

Kärcher Industrial Vacuuming GmbH

Robert-Bosch-Straße 4-8

73550 Waldstetten (Germany)

Ph.: +49 7171 94888-0

Fax: +49 7171 94888-528

Waldstetten, 2024/04/01

Declaration of Conformity (UK) |

We hereby declare that the product described below complies with the relevant provisions of the following UK Regulations, both in its basic design and construction as well as in the version put into circulation by us. This declaration shall cease to be valid if the product is modified without our prior approval.

Product: Dry vacuum cleaner

Product: Wet/dry vacuum cleaner

Type: 9.986-xxx

Type: 9.989-xxx

Currently applicable UK RegulationsS.I. 2008/1597 (as amended)

S.I. 2016/1091 (as amended)

S.I. 2012/3032 (as amended)

Designated standards usedEN 55014-2: 2015

EN 55014-1: 2017 + A11: 2020

EN 60335-1

EN 60335-2-69

EN IEC 61000-3-2: 2019

EN 61000-3-3: 2013 + A1: 2019

EN 61000-3-11: 2000

EN 62233: 2008

EN IEC 63000: 2018

The signatories act on behalf of and with the authority of the Executive Board.

Documentation supervisor:

A. Haag

Kärcher Industrial Vacuuming GmbH

Robert-Bosch-Straße 4-8

73550 Waldstetten (Germany)

Ph.: +49 7171 94888-0

Fax: +49 7171 94888-528

Waldstetten, 2024/04/01

2-2-HC-A5-GS-awx2508