Dry ice blasting in car workshops

Dry ice blasting is an effective particle spray process for removing stubborn dirt coatings from a range of supporting materials. Dry ice cleaning has also proven its worth in automotive workshops or reconditioning shops, especially on complex and delicate surfaces – from upholstery cleaning in cars to cleaning engine compartments and restoration work on classic cars. The main advantage of this technology is that it cleans without leaving any residues, such as waste water, chemicals or spray agent residues.

Engine compartment, body or interior: Dry ice for cleaning delicate surfaces

Why use dry ice in workshops?

Cleaning dirty car parts, tools and machines is usually hard work and often generates a lot of dirt. This is because methods like sandblasting leave behind spray agent, such as sand and glass granulate. Often, there is still cleaning to be done after cleaning the parts.

With this in mind, dry ice has a number of advantages for car workshops and conditioners: Above all, dry-ice blasting can be used without any issues in all applications where water is off-limits. This is particularly true of delicate vehicle electronics or when working on the bodywork of valuable vintage cars. This prevents potential damage to the delicate electronics caused by cleaning with water, protects parts against corrosive chemicals, protects mechanical tools and removes stubborn encrustations without leaving any residues.

Dry ice cleaning even provides a solution for tasks which were previously impossible or could only be accomplished while taking up a great deal of time. This method not only removes chewing gum residue and grease stains, it can also clean dashboards and inside engines immaculately.

It makes all areas clean

Dry-ice blasting can be used in a range of areas. Dry ice blasters can be used to remove varnishes and paints, oils, grease, tar, bitumen, ink, resin, adhesives, wax, silicone and rubber residues, chewing gum and a wide range of dirt coatings from different supporting materials. There are also options for removing old varnish from varnished surfaces layer by layer. Furthermore, this cleaning method has various areas of applications on vehicles.

Dry ice blasting in the engine compartment and on the body:

Metal parts

Engine, chassis, rims, sealing surfaces, thread, tools, lifting platforms

Rubber parts

Hoses, handles, seals, exhaust brackets

Electronic components

Dry ice cleaning in vehicle interiors:

Textiles and plastics inside and on vehicles: Seats, floor mats, roof liners, armrests, vents, dashboards, pedals

How does dry ice blasting work?

Dry-ice blasting is a particle spray procedure which uses CO2 granulate as a spray agent. Unlike most other blasting media, which keep their solid state during the entire work process, the frozen CO2 sublimates instantly to CO2 gas when it impinges on the surface. This means that no spray agent residues are left behind, offering a wide range of applications for this technology.

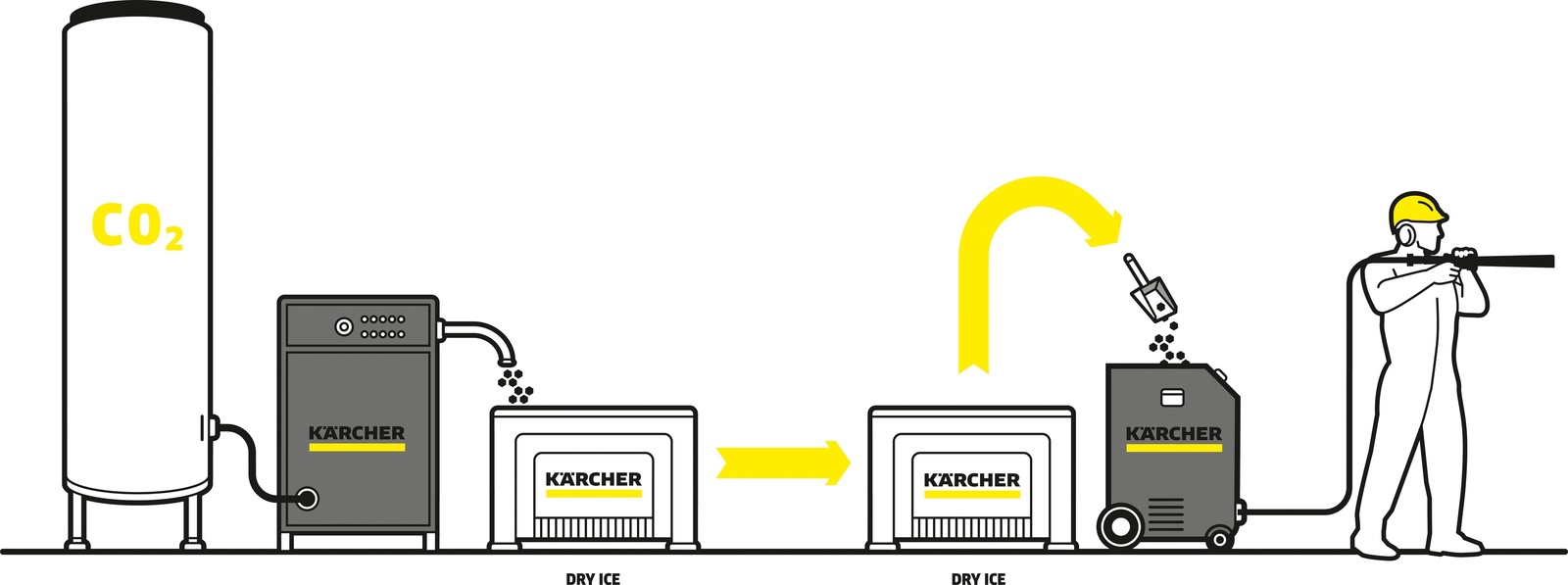

Production of dry ice pellets

The dry ice pellets used must be fresh, otherwise there will be a lower cleaning performance and the pellets will sublimate to gas. Even when kept in appropriate cool boxes, these dry ice pellets can only be stored for a few days.

To date, dry ice pellets have been produced in large hydraulic presses called pelletisers and delivered on request. This usually takes a lot of effort and is expensive, particularly for small quantities. This is why dry-ice blasting is often not used as a cleaning method, even though it enables very efficient work.

However, there is already a machine on the market which produces dry ice for workshop applications – and only during cleaning and precisely in the required quantity. In terms of logistics, only two things are required: Liquid CO2 as a raw material, which can be stored in bottles without any losses, and a compressed air supply or compact compressor.

Procedure and effect of dry-ice blasting

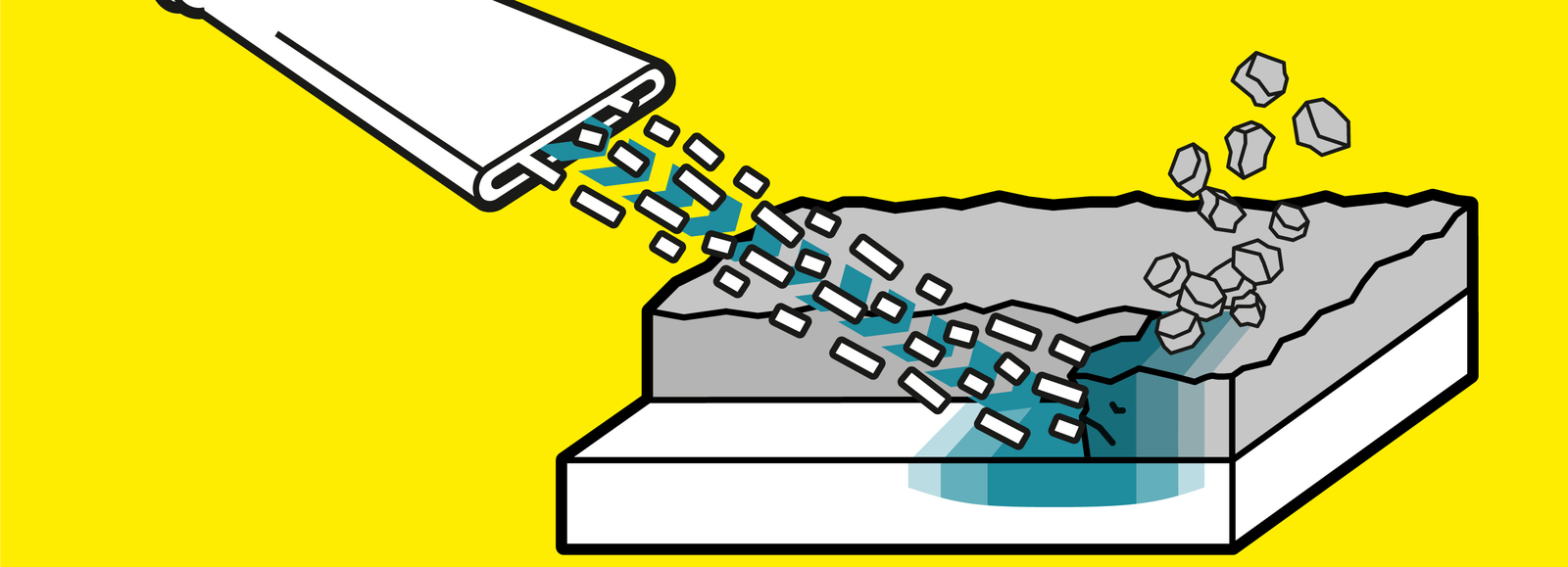

1. The dry ice pellets – solid CO2 at a temperature of -79 °C – impinge on the surface at a high speed of 150 m/s. Like all other spray processes, the accelerated particles lose their kinetic energy when they impinge on the surface. Their Mohs hardness is approximately the same as that of gypsum.

2. When the micro-fine ice pellets at a temperature of -79 °C impinge on the dirt or layer to be removed, the temperature differential/abrupt cooling and kinetic energy cause the dirt to become fragile and brittle and break up. This makes it easier to remove the dirt at a later stage.

3. Subsequent particles penetrate into the cracks in encrusted dirt and applied paint and sublimate there from a solid state to a gaseous state. This involves a 400-fold increase in volume and the dirt is blasted off on a microscopic scale.

Advantages of dry ice blasting

Since dry ice blasters work without chemicals, there is no need to dispose of waste water; there is also no spray agent residue left behind. It is possible to clean particularly delicate surfaces with minimal effort.

- No residue: There is no need to dispose of waste water, chemicals or spray agent residue after dry ice blasters have been used. Only the sprayed substances are left behind. Depending on the amount and composition, these substances are either blown off using the compressed air present or sucked up using vacuum cleaners.

- Cleaning without preparatory work: Vehicle parts do not have to be laboriously disassembled before cleaning. The pellets easily reach into the smallest nooks.

- Time can be saved thanks to quick and effective cleaning with dry ice.

- Environmentally friendly cleaning without additional chemicals or spray agents.

- Surfaces are not damaged.

Correct work protection when working with dry ice in car workshops

The sound pressure of a dry ice blaster is not insignificant, varying between 75 dB(A) and 125 dB (A), depending on various operating parameters. For this reason, operators must wear hearing protection. Touching dry ice may cause skin injuries due to its very low temperature. For user safety, they must therefore wear overalls, safety goggles or a helmet with sight protection, and gloves. The TLV (threshold limit value) for CO2 is 0.5 per cent by volume, which does not cause problems indoors or on factory floors. However, in enclosed spaces or blast cabinets, there must be a ventilation system with a CO2 detector, or a respiratory mask must be worn.