Reference Rief AG, Opfenbach

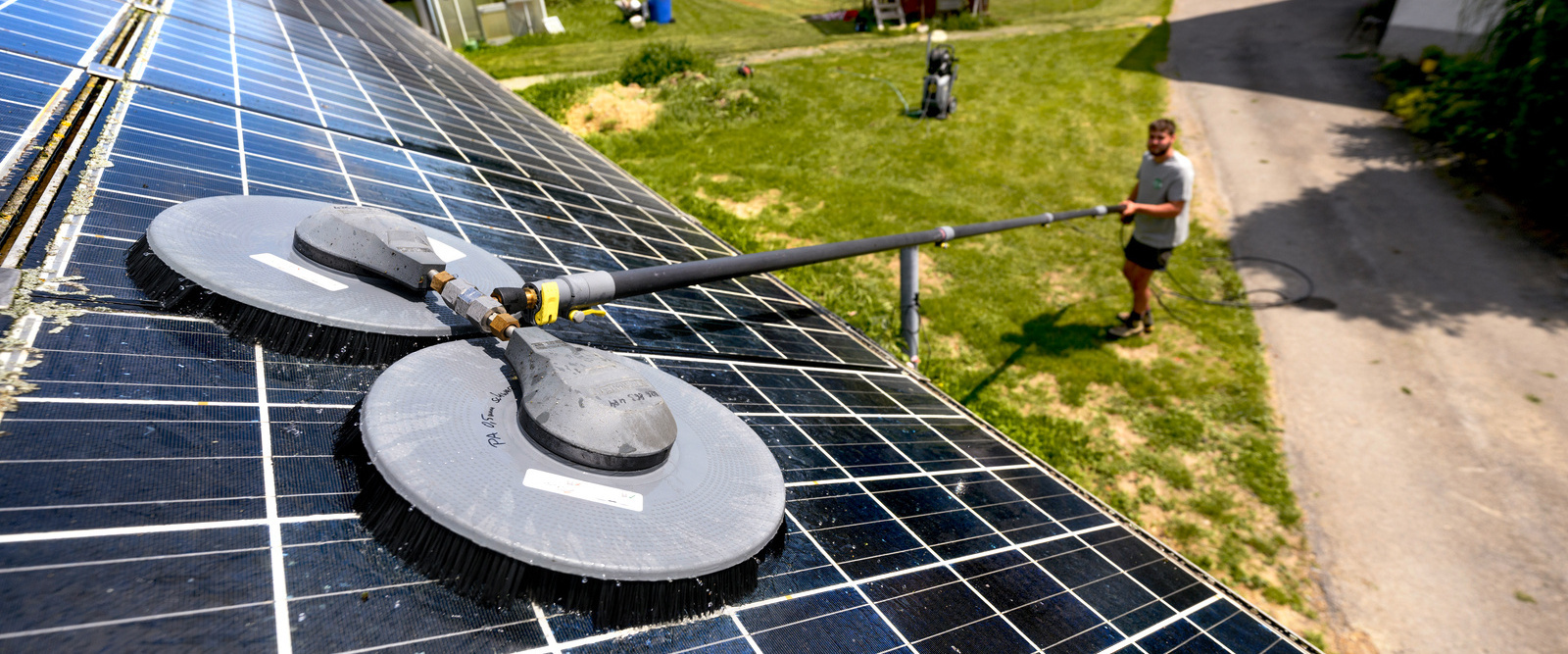

Harnessing the full power of the sun: Farm manager Ludwig Rief is all smiles. Ever since he started regularly cleaning his sensitive solar modules with the clever iSolar System from Kärcher, his photovoltaic (PV) systems have been supplying power at a constantly high level.

A powerful combination

When cleaning the PV systems, the powerful high-pressure machine transports the water to the roof. The water controls and powers the iSolar brush set via the extendable telescopic lance.

Challenge:

acid rain, soot, pollen and bird droppings are factors that can make solar panels dirty and significantly reduce the electricity yield.

Solution:

to maintain the systems’ output, they have regularly been cleaned on the farm since 2020. The Rief farm uses the iSolar accessories with which Kärcher has upgraded its high-pressure machines for cleaning sensitive PV modules.

The project at a glance

PV systems have long been a staple on Rief’s farm. Time and again, dirty solar modules have led to significant power drops – until he discovered the iSolar System.

Challenge

- Power drops of up to 30% due to the gradual soiling of both PV systems.

- Making full use of the solar modules was an important factor in achieving the farm’s aim of having a self-sufficient supply of energy for the entire business in the near future and securing this in the long term.

Solution

- Since regular cleaning of the PV systems has been introduced on the farm, they have been delivering the full yield again.

- This is thanks to the combination of a high-pressure machine and iSolar accessories. This creates an economically attractive complete system for efficiently cleaning the sensitive PV modules.

Safety first! The iSolar System has been tested and certified by the German Agricultural Society (DLG e.V.).

2 × Annually: the iSolar cleaning system should be used regularly every six months (usually in the spring and autumn). It can be used more frequently if necessary (e.g. for Saharan dust).

15 min – Typical set-up time to ensure that the high-pressure machine and iSolar accessories are ready to go. This is made possible by quick-release couplings.

2 h – Duration for completely cleaning the 600 m² PV system. The surface is cleaned in strips – from left to right.