Cleaning and maintaining wooden floors

Natural, oiled, waxed, sealed? To clean and maintain wooden floors properly, it is important to know what type of floor it is. A floor's sensitivity to moisture varies depending on how it has been treated, which, in turn, determines what cleaning and maintenance methods are appropriate. Discover how to carry out maintenance and deep cleaning, and how the right technique can be used to remove greying in outside areas without causing damage.

Not all wooden floors are the same

Natural, oiled, waxed, sealed? To clean and maintain wooden floors properly, it is important to know what type of floor it is. A floor's sensitivity to moisture varies depending on how it has been treated, which, in turn, determines what cleaning and maintenance methods are appropriate. Discover how to carry out maintenance and deep cleaning, and how the right technique can be used to remove greying in outside areas without causing damage.

Know your opponent: the basis for the right approach

Wooden floors are popular thanks to their pleasant, warm look. They also have good insulation properties and low heat dissipation, which generally makes them feel warm under the feet. One type of wooden flooring is laid floorboards, i.e. usually planed or sanded planks of softwood that are suitable for light to moderate loads. Floors made from wood-block paving are suitable for a high footfall and are suitable for heavy loads in commerce and industry. With parquet flooring, which is popular in private homes, boards are laid in various widths, lengths and patterns – although ready-made products can be less durable than real wood parquet.

The key question: how has the floor been treated?

It should be noted that all variants of wooden flooring contract in dry conditions and expand in damp conditions. It is therefore important to ensure the room conditions specified in the cleaning and care instructions are maintained, and to follow the correct procedure when cleaning and caring for the floor. Various treatments are also possible to make wooden floors more resistant to mechanical stress and/or moisture.

Intact sealed floors are less moisture-sensitive, but have to be resealed regularly to preserve them – usually a job for a floor fitter. Unsealed wooden floors come in untreated, oiled or waxed variants. Depending on the design, floors need to be re-oiled or re-waxed at certain intervals to maintain their protective properties. The cleaning and care instructions for the floor specify what type of protection has been applied and will therefore need reapplying. This way, damage caused by improper treatment can be prevented.

Tip 1 – The right room conditions:

Indoor plants can be placed in rooms with wooden floors to prevent an excessively dry indoor climate and in turn reduce shrinkage.

Tip 2 – Wood or laminate:

Wood and laminate floors look very similar – but laminate floors require only a simple clean with a wipe care product to maintain their shine rather than labour-intensive oiling and sealing work. To find out whether flooring is laminate, you can look for a distinctive mark and check whether it repeats several times over in the room. This would not be found in natural wood. Spots where the look does not match the feel are also an indication the flooring is laminate.

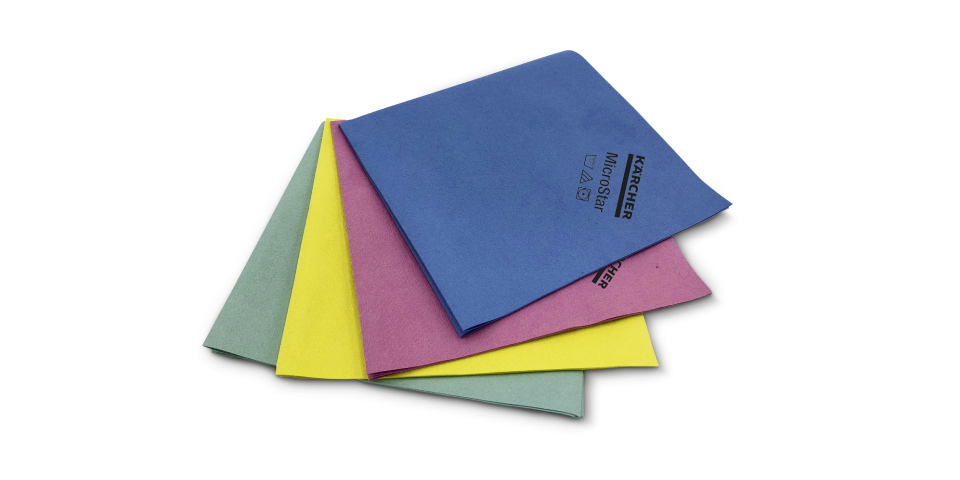

Maintenance cleaning of wooden floors: keep moisture to the absolute minimum necessary

Heavily furnished wooden floors must be cleaned manually to achieve the desired result. Loose dirt such as hair, dust and sand is removed during maintenance cleaning. Dusting and wiping can be done with adhesive-impregnated cloths or microfibre mop covers so that even the finest particles are picked up. A vacuum cleaner with parquet nozzle is recommended for high volumes of dirt. In the second step, ingrained dirt such as drink stains, etc., can be removed by spot cleaning with a wet but well wrung out mop or cloth.

Scrub vacuuming does not damage wooden floors

For larger areas, scrubber dryers with soft brushes (e.g. white) or pads (e.g. beige or red) are the right solution for removing existing soiling or preventing dirt from building up. Ideally, the machine has a roller scrubbing head with a pre-sweep unit to pick up coarser loose dirt. For larger machines, it is important to select the right squeegee lip material and to regularly readjust the squeegee. For compact models, this setting is preset. These are suitable for medium-sized areas if the suction unit is attached directly behind the roller. Because the one-step method is generally used, cleaning water is applied, the floor is scrubbed and the dirty water is sucked back up, all in a single step.

If attention is paid to all these details, scrubber dryers leave no standing moisture on the floor – any residual moisture disappears within a few minutes and does not damage the floor.

Detergents, cornering and double roller system

The working speed, the volume of cleaning water, the speed of the roller brushes and the dosing of the detergent vary depending on the level of soiling. Ideally, a surfactant-free detergent should be used, since surfactants reduce the surface tension, which makes it easier for water to be absorbed into fine joints and cracks and consequently into the wood. The water volume should be reduced when performing a turning manoeuvre, if applicable.

Roller scrubbing heads with a double roller system allow economical application of the cleaning water, since the contra-rotating brushes push the water towards each other. In addition, unlike single-disc machines, where water can escape from the sides, the centrifugal forces prevent water from escaping outwards.

Tip – Regular maintenance cleaning:

Regular maintenance cleaning increases the service life of a floor – sand is the ultimate enemy of every wooden floor, as it creates a sandpaper effect when walked over.

Intermediate cleaning of wooden floors: more shine, more joy

Maintenance cleaning keeps wooden floors looking good and working well, yet the shine may reduce over time. Plus, spot cleaning with a wet mop does not remove marks left by shoe soles. If a deep clean is not yet due, the overall appearance can be refreshed with intermediate cleaning.

Wipe care products based on water-soluble polymers can be used for this purpose. A sufficient amount of wipe care product is manually sprayed onto the floor covering and then distributed in circular movements along evenly spaced tracks using a cleaning machine fitted with suitable pads. In the case of stubborn stains such as heel marks, the affected area can be treated several times, taking care to ensure that the floor does not become dry. If the pad is dirty, it must be turned over or replaced.

Residues of the wipe care product are then polished with a dry pad, and the resulting abrasion is subsequently removed by wiping with a duster. Finally, polishing with a high-speed polishing machine with red or white polishing pads ensures the required shine. Alternatively, there are scrubber dryers that can carry out all these steps.

Tip – The right wipe care product:

Wipe care products that are based on water-insoluble polymers cause a layer build-up and are therefore not recommended for wooden floors.

Deep cleaning of wooden floors

Even with regular cleaning and maintenance, a deep clean will still become necessary at some stage when components of a wipe care product or a greying effect needs to be removed. Firstly, the rooms must be prepared, i.e. emptied and the floors cleared of loose dirt.

Oiled floors

For a deep clean of oiled floors, the most effective solutions are a scrubber dryer with a roller scrubbing head, double roller system with contra-rotating rollers and red or beige pads. A suitable detergent must be selected, depending on the degree of soiling. An alkaline universal deep cleaner or a surfactant-free detergent in the appropriate dosage are recommended. A suitable parquet deep cleaner should be used for water-insoluble soiling. As with maintenance cleaning, use the 1-step method to prevent standing water. If you want to revive the texture of the wood, you can drive over a track several times, depending on the condition of the floor. After drying, the floor is re-oiled.

Waxed floors

If the floor is waxed, the only thing to note is that a dry pad should be used. Residues of protective coatings can be removed mechanically, i.e. machined. Afterwards the floor is waxed again.

Sealed floors

Sealed floors can be deep cleaned in the same way as oiled floors, although the protective effect of sealing decreases depending on the volume of traffic and the frequency of cleaning. This means that floors in a children's nursery, for example, need to be resealed every two years, whereas a rarely used registry office hall needs to be resealed much less frequently.

A single-disc machine with suction or an orbital oscillating single-disc machine is used to sand off the sealant. If the machine does not have a suction system, dirt and wood dust should be cleaned up during and after sanding using a dust class M vacuum cleaner with cartridge filter and automatic filter cleaning (Tact). Alternatively, vacuum cleaners with cyclone preseparators can be used, in which case, automatic filter cleaning is deactivated. Once the floor is sanded and cleared of dust, it is resealed.

Tip 1 – Prevent deposits:

With oiled, sealed and waxed floors, the phenomenon of migration, i.e. colour particles becoming embedded in the sealant, can lead to high cleaning costs. In the worst case scenario, the particles can not be removed at all. If, for example, suitable mats are placed under chairs with rubber wheels or castors that could leave abrasion marks on the floor, the problem of migration can be minimised or eliminated.

Tip 2 – Rubber glides:

Chair glides are often used to protect wooden floors. Felt glides, however, pick up sand particles and can have a sandpaper effect over time. Rubber glides are therefore recommended, since they do not cause any damage as the particles do not stick. To prevent visible signs of abrasion, it is advisable to fit chair glides that are roughly the same colour as the wooden floor.

Tip 3 – Less dirt:

Preventing dirt from reaching the floor in the first place reduces the cleaning workload. As such, entrance areas outside should have a dirt trap zone, for example an aluminium slat profile. A "dry-run zone" should be provided in the indoor entrance area.

Wooden floors in outside areas: a surprisingly robust covering

Whether for decking, jetties or treetop trails, wood is also a popular material for use in outdoor areas – after all, wood species such as Douglas fir, Bangkirai or teak are very resistant to moisture thanks to their inherently high oil content. If a wooden parquet swells due to incorrect cleaning, it is not the wood that is damaged, but the parquet floor.

Wooden floors in outside areas should be swept regularly to prevent discolouration: if, for instance, residues of fertiliser containing iron fall onto the decking during application, a chemical reaction between the iron and the tannins can leave bluish stains. If leaves are not regularly removed, tannin stains will occur.

To remove dirt and discolouration effectively during deep cleaning and to avoid damaging the wood, mechanical force should be kept to the absolute minimum. For example, the floor can be thoroughly wetted beforehand, or alternatively work can be carried out after rain to make it easier to remove dirt. Hot water high-pressure cleaners set to the steam stage (low pressure), scrubber dryers or facade cleaning systems are well suited for the cleaning itself.

Suitable products for your area of application

Find a wide range of technology at lightning speed – with the Kärcher Professional product finder

In no time at all, we'll show you the exact Kärcher Professional machine that best suits your specific cleaning task.