Parts cleaning in car workshops

Cleaning parts that are contaminated with oil, grease or road dust is an indispensable part of repairs in car workshops. It makes the work easier, increases the level of safety at work and significantly improves the quality of engine, gearbox and chassis repairs. There are three options for professional parts cleaning: High-pressure cleaners, dry ice blasters and parts washing systems. This means there is always the right solution to every cleaning problem in the car workshop.

Parts cleaning with a high-pressure cleaner

High-pressure cleaners are especially suitable for cleaning vehicle and engine parts such as cylinder heads, gearboxes, axles and wheels. They are always a good option if a wash bay has already been set up and all water management and construction permits have been obtained for its operation.

Usually, only trained employees of the automotive company work at wash bays used for automotive parts washing. This significantly reduces the risk of accidents, meaning that hot water high-pressure cleaners can also be used. Compared to cold water machines, they can dissolve greasy or oily dirt much faster. This also significantly reduces the consumption of washing chemicals, decreasing maintenance costs.

Stationary high-pressure cleaners

Even if only trained personnel use the wash bay, the washing technology should be designed so that it is self-explanatory in order to exclude the possibility of operating errors. A stationary high-pressure cleaner is the appropriate choice here, especially if the required space is available. Its technology can be stored in a technology room that is not accessible to everybody. Using the separate control terminal at the wash bay, various pre-set programs for washing car parts can be activated easily, without the risk of work accidents. Depending on the equipment, multiple spray lances can be used alongside stationary high-pressure cleaners, meaning that different employees can wash parts at the same time. Particularly in cases of high workshop throughput, this means that bottlenecks can be avoided. Stationary high-pressure cleaners are also recommended wherever the wash bay is in operation for several hours a day, due to their shorter set-up times.

Mobile high-pressure cleaners

Smaller workshops can switch to mobile hot water high-pressure cleaners for washing vehicle parts. Their advantage is that they take up little space, as a special technology room is not required. However, mobile machines always involve longer set-up times. In addition, there is a certain risk of accidents caused by power lines and water and high-pressure hoses lying around.

Oil, gas or electricity?

When selecting the appropriate cleaning technology, the question arises as to whether the high-pressure cleaner should be equipped with an oil or gas burner or an electrical water heater. To answer this question, the workshop infrastructure − the electricity, gas or oil supply − and its efficiency must be considered. If gas or oil is used to heat the water, a connection to a chimney must be available for stationary machines.

Wide range of accessories

The selection of accessories depends on the planned use and desired washing success. Foam lances, rotating wash brushes, short lances or spray attachments with different spray angles are ideally suited to vehicle parts cleaning. Ideally, the water pressure and temperature can be regulated directly at the lance or high-pressure cleaner according to the type of dirt, so oily or greasy dirt can be more easily removed by increasing the washing water temperature.

Where required: Washing chemicals

In the case of very stubborn dirt, washing chemicals are additionally used. Strong alkaline cleaners are especially suitable for stubborn oily and greasy dirt. Acidic cleaners are used for mineral dirt, such as lime or mortar.

The washing chemicals should in no way affect the function of the light liquid or coalescence separator.

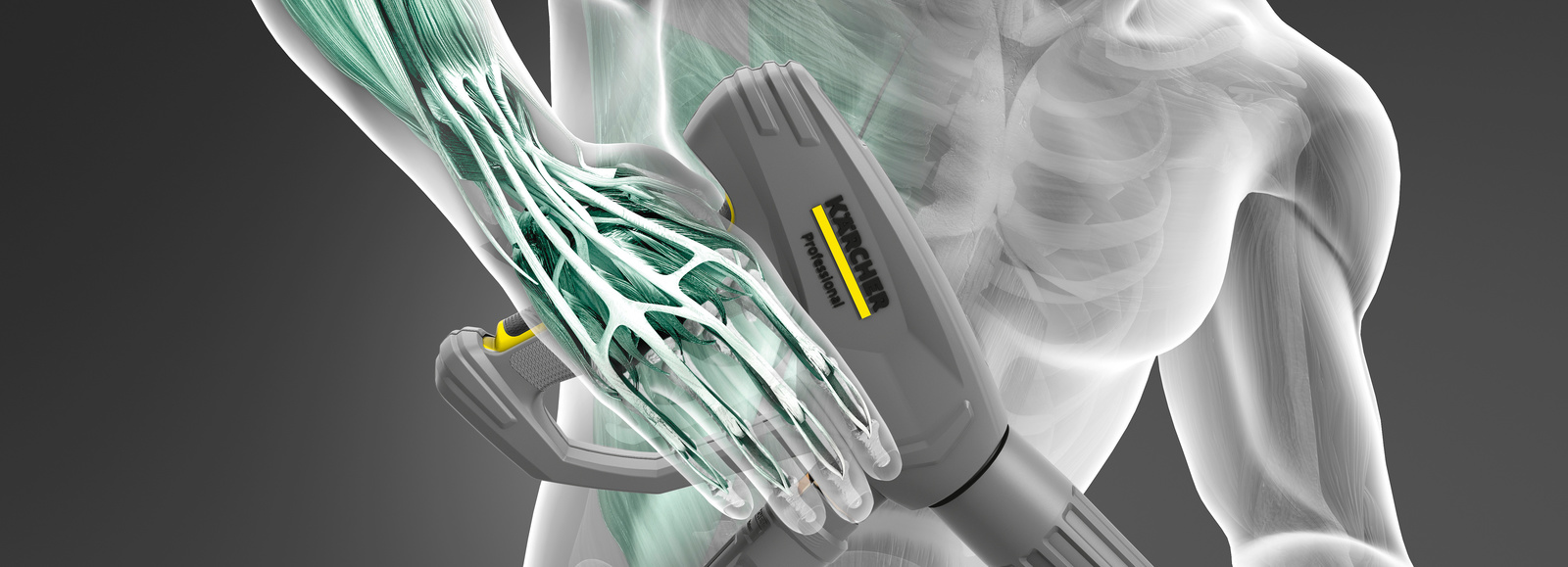

Ergonomics for parts cleaning

Regardless of whether a stationary or mobile high-pressure cleaner is used for parts washing, attention must be paid to the ergonomics of the tools and accessories. Physical injury caused by excessive, continuous strain can thus be reliably prevented. Symptoms of fatigue, which increase the probability of mistakes and therefore of injury, are also avoided.

For selection of the high-pressure gun, ergonomical models should therefore be given preference, for example those which use the recoil force of the high-pressure jet to reduce to a minimum the holding force required for the trigger and at the same time that of the dead man's switch. Automatic hose reels, which eliminate the rolling in and out of the hose, are also very useful. They also significantly minimise the risk of tripping and enable efficient working. Hose reels, particularly where equipped with quick-release couplings for changing lances, significantly reduce the time required for attachment and removal.

A "washing stand" is also a considerable labour-saving device when washing parts. Parts can be fixed to it so that they do not move away during high-pressure washing. Good washing stands are also height adjustable. This means that can be individually adjusted to the ideal working height. "Ceiling booms" also help make work easier and safer, especially when fitted above a washing stand. They guide the hose around the object being washed from a centrally located point above, eliminating the need to pull or carry heavy hoses around.

Parts cleaning with dry ice

Dry ice blasting is an effective particle spray process that can be used to gently remove stubborn dirt from a range of materials. Dry ice cleaning has proven its worth in recent years on complex and delicate components, especially in automotive workshops and reconditioning shops. As a result, this method is being used increasingly often for everything from upholstery cleaning in cars to cleaning engine compartments and restoration work on classic cars. The main advantage of this technology is that it cleans without leaving any residues, such as waste water, chemicals or spray agent residues.

How does it work?

Cleaning with dry ice is comparable to conventional sandblasting methods, but is much gentler. The dry ice pellets, which are between 1 and 4 millimetres in size, are kept in a storage container in the dry ice blaster. During blasting they are then transferred, with the aid of a dosing unit, to the spray gun and nozzle, where they are accelerated using compressed air to a maximum speed of 150 m/s. The speed of release can be controlled using the compressed air pressure, which can be set between 0.7 and 10 bar, and using interchangeable high-performance nozzles on the jet gun. When the dry ice pellets strike the surface being cleaned, the dirt contracts as a result of the extreme supercooling (-79 °C) and becomes brittle. This creates thermal stress and the dirt or coatings detach from the surface. This is then removed abrasively by the pellets that subsequently impinge on the surface. During this process, the CO2 suddenly changes into a gaseous state and increases in volume by a factor of 400 – a process known as sublimation. This also tears dirt or coatings from the surface. After cleaning, only the dirt that has been removed remains in dry form. It can be easily swept up and disposed of via the (hazardous) waste disposal.

Various options for dry ice blasting

Because nothing gets wet during dry ice blasting, components such as engine parts or electrical components no longer need to be removed or protected separately. This saves both working time and money. When used properly, it will not damage surfaces as other blasting methods sometimes do. This completely eliminates the need for expensive surface post-treatment, as is often necessary with sandblasting. Dry ice blasting also prevents thermal distortion when used properly, as the surface is only cooled to 5 °C, and never exceeds 20 °C. Dry ice cleaning even provides a solution for tasks that were previously impossible or could only be accomplished while taking up a great deal of time, such as removing chewing gum residue or grease stains. For vehicle care, it enables dashboards, carpets, panels and engine interiors, in particular, to be immaculately cleaned.

Strict organisation

As easy as this method is to use, when dry ice blasting strict care must be taken to ensure that the dry ice pellets are fresh. Otherwise, this significantly reduces cleaning performance and the pellets sublimate to gas. Even when kept in appropriate cool boxes, they can only be stored for a few days. For this reason, dry ice pellets produced in large hydraulic presses, known as pelletisers, for immediate consumption should be used immediately after delivery. The organisation of work in the car workshop must therefore be coordinated with this requirement if there are to be no delays or loss of quality during parts cleaning.

New solutions

However, there is already a dry ice blaster that can itself produce dry ice in precisely the required quantity when cleaning is to be performed. In terms of logistics, only two things are required: Liquid CO2 as a raw material – which can be stored in a bottle on the machine without any losses – and a compressed air supply with a powerful compressor. This machine is therefore ideally suited for use in automotive workshops of any size.

Training

Although the use of dry ice is very simple and can be quickly learned in user training courses, the method does involve certain health risks that it is important to avoid. Firstly, the user requires a closed protective suit and a helmet with visor in order to be protected from flying dirt particles; secondly, hearing protection is very important. The highly compressed air flows combined with the sublimation of the CO2 generates a very high level of noise during use. For this reason, dry ice blasting should not be performed outdoors, as directly neighbouring buildings will be exposed to considerable noise pollution. Ideally, dry ice blasting is carried out in specially soundproofed and ventilated halls.

Environmental protection

The additional expense of dry ice blasting can be worthwhile for workshops that have to pay high waste water fees. Because hardly any waste water is produced, maintenance costs for oil separators and coalescence separators can be significantly reduced. Ultimately, dry ice blasting harms the environment significantly less than other methods. Even the CO2 required for blasting is a waste product from the chemical industry or power plants and does not need to be produced specifically for dry ice blasting.

Dry ice blasting

Dry ice blasting is an effective particle spray process for removing stubborn dirt coatings from a range of supporting materials. Dry ice cleaning has also proven its worth in automotive workshops or reconditioning shops, especially on complex and delicate surfaces – from upholstery cleaning in cars to cleaning engine compartments and restoration work on classic cars. The main advantage of this technology is that it cleans without leaving any residues, such as waste water, chemicals or spray agent residues.

Parts washing systems and cleaners

In addition to high-pressure cleaners and dry ice blasting, parts washing systems and cleaners have also proven useful in automotive workshops for cleaning engine, gearbox and drive train parts. For these machines, manual parts cleaners are distinguished from automatic parts washing systems.

Manual parts washing

Manual machines are composed of wash basins that use cleaning agents in a closed circuit. After the machine is switched on, the cleaning agent is pumped using an electric pump through a washing brush connected to a hose, enabling the user to easily clean dirty and oily engine and transmission parts. The soiled part is then cleaned manually using the liquid-filled washing brush. The liquid then drains from the wash basin to a filter, before being pumped through the washing brush again. Once the part is clean, it can be left in the wash basin for a few minutes to drip-dry. It is then ready for immediate installation.

This system has the advantage that very little cleaning agent is lost. Only losses from evaporation are to be expected, which can be easily compensated for by occasionally topping up the cleaner. Cleaning can also be carried out as required. It is even possible to wash small parts using special washing baskets and small angled washing brushes. For this purpose, some machines are even equipped with a "water tap function", where the washing liquid comes out through an adjustable tap rather than the washing brush. This makes it easy to clean even the smallest car parts.

Biological parts cleaners

Depending on the washing frequency, the cleaning agent in parts cleaners must be changed regularly. This is expensive and time-consuming, as up to 100 litres of cleaner must be disposed of. In modern parts washing systems, the cleaning agent is biologically purified overnight in the parts washing system's storage tank. As part of this process, the contaminated cleaning agent is fed through a fleece inoculated with special bacteria underneath the wash basin. The bacteria detach from the fleece and use enzymes to break down oils and greases in the cleaning agent. After around 12 hours, this results in fully regenerated cleaning agent. This regeneration is accelerated further by an automatically controlled heating system in the tank. This has an additional effect: The warm cleaning agent dissolves oils, greases and waxes from soiled car parts more quickly.

Manual washing stands with a biological cleaning cycle are perfect for smaller workshops that need to wash parts occasionally. As the machines are on castors, they can be used wherever washing is required in the workshop. Above all, these machines are also characterised by low maintenance costs.

Automatic parts washing

In large automotive workshops with a high throughput of repairs, parts cleaning must be fast and efficient. Automatic parts washing systems help to achieve the required throughput when performing repairs. Similar to manual washing, the parts to be cleaned are first placed in a washing basket. The wash basin is then hermetically sealed using the cover and the cleaning process can be started. Similar to a dishwasher, the parts are washed using rotating high-pressure nozzles and special cleaning agents. In some machines, the wash basket rotates over fixed nozzles. Depending on the type and size of the parts washing system, the temperature, nozzle pressure and length of the washing process can also be regulated via wash programmes. In the case of very stubborn dirt, special washing chemicals are also used in combination with very high temperatures of up to 80 °C. There are universal or special cleaners for all types of dirt. Their use and regulation should be as simple as possible via the parts washing system in order to prevent incorrect or excessive dosages.

Advantages of automatic parts washing:

Large automotive parts washing systems are capable of washing well over 100 kilograms of parts in one wash cycle, while its low loading edge also makes it health-friendly for employees. Automatic parts washing is therefore very efficient. It is especially cost-effective for companies that have to wash several hundred kilograms of vehicle parts per day. In particular, regular disposal of cleaning agent and maintenance of the parts washing system, such as replacing filters and cleaning the tank, are points to consider with regard to amortisation. In order to extend the service life of the cleaning agent, some parts washing machines can be equipped with a "skimmer". The skimmer transports any oil floating on the cleaning agent into the oil catch pan. Any oil separated in this way can then be disposed of in much smaller quantities.

Parts cleaning using ultrasound

Ultrasonic cleaning is a particularly environmentally friendly method for washing parts. As part of this process, the dirty parts are placed in a mild warm cleaning agent and exposed to high-frequency ultrasound. This creates billions of cavitation bubbles in the liquid, which implode and tear the dirt from the surface of the parts. This is usually carried out without aggressive chemicals or mechanical additives. Even ingrained dirt on small porous surfaces can be removed from the surface in this way. However, this method does not work entirely without chemicals. To accelerate the cleaning power, some unit manufacturers offer special rinsing agents. Combined with a heating system for the ultrasonic bath, this significantly reduces washing time. This can be very important, especially for workshops with a high throughput of repairs.

Large ultrasonic cleaning baths are capable of cleaning complete engine parts and wheels. For this, these machines have several hundred litres of washing capacity. For large machines, parts are often loaded by means of a hydraulic lifting device. This lowers the basket containing the parts into the ultrasonic bath and lifts it out again after washing. The washing water can be used for approx. 400 washes. Although the parts are very clean after the cleaning process, it is advisable to rinse them in clean water on a "rinsing rack" in order to remove any washing water residue.

Small ultrasonic bath cleaning machines with a capacity of around 10 litres have proven particularly useful in automotive workshops. They are used for cleaning small components, such as injection nozzles or, for classic cars, carburettor parts. Frequently, however, they are also used for washing hand tools that are covered in oil. This significantly increases safety at work.